You may think thatsand castingis pouring molten metal into a sand mold? Then why are some castings strong and durable, while others are full of holes and break when knocked? The problem is often not entirely in the metal itself, but in a key "iron triangle" combination that is not selected correctly: the metal you use, the formula of the sand that wraps it, and the material used to make the mold. Any improper selection of any of these three links may lead to the failure of the entire project.

Metals such as aluminum, iron, steel, and magnesium are widely used in our sand casting. The core advantage of this process for thousands of years is that it is flexible and allows us to adjust according to the strength and performance of the parts. But you can't choose which metal to use casually! First of all, you have to look at the casting requirements of the parts themselves, production batches, cost control and other factors to flexibly select and optimize metal materials.

In the project I am responsible for, toobtain qualified castings. The first step is to choose this "iron triangle". Metal is the heart, the formula of sand is the protective layer, and the material of the mold is the foundation. The three must be considered in a coordinated manner, carefully matching the design requirements of the parts, the characteristics of the metal and the actual production conditions, in order to find the most suitable combination, effectively control costs and improve efficiency.

Core Answer Summary:

| Material system | Core role | Common materials | Key considerations |

| Casting metal | Forming the final product determines its mechanical properties. | Cast iron, cast steel, aluminum alloy, copper alloy. | Strength, weight, cost, corrosion resistance. |

| Molding materials | Forming the shape of the component is the core of the process. | Casting sand (silica sand), binder (bentonite, resin). | Strength, breathability, fire resistance, and cost. |

| Appearance Material | The "template" for making sand molds determines the accuracy and lifespan. | Wood, plastic (including 3D printing), metal (aluminum, steel). | Production batch size, complexity, and cost. |

This article will answer your questions:

- In this guide, I will focus on the three most critical materials in sand casting.

- Reveal the typical formula of sand casting sand and compare the characteristics of different metals.

- Finally, we will use a real product case to illustrate how the three materials interact to ensure that the castings can operate reliably under harsh working conditions.

Why Trust This Guide? First-Hand Experience from JS Casting Engineers

As casting engineers at JS, the confidence of this guide comes from our practical experience in the workshop every day.

When a customer brings a demand for analuminum sand casting part, our first question is always: Where will this part be used in the end? What will it withstand? This directly determines whether we choose A356 with good fluidity and suitable for complex parts, or a special grade with higher strength. Choosing the right metal is the foundation.

We control the moisture in green sand casting with an accuracy of 0.1%. Why?

Because a little more water will turn into air holes during pouring, and the entire batch of castings may be scrapped. The same is true for choosing mold materials. Should we use cheap wooden molds or durable metal molds? This depends on the future order volume of the customer, not just the present. These are the hard truths we summarize every day in the workshop.

Real skills rely on cases to speak:

A customer's hydraulic valve body, the internal flow channel is always inaccurate, and the processing is time-consuming and labor-intensive. We changed the sand wrapped in the metal from ordinary wet sand to chemically cured resin sand, and the dimensional accuracy immediately increased. The subsequent machining volume was directly cut by nearly 60%,saving a lot of money.

This is the "iron triangle" synergy we emphasize. Metal is the foundation, the sand formula is the key to shaping, and the mold material determines how long it can last.

"David Weiss often said: The mold is the silent process engineer. "

We deeply understand that the quality of the mold and the choice of materials silently but crucially determine the fate of the final casting. The tricks in this guide are the hard-core experience I have accumulated from solving practical problems and optimizing production processes time and time again, and it is the real use of material science on the production line.

System 1: Molding Material - Not Sand

Let me talk about the "sand" of sand casting, which does not look obtrusive yet is indeed crucial - the molding material. Actually, it's the backbone of the success or failure of the entiresand casting process! The operation of this sand largely depends on three elements:

Skeleton material: This is the pillar of the mold.

Silica sand:This is our most extensively used primary force that has low cost and plenty. But you should not be careless in choosing it. You have to take extra care of the size of the sand particles, whether the shape is adequately round, and if it is clean enough. They are all concerned with the quality of the casting surface and air permeability of the mold. If it cannot be avoided, then it will be a gigantic problem.

Special sand:With high-temperature alloys such as cast steel, or when operating with extremely high dimensional precision requirements, normal silica sand is a bit overworked.Now we have to employ special sand:

- Olivine sand: It is more resistant to higher temperatures than silica sand. The secret is that it deforms less when being heated, and the objects cast are more consistent in size and will not be easily warped out of shape.

- Zircon sand: In high temperature thermal resistance, it is perfect, and it also releases heat quickly. Castings made with it havevery fine and smooth surface, particularly those thin-walled parts or precision parts, the effect is superb. Good characteristics come with expensive prices, and the price is comparatively high.

Global casting sand aggregate type share:

| Aggregate type | Main components | Roughly speaking | Typical application scenarios |

| Silica sand (SiO₂) | Silica | 85% | Most castings include cast iron, cast aluminum, copper alloy, etc. |

| Olivine Sand | (Mg,Fe)₂SiO₄ | 8% | High melting point alloys such as cast steel and manganese steel. |

| Zircon sand | ZrSiO₄ | 4% | Precision castings, requiring extremely high surface quality or extremely thin wall components. |

| Other (chromium iron ore sand, etc.) | Mix | 3% | Special alloys or locally critical parts. |

Data source: Comprehensive reference to the 2019 Global Casting Material Trend Report and industry consensus data of the International Foundry Society (IFS).

Binder: "Glue" that makes sand stick together

(1) Wet sand system (clay + water):

This is the most traditional system. Why is it called "green sand"? It is because of the wet state (green means unbaked), not because of the color.

- Ingredients: silica sand + bentonite clay + water.

- Strengths: Cheapest,sand can be recycled, and more environmentally friendly.

- Disadvantages: Tensile strength is not high, and it is comparatively difficult to make fine and intricate molds or sand cores. Dimensional tolerance is poor, and it is highly sensitive to moisture control (±0.1% accurate in JS production), and variation in moisture can easily result in pore defects.

(2) Chemical binder (resin sand system):

- Ingredients: silica sand + liquid resin (e.g., furan resin, phenolic resin) + curing agent.

- Advantages: Strong mold and sand core, good dimensional tolerances, high surface finish of the casting, suitable for complex structures.

- Disadvantages: High cost of material, odor can be created during sand mixing and pouring, ventilation and environmental control should be maintained well.

Additives: Improve performance

In addition to basic aggregates and binders, small quantities of materials are incorporated to facilitate the process or to improve the quality of the casting. Typical applications:

Combining coal dust with cast iron wet sand: Molten iron is very hot, and the coal dust gets consumed when heated and converted into a thin protective film of gas between the molten iron and sand mold. This film is effective to such an extent that it can prevent molten iron from seeping into the sand pores, thus allowingthe casting surface to be smootherand the cleaning workload to reduce. There are some other additives, such as anti-sand sticking and fluidity improvement, depending on specific needs.

"Accurately mastering the "iron triangle" combination of molding materials is the cornerstone of the success of the sand casting process. If you are facing casting quality or cost challenges, please contact us immediately. The JS team will provide proven material solutions and process optimization suggestions based on your specific needs."

System 2: Casting Metal - From Molten Iron to Aluminum

For the casting products that customers finally get, the choice of metal materials is a comprehensive decision-making process that needs to consider strength, weight, corrosion resistance, thermal conductivity and the most realistic cost. The following are several types of casting metals we commonly use:

Ferrous Metals - The Backbone of Industrial Applications

Cast Iron:This is definitelythe first choice for large partsand parts that require stability.

- Gray Iron: It has the best cost and outstanding shock absorption ability. It is often used in places such as machine tool bases and engine cylinders. Its disadvantage is relative brittleness.

- Ductile Iron: Through graphite spheroidization treatment, its strength and toughness are close to steel, and it maintains good wear resistance and impact resistance. It is widely used in key components such as water/gas pipelines, valves, crankshafts, gears, etc.

Cast Steel:

Want a stronger material?

Then you have to look at cast steel. Its strength and toughness are one level higher than cast iron, and it is particularly suitable for core parts that have to withstand huge forces, such as train wheels andkey frames of heavy equipment. The disadvantage is that the casting process is more complicated, and the material and processing costs are usually higher.

Non-Ferrous Metals - Meeting the needs of lightweight

Aluminum Alloys:

- The main advantages are light weight, excellent corrosion resistance, and good thermal/electrical conductivity. It is widely used in the fields of automobiles, aerospace, general machinery, etc., and is a commonmaterial for aluminum sand casting.

- Typical applications include: automobile engine intake manifolds, cylinder head covers, pump housings, housing parts, and parts that have both functional and appearance requirements.

- For parts with complex structures and extremely high precision requirements, the process selection of investment casting vs sand casting needs to be evaluated based on specific needs.

Copper Alloys:

Brass / Bronze: This type of metal has first-class seawater corrosion resistance, good electrical and thermal conductivity, and that classic metallic luster. Therefore, they are often seen in ship propellers, corrosion-resistant valve parts, and those exquisite artistic castings. The cost is relatively higher than that of aluminum alloy.

There is nobest choice of casting metal, only the most suitable one. From high-strength cast steel and ductile iron to lightweight aluminum alloys and copper alloys with special properties, each material has its unique value.

"As engineers of JS, we are very familiar with the matching of material properties and casting processes. We sincerely invite you to tell us your parts requirements, usage environment, performance goals and budget to JS. We will accurately recommend the best metal material and casting solution for you!"

System 3: Model Materials - From One-time to Repeated Use

1. Wood: An Economical and Affordable Starting Point

- Applicable Scenarios: When you only need to make a few samples or asmall batch trial production, the wooden mold is the most cost-effective starting point. It is fast to process and easy to modify.

- Advantages: The lowest initial cost, relatively simple and fast to make and modify.

- Disadvantages: Poor durability, especially afraid of changes in environmental humidity, easy to be affected by moisture and deform, and dimensional stability decreases rapidly over time. It is difficult to guarantee accuracy after repeated use, and it is only suitable for single-piece or very low volume production.

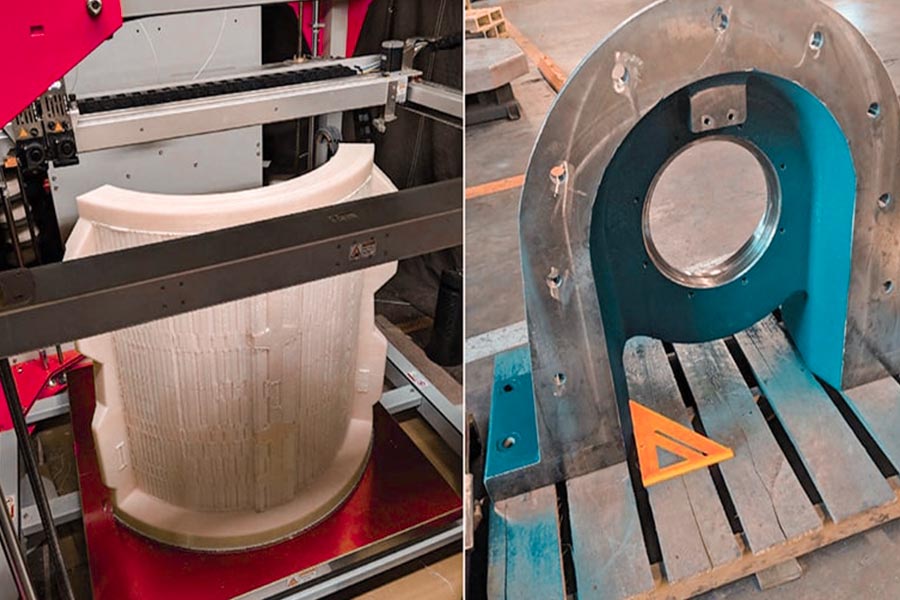

2. Plastic/3D Printing: A Tool for Speed and Complexity

- Applicable Situations: It is an excellent choice for the validation of rapid prototyping and small-to-medium sized batches of manufacturing (tens to hundreds of parts), especially when your part configuration is very intricate and difficult to manufacture through the traditional process.

- Benefits: With the help of3D printing technology, one can directly produce complex inner cavities, curvy surfaces and other shapes, which are almost impossible to achieve through traditional methods, speeding up the product development process. Plastic molds experience less wear and tear than wooden molds and have a more stable dimension.

- Disadvantages: The wear resistance and strength tend to be inferior to metal molds. If used in large amounts over a long period, the risk of deformation and wear exists. More expensive than wooden molds but less expensive than metal molds.

Here we often encounter a choice: if the parts are particularly delicate and complex and the batch is not large, sometimes using 3D printed plastic molds combined withinvestment casting technologywill be more efficient and more accurate than traditional sand casting (of course, the cost model is also different). This is the typical sand casting vs investment casting process selection where the pattern material needs to be considered.

3. Metal (aluminum/steel): the center of mass production

- Situation where you can use it: When you'll be performing long-term, high-volume production (tens of thousands of units) and require high consistency in the size of the castings and surface finish, metal molds are a requirement.

- Benefits: Very strong, extremely long life, well dimensionally stable, able to withstand the reverse box, vibration and demolding processes of the sand casting production line, i.e., the casting is very consistent with very little fluctuation. In the long term, the unit cost is very advantageous after dilution.

- Disadvantages: The initial manufacturing cost is the highest, the processing cycle is the longest, the design and manufacturing requirements are high, and modifications are difficult. Suitable formass production of finalized products.

"At JS, we are too familiar with these looks. If your project is choosing: whether to use wooden molds to save costs and start quickly, or to use 3D printing to quickly verify the design, or to choose metal molds to adapt to long-term mass production, especially in mass production, when taking advantage of the scale advantage of sand casting, don't hesitate! Contact us now for a free consultation!"

Actual Combat Case Analysis: Developing High-Pressure Ductile Iron Valve Bodies for The Petrochemical Industry

I personally participated in this case and was deeply impressed. Let me tell you how I successfully completed this task:

On oil and gas pipelines, valves are safety gates. As the core, the valve body has disastrous consequences once it fails, so the choice of materials is very important!

Customer challenge: Make a large valve body that can withstand high pressure and control costs

Project background: A valve factory we cooperated with needed to develop a DN300 large valve body (300mm in diameter) forhigh-pressure natural gas pipelines.

Dilemma of the original solution:

- Full machining (forged steel billet): Milling out a complex inner cavity from a solid large forged steel? The cost was frighteningly high, and the customer directly rejected it.

- Steel plate welding:There are hidden dangers in the welds, and it cannot pass the most stringent safety certification, and the risk is too great.

- Ordinary gray cast iron: The strength and toughness are not enough, and it cannot withstand the high pressure of the pipeline and the dangerous water hammer impact, so it is directly eliminated.

JS's solution: Playing with the "iron triangle of materials"

We analyzed thatthe key to success lies in finding a perfect combination of materials and processesthat can not only form a complex valve body inner cavity in one go, but also provide top strength and toughness.

(1) Casting metal

Decisively gave up gray cast iron.Chosen ductile iron. Its spheroidal graphite structure is the key, unlike the flake graphite of gray cast iron that will split the matrix. This makes it have strength close to that of steel, as well as good toughness and ductility, and is a natural material for dealing with high pressure and impact.

(2) Molding material

The inner cavity of the valve body has complex flow channels, and the dimensional accuracy and finish requirements are very high. We chose furan resin self-hardening sand to make sand cores and molds. This sand mold has high strength and can withstand the impact of nearly one ton of high-temperature molten iron, ensuring that the cavity size is stable and the inner wall is smooth, laying the foundation for high-quality castings.

(3)Model material

The customer's product is to be mass-produced for a long time. We suggest not to save a little money and directly invest in making a set ofhigh-precision aluminum molds. Although it is more expensive than a wooden mold, it is no problem to use it hundreds or even thousands of times! This sand casting aluminum sand mold ensures that every valve body is the same, with precise dimensions, which greatly dilutes the cost of a single part.

Results: A win-win situation of safety certification + cost advantage

The integrated ductile iron valve body finally delivered passed the rigorous 1.5 times design pressure water pressure test and has reliable performance. More importantly, the cost is only 30% of the original whole steel hard milling solution!

Quantified benefits:

| Indicator items | Achievement Performance |

| Manufacturing cost | Reduce by 70%. |

| Safety certification | 100% pass (meets the strictest industry standards). |

| Fluid efficiency | Increase by about 5% (thanks to smoother inner cavity). |

"This project successfully helped the customer win a key order. It once again proves that an excellent sand casting is the result of a scientific match of the "iron triangle" of metal materials, molding technology, and pattern tools. Mastering this matching ability is the core value that distinguishes JS from ordinary foundries."

FAQ - Answers to More Questions About Sand Casting Materials

1. Can the sand used for casting be taken from the beach?

Don't do this! Beach sand looks similar, but the salt (chloride) and broken shells (mainly calcium carbonate) hidden in it are the enemy of casting. When high-temperature molten iron is poured, these impurities will undergo violent chemical reactions, producing gas and slag, which directly lead to serious defects such as pores, sand inclusions, and even surface pits in the casting.

The sand we generally use is specially treated industrial silica sand. Clean it, select the appropriate particle size, and dry it thoroughly to cast a good casting.

2. What is "green sand"? Is it really green?

Although it is called "green sand", it has nothing to do with color! The "green" in the name actually refers to the "wet" or "unbaked" state of the sand. It is the most commonly used and economical modeling material in our sand casting. The formula is very simple: basic silica sand + clay (mainly bentonite) + water. After mixing, it remains moist, has good plasticity, can be compacted and can be recycled repeatedly.

3. What basic equipment is needed to make sand castings?

The core equipment is inseparable from three things: the furnace for smelting metal is the starting point, the machine for mixing sand and molding, and the flask for fixing the sand mold. After pouring, cutting and grinding equipment is also required to deal with the burrs and pouring risers of the castings. These constitute the basic equipment of sand casting and support the entire production process.

Summary

The secret to really doing well in sand casting is to understand the material thoroughly. This requires not only that we are proficient in metal properties, but also that we must thoroughly understand the chemical behavior of the modeling material and the processing technology of the mold material.In JS's casting practice, we deeply understand that it is the precise coordination ofthe three major systems of metal, molding materials and molds that ultimately produces sand casting productswith strong structure and reliable performance.

Are you evaluating for your next project:

- How to balance cost and technical feasibility?

- Is there uncertainty in material selection?

Don't let material issues become a bottleneck for your project.Contact JS's casting engineers. The value we provide is far more than a single quote. Based on a comprehensive understanding of the material system, we will provide you with professional manufacturing solution analysis to ensure the optimization of process selection.

Upload your design drawings now!Let us start from the most basic material selection and lay a solid foundation for the success of your project together.

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsrpm.com

Resource