Many plastic products on the market come from the same core process:plastic injection molding. Behind this efficient production, the real protagonist is the injection mold. It is responsible for shaping the hot and molten plastic into the final shape we need.

Sounds a bit magical? In fact, understanding how plastic injection molds work is the first step to understand how to make plastic injection molds. Next, we will disassemble the internal structure and workflow ofplastic injection moldsstep by step to see how it turns plastic particles into physical objects in our hands in just a few tens of seconds.

What do we need to know about plastic injection molds?

If you want to make a plastic cup of a specific shape, it is definitely not enough to just pinch it by hand, because the efficiency is too low. At this time, you need to use a plastic injection mold. The structure of this mold itself is quite complex,usually made of several pieces of solid metal (such as steel) that are precisely machined and assembled. It must be able to withstand the high pressure and high temperature during injection, and it must be able to open and close accurately to allow the finished parts to be demolded smoothly.

There are also many types of plastic injection molds. Some are very simple, just open and close. Some are particularly complex, with moving parts inside, and some need to make two-color plastic parts. But no matter what type, the core function is the same: to shape the molten plastic and make the plastic products we want. It is the invisible but extremely important behind-the-scenes hero behind the mass production of plastic parts.

How does the mold for plastic injection molding work?

1. Mold clamping and locking

When the mold starts working, first its two halves (movable mold and fixed mold) will be tightly closed together.

The huge mold clamping force locks them tightly, leaving no gaps. This is very critical, because high-pressure plastic will be injected into it next. If the mold is not locked, the plastic will leak out and the parts will be damaged.

2. Injection of plastic

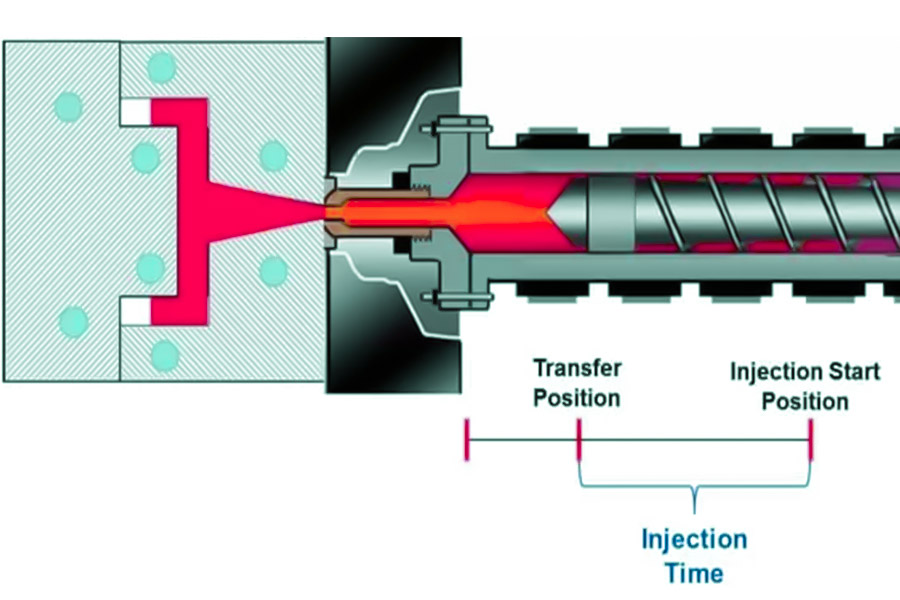

Plastic particles are sent into the barrel of the injection molding machine for heating. The temperature is very high, and the plastic quickly melts into a syrup-like state.

Then, the screw at the front end ofthe injection molding machinepushes forward with force, and the molten plastic is injected into the cavity inside the mold through the gate on the mold at very high pressure. The shape of this cavity is the shape of the plastic part you want in the end.

Special note: If you want to use soft plastic injection molds for processing, the design of the mold may need to be more particular about exhaust to prevent the soft plastic from wrapping the air and forming bubbles or burning inside.

3. Pressure holding and cooling

After the plastic fills the cavity, the screw will not retract immediately. It will continue to maintain a certain pressure and squeeze a little more plastic in. This allows the plastic to stick tightly to the cavity wall,preventing the surface of the part from being sunkenor the internal shrinkage cavity, and ensuring the part size is accurate and full.

At the same time, the mold begins to play a cooling role. There are usually many thin pipes inside the mold, with circulating cold water. The cold water continuously takes away the heat from the mold. The melted plastic begins to harden and take shape. This cooling time accounts for the majority of the entire production cycle and directly affects the production speed.

In some cases, such asmaking samples, small batch productionor parts with particularly simple structures, aluminum plastic injection molds may be used. The advantages of aluminum are fast processing and low cost, but its disadvantages are also obvious: it is not as hard and wear-resistant as steel, and its heat dissipation capacity is not as good as steel, so the cooling time may be longer and the life is much shorter, which is not suitable for mass production of hard plastic parts.

4. Mold opening

When the part is cooled hard enough in the mold and can maintain its shape, the clamping mechanism will loosen and separate the two halves of the mold along the parting surface.

5. Ejecting the part

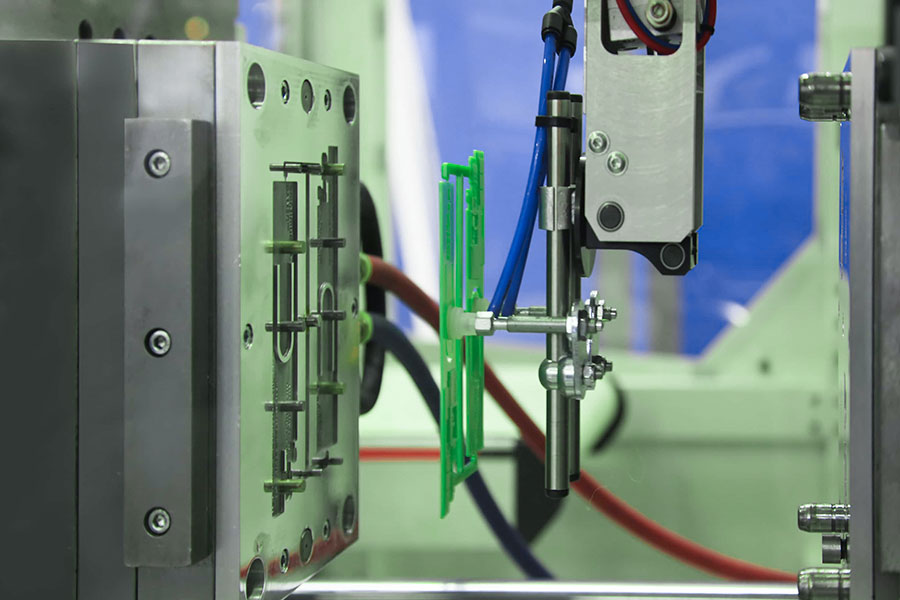

After the mold is opened, the molded plastic part is usually still attached to the cavity on the side of the movable mold. At this time,the ejector structure in the moldwill move to push the part out of the mold and eject it.

The ejection step must be designed cleverly, with sufficient force and accurate position, and the part must not be deformed or ejected with white marks.

6. Reset to prepare for the next round

After the ejector ejects the part, it will immediately retract and return to its original position. At the same time, the movable mold and the fixed mold are closed and locked again. The screw of the injection molding machine rotates and retreats at the same time, injecting new plastic particles, heating and melting them, and preparing for the next injection. The whole cycle repeats itself, and plastic parts are produced continuously.

How are plastic injection molds composed?

When designingcustom plastic injection molds, it is necessary to comprehensively consider factors such as the specific structure of the product, production requirements and costs. The following is a targeted design of these parts:

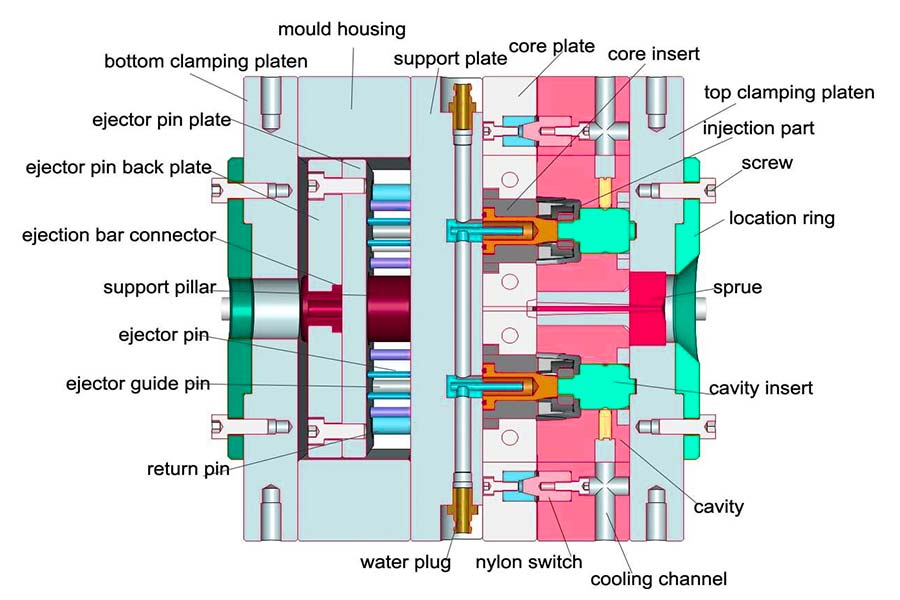

1. Mold fixing device

The mold consists of two halves, upper and lower, and needs to be locked to the template of the injection molding machine with a special fixing plate. Some machines are tightened and fixed with large bolts, while others are directly sucked with strong magnets. This ensures that the mold can be firmly fixed during operation and will not loosen.

2. Plastic inlet and positioning

There is a nozzle at the front of the machine barrel, and the molten plastic is squeezed out from here. This nozzle must be accurately attached to a small interface on the mold, which is called a sprue sleeve. The mold also has a positioning ring, whose function is to ensure that the nozzle can be aligned and pressed against the center of the sprue sleeve to allow the plastic to enter the mold smoothly.

3. Plastic inflow channel

After the plastic enters the mold from the nozzle through the gate sleeve,it will first flow into a main channel, which is called the main branch channel. Then the plastic flows from the main branch channel into smaller channel branches, which distribute the plastic to the entrance of each molding area, that is, the gate. The gate is the last channel for the plastic to actually enter the final shape area.

4. Mold core structure

The final shape of the product is formed in the cavity. Usually, a concave hole is opened inside the steel plate of the upper mold, which is the cavity.

A convex part is fixed on the support plate of the lower mold, which is the core. It is inserted into the space of the cavity and together constitutes the shape of the product.

When the two halves of the mold are combined, the gap between the cavity and the core is the wall thickness area of our final product, andthe molten plastic is injected and filled here to cool and shape.

In order to make the mold evenly stressed, the molding units in a set of molds are usually symmetrical combinations of 1, 2, 4, 8, etc.

Mold cavity functional area division:

| Area name | Major role | Describe |

| Mold cavity | Shaping the main external shape of the product. | Fixed on the upper half of the mold to form a concave contour. |

| Core type | Shaping the internal shape and detailed structure of the product. | Fixed on the support plate of the lower mold, forming a raised contour. |

| Forming unit | The exact area where one or more products are formed. | Quantity planning is the key to designing custom plastic injection molds. |

5. Cooling system

When the molten plastic is injected, the temperature is very high and must be quickly cooled and fixed.A whole set of pipes is pre-buried in the mold. Cold water circulates in these pipes to take away the heat generated when the plastic solidifies. The quality of this system directly affects the production speed and whether the product will deform or warp.

6. Mold alignment guide

The mold opens and closes thousands of times. In order to ensure that the cavity and the core can be 100% aligned every time the upper and lower molds are closed, there are several sets (usually 4) of conical guide pillars on the side of the mold, which are inserted into the corresponding guide sleeves. They are like precision guide rails, allowing the two halves of the mold to complete the opening and closing movements stably and accurately, ensuring that the shape of the product is always consistent.

7. Ejector mechanism

After the product is cooled and solidified, it needs to be removed from the tightly wrapped core, otherwise the mold cannot be opened or the product will be damaged.This is the task of the ejector mechanism.

The main component is a bunch of small pillars or small round rods, which are installed on a movable ejector plate. After the mold is opened, the machine pushes the ejector plate forward, and these small pillars extend out and evenly press against the back of the product or the appropriate position, gently pushing it away from the core.

The ejector plate itself also needs a support frame to fix the position of these ejectors to ensure that they only push forward and backward without shaking or rotating.

Is it expensive to make plastic injection molds?

The price range of plastic injection molds is extremely wide, ranging from a few thousand to millions of RMB (equivalent to a few hundred to hundreds of thousands of US dollars). Whether it is expensive depends on the specific requirements of the product, production goals and budget. The key influencing factors are as follows:

1. Product complexity

The more complex the shape, the higher the cost: Cavities, thin walls, fine textures or structures that require sliders/bevel ejectors to demold will greatly increase the design difficulty, processing time and number of parts, pushing up the price.

Precision requirements determine processing investment: Strict dimensional tolerances (such as ±0.02mm) ormirror polishing requirementsrequire high-precision equipment and more time.

2. Number of molding cavities

For each additional cavity (such as from 1 cavity to 8 cavities), the steel consumption and processing volume of the core components are nearly doubled, and the mold size and weight also increase.

3. Key steel selection

- Steel grade is the basic cost: steel for core, cavity and other core components is crucial.

- Ordinary parts: Domestic P20/718 steel is sufficient.

- High-demand parts: Imported high-grade steel such as H13/S136 is required, and the price is several times higher.

4. Mold size

Large molds have more consumables andrequire large machine tools for processing. The hoisting and cooling designs are complex, and the cost naturally increases.

5. Mold price range reference

| Mold type and characteristics | Representative product | Estimated price range (USD) | Main driving factors |

| Simple and small (single hole) | Bottle cap, simple shell. | 1,000−7,000 | Simple structure, small size, ordinary steel, cold runner. |

| Medium complexity (1-4 acupoints) | Home appliance buttons, tool handles. | 7,000−40,000 | Detail texture, possibly including sliders, cold runner. |

| High complexity/precision (multi cavity) | Automotive interior parts, precision gears. | 40,000−200,000+ | Complex core pulling structure, high precision, hot runner. |

| Large, complex/long-life requirements | Car bumper, household appliance shell. | 110,000−400,000+ | Huge, ultra complex structure, advanced steel. |

Budget control suggestions:

- Clear core needs: Avoid excessive pursuit of unnecessary precision or surface effects.

- Consider second-hand options: If the initial budget is limited and the design changes are small, the used plastic injection molds for sale market is worth exploring. Carefully evaluate the status and applicability of used plastic injection molds to effectively reduce costs.

- Get accurate quotes: It is wiser to provide detailed drawings tocompare quotes from multiple suppliers.

Does injection pressure affect plastic injection molds?

Injection pressure has a direct and important impact on the working condition and life of the mold. This pressure is the power source that drives the molten plastic to fill the cavity at high speed. It not only acts on the plastic, but also on the mold itself. The specific impact is reflected in the following key aspects:

| Impact aspect | The key role that molds bear | Possible negative outcomes |

| Locking stability | Apply to the mold parting interview diagram to open the mold. | Flying edge/trailing edge generation. |

| Internal parts/structural strength | Generate local high pressure points to impact weak areas (thin steel/small parts/moving parts). | Deformation, fracture, and motion jamming of parts. |

| Demoulding resistance | Increase the wrapping force of plastic on the core. | Difficulty in pushing out, product deformation/damage. |

| Long term structural reliability | Continuous impact leads to wear, and structural components are subjected to periodic stress. | Accelerated wear of cavities/gates, shortened lifespan of moving parts such as guide posts/sleeves, and accumulation of mold elastic deformation leading to loss of accuracy or cracking. |

Injection pressure is a necessary condition to ensure the smooth filling of plastic, but it does put forward higher pressure resistance requirements for the mold. Whether it is a newly manufactured precision mold or a device circulating on the market, reasonable injection pressure setting is very important.

Why can't we do without plastic injection molds?

Plastic injection molds are an indispensable cornerstone of modern industry. The core reason is that they solve three key problems:

1. Efficient and accurate replication capability

- Shape realization: No matter how precise the buckle, thin wall or curved structure is, the mold can accurately copy it in an instant. Without it, complex plastic parts are difficult to efficiently mold.

- Mass production: A set of qualified molds cancontinuously and stably produce tens of thousands to millions of highly consistent parts. This efficiency is unmatched by single-piece processing.

2. Guarantee of product accuracy

Dimensional stability: Precision molds ensure that the dimensional deviation of parts molded in each cycle is extremely small. This is the fundamental premise for modern product assembly to be seamless and reliable in function.

3. Cost control

- Functional structure molding in one step: With the help of sophisticated structures such as sliders and inclined tops, the mold can directly produce undercuts, threads, insert assemblies and complex surface textures in one step, greatly reducing subsequent processes.

- Large-scale cost advantage: Although the initial investment in molds is high, the unit cost is much lower than other processes (such as CNC processing and 3D printing) when it is distributed to large-scale products.

What are the key industries served by plastic injection molds?

1. Automobile and transportation

There is an urgent need for high-precision and long-life molds for manufacturing interior and exterior trims (instrument panels, door panels),heat-resistant engine compartment components(ducts, covers) and functional parts (wiring harness connectors, electronic housings). The performance of components in harsh environments depends on professional mold guarantees.

2. Consumer electronics and home appliances

The product iteration is fast, and the integration of miniaturization, thin walls, and complex buckles is required. The mold ensures that the mobile phone/computer housing, internal bracket, charger housing, and home appliance panel have both high-precision appearance and structural strength to meet the consistency of batch assembly.

3. Medical and health equipment

Medical parts plastic injection moldsare directly related to life safety and have strict requirements:

- It is necessary to achieve traceless molding of microstructures (such as liquid medicine channels and precision valve cores).

- Ensure sterile surface (mirror polishing, no dead angle design).

- Compatible with biocompatible materials (such as implant support rings, mask seals).

- Syringes, diagnostic equipment housings, inhaler components, etc. all rely on ultra-precision medical molds.

4. Industrial equipment and accessories

Provide high-strength, wear-resistant engineering plastic parts for equipment housings (power tools, instrument boxes), functional structural parts (gears, pulleys), and pipe joints. Mold design needs to strengthen mechanical performance support.

Summary

Behind every set of easy-to-use plastic injection molds, there is a precise design, suitable materials and excellent manufacturing process. This is the core value of the mold-it is not only a production tool, but also a key support for enterprises to make new products,ensure stable mass production and control costs.

As a partner deeply involved in the field of injection molding, JS provides:

✅ Full-process support from design to mass production.

✅ High-precision mold development.

✅ Quick response and mold verification.

Whether you need automotive precision components, medical-grade sterile parts, or innovative structures for consumer electronics, JS can use professional mold technology to accurately implement your design.

👉Contact us to customize your exclusive mass production solution!

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

FAQs

1. What is plastic injection molding?

Plastic injection molding is a manufacturing process that injects molten plastic into a closed mold cavity under high pressure, and then opens the mold to eject the plastic part after cooling and solidification.

2. What is a plastic injection mold used for?

Plastic injection molds are core tools that give molten plastic a specific shape, size and surface accuracy, and realize the ejection of plastic parts after cooling and shaping.

3. How does plastic enter the mold?

Under the push of the injection molding machine screw, the plastic is forced to fill the internal channel of the cavity through the mold pouring system (runner, gate).

4. What are the commonly used materials for plastic injection molds?

Common materials for plastic injection molds include high-strength and wear-resistant metal materials such as tool steel (such as H13, P20), cemented carbide, and stainless steel (such as 420).