Investment casting, also known as lost wax casting. With a history of 5,000 years, it perfectly combines ancient craftsmanship with modern precision technology. It makes a wax mold, wraps the refractory material, melts the wax mold to form a cavity, and then pours the molten metal to finally obtain the casting.

This method is particularly good at making parts with complex shapes, thin walls or extremely smooth surfaces.It is an ideal choice for castings made of carbon steel, stainless steel and other materials. Because these steels have high strength and are suitable for complex thin-walled designs, at the same time, investment casting can overcome the problem of high melting points that make the surface rough, making more beautiful and practical products. To this day, it is still an indispensable key technology in many high-end manufacturing fields.

What is investment casting?

The investment casting processfirst uses wax to make a model that is exactly the same as the final part, and then wraps the wax mold with high-temperature resistant ceramic slurry. On hardening ofthe ceramic, the wax inside ismeltedanddriven out by heat, leavingbehindavery accurateceramic shell. Then, the molten metal liquid is injected into the shell. After the metal cools and hardens, knock off the outer ceramic shell to get a metal casting.

The power of this method is that it can produce complex anddelicate metal parts with very smooth surfaces. Unlike sand casting, parting surfaces are required, and the interior must be supported by sand cores, and the surface is also prone to roughness. Investment casting has fewer restrictions on mold design, as long as it can be made into a wax mold, it can be copied. Although the cost of the entire process is a bit high, it is exchanged for higher precision and more delicate surfaces, which is particularly suitable for parts with high requirements.

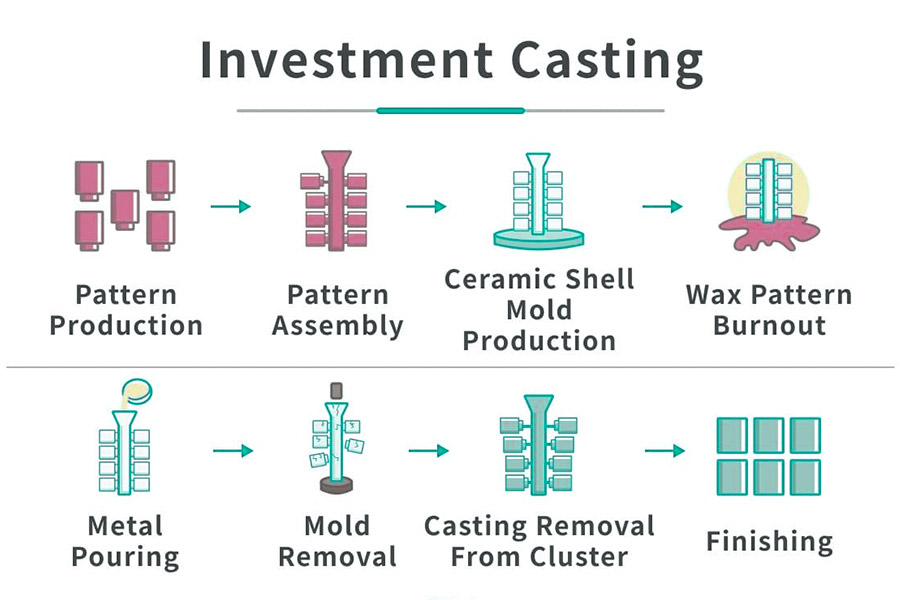

How are the 8 steps of investment casting carried out?

1. Make a wax mold:

The first step is toproduceareplicaof the shape of the part, which iswax.For small-scale production or whenusing 3D printing investment casting technology, you can directly 3D print wax molds or process wax blocks. For traditional mass production, it is necessary to first make a durable metal mold based on the 3D design data (CAD model) of the product, and then use this mold to press out multiple completely identical wax molds.

2. Assemble the wax tree:

It is not cost-effective to cast a single small wax model directly. In order to reduce the cost of parts, we carefully assemble and fix multiple wax models to a wax stick to form a tree-like structure. In this way, multiple parts can be produced simultaneously in one casting process.

3. Make a ceramic shell:

The wax model itself is very fragile and cannot withstand the high temperature of molten metal. We need to make a layer of high-temperature resistant ceramic shell on the outside of the wax tree. The production method is to repeatedly immerse the assembled wax tree in a special ceramic slurry. After each immersion, sprinkle refractory sand to increase the strength, and then dry and harden. This process usually needs to be repeated many times to achieve the required shell thickness and strength.

4. Dewaxing:

Put the shell with the coating completed in a high-pressure steam furnace. Under the action of high temperature and high-pressure steam, the internal wax material will quickly melt and flow out completely, leaving a hollow ceramic shell whose internal shape replicates the original wax model. This step is the origin of the name of lost wax casting.After removing the wax material, the ceramic shell can be used for pouring metal.

5. Metal pouring:

(1)Preheating the mold:

Before pouring the metal, the ceramic shell mold must be heated first. This is done to make the mold hot, so that the cold mold does not instantly absorb the heat of the molten metal, causing the metal to solidify prematurely.Preheating can keep the metal in liquid statefor alongerduration of timeand flow smoothlyintoevery corner of the mold.

(2)Pouring operation:

Turn the heated ceramic shell mold upside down and bury it in the sandbox to fix it. The molten metal is mainly injected into the shell by its own gravity or by applying additional pressure.

A more efficient method is vacuum-assisted pouring: vacuum is drawn at the bottom of the shell, and the negative pressure is used to suck the molten metal into the cavity.Oncethemain components have hardened,vacuum is released to allow the excess unsolidified metal to flow back to the furnace.Vacuum suction casting can greatly reduce waste, with a material utilization rate of up to 95%, which is much more material-saving than ordinary gravity casting (utilization rate 15%-50%). After the pouring is completed, wait for the metal to completely cool and solidify in the shell.

6. Removal of the mold shell:

When the metal cools to a temperature that is safe to touch, the outer ceramic shell can be processed. The ceramic shell is very brittle and is usually broken and removed by high-pressure water jet impact, mechanical vibration or knocking. At this point, the original wax tree structure has been transformed into a metal casting tree. Next, it is necessary to separate the finished parts from the central runner and riser by sawing or grinding wheel cutting.

7. Casting cleaning and post-processing:

Parts cast by investment casting usually have a relatively smooth surface and may not need further processing before they can be used. However, if some places are not ideal, some processing is required. Common operations include grinding to remove residual traces of the runner,polishing the surface, or trimming burrs. For individual defects, hand tool trimming, welding repair or hydraulic correction methods may also be used.

8. Final inspection:

After the parts are trimmed, they must be strictly inspected. First, the dimensions must be measured to see if they fully meet the requirements of the drawings. Secondly, non-destructive testing methods (such as X-ray testing, ultrasonic testing, etc.) are used to check whether there are hidden defects such as pores, shrinkage, cracks, etc. inside. Only when all inspections are qualified, the parts are truly completed.

Which materials are suitable for investment casting?

The material selection of investment casting is very flexible, and different materials have their own characteristics. Knowing these will help you get good castings:

| Material category | Advantage | Common application areas | Key points to pay attention to in casting |

| Stainless steel | Good corrosion resistance and wide applicability. | Food machinery parts, chemical equipment, and general machinery components. | During casting, the surface is prone to roughness, and refractory materials should be selected to control it. |

| Carbon steel & low alloy steel | High strength, particularly wear-resistant. | Automotive components, engineering machinery parts, and tool base parts | The casting process is relatively mature and stable. |

| Nickel based alloy | It can maintain strength even at very high temperatures (>800 °C). | Jet engine components, high-temperature components of power plants. | The casting of high-temperature alloys is difficult and requires precise control. |

| Cobalt based alloy | Specially wear-resistant and corrosion-resistant. | Medical implants, high-performance cutting tools, corrosion-resistant valves. | The cost is usually higher. |

| Brass | Beautiful color (golden), corrosion-resistant, easy to cast (low melting point). | Faucets, valves, marine hardware, decorations. | Zinc may evaporate and lose during casting, so it is important to prevent inhalation and changes in composition. |

| Super alloy | Excellent performance in ultra-high temperature and extreme corrosive environments. | High end gas turbine components, special chemical equipment parts. | Casting is extremely complex and costly. |

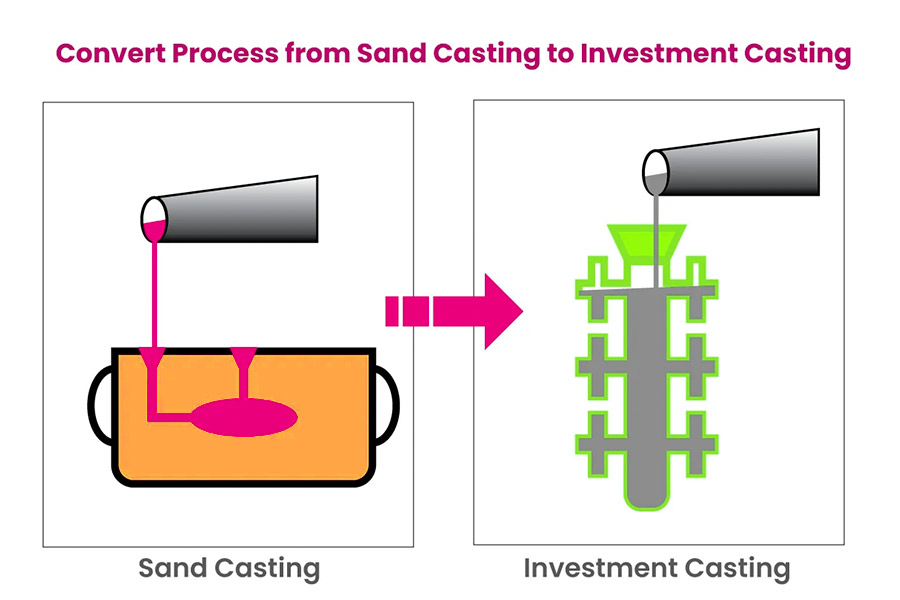

Investment casting vs sand casting: What is the difference between the two?

Investment casting and sand casting are both mainstream methods for manufacturing metal parts, and they differ greatly in process details. Let's focus on the comparison of sand casting vs investment casting.

1. Different process

Sand casting:

- Its operation is simpler. First,wet sand is used to make a cavity in the shape of the part, and the molten metal is poured into the cavity. After it cools and solidifies, the sand mold is removed to get the part.

- Core features: It is based on disposable sand molds. The manufacturing process is relatively simple, and equipment investment is not expensive, making it easily mastered.

- Main limitations: The sand mold is destroyed when it is demolded and cannot be reused. A sand mold can only cast once.

Investment casting:

- This process is more complicated. The first step is to make a wax mold, apply a high-temperature resistant material to form a mold shell, and then harden the mold shell and melt the wax after high-temperature baking.

- Finally,fill it with metal liquid to form the part.It can produce high dimensional tolerance and surface quality castings. However, investment casting is not advantageous in that there are more process steps and production cycle is relatively longer.

2. Material selection and application scenarios

The sand mold material of sand casting is usually quartz sand mixed with clay, which is cheap and easy to find, and is suitable for producing parts with simple shapes and medium precision.

Investment casting uses precision ceramic shell materials as shells, which can withstand high temperatures and have rich details, and can handle high-demand metals such as alloy steel or stainless steel.It is common in small batches and complex-shaped products.

| Comparison of key parameters | Sand casting | Investment casting |

| Surface roughness (Ra value, μm) | 12.5 - 25 | 3.2 - 6.3 |

| Dimensional accuracy (tolerance, mm) | ±0.5 - 1.0 | ±0.1 - 0.2 |

| Minimum wall thickness (mm) | ≥3.0 | ≥1.0 |

| Typical cost difference per unit (relative) | Lower | Higher (about 1.5-2 times higher) |

3. Difference in precision

The surface of parts cast by sand casting is rough and requires additional grinding or processing (for example, the surface Ra value is above 12.5). The dimensional accuracy is also poor, and the tolerance is often stuck at ±0.5mm. It is fine for making simple shapes, but not suitable for micro parts.

Investment casting has high precision, andthe tolerance can be pressed to within ±0.1mm. The surface is smooth directly (Ra value is about 3.2), which saves a lot of subsequent processing steps.

4. Cost and complexity

| Cost influencing factors | Sand casting | Investment casting |

| Comparison of individual unit costs | Lower (set as benchmark). | Higher (about 1.5-2 times that of sand mold). |

| Mold reuse rate | Very low (almost scrapped once). | Higher (ceramic shell can withstand several pours). |

| Main material costs | Very low (sand, clay). | Medium to high (wax, refractory materials, coatings). |

| The complexity of manual operation | Relatively simple and easy to mechanize. | More complex and reliant on skilled manual operations. |

| Typical equipment investment | Lower (sand mixer, molding equipment, etc.). | Moderate to high (wax making, slurry sticking, roasting furnace, etc.). |

| Subsequent precision machining | Frequently required (polishing, deburring). | Less need (good surface, saving polishing money directly). |

The cost of a single piece of investment casting is usually about 1.5 to 2 times that of a sand mold. However, it also has an advantage, that is, one mold has a high multi-use rate, which is more cost-effective when producing complex parts in small batches.

What are the representative applications of investment casting?

Investment casting is in fact widely used, and most industries use it to manufacture parts because it has some special advantages. The first step of the whole process is to make a model of the investment casting wax that is an exact replica with the part.

1. Aerospace

In high-precision places such as making airplanes and rockets, it is used to produce key parts, such as turbine blades, engine parts, and structural parts. Because the precision requirements are extremely high, and various special alloys must be used to meet the ultra-high safety and performance requirements, this process is particularly suitable.

2. Automotive industry

The automotive industry also likes to use it.Parts made with it, such as parts in the gearbox, engine block, and suspension system parts, are not only strong and durable, but also can be made lighter. This is very helpful to improve the fuel efficiency and user experience of the vehicle.

3. Medical applications

In the medical field,investment casting is very good at manufacturing small and complex partssuch as surgical instruments, human implants or precision diagnostic equipment. The key is that the products it makes are of high precision and the materials are biocompatible with the human body, which is very important for medical use.

4. Industrial equipment

Many industrial equipment that we come into contact with in daily life also have parts made by it. For example, the parts in various pumps, valves, and mechanical devices are valued for this casting method that can ensure accurate dimensions and can select various suitable material properties to meet specific needs.

Why choose investment casting?

1. Manufacturing high-precision parts

This is where investment casting is particularly powerful, and the surface of the parts is very smooth, and basically no great effort is required to polish them. This is a big advantage for many parts that require a perfect fit or beautiful appearance.

2. Creating complex structures

It is best at dealing with designs that are particularly complex and delicate in shape. Some parts have a maze-like internal structure, or there are many fine patterns and holes on the surface, which may not be made using ordinary casting methods. But investment casting can solve these problems.It can reproduce the complex shapes on the design drawings exactly.

3. Good at using high-strength and corrosion-resistant materials

For example, some high-performance alloy steels, stainless steels, high-temperature alloys, and even some titanium alloys. These materials are usually difficult to process by cutting, either because they are too hard and the tools wear quickly, or because the processing cost is too high. Investment casting directly casts them into shape with liquid metal, bypassing these processing problems.

Why is investment casting still relevant today?

1. Use new technologies

3D printing wax for investment casting has become the mainstream for making complex molds (wax molds). This has completely changed the traditional manual mold making method, with fast speed, high precision, and lower cost, making production more flexible and efficient.

2. Irreplaceable in high-end fields

In industries that require extreme precision, super durability and reliability (such as aircraft engine blades, medical implants, and energy key parts), investment casting is still the first choice. It can perfectly replicate complex designs andprovide excellent surface finish.

3. Mastering difficult-to-process materials

This process is particularly good atprocessing high-strength alloys and heat-resistant/corrosion-resistant special materials(such as titanium alloys and high-temperature alloys), and can produce parts with excellent intrinsic quality to meet stringent performance requirements.

How does JS plan your investment casting project?

1. Clear demand matching

When you tell us your project requirements, we will communicate with you in depth to accurately grasp the required shape, key dimensions, material properties, use environment and expected production scale of the parts.

2. Design and mold development

Send your requirements,our engineering teamwill design the casting plan and create an accurate product model. Then, use professional mold manufacturing technology to manufacture prototype molds, which is the basis for subsequent mass production of high-quality wax molds.

3. Prototype verification and optimization

We will first produce a small batch of prototype castings and send them to you for rigorous testing and dimensional verification. Your feedback is crucial to help us confirm that the design is correct or guide us to make necessary improvements and adjustments until we fully meet your expectations.

4. Stable mass production and delivery

After the plan is confirmed, JS enters the formal production stage. We strictly monitor every step, from wax pattern making and shell preparation to precision casting, cleaning and post-processing. We focus on quality control and efficient collaboration throughout the process to ensure that you can deliver stable and reliable precision castings on time.

Choosing JS means choosing a professional and reliable investment casting partner. With experience in more than 3,000 alloy materials, perfect production processes and strict quality systems, we are committed to accurately transforming your designs into high-quality end products.

Summary

Investment casting, also known as the lost wax method, is an old method that has become very advanced after being transformed by modern technology.Its biggest advantage is that it is not restricted by shape, allowing designers to turn particularly complex and sophisticated designs into high-performance metal parts. Although it is costly and time-consuming to do, if you really need extremely complex, particularly precise and high-performance metal parts, investment casting is often the best choice.

Have you come into contact with investment castings at work? Or do you have more questions about this process? Welcome to leave a comment in the comment area to share your insights or ask questions!

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

FAQs

1. How to make a wax model?

In investment casting, the wax model needs to be made of a metal mold first, and then the molten wax is injected into the mold under high pressure. After cooling, the wax part is taken out and assembled with the runner after trimming to form a wax model tree. The surface of the wax model needs to be coated with a high-temperature resistant material to form a shell.

2. What is the working principle of investment casting?

Investment casting uses fusible materials (such as wax) to make a precision model, and the surface is coated with multiple layers of refractory materials to form a shell. The wax model is melted out by high-temperature baking to obtain a cavity, and then the molten metal is poured into it. After cooling, the shell is broken to obtain a high-precision casting.

3. What metals can be cast?

Investment casting is suitable for a variety of metal materials, including stainless steel, alloy steel, carbon steel, aluminum alloy, titanium alloy, high-temperature alloy (such as nickel-based/cobalt-based), and copper alloys, gold, silver and other precious metals. This process is particularly suitable for casting metal parts with high melting points, difficult processing and precision forming.

4. What are the limitations of investment casting?

The process is complex and the cycle is long, and the cost per piece is high (especially for small batches). The casting size is limited (generally ≤30kg), and it is difficult to produce thick and large castings. The ceramic shell is prone to cracking, and surface cleaning and tolerance control are challenging.

Resource