シートメタルファブリケーションの中核原理は、材料特性の深い融合であり、進行した製造操作の協調操作です。 大規模な構造部品大量生産。

製造 統合。 新しい製品は、伝統的な産業用のペン> <

製造?

< data-translateId = "6cc04fafbf0ff3e7b1130a9f9cbf1925" data-pos = "0" data-len = "207" data-v-7b79c893 = "" "> ベンドシートメタルは、そのコアコンポーネントの1つです。

< Data-TranslateID = "4B2AC1B3C140156D71108C07E37245F8" data-pos = "379" data-len = "266" data-v-7b79c893 = ""機能と美学の統一を達成するためにリベット。 ですが、最終的な製品の組み合わせの強度と精度を確保するために、材料の延性に応じてプロセスパラメーターを最適化する必要があります。

< data-TranslateID = "626FB2E8E6A7FAFFA5AF83050508080F7C" data-pos = "645" data-len = "221" data-v-7b79c893 = ""> シートメタル製造のコアツールと機器には、主に以下のタイプが含まれます。

一緒に、これらのデバイスはシートメタルカットと形成から精密機械加工までのプロセス全体をカバーします。完成品の精度と機能に影響します。 1。 Data-V-7B79C893 = ""> シートメタル製造対鋳造 利点比較: 制限: シートメタルは複雑な空洞または不規則な構造を処理することが困難であり、鋳造は複雑な全体的な形状でくぼみを形成することができます。

該当するシナリオ: span class =" date-translateid = "08CA87653F8D0D0D8D88D08D08D08D08D08D08D08D08D08D08D08D0D08D08D08D0D08D08D0D08D08D0D08D08D08D0D08D08D0D08D08D0D08D08D0D8 data-pos = "0" data-len = "3" data-v-7b79c893 = "" "> 2。 Data-V-7B79C893 = ""> シートメタル製造対溶接 利点比較: 制限: 溶接は異なる材料(金属やプラスチックなど)を接続できますが、板金は同様の金属シートに制限されます。

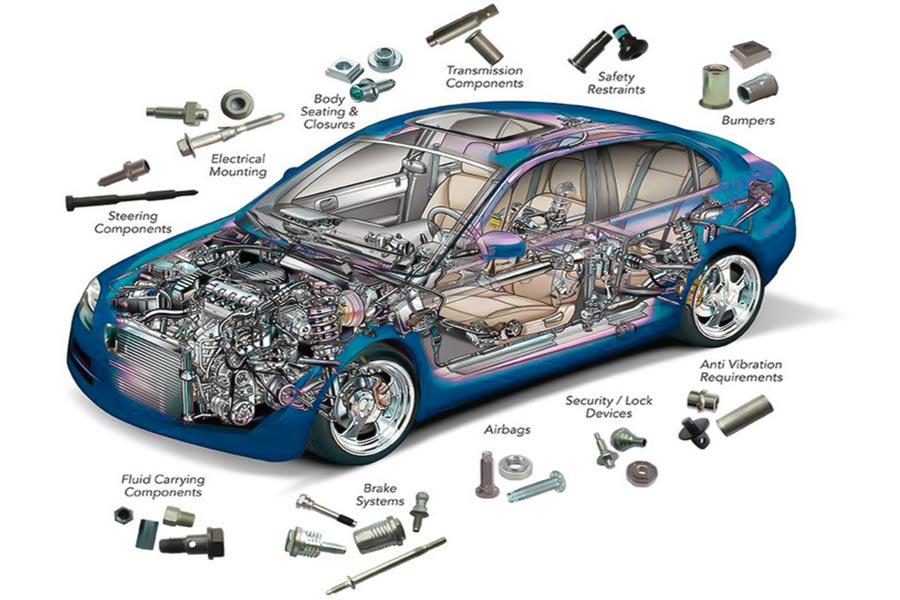

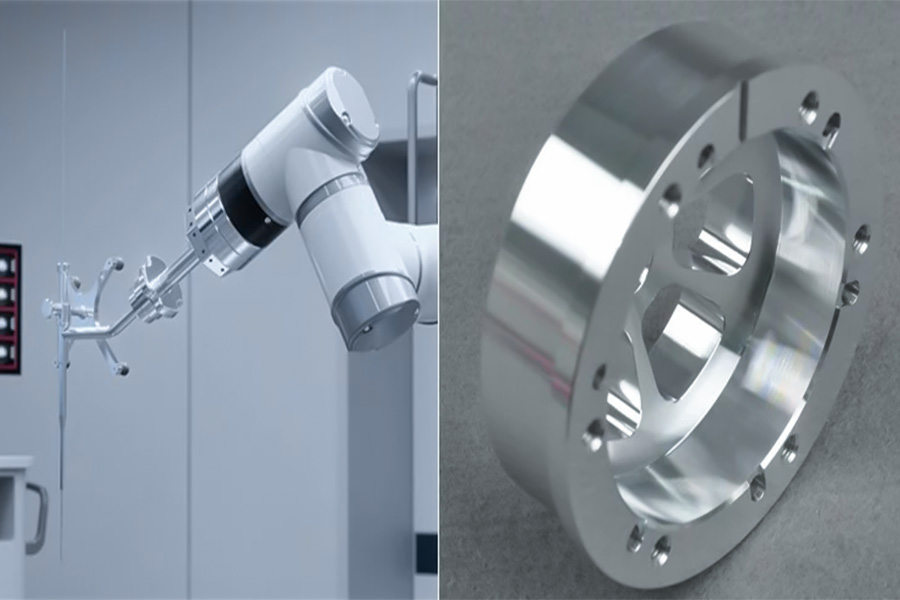

該当するシナリオ: 製造 ">比較 シートメタル製造は、高精度を必要とする小規模および中規模のバッチ生産に理想的な選択肢となっています。 in shety metal 製造、合理的な材料の選択は、製品のパフォーマンスとコストのバランスを確保するための鍵です。 href = "https://jsrpm.com/blog/what-is-sheet-metal-fabrication">シートメタルゲージチャートおよび系統的選択ガイドを提供する関連パラメーター: data-pos = "0" "data-len =" 3 "data-v-7b79c893 =" ""> 1。 Data-V-7B79C893 = ""> アプリケーション要件を明確にする チャート 3.共通物質的な特性 1.Automotive industry 2.Consumer electronics industry 3.Medical equipment industry 4.Industrial automation equipment 5.Recyclable energy 1.Adaptability requirements for sterilization methods Material compatibility screening Surface treatment strengthening: Sheet metal parts need polishing Ra<0.8μm and passivation (e.g. anodic oxidation). JS cases shows that the process can reduce sterilization residue by 80%. 2.Verification and compliance management Biocompatibility verification These ingredients are subject to ISO 10993 series tests (cytotoxicity, allergies, etc.), and JS's needle holder components are sourced from a manufacturer and approved by FDA 510(k). Sterilization Verification Report Data on sterilization process parameters (e.g. ETO concentration, irradiation dose) and material performance were provided to shorten the sterilization cycle by 20% without affecting the assurance level of sterilization (SAL 10^-6). 3.Integration of production processes JS has very strict control over the workshop and the dust-free workshop complies with ISO 7 standards. After sheet metal processing, use ion air, reduce particle residue, combined with automatic packaging and sealing, reduce the risk of secondary contamination. 4.Cost and productivity 5.JS typical cases In the total hip replacement surgery robot project of an international medical giant, JS provided acetabular polishing components using: 1.Choose high-strength alternatives 2.Sheet metal fabrication technology 3.Structural design 4.Welding and connection process 5.Verification and testing Key preventive measures JS as a professional sheet metal fabricators, through the following methods to optimize your sheet metal project: Comparison between JS and other sheet metal fabricators Sheet metal fabrication, as the cornerstone of modern manufacturing, plays an irreplaceable role in automotive, electronics, aerospace and other fields, from instrument casings to complex structural components, sheet metal parts through bending sheet metal technology has become a key support for innovation in many industries. Under the trend of customization, choosing a professional partner is the key to complete sheet metal processing efficiently. With 20 years of industry experience and eco-friendly processes, JS has helped clients around the world shorten project cycles by 15% and costs by 20%. Click on the link for exclusive quotes and professional sheet metal solutions to help you seize market opportunities. The content on this page is for general reference only. JS Series makes no express or implied warranties regarding the accuracy, timeliness, or applicability of the information provided. Users should not assume that the product specifications, technical parameters, performance indicators, or quality commitments of third-party suppliers are completely consistent with the content displayed on this platform. The specific design feature, material standards, and process requirements of the product should be based on the actual order agreement. It is recommended that the purchaser proactively request a formal quotation and verify product details before the transaction. For further confirmation, please contact our customer service team for professional support. JS is an industry leading provider of customized manufacturing services, dedicated to providing customers with high-precision and high-efficiency one-stop manufacturing solutions. With over 20 years of industry experience, we have successfully provided professional CNC machining, sheet metal manufacturing, 3D printing, injection molding, metal stamping and other services to more than 5000 enterprises, covering multiple fields such as aerospace, medical, automotive, electronics, etc. We have a modern factory certified with ISO 9001:2015, equipped with over 100 advanced five axis machining centers to ensure that every product meets the highest quality standards. Our service network covers over 150 countries worldwide, providing 24-hour rapid response for both small-scale trial production and large-scale production, ensuring efficient progress of your project. Choosing JS Team means choosing manufacturing partners with excellent quality, precise delivery, and trustworthiness. 1.What are the characteristics of aerospace sheet metal parts? Highly accurate and lightweight, titanium/aluminum alloy alloy is often used to meet complex structural requirements through bending forming process, meet airworthiness certification standards, and ensure strength and fatigue resistance performance. 2.What materials are commonly used in sheet metal fabrication? Common materials are steel (stainless steel, carbon steel), aluminum alloy, copper and galvanized/aluminium steel, which balance strength, weight and corrosion resistance. 3.What are the technical advantages of sheet metal bending? Sheet metal bending technology can effectively form complex geometric shapes, maintain the ductility and strength of materials, meet high precision design requirements, balance mass production efficiency and cost controllability. 4.What are the production processes for customized sheet metal parts? Design sampling → Material selection and Cutting → Bending formation → Welding/assembly → Quality inspection → Surface treatment → Delivery.

テクニック?

インジケーター

シートメタル キャスティング

溶接

単位コスト

low(金型コストなし)。

high(金型に依存)。

medium(肉体労働に依存)。

生産サイクル

短い(1-7日)。

long(2-8週)。

medium(複雑さに基づく)。

材料利用率

90%-95%

70%-80%

85%-90%

典型的な精度

±0.1mm

±0.5mm

±0.2mm

バッチ制作に適しています

小さなバッチから大規模まで。

大規模。

中小バッチ。

製造材料?

素材

16ga(mm

20ga(mm

24ga(mm

spccコールドロールシート

1.5

0.9

0.6

アルミニウム合金5052

1.6

1.0

0.7

タイプ

アドバンテージ

典型的なアプリケーション

亜鉛メッキスチールシート

腐食抵抗、低コスト。

屋外コンピューターボックス、ホームアプライアンスボックス(塩スプレーテスト基準を満たす必要があります)。 >

アルミニウムマグネシウム合金

軽量、良好な伝導性。

電子ヒートシンク、航空宇宙コンポーネント(硬度要件に応じて選択)。

ステンレス鋼

抗酸化、耐熱性、抗菌性。

化学および医療機器(コストと衛生要件のバランスをとる必要があります)

What fields does sheet metal fabrication mainly serve?

What are the sterilization requirements for surgical robot sheet metal components?

How to replace stainless steel with galvanized sheet metal to achieve the same strength?

How can JS optimize your sheet metal project?

Optimize dimensions

JS Precision Manufacturing

Peer manufacturer A

Peer manufacturer B

処理精度

±0.005mm

±0.01mm

±0.02mm

Plate utilization rate

92%

85%

80%

Standard delivery cycle

1-2 weeks.

3-4 weeks.

4-6 weeks.

マテリアルタイプ

More than 50 types.

20 types.

15 types.

Cost saving rate

On average 20%.

≤8%.

Equipment depreciation optimization only.

Sustainability certification

ISO 14001

Not have

Partial Process Environmental Declaration.

Summary

免責事項

jsチーム

For more information, please visit the official website: jsrpm.com FAQs

Resources