In 1872, the world's first injection molding machine was born, which laid the foundation for the rise of the plastic injection molding process. Now, countless plastic parts in our lives, from large auto parts to small home appliance shells, are made by injection molding, and are extremely widely used.

The reason whyplastic injection moldingcan be the first in the field of plastic processing is that it can stably and efficiently produce large quantities of high-quality plastic parts. In fact, the entire injection molding industry is on a good track, and forecasts show that by 2028, its market will grow at a compound annual growth rate of 4.6%.

But then again, although injection molding machines can make things fast and produce large quantities, in order to ensure that every part is up to standard, every step in the whole process cannot be sloppy and must be strictly controlled!

So, what is plastic injection molding? How doexperienced manufacturerscontrol it to produce the best plastic parts? Next, let's talk about these key basics and control techniques.

What is plastic injection molding?

Plastic injection molding is one of the most mainstream processes. Simply put, it is injection molding, which is a method of mass production of plastic parts.

Plastic injection molding (often referred to as injection molding) is indeed one of the most common and efficient processes for manufacturing plastic parts today. Simply put, it is a plastic injection molding services designed specifically for mass production.

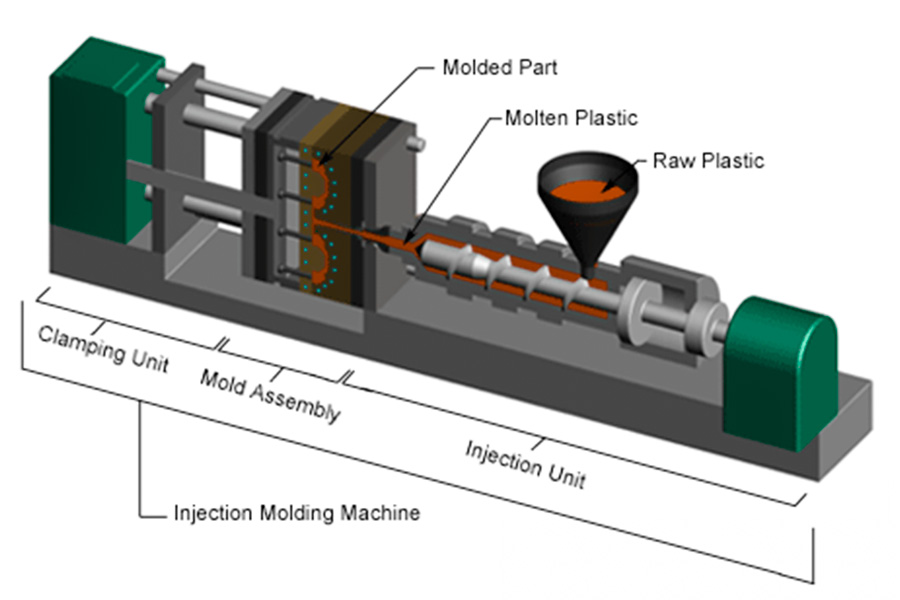

The entire injection molding process is inseparable from three core elements: injection molding machine, plastic raw materials, and designed and manufactured molds.

The core process is very clear:

- Feeding and melting: Plastic particles are placed in the hopper of the injection molding machine and heated in the barrel until they are completely melted into a flowing melt.

- Injection molding: The molten plastic is quickly injected into the pre-processed cavity in the mold under high pressure. The shape of this cavity directly corresponds to the geometry of the final part.

- Cooling and shaping: The plastic melt cools and solidifies in the closed cavity.

- Ejection of parts: The mold is opened, the molded part is ejected, and a production cycle is completed.

Therefore,when you need to mass-produce plastic partswith stable shapes and strict quality requirements, injection molding is almost always the preferred technical solution.

What are the main features of plastic injection molding?

1. Extremely high repeatability and dimensional consistency

This is the core advantage of injection molding. Through precise plastic injection molding jobs, injection molding can continuously and stably produce parts with highly consistent geometric shapes and dimensional tolerances. Even in large-scale production, the repeatability of parts is excellent.

This is critical for applications that require strict tolerance matching and interchangeability.Custom plastic injection moldingrelies on this, and the complex custom design is perfectly restored through precision molds to ensure that each one meets the standards.

2. Large-scale production efficiency and economy

Once the injection molding machine is started, the production rhythm is very fast. Injection molding is very suitable for mass production. The molding cycle of a single part is usually short (ranging from seconds to minutes), and the production process can be highly automated.

This means that when you have to make thousands of parts, the cost of a single part will be shared on average. This is its huge costadvantage over 3D printing, especially for products that need to be mass-produced.

3. Design flexibility

Injection molding is outstanding in handling customized complex shapes. Whether it is a particularly smooth curved surface or a complex internal structure, it can be accurately reproduced. At the same time, the process also supports special technologies such asinsert molding, two-color molding, and in-mold decoration, which greatly expands the possibilities of product design.

4. Material adaptability

Most thermoplastics, from common general-purpose plastics to high-performance engineering plastics, are suitable for injection molding. This allows us to flexibly select materials according to needs when designing products,which is a key factor in supporting customized products.

5. Excellent surface quality

A good mold not only determines the shape, but also the surface effect. From high gloss to matte, various textures to fine patterns, they can be directly molded, reducing the need for secondary processing. Some surface treatments can even be completed simultaneously in the mold.

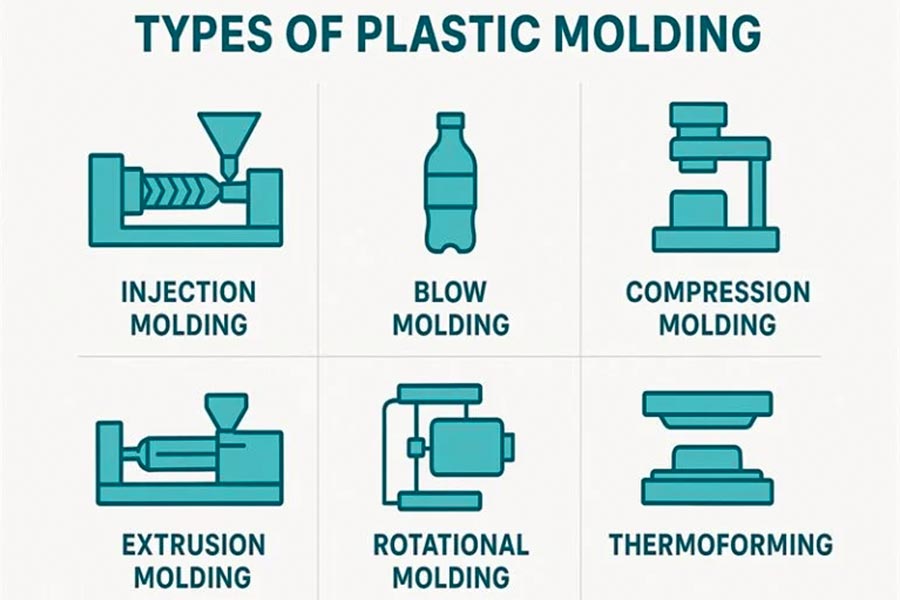

What are the main types of plastic injection molding?

1. Blow molding

The basic principle of plastic blow molding is to blow air into a piece of heated and softened plastic. This bulging plastic bubble will continue to expand until it completely fills every corner of the mold and becomes the shape of the mold tightly. When the plastic cools and hardens, open the mold and the newly made plastic part can be taken out.

This blow molding methodcan quickly and economically produce a large number of hollow, one-piece plastic parts. Because the wall thickness of the things blown out is relatively uniform and relatively thin. Therefore, from small ones such as beverage bottles and medicine bottles to large ones like storage tanks and barrels, as long as it is such a hollow container, blow molding is particularly good.

2. Compression molding

Compression molding is to put the preheated and softened plastic block into the heated mold, and then close the mold and press hard, and the plastic is pressed into the shape of the mold. After it cools and hardens, open the mold and take out the finished parts. This heating and pressurizing process is called curing, which can make plastic parts stronger and more stable in shape.

This process is particularly popular. It often uses some reinforced plastic materials. These materials are strong in themselves. Coupled with the curing process of compression molding, the parts made are stronger, more durable, and have a longer service life than those made by commonplastic injection molding service. Therefore, compression molding is particularly good at making parts that require high strength, such as automotive parts, electrical parts, buttons on clothes, and even key components in bulletproof vests.

3. Injection molding

Among many plastic molding processes, injection molding stands out for its excellent versatility. It can efficiently produce parts with a wide range of sizes and shapes.

The basic principle of injection molding is relatively straightforward. Molten plastic is injected into a precision steel mold under high pressure. The mold contains a cavity that is consistent with the shape of the final part. After cooling and solidification, the mold is opened and the molded part is ejected through an ejector system. Although the principle is simple, process control in actual production is key to ensuring that thousands of parts remain highly consistent.

4. Extrusion molding

Extrusion molding is a bit like squeezing toothpaste, but it squeezes molten plastic. The biggest difference between it and some other plastic processing methods is that the shape of the mold outlet determines what the final product looks like. The mold itself is more like a fixed outlet here, rather than a closed space.

There is a rotating screw inside the extruder, which heats and melts the plastic particles, and then pushes the molten plastic forward and forces it out of the specific shape of the opening of the mold. In this way, the extruded plastic strip becomes the shape of the mold opening.

Common mold opening shapes and product examples:

| Mold opening shape | Typical extruded products |

| Rotundity | Water pipes, beverage straws, wire casings. |

| Square | Door and window seals, decorative lines, profile frames. |

| L-type | Wall corners, edge guards, frame reinforcements. |

| U-shaped | Slide rails, channels, water guides, decorative grooves. |

| T-type | Seal strips, dividers, decorative moldings. |

| I-shaped | Structural profiles (such as lightweight building materials, support beams). |

The plastic profile that is extruded will be the same as the mold opening. This process is particularly good at making things that have the same shape from beginning to end,especially products that require continuous lengths, such as pipes, ducts, and door and window seals.

5. Rotational molding

It is a relatively special method for manufacturing plastic parts, also known as rotational molding. Its core idea is to use heating and biaxial rotation to allow powdered plastic to form an integral part on the inner wall of the mold.

The process is as follows:

- Feeding: Put the plastic powder into a hollow mold.

- Heating and rotating: The mold is sent into the heating furnace and starts to rotate slowly around two vertical axes. In this way, the powder gradually melts and becomes sticky with heating and rotation, and then evenly sticks to the inner wall of the entire mold.

- Cooling and shaping: When the powder is completely spread and fused into shape, the mold continues to rotate while cooling down to allow the plastic part to harden inside.

- Removing the part: When the mold is opened, you can take out a hollow part with a complete shape and uniform wall thickness.

This process is cost-effective and material-saving,suitable for making some large and hollow containers, which is both economical and environmentally friendly.

Which industries use plastic injection molding?

1. Electronic appliances

The mobile phone case in your hand, computer keyboard keys, display frames, various chargers, plug shells, terminal blocks inside the machine, and even the button remote control shell on the TV, all have to be made by injection molding. Many small parts can also be done this way, and the materials are mainly thermoplastics.

2. Automotive industry

Automotive plastic injection molding is particularly widely used here!From the headlight covers, bumpers, and grille decorations you can see outside the car, to the dashboard shell, air-conditioning vents, various button switches inside the car, including some parts in the engine compartment that are not directly exposed to high heat, they are all made by injection molding. Large quantity and high requirements.

3. Daily consumer goods

The toothbrush handles, combs, washbasins and buckets, hanger clips, trash cans, various small tools in the kitchen, and toy shells that you use every day are all made by injection molding. Simple, cheap, and practical.

4. Medical equipment

This area has very strict requirements. The syringe core rod (the part that pushes), some equipment shells that do not need to contact liquid medicine or blood, the cover of the testing equipment, disposable culture dishes, surgical trays, etc. The requirements for materials, environmental cleanliness and product size accuracy are very high, and theyneed to be made with precision injection molding.

5. Industrial products

For example, tool handles, tool box shells,button shells and covers of various machines, parts on conveyor belts, fan blades, and some relatively strong parts such as gears, pulleys, and pipe joints made of engineering plastics, durable and strong.

How is an injection molding machine made up?

A typical injection molding machine is usually a horizontal long strip structure. Its core function is to melt plastic pellets and then inject them into the mold under high pressure. The main components include:

1.Hopper:Located at the back or top of the machine, shaped like a large funnel. Plastic raw material pellets are added to the machine from here.

2.Material cylinder:A long cylinder connected to the bottom of the hopper. Plastic pellets start their journey from here.

3.Screw:A thick spiral rod installed inside the barrel that can rotate. It is driven by a motor and conveys and compacts the plastic pellets forward while rotating during operation.

4.Heating coil:An electric heating element wrapped around the outer wall of the barrel (usually a circle of heating belts). They provide heat to gradually heat and melt the plastic pellets in the barrel into a viscous molten state. The barrel temperature is usually precisely controlled in sections.

5.Mold clamping device:

This is the entrance and power of the machine, responsible for two core actions:

- Lock/open the mold: Provides huge force to tightly close the two halves ofthe mold during injection to resist the high pressurewhen the plastic is injected.

- Ejection of parts: After molding and cooling, the mold is opened and the solidified plastic parts are pushed out of the mold with an ejection mechanism (usually an ejector pin or ejector plate).

Common mold clamping methods:

| Characteristic | Elbow style (mechanical) | Direct pressure (hydraulic) |

| Working principle | Use the elbow linkage mechanism to amplify the hydraulic cylinder force for mold locking. | The hydraulic cylinder directly generates and transmits the locking force. |

| Speed | The opening and closing speed of the mold is fast. | The opening and closing speed of the mold is relatively slow. |

| Energy consumption | Maintaining pressure energy consumption after mold locking is relatively low. | The entire locking process requires hydraulic maintenance, resulting in high energy consumption. |

| Clamping force | Usually used for small and medium-sized machines, the locking force range is limited. | The locking force is large and uniform, suitable for large molds/high locking force requirements. |

| Structure | The structure is relatively complex (linkage mechanism). | The structure is simpler and more direct. |

| Common applications | Small and medium-sized injection molding machines are used to produce small or medium-sized parts. | Medium to large injection molding machines are used to produce large, precision, or high demand parts. |

6.Mold:

This is the core custom component that determines the final shape of the product. It usually consists of two parts:

- Fixed mold: Fixed on the stationary side of the machine.

- Moving mold: Fixed on the movable side of the clamping device.

When the clamping device pushes the moving mold toward the fixed mold and locks it, the cavity they form together is the shape of the plastic part. The molten plastic is injected into this cavity to form.

In the plastic injection molding factory, it is these parts that work together, from feeding, heating and melting, high-pressure injection, mold locking molding, cooling and curing to the final ejection of parts, to achieve efficient, accurate and large-scale production of plastic products.

How does JS's injection molding process make plastic parts suitable for you?

At JS, we focus on accurately transforming your design into high-quality and high-consistency plastic parts through precision injection molding technology. The key lies in how we do it:

- Precision mold is the core: We invest in creating high-precision molds that fit your design perfectly, which is the cornerstone of accurate part size and perfect appearance.

- Knowing materials, knowing you better: With rich experience,we help you choose the most suitable materialfor performance and cost from a wide range of plastics.

- Process control:Our equipment and engineering teamaccurately control key parameters such as temperature, pressure, time, etc. to ensure that each batch of parts is stable and reliable, reducing problems such as flash and shrinkage.

- Fast problem solving: From design review to production, our engineering team participates in the whole process, quickly identifies and solves potential problems, and ensures smooth mass production.

Choosing JS,an experienced plastic injection molding companies, means that you get not only parts, but also reliable solutions from design to delivery, and an efficient, stable, and plastic parts manufacturing partner that meets your stringent requirements.

Summary

Plastic injection molding can make various specifications of products by circulating the hot plastic melt for tens of seconds, fromsmall and precise medical devicesto large automotive parts. The key is to look at the careful control of design, materials, molds and parameters.

I hope the above can help you understand how injection molding works. For any plastic injection molding company, mastering this technology is the core ability to realize product manufacturing.

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

FAQs

1. What is the core principle of plastic injection molding?

After melting the plastic raw material, it is injected into the closed mold cavity under high pressure, cooled and solidified, and finally ejected to obtain a plastic product consistent with the shape of the cavity.

2. How does the injection molding machine work?

Heat and melt the plastic particles, inject them into the closed mold cavity under high pressure, maintain pressure, cool and solidify them, open the mold, eject the product and execute it in a cycle.

3. What is the function of the plastic injection molding mold?

Give the molten plastic a precise shape and structure, control the plastic flow through the cavity, cool and solidify, and finally form a plastic product with specific geometric characteristics and dimensional accuracy.

4. What are the advantages of plastic injection molding?

Efficient mass production of complex precision plastic parts, high product dimensional accuracy, good surface quality, and extremely low unit cost, suitable for automated large-scale production

Resource