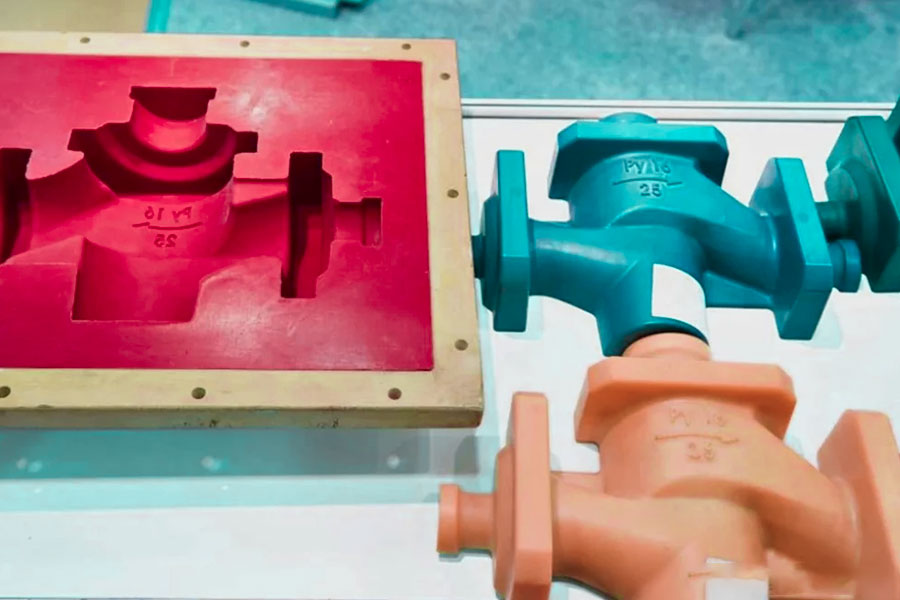

Plastic injection molds are essentially highly precise metal molds.Their core function is to quickly fill the molten plastic into a specific cavity inside the mold under the strong pressure applied by the plastic injection molding machine. After the plastic cools and solidifies in the cavity, a plastic part with a shape, size and surface effect that meets the design requirements can be obtained.

The key is that once the mold is made, it can be used repeatedly to produce thousands of identical parts, whether it is a small batch trial production or a large-scale mass production, it can easily cope with and perfectly adapt to various production needs.

Now, we will take you to understand the types of plastic injection molds, mold design considerations and typical application scenarios.

What is a plastic injection mold?

Plastic injection molds are essentially the precision steel partner of the injection molding machine,which is specially used to shape molten plastic into the specific plastic products we want. Its main construction consists of two halves: one rigidly fixed and the other half open and close in a flexible state. While these two halves are fitted together, a closed-in middle cavity is formed. The shape and details of this cavity directly determine what the final plastic part looks like and whether it is good or not.

So you see, if you want to produce plastic parts with unique shapes or precision requirements, you almost have to design and manufacture a set of custom plastic injection molds. This is exactly what JS is good at!We have been deeply involved in this field for more than 20 yearsand have accumulated very mature processes and experience. We can help you make custom molds well and finely, and ensure that the plastic parts produced fully meet your requirements.

How to make plastic injection molds?

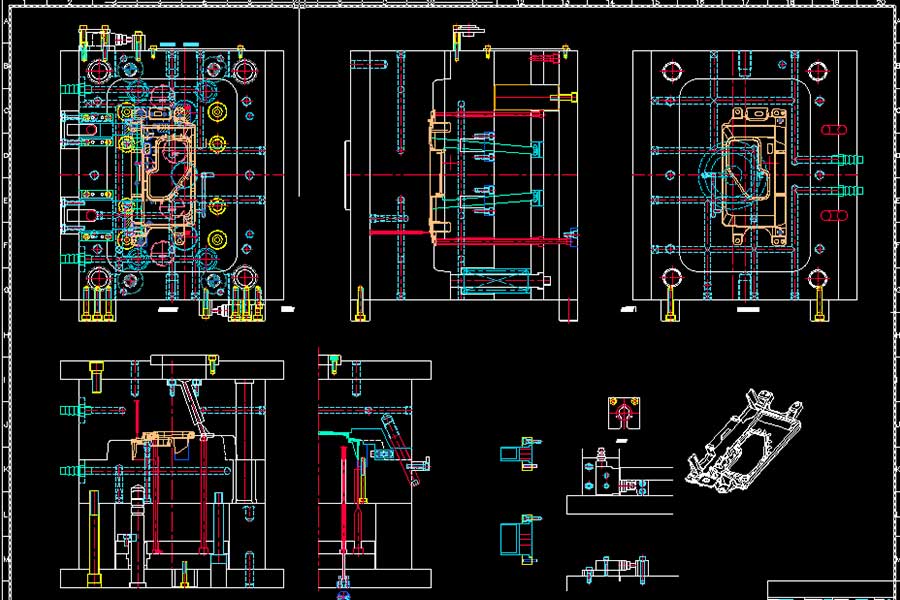

1. Demand analysis and design

Our engineersuse professional software (such as CAD/CAE) to refer to the requirements of plastic parts for 3D design. It is necessary to scientifically plan the molding cavity inside the mold, the channel for the molten plastic to flow in, the pipeline for the circulation of coolant, and the mechanism for ejecting the finished product. Our team can provide more predictable and efficient design at this stage.

2. Material selection and preparation

Select appropriate mold steeldepending onthe characteristics of plasticcomponents.The hardness, wear resistance and corrosion resistance of the steel must meet the use requirements to ensure the life of the mold.

Cut and mill the selected mold steelinto a rough shape according to the design size to prepare for subsequent precision processing.

3. Precision processing

CNC machining (CNC):

This is what everyone usually understands as machining. In the early years, it was done by the old master manually operating the lathe, milling machine, and drilling machine. Now that technology has advanced, the mainstream is touse CNC machine toolsto complete most of the processing. Computers control the movement and operation of these machine tools, and can make molds with more complex shapes and higher precision.

The engineer first uses the design software (CAD) on the computer todraw the 3D drawing of the mold, and then another manufacturing software (CAM) will map out the detailed processing procedures of the machine tool based on this drawing. Then convert these steps into commands that the machine tool can understand. The machine tool automatically starts milling or cutting steel according to the instructions, and processes the mold bit by bit.

This process is particularly common and effective for making molds that are not very demanding or relatively soft materials such as aluminum plastic injection molds.

Electrodischarge machining (EDM):

This machining method is widely used in the mold industry. Its secret is to use a pre-made electrode (usually graphite or copper) to replicate the shape required by the mold.

(1)Processing process:

- Clamping and positioning: The electrode is mounted on the spindle of the EDM machine, and the workpiece (mold steel) is fixed in a working tank containing an insulating medium (usually kerosene).

- Setting the gap: Position the electrode so it just travels over the area of the workpiece to be machined.

- Discharge etching: Maintain a very small gap (usually a few microns to hundreds of microns) between the electrode and the workpiece. The machine tool power system applies a pulse voltage in the gap, breaking through the insulating medium to produce high-energy electric sparks.

- Material removal: The machine tool releases high voltage electricity, which produces sparks in the tiny gap between the electrode and the steel. These sparks are extremely high in energy, so they can accurately erode metal point by point.

(2)The advantages of this method are:

- Can make complex shapes: It has a relatively slow processing speed, but it can process some dead corners, deep grooves, and fine contours thatCNC milling cutterscannot reach or are difficult to process. For example, if there are very small text or patterns on the product, CNC may be difficult to process, but EDM can do it.

- Not afraid of hard materials: The steel used for molds is usually hardened first to be more durable. But the hardened steel is too hard, and ordinary tools are difficult to process.EDMhas no concern for these factors. Itmills onasingle spoton the surface of the steelusing high-voltageelectricalsparks, so it iswell suitedfor very hard materials.

- Good surface quality: The surface processed by EDM sometimes produces a particularly delicate texture. When JS processes the grille mold of the speaker, it will directlyuse this EDM texture as the surface effect of the final product, and even the polishing and grinding process is omitted.

4. Assembly, debugging & trial mold

Install the installed mold on the injection molding machine for the first trial production (T1 trial mold).

Check the samples produced by the trial mold: dimensional accuracy, appearance quality, whether there are defects such as missing materials, flash, deformation, etc.

According to the trial mold results, it is usually necessary to make necessary corrections and optimizations to the mold, and multiple rounds of trial molds (T2, T3, etc.) may be required until the sample fully meets all requirements.

5. Final delivery & mass production

The mold iscomplete only after the trial moldoperates successfullyand the samplehasqualified.The mold will becleaned and rust-proofedfinally at this stage.

Then it can be handed over to the customer and installed on the injection molding machine for production, and the plastic parts you need can be produced in large quantities and stably.Awell-designed custom plastic injectionmoldscan be used hundreds of thousands or evenmillion times.

What are the main features of injection molds?

1. Complexity and flexibility of design

The mold structure can be highly customized according to the shape of the product. By combining complex mechanisms such as modules, sliders, inclined tops, and cylinders, plastic parts with complex geometric features such as concave and convex, threads, and holes can be formed.

The sophistication of mold design directly determines the feasibility of the product shape. Especially whendesigning and manufacturing soft plastic injection molds,special attention must be paid to the softness of the material used and the pressure effect of its fluidity difference on themold'sinternal structure.

2. High precision requirements

For high-demand injection molded parts, accurate size, smooth surface, and long-lasting mold use are all very important.

The following are the differences in precision and finish requirements between ordinary plastic parts and their corresponding mold parts:

| Request project | Requirements for ordinary plastic parts | Requirements for mold parts | Laser optic disc mold |

| Dimensional accuracy level | IT6-7 level (quite precise). | IT5-6 level (more precise). | Extremely high (far exceeding IT5 level). |

| Surface smoothness (Ra) | 0.2-0.1 microns (very smooth). | <0.1 microns (very smooth). | Mold surface<0.01 microns. |

To improve efficiency and reduce costs, molds must last a long time. In the current industry, better injection molds usually have to be able to withstand more than 1 million productions. To be so durable, the structure of the mold itself must be strong enough. Precision molds usually:

- Use a particularly strong mold frame.

- Thicken the template (the main support plate of the mold).

- Add support columns or use tapered locating pins to prevent the mold from deforming and bending under the huge injection pressure. This pressure can sometimes be as high as 100 MPa, which is equivalent to more than 1 ton of force per square centimeter!

The ejector mechanism that allows plastic partsto be ejected from the mold is also very important. If it is not done properly, the product will be deformed or inaccurate in size. Therefore, the position of the ejector must be selected to ensure that all parts of the product can be evenly and smoothly demolded without getting stuck or being knocked out.

3. The key to high production efficiency

Once the mold is debugged and put into production, its cycle (from mold closing, injection, cooling to mold opening and ejection) is very fast. This feature makesthe injection molding process extremely efficient in large-scale production.

4. Maintenance is essential

During long-term use, molds will inevitably have problems such as scratches and burrs due to wear, corrosion, and fatigue. Therefore, it is necessary to formulate a periodic maintenance plan, including cleaning, lubrication, inspection of various moving parts (such as ejector pins, sliders), and repair of worn parts.Maintenance canextend themoldlifeconsiderably and ensure product quality and production continuity.

What are the main types of injection molds?

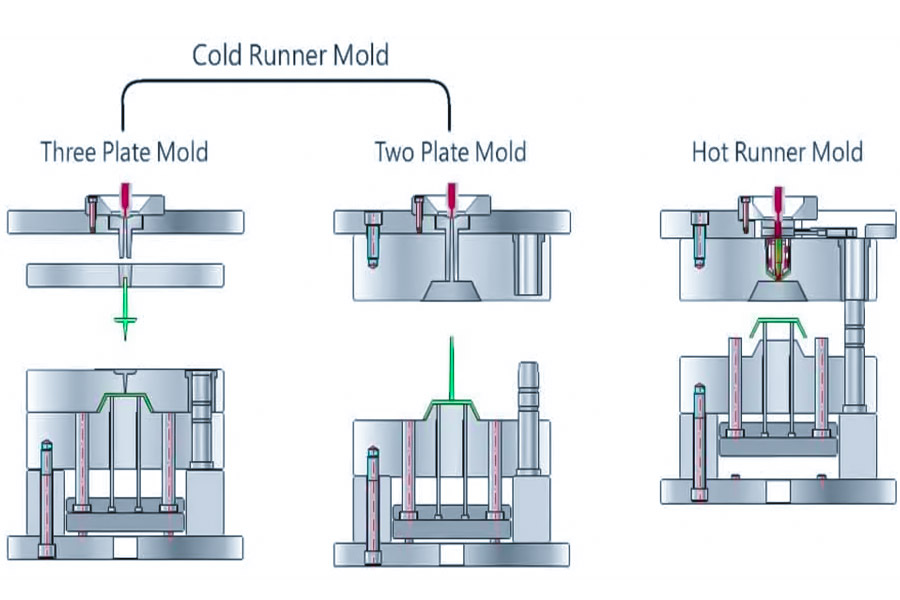

1. Gate edge mold

When the injection mold is opened, the finished part is usually ejected with the runner andgate solidified on the dividing line(also called the parting line). The biggest advantage is that the structure is simple, it is cheap to make, and it is fast to process. Because of this, the side gate technology, which is convenient and affordable to use, is very common in many factories that do injection molding.

2. Single-cavity mold and multi-cavity mold

- Single-point hot gate: It is ahotnozzle that directly injects the molten plastic into the mold cavity.Itis particularly suitable formolds'designs with onlya singleinjection point anda singlecavity.

- Multi-cavity mold:A mold with multiple molding cavities at the same time, which can mass-produce multiple identical products in one injection molding.

| Mould type | One production output | Unit cost | Suitable for the scene |

| Single cavity mold | 1 component | Relatively high | Small batch (several hundred to a thousand) |

| Family mold | 2 or more components | Relatively low | mass production |

3. Hot runner system

This type of mold generally includes several key parts: a nozzle that can be heated, a hot runner plate that centrally heats and transports plastic to all nozzles, and an electrical box that controls the temperature. There are two common forms:

- Single-point hot gate: It is a heated nozzle that directly injects the molten plastic into the mold cavity. This is particularly suitable for mold designs with only one injection point and one cavity.

- Multi-point hot gate: A hot runner plate with several heated nozzles connected to it will be used.The plastic flows to each nozzle through the hot runner plateand then injects it into each cavity separately. Therefore, this method can be used for multi-cavity molds and for multi-point feeding of a complex single-cavity part.

The working method of the hot runner system is somewhat similar to the point gate. The core difference is that the channel of the molten plastic is wrapped in the heated runner plate and the heated nozzle for insulation, and it will not cool and harden inside. In this way, only the finished part is demolded when the mold is opened, and there is no cold material to clean up at all. Because the material in the runner is always hot and flowing, it is directly connected to the product and does not need to be removed. Therefore, this system is often called a waste-free gate system.

Its most obvious advantage is that it saves plastic raw materials!It is especially suitable for products that have high precision requirements, or the plastic raw materials themselves are very expensive, or the parts are difficult to design and process, resulting in high overall injection molding costs. Some soft plastic injection molds that require special treatment often benefit from the stable and precise injection control of the hot runner system.

In mold design, what aspects need to be considered?

1. The shape of the part itself

The complexity and specific geometric shape of the product directly determine the required mold structure. Complex structures are usually more suitable for multi-piece molds such as half molds, which are convenient for parts combination molding.

At the same time, the complex characteristics of the parts will also affect the selection of gates and the layout of exhaust design, so as to ensure that the plastic flows smoothly into the mold and can be cooled evenly.The mold precision requirements are extremely high, and it must be ensured that it is made correctly before production.

2. Material properties

The properties of the selected injection molding material are the key basis for design. The selection of materials directly determines: the selection criteria of mold steel, the arrangement of cooling water channels, the design ideas of the ejection system, and the specific settings of the later molding process parameters.

3. Reliable and efficient ejection system

After the plastic parts are cooled and shaped in the mold, they need to be ejected from the mold through structures such as ejectors, push plates or sleeves. The design focus of the ejection system is to determine the reasonable ejection position, accurately calculate the required ejection force, ensure the balance and stability of the ejection process, andprevent the plastic parts from deforming during ejection.

4. Considering both manufacturing cost and feasibility

The design plan must be feasible and must fully consider the factory's processing capabilities (such as CNC processing, EDM, surface polishing) and cost control. Cost is the big deal! Don't make it too complicated if you can solve the problem with a simple structure.

For cost-sensitive or specific low-volume projects, it is also a practical choice to find a good quality used plastic injection molds on the premise of meeting the requirements. It is also important to find a reliable used plastic injection molds for sale sales channel.

How does JS solve the difficulties of injection molds?

1. Complex structural problems

When encountering products with undercuts, undercuts and other places that are difficult to take out,JS is good at designing sophisticated and reliable slidersand inclined ejector mechanisms to allow these moving parts to work smoothly during mold opening and ejection, ensuring that complex products can also be demolded smoothly, and the mold movement is stable and durable.

2. Accurately meet the requirements of medical parts

For the high cleanliness, ultra-precision and zero-defect requirements of medical parts plastic injection molds, JS strives for excellence in material selection, exhaust design, tolerance control and ejection solutions to ensure that the medical parts produced are accurate in size, perfect in surface, safe and reliable.

3. Production efficiency and stability

Whether the mold is easy to use depends on whether the production is fast and stable. We pay special attention to optimizing the design of cooling water channels to allow heat to dissipate quickly and evenly, significantly shortening the molding cycle. At the same time, the precise exhaust design eliminates the problems of trapped air and burning, ensuring that long-term continuous production can also stably output good products and reduce downtime waste.

4. Cost and performance

In the face of cost pressure, we provide professional advice: invest generously where hot runners are needed, and be thrifty where the structure should be simplified. We are proficient in the characteristics of various steel materials, use good steel and long life in key stress-wearing parts, andselect materials reasonably for secondary parts, while ensuring the durability of the mold and controlling the overall cost.

Summary

Plastic injection molds are key tools for large-scale, high-efficiency, and low-cost production of various complex plastic products in factories today.It usesthe technologies of machining, material knowledge, temperature management, and how plastics flow. Mastering the relevant knowledge of injection molds can provide a more solid basis for your decision-making and effectively improve work efficiency.

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

FAQs

1. How does injection molding work?

Injection molding is the process of injecting molten plastic into a closed mold at high pressure, cooling and solidifying it, and then opening the mold to eject the product. The process includes: mold closing → injection → pressure holding → cooling → mold opening → ejection → cycle operation.

2. What materials are injection molds made of?

Injection molds are usually made of tool steel (such as P20, H13) or carbide, and the surface can be chrome-plated or nitrided to improve wear resistance. Some simple molds use aluminum alloy to reduce costs.

3. Can injection molds have multiple cavities?

Injection molds can be designed with multiple cavities. This is a key technology to improve production efficiency. Through one injection, multiple identical or different parts can be molded at the same time, greatly reducing the cost per piece and cycle time.

4. How long can an injection mold be used?

The life of an injection mold is usually more than 150,000 to 1 million times, depending on the quality of the steel, frequency of use, maintenance status and production environment. High-quality steel molds can be properly maintained for millions of times.

Resource