Thesand casting processcan be traced back to ancient Egypt nearly 5,000 years ago. Although the core is still to use sand as a mold to cast metal, it has long been upgraded and is still the main technology in the field of metal casting.

Sand casting has been perfectly integrated into modern manufacturing. More than 60% of the world's metal castings are produced by it, especially when it is made in small batches or medium-sized, it is usually the most cost-effective choice. Many metal objects around you, from car engine housings to complex art castings, are sand casting products.

Of course, it also has shortcomings, such asthe surface of the parts is usually slightly rough, and the dimensional accuracy is not as good as those more expensive precision casting methods, but it is still the preferred method for many industrial manufacturing with its strong adaptability and cost advantages. Next, we will start with the basic definition, see where its advantages are, and what are its shortcomings, to help you fully understand the sand casting process.

What is sand casting?

The core process of sand casting is relatively direct. First, make a cavity according to the shape of the part, then pour the boiling molten metal into it, and wait for it to cool and solidify, and then you can get the final part.

After hundreds of years of development,sand casting has become one of the most flexible and widely used methods in metal casting. Whether to choose it depends on the design requirements, cost considerations, production batches and factory manufacturing feasibility of the parts you want to make. Its most powerful feature is its strong design freedom, which can produce parts of various shapes and complex structures, especially large workpieces and components with internal channels.

The main reasons why sand casting is popular:

- Cost-effective: Cheap! The mold cost is low, the sand itself is not expensive, and the overall process economy is good.

- Super high flexibility: It can meet small batch customized production and is also suitable for large industrial applications (such as automotive parts).

- High shape compatibility: It can process simple shapes or delicate and complex structures, and even parts that need to make internal cavities.

- Wide material universality: It is applicable to a variety of metal materials.

How to complete sand casting in steps?

1. Prepare materials

Sand is the main ingredient, and needs to be mixed with a binder to hold the sand grains together. Sometimes additives are added, such as clay, coal powder or special chemicals, to make the sand mold stronger, more breathable and easier to break up after cooling.

The key is to choose the right sand:it must be able to withstand the high temperature of the molten metal, have good breathability to allow the gas to be discharged smoothly, and be easy to remove the casting. For example, aluminum sand casting, which is commonly used when casting aluminum parts, has specific requirements for sand performance.

In addition, it is also necessary: the molten metal liquid to be poured, the model of the final casting shape, and various tools for making sand molds.

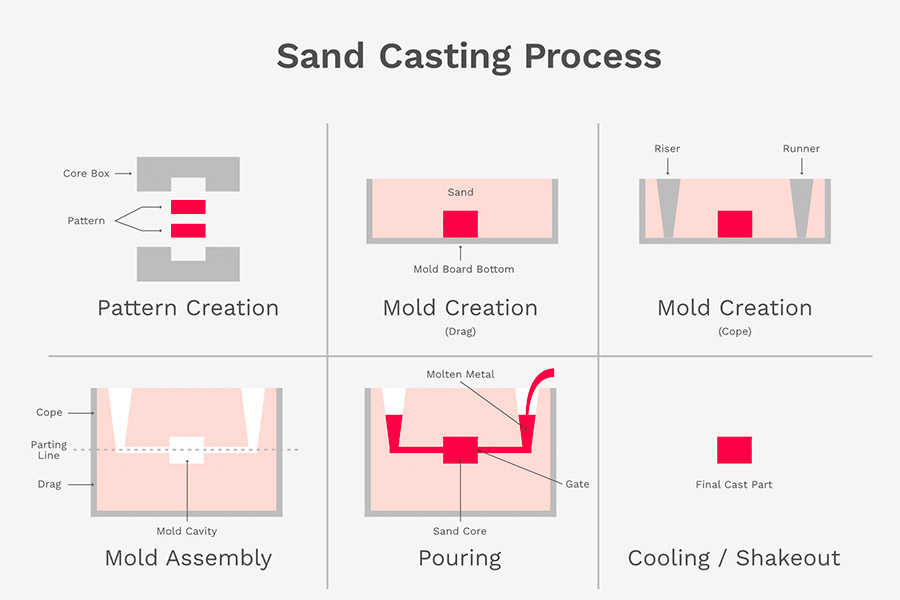

2. Make a model

First, use wood, plastic or metal to make a model of the final casting shape.

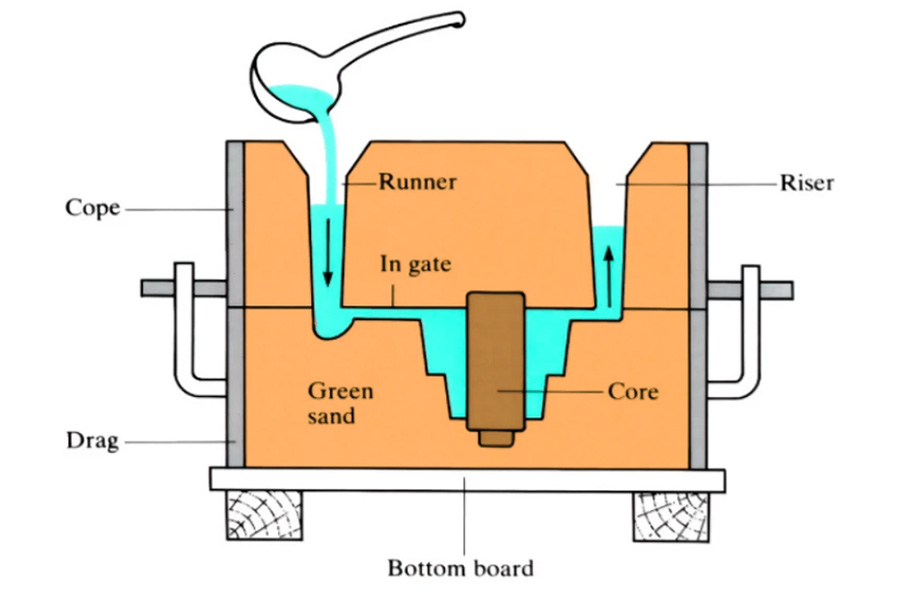

Press this model into the mixed sand, usually by pressing out the corresponding cavities in the upper and lower sand boxes respectively. The upper and lower sand boxes are combined to form a complete cavity, which is wherethe molten metal will eventually fill and form the casting.

3. Design the pouring system

The molten metal needs a special channel to flow into the mold cavity, which is the pouring system. The quality of the casting is directly determined by the design of this system. A good system should be simple, efficient, reduce turbulence of the molten metal, and block slag and gas.

The pouring system mainly includes these parts:

| Component | Function | Key points |

| Gate cup | Funnel for pouring molten metal. | First entrance. |

| Sprue | Channel for molten metal to flow vertically from the pouring cup. | Flows by gravity. |

| Runner | Horizontal channel connecting the sprue and the ingates. | Distributes molten metal and often blocks slag. |

| Ingate | Last entrance for molten metal to enter the cavity. | Controls flow rate and direction to prevent flash. |

| Riser | Storage for excess molten metal. | Supplements missing metal when the casting cools and shrinks. |

4. Place the core

If a cavity or hole is required in the middle of the casting, the core must be placed before the box is closed. The core is also a solid block made of sand, which is precisely placed in the reserved position in the mold. During pouring, the molten metal will flow around the core to fill the space. After cooling and solidification, the core is removed, and the required cavity or hole is formed on the casting.

5. Pouring metal and cooling

Pour the molten metal carefully from the pouring cup to fill the entire cavity and pouring system.

After the molten metal is filled,let it slowly cool and solidify into a solid casting. It is important to control the cooling speed. Too fast or too slow may affect the final performance and dimensional accuracy of the casting. The cooling method can be natural cooling, and sometimes fans, water mist and other auxiliary means are also needed to control it.

6. Handling sand and castings

After the casting is completely cooled and hardened, the sand is removed, the sand box is disassembled, and the sand mold is knocked and shaken to let the sand wrapped around the casting fall off and take out the casting inside. The removed casting will be sent forcleaning of flash, burrs and subsequent machining processes.

Most of the removed sand, which we call old sand, can be recycled and reused. Each time it is recycled, some sand will be lost, which requires some new sand to be added to meet the requirements of the next casting.

What are the different types of sand casting processes?

1. Green sand casting:

It is the most popular and traditional method of sand casting. Its simple sand mold contains clay and a little bit of water. "Wet" is used for water content in the sand, which is like glue, that can be used to bind sand and clay, thereby making it simple to make models.

The advantage of this method is that it is easy to modify when making sand molds, it is also convenient to take out the model, and the size of the casting is relatively accurate.

Because it is simple, flexible and economical, it is particularly used in places wheremass production is required, such as automobile parts and machine parts. It is the basic process of our company's foundry.

2. Dry sand casting:

This can actually be regarded as an upgraded version of wet sand casting. After the wet sand mold is made, instead of pouring molten metal immediately, it is put into the oven to dry the water thoroughly.

After drying, the sand mold becomes stronger and harder, and there are fewer gaps inside.The castings made in this way have smoother surfaces, more precise dimensions, and fewer internal defects. With an additional drying process, the time and cost are slightly higher than wet sand.

3. Shell casting:

This is a method invented by the Germans during World War II, which is particularly suitable for mass production of small parts with smooth surfaces and precise dimensions.

The sand used is very special: it is very fine silica sand with almost no clay, and then mixed with a resin glue that hardens when heated, usually phenolic resin.

The method is also unique: sprinkle the mixed sand on the metal mold plate. When the sand hits the hot plate, the resin on the surface melts and sticks to the sand, forming a hard shell about 6 mm thick. This shell needs to be heated for a few more minutes to become a solid shell mold.

This shell mold is very thin and smooth, so the surface quality of the casting is good, the size is accurate, and the amount of sand used is much less than wet sand.It is very suitable for making precise partsthat need to be mass-produced, such as some parts of automobile engines.

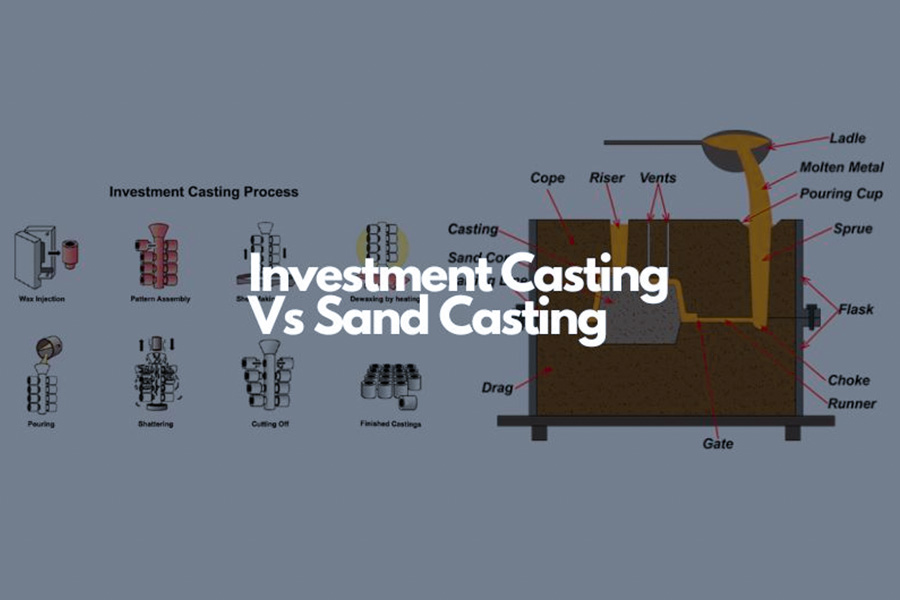

Sand casting vs investment casting: What is the core difference?

1. Different mold materials

The core difference between the two methods is the material of the mold.Investment casting relies on ceramic materials to make molds. It is on a wax model, and a special ceramic slurry is applied layer by layer to form a hard shell structure.

In contrast, sand casting uses sand as the main material, usually mixing silica sand with clay or resin to shape.

2. Design capability comparison

If your part design is very complex, thin structures or fine details, the advantages of investment casting are more obviously evident. It utilizes wax mold characteristics to easily mold various details.

Althoughsand casting can also produce many complex shapes, it is difficult to produce thin or fine structures because sand easily collapses.

3. Production scale and cost

When it comes to the cost of investment casting vs sand casting, the production quantity is the key. Sand casting molds are simple and low-cost, especially suitable for mass production. The unit price is very affordable when the number of parts processed is large.

Investmentcastmolds arecostly andtime-consuming, andmoresuitedfor small batchruns. They are worth choosing when high precision and finish requirements are required. The following is a cost comparison under typical production volume (unit is the cost range per product), and the data is based on the industry average:

| Production volume range | Investment casting cost (per piece) | Sand casting cost (per piece) |

| Small batch (1-100 pieces) | $50-100 | $10-30 |

| Medium batch (100-1000 pieces) | $30-60 | $5-15 |

| Large batch (1000+pieces) | $50+(not very cost-effective) | $2-8 |

4. Finished product quality and precision

Investment casting hasits definiteadvantagesofsurface smoothness and dimensional control. Itwill castparts with finerdetailandlessdimensional errors. Sand casting, due to the nature of sand itself, will have a relatively rough surface and poor dimensional accuracy. When you want high-precision, smooth-surfaced parts,investment casting is usually the first choice.

What are the principal raw materials used in sand casting?

1. Sand:

Natural sand, specifically in this instance quartz sand, is utilized since it can withstand the heat of high-temperature metal melting and will not de-form too much. The sand is utilized to form the body of the mold and as an easy skeleton to shape metal parts.

2. Binder:

Sand itself is too loose, so "glue" such as clay or resin needs to be added to hold it together tightly. Thiskeeps the mold from falling apartwhen pouring metal. Common binders are bentonite or phenolic resin, which are selected according to the type of casting.

3. Additives:

In order to improve the performance of sand, such as making it easier to demold or reduce adhesion problems, coal powder, sawdust or starch are usually added. These things are like seasoning. After adding them, the sand surface is smoother, the castings are cleaner when they come out, and the risk of residue is reduced.

4. Water:

Used to mix sand, adhesives and additives, and adjust the humidity so that all materials can be evenly bonded. Only when the water is added in the right amount can the mold have sufficient strength and air permeability to discharge the hot air during pouring.

What factors should be considered in sand casting design?

1. Rounded corner treatment

All intersections on the casting cannot be sharp corners,and must be designed as rounded corner transitions. This is very important, so that the cast castings are not easy to shrink or crack, and the risk of cracks caused by stress concentration can be reduced.

2. Casting system design

The casting system, including the pouring cup, straight runner, cross runner and inner gate, must be carefully designed. Its core function is to allow molten iron or aluminum to flow smoothly into the entire mold cavity to avoid splashing or insufficient pouring.

3. Parting surface selection

The parting surface of the mold should be a flat horizontal surface as much as possible. According to the shape requirements of the casting, the position should be as low as possible. This is for the sake of mold production simplification, easy demolding, andeasy removal of burrs from the casting.

4. Reserve machining allowance

If the casting is to be processed on a lathe or milling machine later, a certain thickness must be added to the machining surface of the casting during design, that is, the machining allowance. This thickness is usually between 1.5 mm and 6 mm, depending on the size, complexity, processing requirements and casting process level of the casting.

5. Set the draft angle

In order to allow the casting to be smoothly removed from the sand mold after cooling,the surface perpendicular to the parting lineon the mold must be designed with a certain inclination angle, called the draft angle, generally 3° to 5° is enough

6. Minimum wall thickness limit

The wall thickness of the casting cannot be too thin, otherwise the molten metal may not flow smoothly to fill the entire area, and it is easy to produce defects such as cold shut or insufficient pouring.

For lightweight nonferrous metal castings, such as sand casting aluminum, the recommended minimum wall thickness is usually not less than 5 mm. For metals such as cast iron and cast steel, it must be at least 6 mm.

7. Economic batch considerations

The sand casting process can produce a wide range of casting weights, theoretically from less than 1 kg to more than 20 tons. Due to the inherent costs of mold making, modeling, smelting and other links, in order to achieve economic feasibility, the metal feed volume for a single production is generally at least 300 kg to be cost-effective.Below this, the cost per piece willbe much greater.

What type of parts or products are suitable for sand casting?

1. Medical and energy equipment

Although high precision requirements are required, sand casting is still used in large or basic parts, such as the heavy base and support frame oflarge medical imaging equipment(such as CT, MRI). Large valves and pipe fittings of central gas supply systems in hospitals. Huge shells and valves of turbines and steam turbines in the energy field. These parts are often large in size and complex in structure.

2. Industrial equipment and general machinery

This is the core stage of sand casting, including the housing, impeller and end cover of various industrial pumps. Cylinders, cylinder heads and crankshafts of compressors and blowers. Valve bodies and valve covers of various valves. Gears, pulleys and flywheels. Sand castings can be found in almost all factories.

3. Agricultural machinery

Agricultural machinery often works in harsh environments and requires strong and durable parts. It is widelyused in tractor gearbox housings and rear axle housings. Key structural frames and wear-resistant parts of seeders and harvesters, as well as large pump housings and valves of irrigation systems.

4. Other fields

- Consumer electronics: heavy housings and large heat sink bases of some high-end audio equipment.

- Art and architecture: large sculptures, decorative components for the restoration of historical buildings, metal railings and decorative parts in parks.

- Education: large mechanical models for lecture demonstrations, metal bases and framework of engineering laboratory benches.

Summary

As aconventionalprocess, sand casting is stillwidespread in the manufacturing industry. Its biggest advantages are high cost-effectiveness, strong material adaptability, and great design freedom. From the core parts of a car to the supporting structure of a building, many can be economically realized through sand casting.At JS, this is one of our most core and mature processes.

Many customers choose JS for sand casting. The key is that we integrate traditional processes with modern technology, significantly improve efficiency by 30%, and shorten delivery cycles. Apply optimized molding materials to help reduce 15% of defects. All this allows us toprovide you with efficient solutionswith high cost-effectiveness and reliable quality while maintaining the original cost advantage of sand casting.

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

FAQs

1. What is the working principle of sand casting?

The molten metal is poured into the hollow mold cavity of molding sand. The molten metal fills the cavity by gravity action. The sand mold is ruptured after solidification and cooling, and the casting is taken out. It is suitable for the production of large and medium-sized simple to medium-complex metal parts.

2. How is a sand mold made?

Place the prototype model in the sand box, fill the molding sand in layers and compact it. Then take out the model to form a cavity, combine the upper and lower sand boxes, and open the pouring system to finally form a pourable hollow sand mold. The whole process relies on manual or mechanical compaction of the sand.

3. Why can metals be cast using sand molds?

Sand casting uses refractory sand to form a hollow cavity, which possesses high temperature resistance (>1600℃) and is able to withstand molten metal erosion. The sand is bound together by a binder for shape maintenance, and the molten metal is gravity poured into the cavity. The sand mold may be broken and removed after cooling to complete the metal forming.

4. What is a parting surface?

The parting surface refers to the contact surface that divides the sand box into upper and lower or multiple parts in sand casting. It is usually set along the largest cross-section of the model to facilitate the smooth removal of the model from the cavity, while ensuring that a visible parting line or burr is formed at this position after the casting is formed.