In JS, we often have such a demand: to make a 50 kg pump body with a complex structure. If the whole block of metal is cut and processed, the waste of material and cost is tremendous.Sand casting, a century-old technology that can be regarded as the ancestor of casting, uses the most common sand as a mold to directly "shape" the molten metal into your desired complex parts.

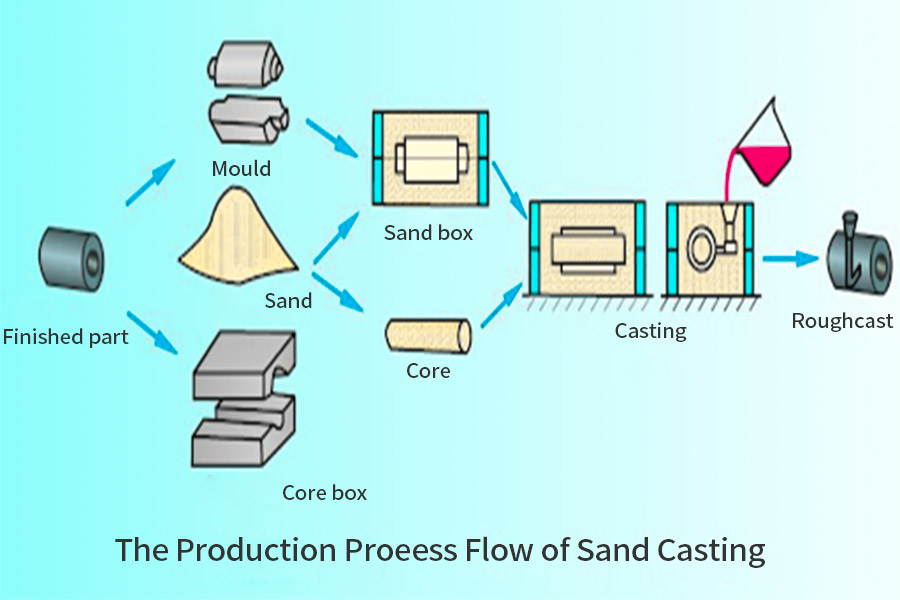

The process is very simple:

- We first make a model of your part in metal or wood. Put it in a special sand box, fill it with prepared sand, and pack it.

- Then, remove the model carefully, and the part cavity in the exact shape is left in the sand.

- Then pour the seething molten metal into it, allow it to cool down and become solid, knock off the sand, and the part is out.

You see, the money and material-saving tip in this case is that the sand mold is disposable and can create complex shapes.

This process in our workshop is used every day. It is best suited for making parts that are large in size, complex in shape, and do not want to waste too much material, such as large pump casings,valve bodies, engine cylinders, etc. While experience is required in sand selection, modeling, and pouring temperature, it is precisely this flexibility, economy, and dependability that have allowed sand casting to maintain a place in the automobile and machinery industries securely.

Core Answer Summary:

| Characteristic | Sand Casting | Investment Casting | High pressure die casting |

| Mold materials | Sand (usually disposable). | Ceramic shell (disposable). | Steel molds (reusable). |

| Dimensional accuracy | General | Tall | Very high. |

| Surface smoothness | Rough (requiring secondary processing). | Smooth | Very smooth. |

| Production cost | Low (especially in terms of mold cost). | Tall | The cost of molds is extremely high, but the cost per piece is low. |

| Applicable scenarios | Large, thick walled, and complex internal cavity components. | Small, complex, high-precision parts. | Large quantity, thin-walled, high smoothness parts. |

This article will answer your questions:

- This guide will take you through the complete steps of sand casting in detail.

- Analyze the core green sand casting process and list its typical sand casting products.

- And use real cases to explain why it is still an irreplaceable key process in today's industrial manufacturing.

Why Trust This Guide? The Front-Line JS Casting Engineer's Reality

As a casting engineer of JS company, the customer sent an order foraluminum alloy sand casting. We must first ask: Where will this part be used in the end? What amount of force will it bear?Because this directly determines which aluminum alloy we use! For example, the A356 alloy with particularly good fluidity is suitable for thin-walled parts with complex shapes. If the part is subjected to high force and requires to be stronger, then you have to change to another tougher grade. This is not a random choice.

Let's talk about the wet sand we use. We strictly control the moisture content with an accuracy of 0.1%. We know that if there is too much water in the sand, when the hot aluminum water is poured into it, the excess water will instantly turn into gas, resulting in bubbles and sand holes in the casting, and the entire processing will be ruined! This is the experience gained from the bloody lessons.

The same is true for choosing molds for customers. Should we use wood or metal? This is not just a cost issue. This is based on the accurate prediction of customers' long-term needs.

Experience is the best teacher:

- We once helped a water pump manufacturer to process a large hydraulic valve body, which was difficult to process because of the inaccurate size of the flow channel.

- We carefully studied the problem and finally suggested that they replace the original wet sand with aresin sand hardened by chemical agents. The dimensional accuracy of the complex inner cavity flow channel was significantly improved. In this way, the cutting allowance of subsequent processing was reduced by 60%, saving time and cost.

"As the casting industry leader John Campbell often emphasizes: 90% of casting quality is determined by the mold preparation stage."

This guide is the result of how our group of JS engineers closely combine this kind of profound material science knowledge with first-line process practice. It is not a textbook theory, but a crystallization of practice and theory at the furnace.

Core Principle: The Art of Using "Negative Space"

Imagine pressing a footprint on the beach, then pouring water into the footprint, and the water solidifies to form a "foot" shape.The essence of sand casting is similarto this, except that we use special sand casting sand and molten metal. Simply put, it is to use a solid "pattern" to create its "cavity" (negative space) in the sand, and then pour molten metal into this cavity. After it cools, it is the metal part you want.

This process relies on three basic elements:

(1)Pattern:

This is the starting point of our work, which is equivalent to a "stand-in" for your final part. It is a physical model made according to the part drawing, usually made of wood, plastic or metal.

Key point: The pattern is not a 1:1 replica of the part! We will enlarge the size in advance when designing, and we have to calculate and reserve this shrinkage in advance. Make the pattern larger so that the part size after cooling is just right.

In addition, the mold surface must be designed with a draft angle, otherwise the mold will not be able to come out of the sand smoothly after compacting the sand mold.

(2)Sand mold:

This is our core battlefield! Buried in the special casting sandspecially prepared by our JS. When the mold is carefully taken out, the cavity we need is left in the sand mold.

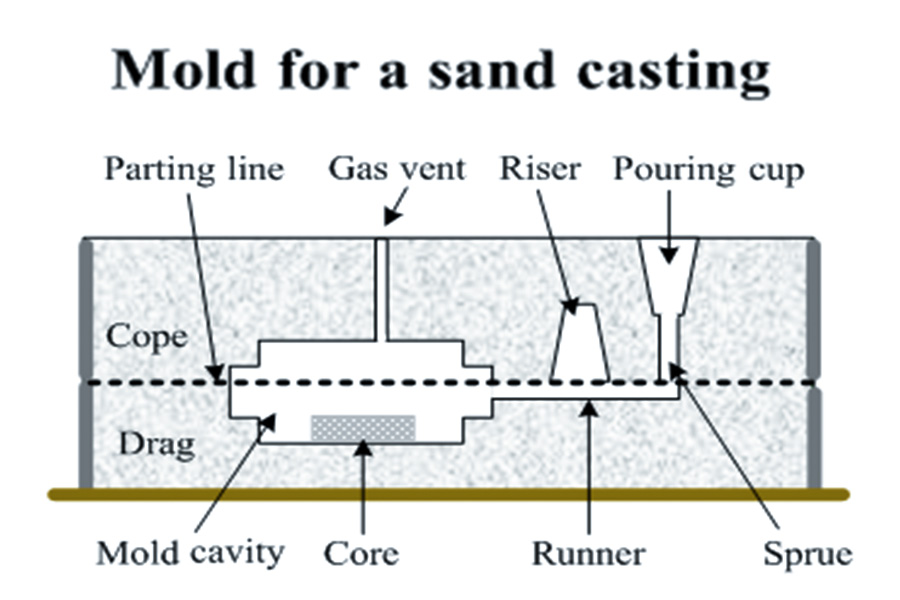

In order to facilitate operation and ensure the quality of castings, the sand mold is usually divided into two halves and placed in a dedicated sand box:

- Lower box (Drag): placed in the lower half of the sand box, usually contains the main outline of the part.

- Upper box (Cope): placed in the upper half of the sand box, covering the top of the lower box, together forming a complete cavity, and containing a channel for pouring metal.

After taking away the mold, the upper and lower sand boxes are combined, and the cavity in the middle is the "hollow mold" we want.

(3)Casting:

- This is our final target product. Pour the melted high-temperaturemolten metal into the "hollow mold"from the opening on the top of the sand mold. The molten metal fills and flows in the mold cavity, and eventually cools and hardens.

- Finally, disassemble the sand box, take out the initially formed metal parts, and then go through cleaning (removing pouring risers, flash burrs, surface sand, etc.), inspection and other processes to get the casting.

The charm of sand casting lies in that it uses the most basic sand materials to replicate complex spaces through patterns, allowing the flowing metal to solidify into the required shape. This method has extremely high design freedom and economy, and is particularly suitable for the production of single pieces,small batches or large complex parts.

"If you have a part that you want to do sand casting, just give it to us JS!We know the tricks best, so let us help you cast your next key component."

Step By Step: The Complete Process of Sand Casting

Today, I will talk to you in the most realistic words about how a metal part is transformed from a piece of wood. In this process, every step hides our experience and wisdom.

Step 1: Pattern Making

After getting the part drawing, the first step is tomake a physical model, which is the pattern. The materials are most commonly wood, plastic or metal.

There are two key points here:

- First, the pattern size must include the shrinkage margin after the metal cools and solidifies (for example, the shrinkage rate of aluminum alloy is about 1.3%).

- Second, the pattern cannot be made straight up and down, and it must be designed with a slope (usually 1-3 degrees) to ensure that it can be smoothly removed from the compacted sand later.

Step 2: Sand Core Making

If your part is hollow inside, such as a water pipe or a valve cavity, the pattern itself cannot form these "negative spaces". You will need to make a "sand core" now.We use special core sand, add special adhesives to make it hard, and put it in the middle of the sand mold.When we cast, it forms theinsideshape of the part.

Step 3: Make the lower box

We take a bottom sand box (called the "lower box"). First, place the lower half of the pattern steadily on the bottom plate of the lower sand box.

Then, use the special casting sand prepared by JS (green sand is the most common, which is wet sand mixed with water and kaolin) to carefully fill the lower box, and compact it uniformly and completely using any tools or devices. This step is the basis. If the sand is not compacted, the cavity behind will easily collapse.

Step 4: Turn over and build the upper box

Turn the built lower box and the pattern over as a whole, so that the bottom is facing up. Remove the bottom plate to expose the parting surface of the pattern. Spread a uniform layer of parting sand over the parting surface to prevent the sand of the upper and lower boxes from sticking.

Next, put the upper half of the pattern on and buckle the upper sand box. At this time, we will make the channel (gate) for the metal water to flow in and the place where the metal water finally emerges (riser). This is calledthe pouring system, and that is very critical!

Step 5: Mold removal, core lowering, and box closing

- After the sand is compacted, you can carefully separate the upper and lower sand boxes. Open. Gently remove the pattern from the sand.

- Now, a cavity that is precisely an impression of the part is left in the sand mold.

- If the part requires a sand core, place it accurately in the reserved position in the lower sand box now.

- Finally, close the upper box accurately and smoothly to the lower box, fasten it or press it with a heavy object to prevent it from being pushed open by the metal water during pouring. A complete cavity is ready!

Step 6: Pouring

Here comes the highlight! Put the metal (for example, aluminum sand) that is heated hot in the furnace and turned into water into a mold. In casting, aluminum alloy is usually at 700-750°C), and is quickly poured into the closed sand mold through the gate until the metal water is seen overflowing from the riser. The temperature and speed of this step must be controlled well. Too fast will easily cause sand washing, and too slow may cause cold shut defects.

Step 7: Cooling and sand removal

Let the casting cool naturally and completely solidify in the sand mold. The cooling period is dependent upon the size, wall thickness and nature of metal in the casting. After solidification, open the locking device, destroy the sand box, and remove most of the sand from the casting by vibration, knocking, etc. Falling (this process is called falling sand). The casting obtained after falling sand still has the gate, riser system and adhered sand. We recycle most of the molding sand and core sand to reduce costs.

Step 8: Post-process the casting

The casting is still in a raw condition just after it comes out of the sand. We need to use cutting tools to remove the excess parts such as the gate and riser, and use grinding tools to clean the flash burrs. Sometimes it is necessary to perform sandblasting or shot blasting to completelyremove the surface sticking sandand oxide scale to obtain a smooth surface. Finally, you get the finished casting that meets your requirements.

"You see, the sand casting process is sequential, model to sand mold to pour and cool, which is somewhat akin to each other. Experience and control of one step directly affects the quality of the finished product. At JS, we are most familiar with every problem and trick in this process.If you have a part that you want to make with sand casting, you can't go wrong by leaving it to us."

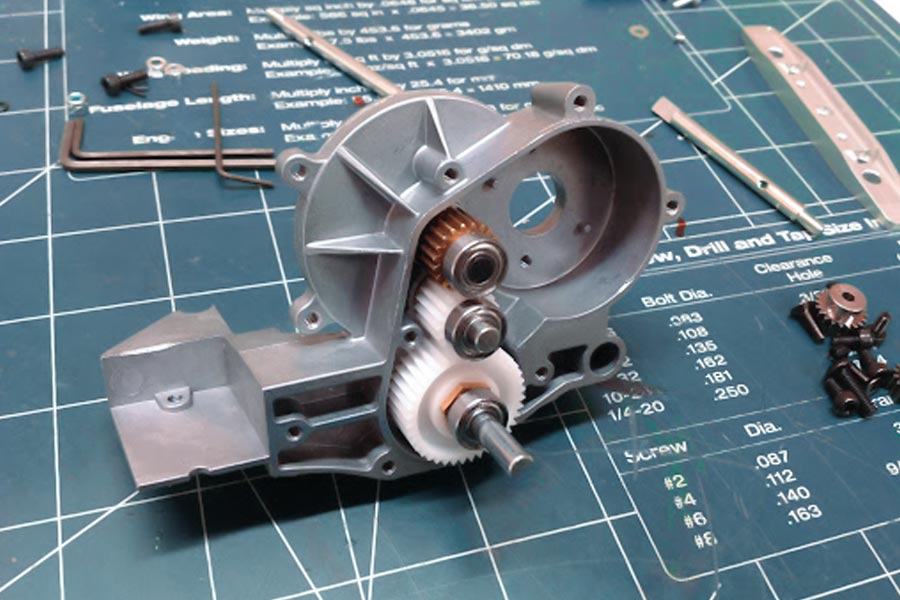

Actual Combat Case Analysis: Manufacturing Cost-Effective Gearboxes for Heavy Machinery

As the engineer in charge of this project at JS, I will analyze for you how weused sand casting technologyto successfully solve the manufacturing problem of large gearboxes for an agricultural machinery manufacturer.

Customer pain point: The high cost of welding and assembly

The customer is a well-known agricultural machinery manufacturer. The large gearbox of one of their main tractors was originally welded together with several thick steel plates. At this time, they faced severe challenges:

- Huge cost pressure: The original process used multiple thick steel plates to weld and form, relying on a large number of highly skilled welders and long working hours, resulting in high unit costs.

- Prominent performance risks: The weld becomes a weak point of fatigue failure, and the risk of cracking is high under continuous heavy load conditions, threatening product life and reliability.

- Production capacity encounters bottlenecks:Complex weldingand subsequent assembly processes limit the production cycle, making it difficult to meet the needs of market growth.

JS's solution: Sand casting achieves one-piece molding

We carefully analyzed the core needs of customers and manufactured complex and high-strength shells in an economical and efficient way. We strongly promotethe ductile iron sand casting solution:

Why choose ductile iron?

This material is amazing! The strength is almost catching up with steel, and the key is that it is particularly shock-absorbing. It is naturally suitable for impact and fatigue resistance, and ismuch more reliable than welded parts.

Integrated design:

We completely overthrew the original patchwork welding design. Using our sand casting expertise and combined sand core technology, we cast a complete shell, internal ribs, bearing seat holes and built-in oil circuits at one time. The trouble of welding and assembly is eliminated.

Cost efficiency win-win:

Our sand casting molds are low-cost.Moreover, the production process is easier to use automated equipment, and the efficiency is further improved, so the unit cost naturally comes down.

| Manufacturing process | Mold/tooling cost | Single piece production cost (large parts) | Production speed |

| Steel plate welding | Medium | Tall | Slow |

| Sand casting | Low | Low | Fast (especially in bulk). |

Source: American Foundry Society AFS.

Significant results: Comprehensive improvement in strength, cost, and reliability

When the first batch of cast boxes were delivered to customers, engineers looked at the seamless structure and dense material, and their first impression was that they were no longer welded together.

The implementation of the plan has achieved remarkable results: Eliminating welds, optimizing wall thickness, and significantly improving overall rigidity and strength.

Outstanding economic benefits:

- The cost of a single piece dropped by 45%: Material and labor savings and efficiency improvement work together.

- Production efficiency tripled:Sand casting process(especially resin self-hardening sand) is much faster than complex welding.

Reliability leap:

- Fatigue life increased by >50%: No weld stress concentration + excellent fatigue resistance of ductile iron.

- Customer after-sales cost greatly reduced: The problem of box cracking has been completely solved.

Industry insights and authoritative evidence

This case confirms the irreplaceable nature of sand casting in specific scenarios.

"As David C. Schmidt, former president of the American Foundry Society (AFS), emphasized: The core value of casting is to transform the material potential into structurally complete functional parts with the best cost-effectiveness, especially when dealing with large and complex geometries."

Sand casting perfectly embodies this concept here:

| Key indicators | Original welding plan | JS sand casting solution (ductile iron) |

| Unit cost | Benchmark (100%). | Reduce by 45%. |

| Production cycle | Benchmark (100%). | Shorten by 67% (efficiency x3). |

| Life | Benchmark (100%). | Increase>50%. |

| Applicability | Small and medium-sized batches. | Preferred for large/single/small batches. |

| Design freedom | Restricted by welding process. | Extremely high (complex lumen/shape). |

Source: American Foundry Society Industry Report.

For large, complex, cost-sensitive structural parts that do not require micron-level precision (such as the requirements of somesand casting aluminum parts), sand casting has shown strong vitality with its classic design freedom and economy.

"At JS, we focus on deeply understanding customer needs and providing customers with the best sand casting solutions with our deep material knowledge and process experience. If you have similar large, complex or cost-sensitive key component needs, we are very happy to discuss in depth."

FAQ - Answer More Questions About Sand Casting

1. What are the advantages and disadvantages of sand casting?

Advantages:

The biggest advantage is that the mold is relatively cheap and the preparation time is short. It has little restrictions on the size and weight of the casting, and can make parts as small as tens of grams or as large as tens of tons. And almost any metal material can be cast with it, especially good at making parts with very complex internal structures.

Disadvantages:

The precision and surface finish of the casting will be worse, and usually it needs to be processed later. In addition, the production efficiency is not too high, and it is a bit difficult to fully automate the production with machines. In addition, it is not suitable for parts with particularly thin walls.

2. What products are generally produced by sand casting?

Sand casting has a very wide range of applications. Like the engine block and cylinder head on the car, the water pipes and valves used in municipal engineering, and the pump body, large machine tool base, gearbox housing and other parts with large size, relatively complex structure and certain strength required in the industrial field, many of them are produced by sand casting, especially when the shape is relatively complex, it is quite suitable.

3. Sand casting vs investment casting (lost wax method): What is the difference?

As an engineer of JS company, let me talk about the core difference between investment casting vs sand casting:

Sand casting:

We use a "pattern" that can be used repeatedly to press out the cavity in the sand. The advantage is that the mold is cheap and fast to make. But the disadvantage is that the size accuracy and surface finish of the parts made will be a little worse.

Investment casting (lost wax method):

It uses a disposable wax mold, which is coated with ceramic slurry to make a cavity, and then the wax is melted. The mold obtained in this way is very precise, so the casting has extremely high precision and surface finish. However, the price is high cost and complicated process.

Sand casting pursues economical and versatile, and can process large parts and complex cavities. Investment casting pursues extremely fine surfaces and sizes, which is suitable for parts with particularly high requirements.

Summary

Although sand casting has a long history, it still occupies an important position in modern industry with its unique flexibility and cost advantages. It proves that with seemingly ordinary sand andreasonable engineering design, strong and reliable core components can still be made.

Have you encountered these situations in your project?

- Need to make a strong, complex-shaped component, and control the cost.

- Still worried about the high machining cost or unstable quality of welded parts.

Don’t hesitate to talk to us:Our JS team has more than ten years of rich experience in casting! We will carefully look at your needs and designs, make a comprehensive evaluation and analysis, and help you determine whether sand casting is the most suitable solution for your project.

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsrpm.com

Resource