Insert molding and overmolding are both injection molding categories, which often get mixed up. However, there are essential differences between these two processes in terms of implementation principles and application fields.

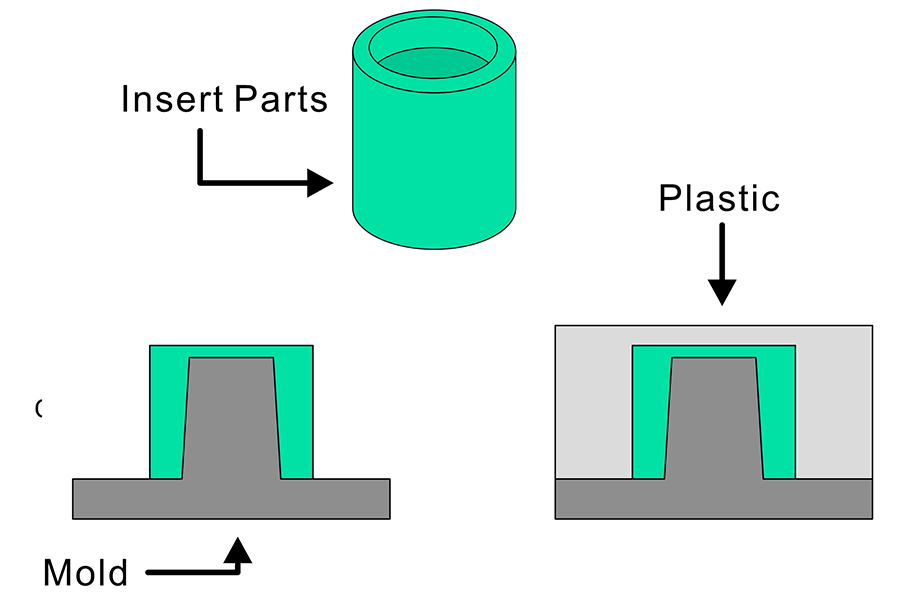

We are referring to insert molding here. Its primary process is inserting first and then overmolding. It particularly finds and pre-fixes an already produced part (known as an insert) in the mold cavity before that. Then, molten thermoplastic material is inserted into the mold.

After cooling and solidifying the plastic, it tightly encases the insert and brackets around the insert, andfinally demolds to form a composite structural part. Such is a process that captures strengths of different materials by mechanical interlocking, thus a process of unique value.

Below content will analyze the process steps, general applications and essential parameters which must be taken into account before use of insert molding in detail.

What is insert molding?

Insert molding is a process of injection molding. Its core process is to place a previously formed part (we call it an insert, usually a metal insert) in the mold before putting the plastic melt into the mold. After the plastic is injected, it surrounds the insert. When it cools and solidifies, the plastic and insert are closely fused together as a whole piece and become part of the final part.

The products obtained from this process can combine the durability and strength of metal with plastic's lightness, thereby creating the final product strong but light. For the above attribute, to some high extent, it has been applied in numerous industries. For simplicity, insert molding is a very efficient way of leveraging metal parts so that plastic parts can be optimized for their performance.

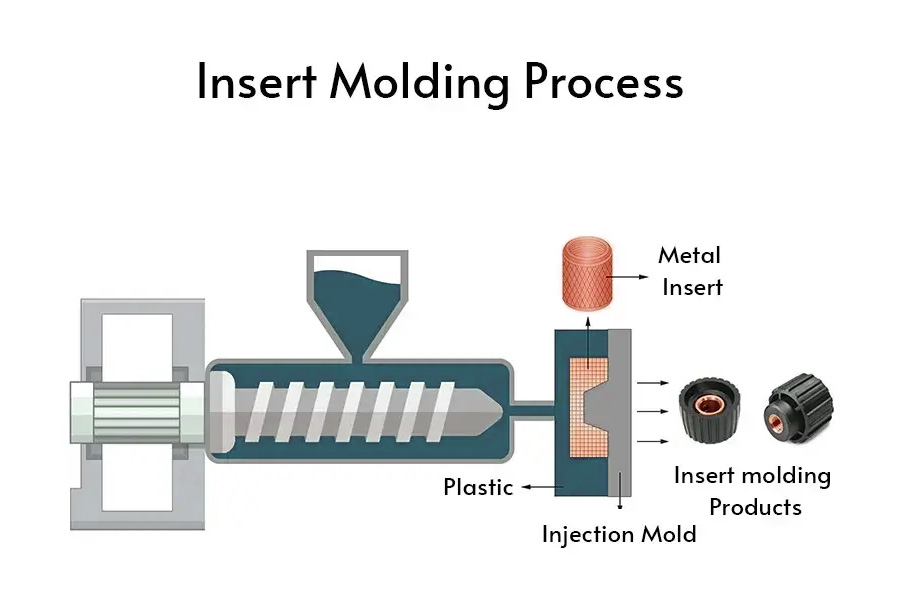

How does the insert molding process work?

1. Prepare inserts

Before molding, we need to prepare the inserts to be used. Theseinserts can be metal (like steel, aluminum), ceramic, or even another plastic part, with the purpose of bringing their unique properties (such as strength, conductivity, special shape) to the final part.

The design of these inserts is critical: they must be strong enough to withstand the high pressure and temperature during injection. At the same time, we have to find a way to make the subsequent plastic grip it, which can be done by making some textures, grooves, or designing it into a complex shape.

2. Load the insert into the mold

This step determines how to put the insert firmly in place.

Large-scale productionprefers machine loading: At this time, automatic equipment will be used to quickly and accurately insert the insert into the specific position of the mold. The machine has a fast loading speed and a large output of parts, which is suitable for making many parts. However, the machine equipment also costs a lot of money at the beginning.

Small batches or trial production are loaded manually: If the quantity is not large or it is in the proofing stage, skilled workers will manually put the insert carefully in the mold. This method costs less in the early stage, but it is relatively slow.

3. Inject plastic into the mold

When the insert is in place and the mold is closed, the high-temperature molten plastic liquid (that is, thermoplastic material) is injected into the mold at high pressure. This pressure is very important. It ensures that the plastic liquid can flow evenly, wrap every corner of the insert, and fill the entire mold cavity at the same time.

4. Pressure holding and cooling and shaping

The mold cannot be opened immediately after the plastic is filled. It is necessary to maintain a certain pressure for a period of time, firstly toprevent the plastic that has not yet been formed from flowing back, and secondly to make the plastic more compact to compensate for shrinkage and reduce shrinkage deformation. At the same time, the mold needs to be kept at a suitable temperature so that the plastic can cool and harden evenly and completely solidify.

5. Open the mold to take out the part

After the plastic is fully cooled, hardened and formed, the mold is opened, and we can take out the newly formed new part with the insert and plastic tightly combined.

6. Clean the gate residue

During the injection process, the channel for the plastic liquid to enter and exit the mold (called the gate or runner) will also be filled and hardened, forming excess plastic scraps attached to the part.These excess materials need to be removed, and the methods include manual trimming or machine cutting to restore the part to its proper shape.

7. Post-processing of the part

Sometimes, the parts that have just been taken out need some finishing work to be truly completed:

- Remove burrs:Some small flash or burrs of some plastics may affect the appearance and feel. JS usually cleans them with hand tools or simple equipment.

- Heat treatment: Internal stress may be generated inside the part during molding, which will affect the life of the part or even deform it. Proper heating treatment can relax the material. The heating temperature should be controlled well, generally a little higher than the temperature that the part will encounter when working later, or lower than the temperature at which the part itself will begin to soften.

- Surface treatment:JS provides various types of surface treatment. This step is mainly to make the parts not only better looking, but sometimes more durable. From painting to electroplating, the final choice of which method depends entirely on your requirements for the specific function and appearance of the finished product. The parts processed by plastic insert molding will also arrange this process according to your actual needs.

Insert molding design guide key points

(1) Insert design and placement

- Matching shape and size: The insert must match the shape of the plastic part, and there must be enough space around it for the plastic to flow in and completely wrap it, so that it can stick firmly.

- Surface treatment: It is better if the surface of the insert is slightly rough, so that the plastic can grab it more easily and stick more firmly. An overly smooth surface may cause shedding.

- Precise positioning and fixing: The insert must be placed in the right position in the mold to avoid it being displaced by the injection pressure. It can be firmly fixed with structures such as positioning pins and buckles.

- Dimensional tolerance control: The size of the insert must ensure strict dimensional tolerance. Too large tolerance will lead to final assembly difficulties or part deformation.

- Metal insert reinforcement: If the insert is metal (such as steel, aluminum, copper, stainless steel), you canconsider treating or coating its surfaceso that it can adhere more tightly to the plastic, thereby increasing the overall strength of the part.

(2) Material matching should be appropriate

1. Plastic and insert matching:

When choosing plastic,make sure it is compatible with the insert material you use. Otherwise, it will either not stick well, or the part will be easily deformed or cracked due to different degrees of thermal expansion and contraction.

2. Coefficient of thermal expansion (CTE) matching:

The difference in expansion and contraction between the insert and the plastic during heating or cooling is the core factor affecting the bonding quality, plastic part deformation and long-term reliability. According to the characteristics of different insert materials, the design focuses on different aspects:

| Type of embedded material | Characteristics of coefficient of thermal expansion (CTE) | The main impact on plastic parts | Key design strategies |

| Steel inserts | Low (10-13 x 10 ⁻⁶/°C) |

Limit the shrinkage of surrounding plastic during cooling.

|

Choose low shrinkage plastic. Carefully design the thickness distribution of plastic wrapping. |

| Aluminum inserts | Higher (20-24 x 10 ⁻⁶/°C) | After cooling, the shrinkage is significantly uneven. |

Extremely cautious design of the wall thickness transition zone, with locally added reinforcement bars.

|

| Copper alloy inserts | Moderately high (~17 x 10 ⁻⁶/°C) | High thermal conductivity affects local cooling rate. | Pay attention to the overall wall thickness design and pay special attention to the arrangement of cooling water channels around the embedded parts. |

|

Stainless steel inserts

|

Low (similar to steel, 10-18 x 10 ⁻⁶/°C) | Similar to the influence of steel inserts. | The design principles are the same as steel inserts. For high bonding strength requirements, it is recommended to add mechanical locking structures. |

3. Gate blade material:

The blade used to cut the plastic flow channel orgate in the mold(also called gate blade), its selection (commonly used steel, aluminum, brass, stainless steel) needs to comprehensively consider the key requirements of the component:

- Hardness/wear resistance: Ability to withstand plastic erosion and wear.

- Thermal conductivity: Affects local area temperature control.

- Economic efficiency: Balance between cost and service life.

Usually high-hardness steel (such as cemented carbide, high-speed steel) is used in areas requiring high wear resistance.

(3) Key to mold design

- Gate design and location: The location and type of the gate are very important. Choose a good place and method (such as side entry, tunnel entry or hot runner) so that the plastic can flow evenly around the insert to wrap it. In this way, the parts are evenly stressed and stronger.

- Mold exhaust design:When plastic rushes into the mold, it squeezes the air inside, and the mold must have a place for these gases to be effectively discharged. Insufficient exhaust will cause plastic parts to burn and insufficient filling. Proper exhaust grooves (usually 0.01-0.03mm deep) should be set in the gap between the inserts.

- Cooling system: The mold cools down quickly and the production efficiency is high. How to arrange the cooling pipes is critical, especially around the inserts, the temperature should be controlled evenly.

- Convenient to take out: The mold design should make it easy for people to put the inserts in and position them, and then eject the parts smoothly after molding. A special ejection mechanism needs to be designed.

- Mold strength: The mold wall cannot be too thin, and it must be able to withstand the high pressure and impact during injection molding. To ensure that the mold does not deform, production can be more stable.

(4) Tips for easy demoulding:

Plastics will shrink after cooling, and parts may get stuck in the mold and cannot come out. On the vertical surface of the part, design a little slope (usually ≥1°, minimum not less than 0.5°), so that demoulding will be much easier.This slope is the draft angle, which can reduce part damage and make production smoother.

Insert molding vs overmolding: What are the differences?

In the field of injection molding, overmolding vs insert molding is often mentioned, but there are obvious differences in their process principles and purposes:

1. Overmolding: Secondary injection molding to form a functional surface layer

This process is divided into two steps:

- Substrate molding: The first step is to use ordinary injection molding methods to manufacture basic plastic parts (substrate).

- Secondary molding: Treat this finished plastic part as an insert, put it into another mold, and inject another material into the surface of the substrate through a second injection molding and solidify it.

The core goal is to add a layer of specific material to the original substrate. This layer of material is usually used to:

- Improve the touch and grip of the product.

- Provide cushioning to protect the parts inside from bumps, vibrations or moisture.

- Insert molding injection (Insert Molding):Material encapsulation is completed in one injection.

When insert molding injection, first put a ready-made part into a specific position in the mold. Close the mold and inject liquid plastic directly into it. After the plastic cools, the ready-made part is firmly wrapped inside it, and it is done in one go. When the part is taken out of the mold, the two parts have been combined into a whole.

The benefits of doing this are very real:

| Advantage category | Specific explanation |

| Improve production efficiency | No need to produce and assemble in two stages, greatly increasing production speed. |

| Simplify multifunctional materials | Directly combining different materials (such as metal and plastic) into a structurally complex component in a single process. |

| Optimize components | The produced parts usually have more compact dimensions and lighter weight. |

| Combining material advantages | Integrating the mechanical strength of metal inserts with the lightweight and design flexibility of plastics. |

What equipment is needed for insert molding injection?

1.Injection molding machine:The core host is responsible for melting plastic particles and injecting them into the mold under high pressure.

2.Special mold:Key tool, whose interior must be designed with precise insert positioning devices (such as slots, pins) to ensure that the inserted metal parts, electronic parts and other inserts do not move during injection molding.

3.Insert processing equipment:

- Placing equipment: Choose manual placement, automatic robot grasping and placing, or conveyor belt feeding according to production.

- Preheating equipment: Such as ovens or heating plates, used for heating certain inserts before injection molding to improve the bonding effect.

4.Auxiliary equipment:

- Plastic dryer: Dry plastic particles to prevent moisture from causing product defects.

- Mold temperature controller: Precisely control mold temperature to ensure product quality and efficiency.

- Hot runner system:Heating pipes in the mold to optimize plastic flow and reduce waste.

- Pick-up equipment: Such as robots, automatically take out finished products to ensure safety and efficiency.

A complete set of insert molding solutions is to make the injection molding machine, special molds with precise positioning, insert processing equipment, and necessary auxiliary equipment such as dryers and mold temperature controllers work together. Only in this way can products with a strong combination of plastic and inserts be produced efficiently and stably.

Why use insert molding technology?

Insert molding technology is mainly used when some key small parts of metal or other materials need to be embedded in plastic parts. When you find that pure plastic is not competent for connection, conduction, or some places need special reinforcement, this is a good choice.

- The most common use is to create strong and durable connection points. We use plastic to make screw holes and the like, which may not be reliable if the screws are repeatedly screwed or subjected to large forces. Insert molding first puts the metal nut or threaded sleeve, and then wraps it with plastic, so that the screw hole is particularly durable.

- The second is to embed small functional parts. For example, a certain point on the plastic part needs to be conductive or heat-conductive. At this time,put the metal conductive column or heat sink into the mold, and the plastic will wrap it and clamp it during injection molding, which is much more reliable than glue bonding later.

- The third is to strengthen the key parts of plastic parts. For places with high stress, such as places where bearings are pressed, hinges that are often active, and points where the shell needs to be fixed, burying metal parts in advance and then plastic wrapping can greatly enhance the strength of this position, and the parts are not easy to crack or deform after a long time of use.

Which industries will frequently use insert molding?

1.Automotive parts:

Used in connectors, sensor shells, and instrument panel parts. The advantage is that the parts are more durable, the assembly steps are omitted, and the design is more compact.

2.Electronics and daily necessities:

Like electrical plugs, mobile phone cases, and remote control buttons. It can accurately integrate small parts, achieve stylish and compact designs, and enhance product functions.

3.Medical tools:

From tubes, nursing equipment parts, dental tools, to prostheses,surgical instruments, and medical equipment shells. It ensures high-precision and reliable medical device production.

4.Aerospace parts:

Used for aircraft seats, luggage locks, handles, control buttons, interior parts, etc. The advantage is that the parts are lighter, stronger, and more durable, while shortening production and assembly time.

5.Other fields:

This technology is also applicable to other industries that require strong composite parts. For example, RV insert molding, or various occasions where hard materials such as metals and ceramics need to be firmly wrapped in plastic to make powerful integrated parts.

Summary

Insert molding is a very practical injection molding method. It can cleverly combine the strong, thermal or electrical properties of materials with the light, easy to process and cheap characteristics of plastics.The parts designed in this way are easier to install, not only stronger and more durable overall, but also often save costs.

Whether you need to make strong screw holes on plastic parts, add heat sinks, set electrical contacts, or combine the feel of different materials, insert molding is worth careful consideration. It can help you simplify the structure and improve performance. If you want to use this technology well, the specific design is the key, which is exactly the expertise of our JS company as insert molding solutions inc.Welcome to communicate your needs at any time.

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

FAQs

1. How does insert molding work?

Pre-set metal or plastic parts in a mold, inject molten plastic to wrap the insert, and after cooling, the insert and plastic are solidified as one, achieving structural reinforcement and functional integration.

2. Is insert molding more expensive than secondary assembly?

Insert molding is usually cheaper in mass production because its one-step molding process eliminates the labor, equipment and time costs of secondary assembly, while improving structural stability and yield.

3. Are all plastics suitable for insert molding?

Not all plastics are suitable. Plastics with high heat deformation temperature, shrinkage matching the insert, and strong bonding (such as ABS, PC, nylon) should be selected to avoid cracking or debonding due to thermal stress.

4. Can insert molded parts be recycled?

Insert molded parts are difficult to recycle because metal/plastic need to be separated. The separation cost is high and the process is complicated. It is usually treated as industrial waste, but the pure plastic part may be crushed and reused.

Resource