If you ask us which plastic injection molding material is the best choice. To be honest, there is no single standard answer to this question. The most suitable material must be the one that best suits your specific situation and needs. There are many types of plastic materials available on the market, and many materials have similarities in performance and their own characteristics, which means that our choice space is actually quite broad.

In the plastic injection molding process,choosing the right material is definitely a key step! The choice of material directly determines the performance and durability of the final product, whether the appearance can meet the requirements, the overall cost-effectiveness, and even whether it can be successfully put into production. Faced with so many kinds of plastics, how to choose the right one?

Next,JS will introduce you to several types of plasticsthat are most commonly used in injection molding, and explain their key characteristics and typical application scenarios.

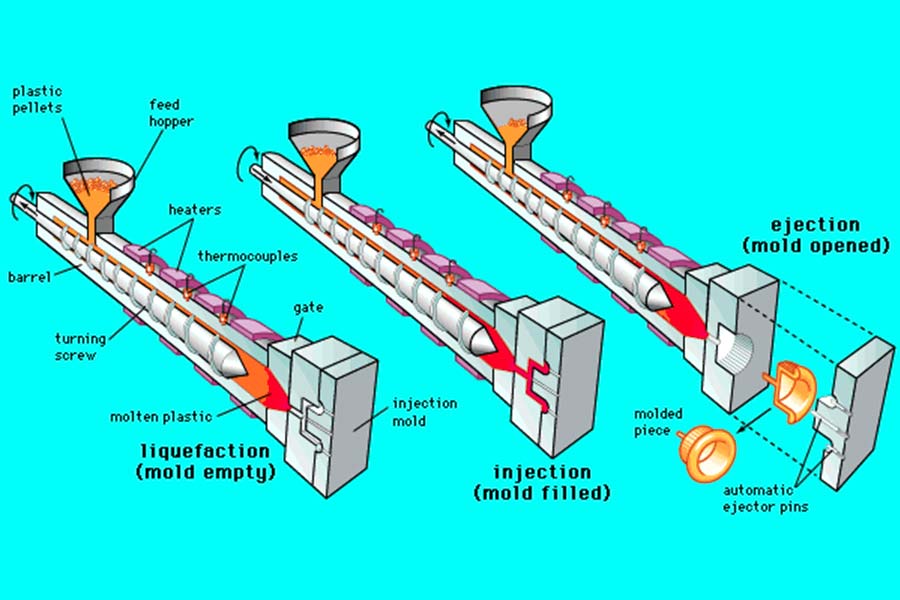

What is plastic injection molding?

Plastic injection molding is an efficient and precise manufacturing process, which is to inject hot melt plastic into the prepared mold space under high pressure, and wait for it to cool and shape, and then you can get the desired plastic parts.This method is very suitable for mass productionof various complex or precise products, such as mobile phone cases, auto parts, and daily necessities.

As a professional plastic injection molding services provider, JS can provide customers with one-stop solutions from mold design to material selection, custom plastic injection molding and subsequent processing, helping customers achieve efficient, stable and cost-effective large-scale production.

What materials are the mainstream choices for plastic injection molding?

1. ABS

ABS is definitely one of the most widely used materials. With its balanced performance and relatively affordable cost, it has become a popular choice for manufacturinga variety of daily and industrial products.

The core advantages of ABS:

- Economical: ABS is reasonably priced and has good rigidity. Thus, goods made from it are not easy to deform or flex and have good resistance to impact, and are not easy to break or break.

- Good chemical resistance: It can resist the erosion of many common acids, alkalis and other chemicals (of course, it is not effective for all chemicals).

- Easy to process and color: Pure ABS raw materials are usually white or translucent, but it is very easy to add colorants and can be flexibly made into various colors of desired appearance.

Acouple of thingstoremember while working withABS:

- Non-food grade: ABS itself does not meet the safety material standards for direct contact with food.

- Flammability: It is a flammable material.

- Poor weather resistance: ABS is prone to yellowing, brittleness and performance degradation when exposed to sunlight (ultraviolet rays) for a long time.

Typical application scenarios of ABS:

Because it is strong, durable, cost-effective and easy to process, ABS is particularly suitable for manufacturing:

- Electronic product housings: such as mobile phone cases, computer monitor housings, keyboards, remote controls, etc. (these products are often mass-produced through plastic injection molding services).

- Automotive parts: Especially the parts of interior parts that need to withstand impact, such as dashboard components, grilles, etc.

2. Acrylic (PMMA)

Acrylic, also referred to as plexiglass, is a hard and translucent plastic. It is most ideally suited to be processed using the plastic injection molding process. You can see it on many electronic product housings,car headlight covers, and dashboard parts.

Core advantages of acrylic:

| Characteristics of Acrylic | The practical benefits brought by it |

| High transparency | The resulting product has high clarity. |

| Good weather resistance | Not afraid of wind and sun exposure, long-term outdoor use is not easy to age. |

| Resistant to common chemicals | It is not easy to damage when exposed to daily water, cleaning agents, etc. |

| High hardness/good rigidity | More wear-resistant, impact resistant, and less prone to bending. |

| Dimensionally stable | After injection molding, the product has high precision and reliable shape. |

In the large plastic classification, acrylic belongs to the 7th category of other plastics. It is also classified with materials such as polycarbonate (PC), nylon, and glass fiber reinforced plastic.

3. Polycarbonate (PC)

Polycarbonate is a transparent and tough plastic. It is very transparent and easy to sterilize, so it is particularly popular in the manufacture of medical devices.

However, PC is not omnipotent. Its shortcomings need to be noted:

- Loss of surface wear resistance: PC material surface is relatively soft and scratch-prone. Thus, for PC parts that need to be touched often or exposed to the outside for a long time,a surface treatment process following moldingneeds to be incorporated. Either spray a harder wear-resistant coating or harden a film.

- Limited fatigue resistance: If placed in a place where it needs to withstand vibration or bending for a long time (e.g., parts in the engine compartment of a car that is constantly vibrating), the PC material's resistance to fatigue is poorer than some metals or engineering plastics designed specifically for this use. In such demanding environments, the use of more fatigue-resistant material alternatives should be given priority.

- Cannot be used in the body: Although it is easy to sterilize, it is definitely not suitable for implants placed in the human body (such as artificial joints and heart valves).

How to use it best:

| Core features | Impact on usage | Typical Applicable Scenarios |

| High transparency & easy disinfection | It is suitable for occasions with high visual requirements and the need for sterilization. | Non implantable medical equipment, transparent observation window. |

| High strength & strong impact resistance | It is very reliable to make things that are resistant to falls and collisions. | Glasses lenses, safety shields, lightweight bulletproof materials. |

|

Weak scratch resistance

|

The surface is easily scratched. | Further surface treatment is required when high surface hardness is required. |

| Moderate fatigue resistance | Unable to tolerate repeated bending and vibration. |

Not recommended for use in places that frequently experience dynamic stress.

|

4. Polypropylene (PP)

It has become a common material in daily life and industry due to its excellent comprehensive performance. It has good flexibility and impact resistance, which makes it very suitable for making luggage and as a waterproof layer for clothing. At the same time, PP has excellent insulation properties, which makes it widely used in wire and cable sheaths and electronic equipment casings.

PP hasvery goodchemical stability and is often used to make containers forchemicals andday-to-day use detergents. Another noteworthy feature is its good fatigue resistance, which allows PP to act as a lightweight and reliable movable hinge on non-load-bearing parts that need to be opened and closed repeatedly (such as bottle caps and food box buckles).

5. Polyethylene (PE)

Polyethylene (PE) is arguably one of the most common plastics in our daily lives. It is light, chemically inert, elastic, and well-insulated. Even though its strength and hardness are poor, it is low in cost and economical.It is present in most of our daily needs and most ubiquitous plastic parts. Because of its non-toxic nature and shatter-proof property, it is also the most used injection molding plastic to manufacture children's toys.

6. Thermoplastic polyurethane (TPU)

It is a soft and tough material with outstanding resistance to pulling and tearing. Plastic injection molding factories often use TPU materials to make elastic parts. Although TPU is more expensive than common plastics, it has irreplaceable advantages in some places, such as acting as a protective layer for wires and cables. In addition,the surface of TPU can provide good friction, which is particularly suitable for product parts that require users to hold firmly (such as tool handles and protective covers).

7. Nylon (PA)

Nylon is a common and widely used engineering material in plastic injection molding jobs. In order to improve performance, it is often used in combination with other materials. Nylon itself has a high melting point and an unusually smooth surface (low friction coefficient). These advantages make it appear in many products: from common ropes, automotive parts that require high strength (such as cooling fans, gear bushings), to wear-resistant clothing fabrics.

Its core advantages are very real:

- Wear resistance: low friction, not easy to heat up, naturally wear-resistant, especially suitable for parts and elastic materials that require frequent sliding friction.

- Chemical resistance: It can resist corrosion from a variety of common chemicals (but pay attention to the differences in different formulas).

- Large modification space: Its hardness, strength or heat resistance can be greatly enhanced by adding glass fiber, carbon fiber or other materials, and it is very flexible.

Therefore, nylon plastic injection molding is an important process for manufacturing high-performance, wear-resistant engineering parts. However, special attention should be paid to its hygroscopicity during processing, and the raw materials must be fully dried before injection molding.

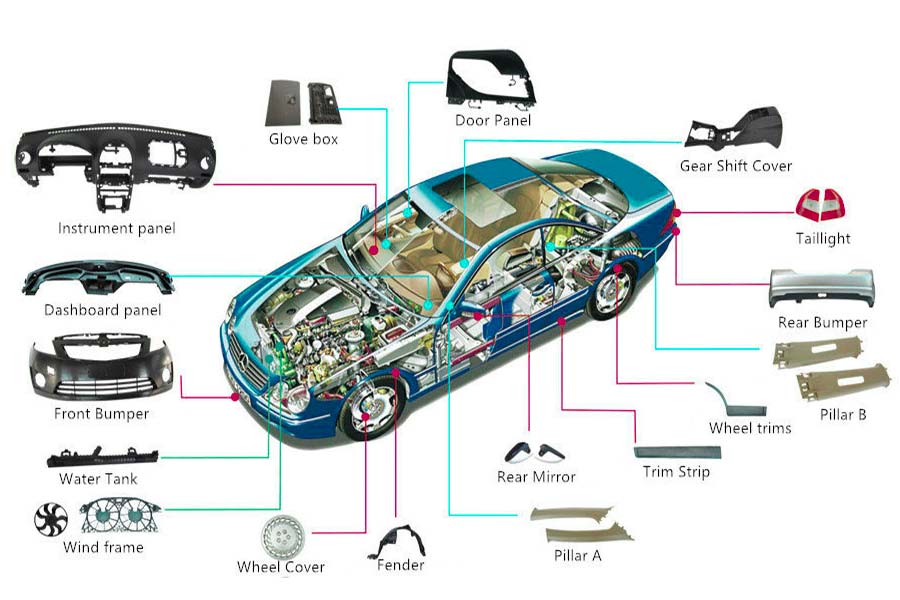

How to choose special materials for automotive injection molding?

Cars are full of parts made of plastic, from interior panels to exterior components to functional parts under the hood, many of which are efficiently producedthrough automotive plastic injection molding processes. The following are the key aspects to consider when choosing:

1. Reference for material selection direction of different automotive parts

| Component location | Key performance requirements | Common materials |

| Surrounding the engine compartment | High temperature resistance (often>120°C), oil resistance, and chemical corrosion resistance. | PA66 (Nylon 66) with added fibers PPS, High temperature resistant PBT. |

| Exterior components (bumper, door handles, etc.) | High impact resistance, good weather resistance (UV resistance), stable size, and can be coated. | Modified PP (polypropylene) ASA, PC/ABS, Weather resistant nylon. |

| Interior components (dashboard, door panels) | Good tactile sensation, low odor/VOC release, flame retardant, wear-resistant. | PP/EPDM (modified soft polypropylene) ABS, PC/ABS, TPO. |

| Activity/connection components (buckles, gears) | Fatigue resistance, high strength, wear resistance, and smooth repeated movement. | PA6/PA66 (nylon), POM (polyoxymethylene), and fiber-reinforced PBT. |

| Transparent component (lampshade) | High transparency, high heat resistance, and weather resistance. | PC (polycarbonate). |

2. Core Competency Assessment

- Heat-resistant temperature: Confirm the maximum temperature of the component's working environment. The heat deformation temperature (HDT) of the selected material must be significantly higher than this value, and a safety margin must be reserved.

- Mechanical properties: Evaluate the type (static or dynamic) and size of the load the component bears, as well as the impact resistance requirements. Automotive parts generally require good impact strength.

- Dimensional stability: For parts with high precision matching or assembly requirements, the shrinkage and warpage of the material after injection molding must be strictly controlled. Reinforced materials (such as glass fiber) generally provide better dimensional stability.

- Flame retardancy: Especially for parts near the interior and engine compartment, meeting specific flame retardant standards is a mandatory requirement.

- Lightweighting: On the premise of meeting performance, choosing materials with lower density can help reduce the weight of the entire vehicle and improve fuel economy.

3. Cost and processability

- Material cost: On the basis of meeting all performance requirements, the economic feasibility of the material itself must be considered. General plastics (such as modified PP) are usually less expensive than high-performance engineering plastics (such as PEEK).

- Processing performance: Evaluate the material's fluidity, thermal stability, drying requirements and demolding difficulty during the automotive plastic injection molding process, which directly affects production efficiency and yield. Easy-to-process materials can reduce overall costs.

How to avoid common mistakes in plastic injection molding material selection?

1. Ignore the use environment

Don’t just focus on the material’s high strength and good wear resistance to make a decision, this is a wrong idea.The key is to select materials based on the actual working environment of the part. Specifically, it is necessary to find out whether the part will be exposed to oil, exposed to the sun for a long time, subjected to severe impact or continuously exposed to cooling water.

For parts used in the engine compartment, it is not enough to have enough strength. In particular, it is important to pay attention to whether it can withstand high temperature environments, which is as important as strength requirements.

2. Cost evaluation is too superficial

Only focusing on the highest or lowest unit price of the material itself is a misunderstanding in cost evaluation. The key is to conduct comprehensive cost accounting and measure the impact of materials on the overall cost of the product.

For example, whenentrusting a plastic injection molding companyto produce thin-walled complex parts, if a material with poor fluidity is selected only because of the low unit price, it will significantly increase the difficulty of injection molding and the scrap rate. In the end, the cost savings of materials are likely to be offset by the additional production costs.

On the contrary, for ordinary daily necessities, it is often unnecessary to choose top-level engineering plastics. Therefore, material selection must be combined with specific application scenarios to conduct an overall cost-effectiveness evaluation.

3. Material properties do not match equipment

Select only based on material performance data, without evaluating its performance during the injection molding process.

Correct approach: Verify the matching degree of materials, equipment, and molds in advance. Key factors to consider include: material flow characteristics, required mold temperature range, and whether the raw materials need to be strictly dried. Find out these processing characteristics in advance to better select suitable materials.

4. Sample testing

Skip the testing stage and go directly to mass production.

Correct approach: Be sure to make samples for experiments! Especially for new materials, complex structures, and products with strict performance requirements.Small batch trial production (T0, T1) is a golden opportunity for verification: actual inspection of part strength, dimensional stability, appearance, assembly and aging tests. The investment in preliminary testing is the key to ensuring the success of subsequent mass production.

How does JS meet your material needs for plastic injection molding?

1.Provide a variety of plastic materials:We provide a variety of plastics and composite materials, and have experience in processing more than 50 materials.

2.Provide expert guidance:Our experienced team provides professional support throughout the process to help plastic injection molding companies choose the materials that best suit their part performance and durability requirements.

3.Experience in handling a large number of materials:JS has handled more than 50 different typesof materials and has the practical ability to meet the needs of diverse plastics.

Summary

There are many types of materials that can be selected for plastic injection molding. From economical and practical polypropylene (PP) and polyethylene (PE) to ABS, polycarbonate (PC), and nylon (PA) with excellent comprehensive performance, each material has its own unique personality and areas of expertise.

Remember, there is no best material, only the most suitable material! This is the first step towards high-quality injection molding products.

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

FAQs

1. What equipment is generally used?

Plastic injection molding mainly uses injection molding machines (core equipment, including mold clamping, injection device), molding molds, hoppers, dryers and auxiliary manipulators and temperature control equipment.

2. Can the color of plastic be customized?

The color of plastic injection molding materials is completely customizable. By adding precise proportions of masterbatch or color powder to the raw materials, or directly using pre-dyed plastic particles, color effects of almost any color number can be achieved. The key lies in mixing uniformity and formula control to ensure stable and consistent color between batches to meet the personalized needs of different products. Small batch customization will increase costs.

3. How environmentally friendly is the plastic material?

The environmental friendliness of plastic injection molding materials depends on the specific material type and process. Traditional petroleum based plastics (such as PP and PE) are difficult to degrade, but they can be recycled to enhance environmental friendliness. Biobased plastics (such as PLA) and biodegradable materials have significant environmental advantages, but the cost is relatively high.

4. How does cost affect material selection?

In plastic injection molding, raw material cost is a key factor in material selection. Usually, general plastics (such as PP and PE) with lower prices and simpler processing are preferred, and engineering or special plastics with higher costs are only considered when high performance is required. Pursue cost-effective solutions.

Resource

Multi-material injection molding