Every time I see perfectly delivered plastic parts, I think of the unsung hero behind them - the mold. Before you get the finished product, there is a big project thatmust be completed first: the manufacturing of this mold.

In this process, the investment is not small and it is also quite complicated. You may not know that the material you choose to make this mold directly affects the total cost of your project, how fast the production can run, and how many parts can be made in the end. This is not a trivial matter.

As an engineer at JS, I talk to customers about this every day. The reason is simple. Just like your choice of plastic resin determines the performance of the part itself,we choose materials for plastic injection molds, which affects the production efficiency and product quality.

Why? Because it is related to every production link. Think about it, you may need a hard ABS shell or a smooth POM handle, which has completely different requirements. The choice of mold material must change accordingly. In fact, there are only a few commonly used mold materials on hand, each with its own strengths and suitable scenarios. If you choose the wrong one, you will have a lot of trouble. If you choose the right one, you will get twice the result with half the effort.

We can help you understand the key points of part design and the actual needs of the application, and then combine our experience in this industry to pick out the most suitable "golden partner" of mold materials and plastic formulas.This is the basis for making a large number of high-quality parts stably and efficiently.

Summary of The Core Answers:

| Type of mold material | Main advantages | Mold lifespan (times) | Relative cost |

| Quenched steel | Extremely durable, wear-resistant, and high-precision. | 1,000,000+ | Highest |

| Pre hardened steel (not quenched) | Balancing performance and cost, fast processing. | 50,000 - 1,000,000 | Medium |

| Aluminum alloy | Fast processing, lowest cost, and good heat dissipation. | <10000 (generally lower) | Minimum |

This article will answer your questions:

- Let's start with a key basic concept.

- Next, I will focus on the different types of plastic injection molds, from aluminum plastic injection molds to various tool steels.

- Finally, I will combine my experience to give you some practical advice to help you better understand how to choose the most suitable mold material.

Why is This Guide Worth Your Reference? Listen to the Honest Words of Our JS Mold Veterans

At JS, we deal with not only operating injection molding machines every day, but also managing the entire process of molds from design to retirement.Helping customers choose mold materials is a big responsibility, and we know it very well.

- For example, a startup company was eager to launch a product, and we suggested that they use 7075 aluminum alloy to open the mold. As a result, the first product was made in 6 weeks.

- Another customer wanted to make millions of medical parts with extremely high precision. Without saying a word,we directly helped them use professional medical parts plastic injection molds-usinghigh-precision S136 stainless steel. This investment is very worthwhile!

Experience is confidence:

How to cut P20 steel well? How critical is the heat treatment process of H13 steel? We study these tips every day. We help you find a balance between time, cost control and quality, and finally implement it to the choice of mold material.

The things in this guide are not empty talk, but our experience accumulated by doing real projects and checking for customers with real money.

"As Joseph Datsko, an authority in the field of materials engineering, often says: Improper material selection is the main cause of industrial failure."

I have been in this industry for more than ten years and I agree with it. Especially in projects like medical parts that cannot tolerate any mistakes, choosing the right material is the cornerstone of success.

Before We Start: Mold Material vs. Part Material

After so many years in the injection mold industry, I found a basic problem that is easy to cause misunderstanding:the difference between mold material and part material. These are two completely different things, just like the difference between a mold for baking a cake and cake batter. If we don't understand this, it will be easy to make deviations when we discuss mold material selection, process parameters or product requirements later. So today, let's focus on making this distinction clear.

(1) Mold Material - This is the "cake pan"

Simply put,it is the metal used to make the mold itself.This mold needs to repeatedly withstand high temperature, high pressure, frequent opening and closing movements, and mechanical wear caused by the flow of plastic melt during the injection molding process. So it must be hard, strong and durable enough.

Core requirements:Must have high hardness, high strength, excellent wear resistance, while taking into account good thermal conductivity, processability and heat treatment stability to ensure the reliability of the mold in long-term use.

Common materials:

- P20 steel (pre-hardened state): Good comprehensive performance, convenient processing, is the most widely used general mold steel.

- H13 steel (heat treatment required): Excellent heat resistance and impact toughness, suitable for complex structure molds, high temperature plastic products or high wear-resistant applications.

- 7075 aluminum alloy: Fast processing but not so durable, relatively low cost,mainly used for prototype mold manufacturing or small batches, its strength and wear resistance are usually lower than tool steel.

What does it determine?

This material selection is directly related to:

- How long can the mold be used? If the selection is good, the mold life will be long, and the cost per product will be low.

- Is production fast? Some materials have good thermal conductivity, fast cooling, and short production cycle.

- Is the mold expensive?Good steel is naturally expensive, but it depends on whether it is worth it.

Today we are mainly going to talk about how to choose these metal materials for molds and what are the requirements.

(2) Part Material (Part Material) - This is the "cake batter"

This is the ball of plastic that isfinally injected into the mold and solidified to become the product in your hand. Customers often ask what plastic you use for injection molding? This is what I mean.

Variety of types: There are many types of engineering plastics,such as:

- ABS: Strong and shatterproof, good toughness, good processing performance, widely used in home appliance housings, toys, electronic equipment housings.

- PC: Transparent and impact-resistant, used for optical lenses,car lamp covers, and safety protection parts.

- PP: Light weight, strong chemical corrosion resistance, low cost, commonly used in daily containers and automotive parts.

- Nylon/PA: Wear-resistant, self-lubricating, high strength, commonly used in moving parts (gears, bearings), fasteners, and structural parts.

How does it affect the mold?

This is particularly critical! The performance of the part material you choose directly determines what kind of mold you need:

For example:

If the thing you want to make is made of nylon material mixed with glass fiber, this material is very hard and easy to wear, then you will be in trouble if you use soft mold steel. The mold will be scratched and damaged quickly. At this time, you must choose high-hardness and high-wear-resistant steel, such as hardened (quenched) H13 steel, to withstand this kind of glass fiber abrasion. Ensure the long-term stable operation of the mold and product quality.

Clearly defining mold materials and part materials is the first step to successfully implement injection molding projects.Mold materials are the basis of production, which determines the service life and production efficiency of the mold. Part materials are the core of the product, which determines the function and appearance of the final product.

"With many years of experience in the application of mold materials, I can help you solve the problem of material selection. We will learn about the plastic characteristics of your product in detail, as well as the production goals, and then help you pick the mold steel and engineering solutions that best match the performance and save money and efficiency!"

In-Depth Analysis of Injection Mold Materials

The materials used in injection molds are the key to product quality! Although there are many types of materials to choose from,the core is still two major camps: steel and aluminum.

1. Steel molds: the key to meeting high requirements and long-life production

Steel molds have become the first choice for high-quality, medium-to-high-volume production with their excellent rigidity, wear resistance and thermal stability. It is mainly divided into two categories:

(1) Pre-hardened steel: the "main force" that saves trouble

Common grades: P20 (the highest appearance rate), NAK80 (pursuing brighter effects).

Core advantages: The hardness is adjusted for you at the factory (about 30 HRC), and there is no need to take it back for quenching. It can be directly processed on the machine tool. Saving one process saves a lot of money and time.The surface can also be polished beautifully.

When to use it?

When you plan to produce tens of thousands to hundreds of thousands of pieces (for example, 50,000 to 500,000 times), and you are also making common plastic parts (ABS, PP, etc.), choose P20 with your eyes closed, and the performance and cost are best balanced. Most of the standard molds on the market are made of P20.

(2) Quenched steel: pursue the ultimate, not afraid of expensive!

Tough role representatives: H13 (the main force of high temperature resistance), S7 (impact resistance), S136 (stainless steel, rust and corrosion resistance).

Main features:

Throughthe overall quenching + tempering heat treatment, high surface/core hardness (HRC 48-52+) is obtained, which is greatly improved:

- Wear resistance: resist high abrasive components such as glass fiber (GF) and mineral fillers.

- Corrosion resistance: resist acidic gas erosion released by PVC, flame retardants, etc.

- Polishability: can achieve super mirror surface (SPI A1/A0 level) and meet optical surface requirements.

When is it necessary to use it?

- The target output is millions of pieces.

- Plastics contain reinforcements/fillers such as glass fiber and mineral powder.

- Parts are used in medical treatment, need to contact the human body, and require sterility.

- To make highly transparent parts (such as lenses and transparent parts),the surface must be free of defects.

I suggest you choose carefully:

At this time, you have to use hardened steel.Stainless steel like S136 is the first choice for medical, transparent parts,and occasions with high corrosion resistance requirements. Although it is much more expensive, the money should be spent, and the quality is worth it! For the pursuit of extreme durability, H13 and S7 are also good choices.

Global application share and growth of mold steel:

| Material type | Main application scenarios | Global market share (estimated) | Annual growth rate (forecast) |

| Pre hardened steel (such as P20) | Medium to large quantities of universal parts, automotive interior components, etc. | 65% | 3.5% |

| Quenched tool steel (such as H13) | Large batch parts, engineering plastics, wear-resistant parts. | 25% | 4.8% |

| Stainless steel mold steel (such as S136) | Medical, optical, food grade, corrosion-resistant parts. | 8% | 6.2% |

| Other steel materials | Special applications. | 2% | - |

Data source:

- Grand View Research (2024).

- Statista - Tooling Sector (2023).

- AMT - The Association For Manufacturing Technology (2023).

2. Aluminum molds: the king of speed and economy

Common materials: 7075-T651 (aircraft-grade high-strength aluminum alloy), Alumec 89 (high-hardness aluminum alloy optimized for mold applications).

Core advantages:

- Fast processing speed! : For molds of the same complexity,the cutting force of aluminum alloy is much lower than that of steel, and the processing speed is 30%-40% faster than that of steel molds, which greatly shortens the mold manufacturing cycle.

- Aluminum conducts heat particularly well: Aluminum alloy has a high thermal conductivity coefficient, and plastic cools quickly in the mold, shortening the injection molding cycle and improving overall production efficiency.It is the fastest way to get started with how to make plastic injection molds.

- Cost advantage: The price of aluminum alloy raw materials and processing fees are much lower than those of steel molds. The investment cost can be effectively controlled in the initial stage of the project.

3. Other special materials - soft molds

The name "soft mold" is a bit misleading. It does not mean that the material is soft, butrefers to molds made of materials that are easier to process and have lower costs.The goal is not long-term production.

Common materials and technologies:

- Non-hardened steel (such as AISI 1018/1020).

- 3D printing molds (photosensitive resin, metal powder and other materials).

- Low-pressure casting molds (epoxy resin-based composite materials, etc.).

- Best for: soft plastic injection molds used only for design verification and functional testing.

"The key to mold material selection is to look at your "quantity" and "quality" requirements. For high requirements of millions of units, choose hardened steel (such as H13, S136). For tens of thousands to hundreds of thousands of conventional parts, P20 pre-hardened steel has the best cost-effectiveness. For rapid prototypes/small batches, aluminum molds are the most suitable. Non-steel molds for pure design verification. Materials directly affect mold life, product quality and cost. Please tell me the specific needs of your project, and JS will match the best solution for you."

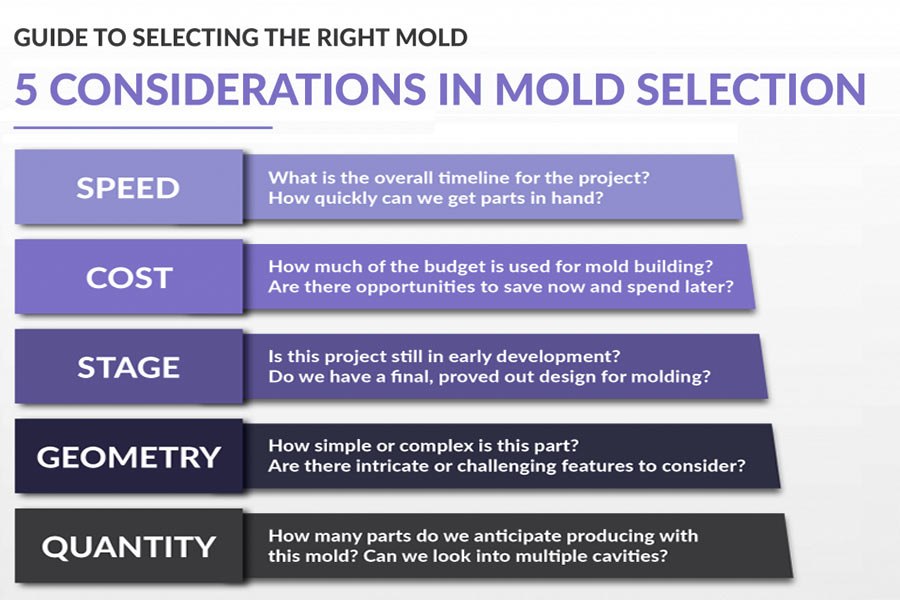

How to Choose the Right Mold Material for Your Project? 4-Point Decision Checklist

Choosing the right mold material is critical to the success of a project. If you choose the wrong one, it may affect quality, delay construction, or even exceed budget. This is not a trivial matter. Don't worry, below,I will use these four key perspectives to help you choose the most suitable one:

Key point 1: How many parts do you plan to make?

This is the first big thing to consider! Do you want to make a thousand to test the waters, or do you plan to make millions? The quantity is directly related to what material the mold is used for.

- If you only make a few hundred or a few thousand samples or a small batch,aluminum molds are fast and cheap, and are the first choice.

- If you want tens of thousands or hundreds of thousands of pieces, pre-hardened steels such as P20 are much more reliable and have a long life.

- If the goal is millions or even more, you need hardened steel (such as H13, S7, S136), which has a high initial investment, but is durable and has a low cost per part.

Key point 2: What plastic do you use for your parts?

Not all plastics are equally gentle. The material you use determines how wear-resistant the mold is.

- If it is common materials such as PP, PE, and ABS, the wear on the mold is small, and the range of materials to be selected is wider.

- But if glass fiber is added (especially with a high proportion), or difficult-to-process materials such as some nylons (PA66) and POM, it is simply sandpapering the mold! In this case, the mold material must be hard and wear-resistant enough, otherwise it will be worn out in a few strokes, and the size and surface of the part will not be maintained.

Key point 3: Is your part complex? Are the surface requirements high?

If the part structure is simple and the surface requirements are average, many materials can do it.

If the part structure is fine and complex (such as many thin walls and small features), or the surface requirements are extremely high, you must choose high-grade steel with good processing performance, such as S136. This kind of steel has high hardness and good purity after heat treatment, and the polishing effect is first-class, and the details are also well controlled. It is difficult to achieve this effect with ordinary materials.

Key point 4: What is your budget and time planning?

Money and time are what you need to consider first every time you process plastic parts.

- Time is tight and budget is low:especially for initial verification or small batches, aluminum molds are almost the only choice. Samples can be produced in a few weeks, and the cost is much lower. Remember, the life of aluminum molds is limited, and the main problem is whether they can be produced and how fast they are.

- Don't rush, pursue long-term cost-effectiveness: if you value the production of millions of parts in the next few years, and the cost of each part is the lowest, then it is absolutely wise to invest in steel molds. Although it costs more money in the early stage, the cost of each piece will be greatly diluted later, and the mold life will be much longer.

The core of choosing mold materials is to see how much you want to make, what plastic you use, how fine the parts are, and how to balance money and time.

"As management guru Peter Drucker said: efficiency is doing things right, and effectiveness is doing the right thing."

In mold engineering, scientific material selection is the key starting point for achieving effectiveness. By clarifying these four elements, you can choose the right core material for your project, avoid high rework costs in the later stage, and ensure the efficient operation of the project. If you need a project evaluation, please feel free to communicate with us,JS will work with you to optimize the solution!

FAQ - Answer All Your Questions about Molds

Question 1: Is it cost-effective to buy a used injection mold?

To be honest, we usually don't recommend it.

The reason is simple: each injection mold is tailored to produce a specific part and run on a specific machine. Buying a used mold is usually difficult to match. Unless you want to produce something exactly like the original design, the risk is high.

There are indeed used plastic injection molds for sale on the market, but taking over used plastic injection molds or unverified plastic injection molds for sale is likely to cause adaptation problems, increase maintenance costs and even affect product quality.

Question 2: What equipment is needed to get injection molding done?

The core is definitely the injection molding machine, which is the main force of production. But having a machine alone is not enough. To ensure stable and efficient production,several key auxiliary equipment are also required:

- Mold temperature controller: used to control the mold temperature, which is important for product appearance and dimensional stability.

- Chiller: Responsible for cooling the hydraulic oil and mold cooling water circuit of the injection molding machine to ensure that the machine does not overheat and the cycle time is stable.

- Dryer: If the plastic particles contain water, the products made will be defective, so they must be thoroughly dried before feeding.

- Robot (piece picker): Automatically take out the molded parts to improve efficiency, ensure operation safety, and ensure product consistency. These devices work together to run an injection molding line well.

Question 3: Where can I find reliable plastic raw materials?

Large chemical companies such as BASF, DuPont, and SABIC are direct sources of raw materials. In addition, there are also professional plastic particle distributors in various places, whose services are more flexible and small-batch purchases are also convenient.

As JS, we have established long-term cooperation with many high-quality suppliers. If you are unsure about raw material selection or procurement channels, we are happy to share our experience and even use our procurement network to help you find cost-effective and performance-matching raw materials, saving you worry and effort.

Summary

To be honest, over the years, I know that choosing the right mold material is not as simple as just picking a good piece of steel.It directly determines whether your entire product project can be successful!This is not just a technical issue, but also a few key factors such as cost budget, project cycle, and long-term product strategy. Being able to find the right balance between aluminum and steel is the value of our professionalism.

Don't let material selection become a blind spot for your project! JS team will provide you with precise navigation

Don't make rash decisions based on feelings or experience in the key link of mold material selection.Let the mold experts of JS team use our experience and analysis toolsto clear the fog for you.

If you are planning a new product and have questions or entanglements about mold material selection, please take action!

- Tell us your project information: The more detailed your needs, the better.

- Upload your preliminary design or product information: Even if it is just a concept map, it can help us make a judgment.

- Communicate with me in depth: Aboutcustom plastic injection molds,talk to me directly about your ideas and concerns. We promise to provide you with a clear "Material Selection and Cost-Benefit Analysis Report" within 1-2 working days, clearly listing the pros and cons of aluminum molds/steel molds (or combination solutions), cost estimates and our professional suggestions.

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com