Look at the chair in your office, or the bridge across the river in the distance, and think about the sturdy body of the car and the exhaust pipe under the chassis. Have you ever wondered how these metal parts are permanently and firmly connected into a whole?The answer is metal welding.

Simply put, welding is the technology of bonding two pieces of metal together using heat, pressure, or a combination of both. Its core secret is to melt and fuse the metal where it touches, or to press it tightly under strong pressure. In the end, the originally separate parts are truly integrated into one, forming an inseparable, super-strong connection point.

The original metal pieces that are being joined together are called "parent materials."When welding, other filler metal materials are used at times to aid, also called filler material. And after the welding process, the stiff joining itself is referred to as the weld.

In order to cope with different metals and connection requirements (such as common arc welding, gas welding, etc.), a variety of welding methods have been developed with only one goal: toensure that the connection is both strong and reliable. It is both a practical technology and a special skill to fuse metals at the microscopic level.

Summary of Core Answers:

| Aspect | Describe | Value to you |

| Core principle | Use heat (sometimes combined with pressure) to melt and connect two or more pieces of metal together. | Create permanent connections (joints) that are stronger or equally strong than the original material. |

| Key elements | Heat source, filling material, protective gas/flux. | Ensure the strength, purity, and integrity of the weld seam. |

| Mainstream process | Arc Welding is the most common technology family. | Covering various needs from manual maintenance to automated production. |

| Application Fields | Almost all industrial fields, including construction, manufacturing, aerospace, and maintenance. | Almost all metal structures cannot be manufactured without it. |

This article will show you:

- In this guide, we will explain the core principles of welding.

- Focus on the 4 most commonly used welding methods.

- Analyze the technical characteristics, applicable materials and typical application scenarios of each of the above welding methods.

- And choose the right welding process for your project based on project requirements, material properties and process characteristics.

Where Does This Guide Come From? The Practical Experience of The JS Welding Team

"Welding is not simply sticking metals together, but letting materials reunite at the atomic level."

This is exactly what our JS team does every day.

At JS, welding is much more than operating a welding gun for us.We are a professional team of welding engineers. The knowledge in this guide is not copied from books, but we have learned it from real projects.

- We know what TIG welding parameters should be used for thick stainless steel to produce beautiful and rust-free welds.

- We know which MIG welding settings should be selected for heavy steel beams to ensure deep welding, firm connection, and withstand heavy forces.

- From aluminum sheets as thin as paper to steel beams half a meter thick, from precision instrument housings to huge building frames,we have welded all kinds of strange materials and structures.

- We know how to arrange the welding sequence to prevent deformation, and know what kind of fixtures to use to ensure that each component fits perfectly.

This entire guide is filled with the experience we have accumulated in solving practical problems for hundreds of customers. It embodies the most critical core technology of welding technology.

Principles of Welding: A Science of Melting and Fusion

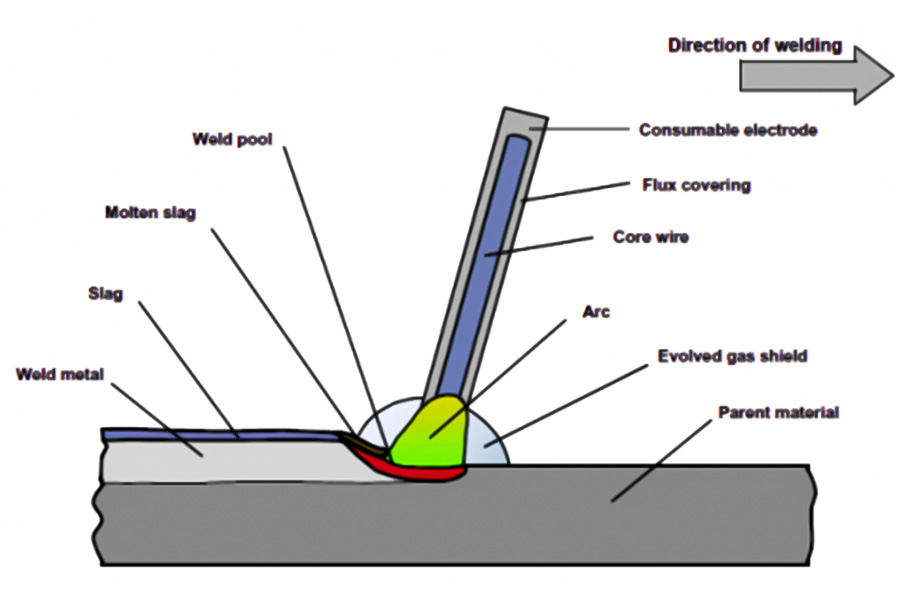

The secret tometal welding is to generate localized high temperatures at the joint of weld, melting the edges of parent metal (original pieces being welded) into a pool of liquid metal. They are melted together sometimes using welding rods or welding wire. When cooled and solidified, the parent metal and filler metal are joined together firmly to form a strong weld.

The realization of this reliable fusion process mainlydepends on three key factors:

Element 1- Heat source: Provide melting energy

Function: Provide a high enough temperature to generate enough for the metal to reach the melting point.

Common types:

- Arc: High-temperature discharge generated by a welding machine is the most widely used heat source in industry (such as arc welding).

- Gas flame: For example, the flame generated by the mixed combustion of oxygen and acetylene (gas welding).

- High-energy beam: Such aslaser beam and electron beam, with concentrated energy and high precision.

Why is arc welding the most common? High efficiency, wide application, and relatively cost-effective.

Element 2- Filling metal: Strengthen the connection

Where is it used?It is used mostly in two places:

- One is to fill up the space between two metal pieces.

- The other is to harden and toughen weld zone.

Form: Typically welding wire or coated flux electrode.

Choosing the right one is the key:The metal filled in must match the parent material you want to weld (such as low carbon steel, stainless steel, aluminum alloy). In this way, the welded area is strong enough and not easy to rust. This directly answers the question of what welding material to use.

Element 3- Protection measures: Isolate from air damage

Function: Molten metal easily reacts with oxygen and nitrogen in the air, causing weld embrittlement and pores, which seriously damages the quality. The protective layer is to cover the molten pool with a protective cover to separate it from the air.

How to protect?

- Shielding gas: Like argon and carbon dioxide, it is sprayed directly from the welding gun to cover the molten pool (like MIG/MAG welding, TIG welding).

- Flux: Coated on the outside of the electrode or wrapped inside the welding wire (flux-cored wire). Once heated, the flux will produce shielding gas and form a layer of slag covering the weld, providing double protection (like manual arc welding and flux-cored wire welding).

"As JS's welding engineers, we know that principles are the basis of practice.If you have a project that requires reliable metal welding services, understanding these principles can help you better understand process selection. We are happy to use our expertise and experience to help you analyze your needs, select and implement the most appropriate welding solution."

4 Most Major Welding Processes and Their Applications

Among the many welding technologies,the following four welding methods have undertaken most of the connectiontasks in the industrial field due to their maturity, reliability and wide applicability. Understanding their characteristics and areas of expertise is the key to choosing the right process.

Overview of mainstream processes and market application share:

| Process abbreviation | Full name of process | Typical applicable materials | Global proportion of industrial applications |

| MIG/MAG | Melting inert/active gas shielded welding. | Carbon steel, stainless steel, aluminum. | 55% |

| TIG | Tungsten inert gas shielded welding. | Stainless steel, aluminum, titanium, thin plate. | 20% |

| SMAW | Welding rod arc welding. | Carbon steel, low alloy steel, cast iron. | 15% |

| FCAW | Flux cored wire arc welding. | Medium thick carbon steel and structural steel. | 10% |

Data source:"Welding Research Institute - Annual Report 2025"(The data in this table are approximate values, reflecting the overall trend of global industrial welding applications. The specific project selection needs to be combined with actual needs.)

In-depth analysis of each process:

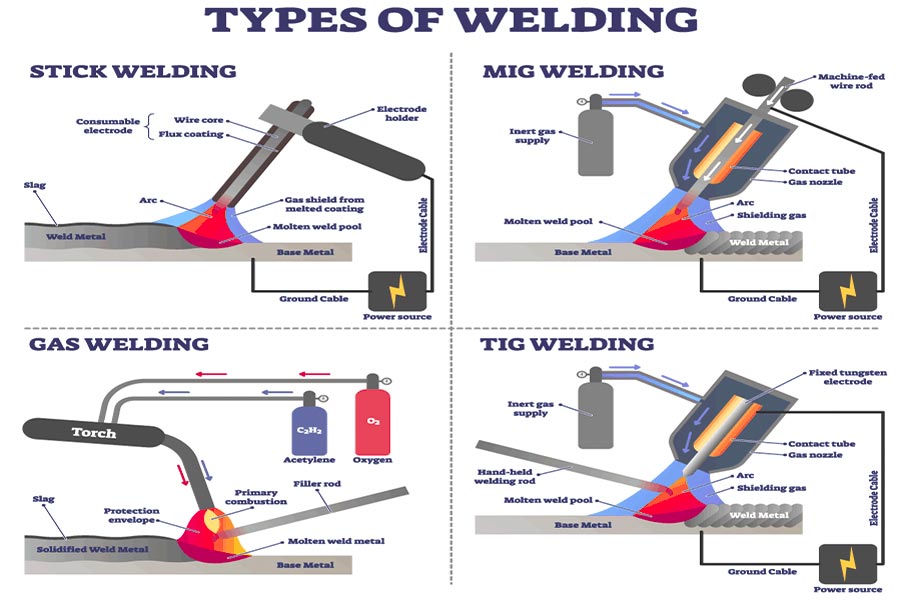

1. MIG/MAG welding

Working principle:The machine automatically feeds an arc welding solid wire metal as a filler metal and electrode, and the welding wire touches the workpiece to produce an arc. The welding gun also sprays out a protective gas (such as inert argon, or active carbon dioxide) to form a protective barrier to prevent air from damaging and prevent oxidation and nitridation of the molten metal.

Core advantages:

- High efficiency: The welding wire is continuously supplied and the welding is almost non-stop.

- Easy to master (relatively): It is convenient to achieve semi-automatic or machine automatic welding.

- Wide range of applicable materials: Applicable tothe welding of various metals such as ordinary steel, stainless steel, aluminum and its alloys, both thin and thick plates.

- Typical applications: Automobile manufacturing (car body, parts), steel structure frame, various mechanical equipment parts, pipeline welding (especially MAG welding).

2. TIG welding

Working principle: Use an extremely resistant tungsten rod as an electrode to initiate the arc. If metal needs to be added, the welding wire must be manually fed into the molten pool. The entire process is protected by a high-purity inert gas (mainly argon) to ensure that the welding area is clean.

Core advantages:

- Excellent weld quality: The welded seam is beautiful, strong and dense, with basically no spatter.

- Heat input control: The welding heat input can be precisely controlled, and it is particularly good at welding thin plates and precision parts.

- Suitable for high-demand materials: Welding high-demand materials such as aluminum, magnesium, titanium and its alloys, stainless steel, and nickel-based alloys has outstanding performance, especially where ultra-clean and ultra-reliable welds are required.

- Typical applications:Aircraft rocket parts, food and pharmaceutical pipelines, precision instruments, and high-end decorative parts.

3. SMAW welding

It is also known as coated electrode welding, and the operator holds a coated electrode both as filler metal and electrode. The electrode's solid core produces an arc and deposits filler metal. When the coating melts, it generates shielding gas and forms a layer of slag on the weld, providing double protection.

Core advantages:

- Flexibility and high adaptability: The equipment is simple and light, and easy to carry to various workplaces.It is not so picky about the surface of the weldment being a little rusty or oily.

- Suitable for welding thick and large components: It has advantages in welding thick-walled structures and large workpieces.

- Typical applications: Steel structure installation at construction sites, outdoor pipeline maintenance, equipment repair, shipbuilding, and heavy machinery manufacturing.

4. FCAW welding (flux-cored arc welding)

Working principle:It looks very similar to MIG welding,and the wire is also fed automatically by a machine. But there is a catch in the welding wire itself, which is a hollow tube containing flux powder. During welding, the flux decomposes under heat, and can produce shielding gas and slag to isolate the air (some types also use a small amount of external gas).

Core advantages:

- High deposition efficiency and deep penetration: more metal is melted per unit time, the weld is melted deeply, and it is especially suitable for welding thick plates and large grooves.

- Strong wind resistance: The generated gas and slag have good protection effect, and stable welding can be achieved in outdoor environments with a little wind.

- Typical applications: welding of large-scale steel structure workshops, welding of mining machinery structures, basic components of heavy equipment, shipbuilding (especially cabin structural parts), large-area cladding, etc.

"We deal with these processes every day. If you have specific metal parts to connect, our custom metal welding manufacturing services can help. Don't worry about which process to choose, tell us your project requirements. We will help you analyze the pros and cons, choose the most suitable welding method, and deliver strong and reliable welded parts. Contact JS at any time, and we will solve your metal connection needs together!"

Application and Design Considerations of Welding

Welding is not as simple as sticking two pieces of metal together! It is very useful in our manufacturing industry, and if you use some brains when designing, you can really save a lot of money,especially affecting the final metal welding price.Let's talk about its application and the ways to save money in design separately.

How common is welding?

This thing is used more widely than you can imagine, almost everywhere:

(1)Buildings and bridges:

The skeleton of skyscrapers, the main body of cross-river bridges, and the thick and strong steel beams and columns inside are mainly welded together to carry the entire weight.

(2)Automobile manufacturing:

Fromthe visible body shell, to the chassis frame hidden underneath, to the exhaust pipe, many key parts inside and outside the car are welded and assembled.

(3)Aerospace:

The airplane's giant wings (wings), the cylindrical body, and the high-temperature and high-pressure precision parts in the engine all rely on extremely fine welding technology to connect them tightly, error-free, safety first.

(4)Pipelines and pressure vessels:

In the petrochemical industry,the welding of long pipes for transporting oil and gas and large tanks(pressure vessels) for storing chemicals must be leak-proof, strong and durable, without any gaps, and the safety requirements are extremely high.

(5)Daily manufacturing:

From heavy machine tools and excavators in factories to metal tables and chairs at home and exquisite metal artworks, as long as it is made of metal, it is likely that welding is indispensable.

Design tips for engineers: Make welding more cost-effective

Want to make metal welding more cost-effective? When designing drawings,you must think about these key factors in advance:

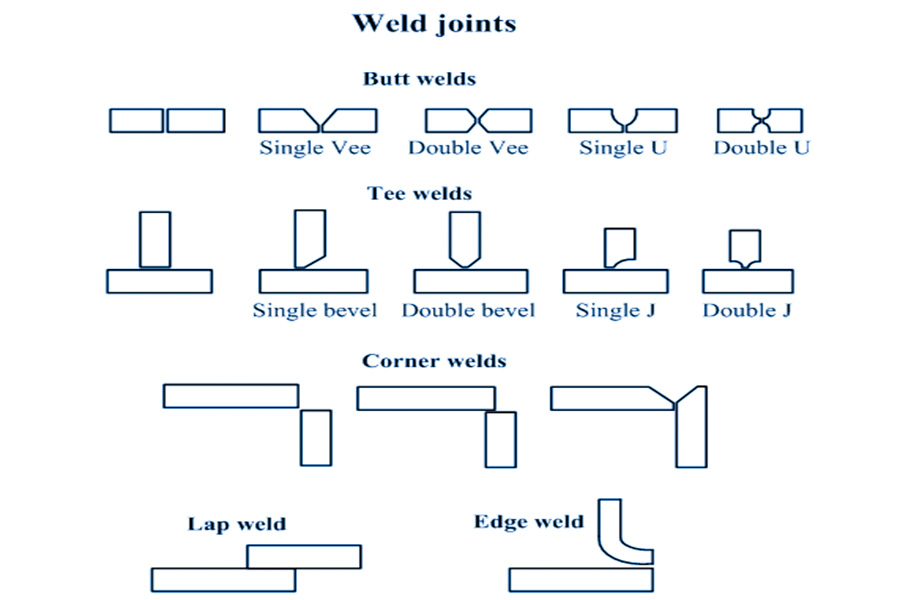

(1)Joint design:

- Preferably use butt joints or lap joints.

- Avoid joints with complex designs, poor accessibility or limited operating space.

- Complex joints will significantly increase the difficulty and working hours of welding operations, reduce efficiency, increase the risk of defective products, and thus push up overall costs.

(2)Material selection:

- Different metals have different degrees of difficulty and cost in welding.

- On the premise of meeting the performance requirements of the components,materials with good welding processability and better cost are preferred.For example, 304 stainless steel is generally better weldable and economical than 6061 aluminum alloy.

(3)Drawing marking:

- Clearly mark the weld type (such as butt weld, fillet weld), size requirements (such as weld leg size, weld thickness) and specific location in the drawings.

- Clear and accurate marking can reduce the understanding deviation and communication cost of workshop construction personnel, effectively avoid incorrect welding or rework caused by misunderstanding, and reduce related costs.

(4)Batch production:

- Similar to other manufacturing processes,expanding production batchescan effectively share fixed costs such as welding preparation and equipment commissioning.

- Try to arrange centralized production of welded parts with similar or identical structures to reduce the cost of single piece welding.

"Good design = good quality + good price. As an engineer at JS, if I have a welding design project in hand, the first step is to conduct design feasibility analysis and cost analysis. Take these factors into full consideration and implement them in the design drawings, and the final product will definitely be more competitive!"

FAQ - Answers to All Your Questions About Metal Welding

Question 1: What is the difference between welding, brazing and soldering?

Next, let me give you a clear comparison of thesethree common metal joining methods:

| Characteristics | Welding | Brazing | Soldering |

| Working temperature | Highest (melted metal body). | Medium (generally>450 ° C, melting solder). | The lowest temperature (generally<450 ° C, melting solder). |

| Connection method | Melt the metal body to be connected and mix. | Melt the brazing material, which wets the base material and flows into the gaps. | Melt solder and connect it to the base material by adhering it. |

| Connection strength | The highest, close to or equal to the strength of the base material. | Medium, depending on the solder and connection design. | Low, suitable for small forces or electrical connections. |

| Typical application scenarios | Buildings, ships, pipelines, and heavy-duty structures. | Radiators, pipes, tools, and dissimilar metal connections. | Electronic circuit boards, precision components, and small connectors. |

Question 2: How to get PDF materials on welding processes?

Don’t just look for PDFs online! The quality of welding materials online varies greatly. It’s more important to understand the basics.

Want to actually improve your design efficiency? Why not take a look at the PDF of the "Self-check List for Welding Joint Design" written by our engineers? It can help you avoid common problems in advance at the beginning of the design.

It’s easy to get it for free: send us an email or leave a message online to let us know your needs, and we will send you this practical PDF immediately.

Question 3: What is arc welding?

Simply put,it is a method of welding metals with an electric arc.

How to generate an arc? Use electricity to ignite a very high temperature between the electrode and the metal to be welded. This arc is the core heat source.

The welding methods commonly used in our workshop, such as manual arc welding (SMAW), argon arc welding (TIG), metal arc welding (MIG), and flux-cored wire welding (FCAW), are essentially arc welding. They all use arc heat to melt metal to form a connection, and the main difference is in the electrode and protection method.

Summary

Welding is far more than a simple metal connection.It is a key technology that transforms independent metal parts into high-performance, integrated structures. A deep understanding of the characteristics and applicable scenarios of different welding processes, and full consideration of weldability design principles in the design stage are the decisive factors to ensure the success of the project. A successful welding project starts with scientific design and process selection.

Next, it's up to you to take action!

When your project requires reliable, high quality metal welding parts, the JS team is your solid partner with professional engineering strength and strict quality system.

Choosing the JS team, you will get:

- In-depth engineering involvement: We provide professional advice from the perspectives of design feasibility, material selection, deformation control, etc. to optimize your design, improve product reliability, and control comprehensive costs.

- Strict quality assurance: Follow international/domestic welding standards and perform comprehensive welding process assessment and process monitoring.

- End-to-end solution: From raw material cutting, forming, welding, to post-processing and final inspection, we provide one-stop service.

Please contact the JS team now.Let us know your design drawings, 3D models or project requirements. Our welding engineers will contact you as soon as possible.

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com