I designed a part that requires a brass nut to be firmly embedded in a nylon shell. I carefully selected brass and nylon, and I felt that the materials themselves were fine. But did you know? If the mold material used to make it is wrong, the entire project may still fail.

This is why werely on the insert molding process to make complex and durable partson a daily basis. Simply put, it is to place the inserts of metal parts or other materials in advance, and then directly cover it with plastic during injection molding to form an inseparable whole.

The benefits of doing this: metal and plastic are truly integrated, which fundamentally avoids the risk of loosening or falling off of the insert. The parts are stronger, the size is more accurate, and the design space is larger. Especially for key places such as automotive core components or medical equipment, the reliability of this one-piece molding is a hard requirement.

The key to the success or failure of this process is the selection of the right material. A truly perfect insert molding part comes from the harmonious symbiosis of the three materials of insert, plastic and mold.

Quick Reference Table for Core Answers:

| Material category | Central role | Common choices |

| The Insert | Provide key functions such as strength, conductivity, threading, and sealing. | Brass, stainless steel, aluminum, ceramic. |

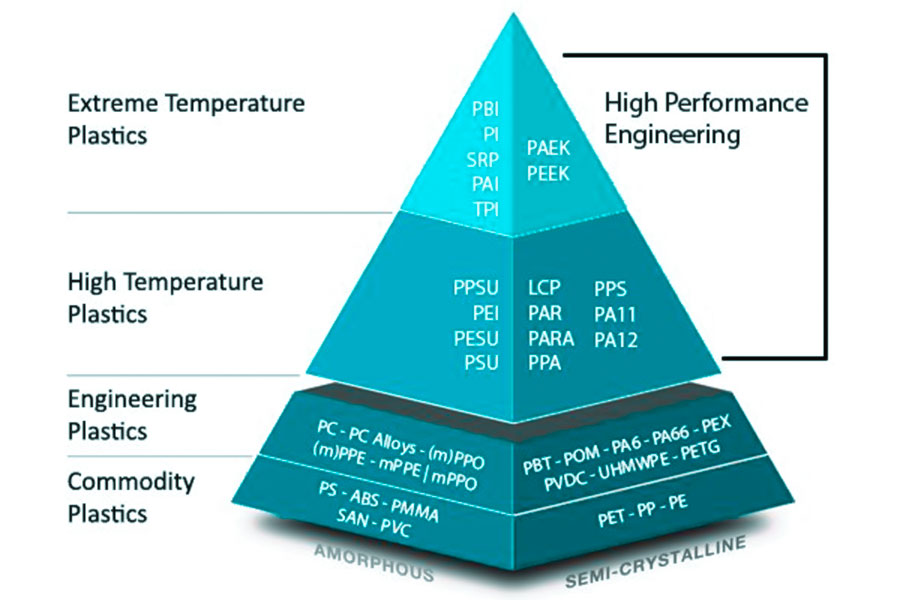

| The Plastic | Provide shape, insulation, lightweight, and appearance. | ABS, Nylon (PA), PC, PEEK (high-performance). |

| The Mold | Endure high temperature and high pressure during the injection molding process, accurately shape the final part shape. | P20 pre hardened steel, H13 quenched steel. |

In this article, we will focus on the selection of these three key materials:

- We will explore in depth, what exactly is an insert?

- Share practical suggestions for material selection for insert molding.

- And finally reveal a professional question: What materials are used to make the cavity and core of the mold cavity/core?

Why is This Guide Worth Your Reference? Commitment From JS Material Science and Mold Experts

At JS, we deal with materials every day, especiallythe three key musketeers in the insert molding process, inserts, plastics and mold steel.

- This is not just talk. We have personally experienced, for example, the difficult problem of finished product cracking due to the mismatch between the thermal expansion and contraction of the insert and plastic, which was finally solved by adjusting the material combination.

- We have also helped customers extend the life of insert injection molds by nearly one third by selecting specific high-strength mold steel.

We know how important the conductivity and easy processing of brass are, and we have also figured out how high-performance plastics likePEEK can adhere to stainless steel at high temperatures. More importantly, we understand how to decide whether to use the cost-effective P20 steel mold or the more durable but more expensive H13 steel mold based on whether the project is short-term proofing or long-term mass production. These decisions directly affect the final quality of the part and your production cost.

"These practical experiences are not empty words. As the predecessors in the industry often say: the mold is the silent partner of the injection molding process. If you choose it wrong, even the best design may fall short."

This guide is summarized based on these real project experiences. We hope to help you avoid the pitfalls we have stepped on and make more reliable choices.

Part 1: Insert Material - The Functional Core of The Part

The insert is the core part that is pre-placed when we perform plastic insert molding.It determines the most critical function of the final part, is it conductive, force-bearing, or sealing? What insert to choose depends on what function you want the part to achieve in the end.

Metal inserts: the main force of processing materials

- Brass: This is the one we use most frequently. It has good conductivity, is not easy to rust, is easy to process (easy to turn and drill), and can match various plastics. So for contacts thatneed to be conductive, or threaded inserts such as nuts and studs, choosing brass is basically a good choice.

- Stainless steel: When parts need to resist force and strong corrosion, or need to directly contact the human body, or even deal with harsh outdoor environments (such as key components in RV insert molding solutions), stainless steel is our first choice. It is hard enough, durable enough, and clean enough.

- Aluminum: If the part needs to be light and the heat needs to be dissipated quickly, aluminum is very suitable. Because of its light weight, it also conducts heat quickly, but of course it is weaker than steel in strength.

- Carbon steel: The hardest and most inexpensive. But there is a flaw: it loves to rust. So when used,it must be equipped with electroplating or coating protection prior to further processing.

Non-metallic inserts: experts at dealing with unique issues

- Ceramics: Use where insulation is required, no electricity can leak, or is particularly wear-resistant. For instance, somehigh-precision electronic parts or wear-resistant seals.

- Other plastics/polymers: We sometimes have to create plastic with plastic wrapping. For instance, initially create a rigid plastic component, and then cover it with a soft glue layer (such as the anti-slip handle layer), then the inner hard plastic component becomes an insert. It is quite common for two-color injection molding or soft and hard glue combination.

- Circuit boards (PCBs): It is too broad in the electronics field. It is to directly use the entire circuit board as an insert, place it into the mold, and encapsulate it with plastic to create the shell. It can be done in one step, simple and reliable.

To be honest, the core small parts in the mold can't just be made by feeling. From the data of my project, brass is the most used, accounting for 60% to 70%, which is the most commonly used.In the medical industry or in particularly demanding environments, stainless steel becomes the protagonist, accounting for about 20%. As for aluminum and ceramics, although they are used less, they are used in places where parts need to be particularly light or insulated.

"If you happen to have this kind of insert molding project, let's look at the drawings together and discuss what the core problem of this part is to solve, so that we can decide which material is most suitable. At JS, our team thinks about the matching and application of these materials every day."

Part 2: Plastic Materials - Part Shape and Protective Layer

The encapsulating plastic (encapsulating resin) surrounding the insert has a dual role to play:it must be able to pass the injection molding process's high temperature and high pressure test,and it must also contribute towards making the part strong, durable, and ultimately perform as needed. We JS engineers use these materials every day. The key to choosing the right plastic is to keep in mind the insert matching, part function, and cost control.

The key engineering plastics that find application in everyday life are as follows:

- ABS: Its overall strength is quite good! It has good impact resistance, andthe surface of products produced by it looks fine. Most importantly, the price is relatively low and it is particularly worry-free. So we'd like to apply it in the manufacturing process of consumer electronic casings, tool handles, etc. And it also performs quite well with metal inserts such as brass.

- Nylon (PA): The most notable property is that it is wear-resistant, strong, and also resistant to corrosion by various chemicals. It is extremely tough and less likely to crack or break easily.It is extremely suitable for manufacturing gears, bearings, or certain structural partsthat must endure force. Nylon materials constitute a substantial portion, close to 30%, in our insert-making business.

- Polycarbonate (PC): The "champion" of clear plastics! Transparency, strength, and toughness are high. It is therefore the best material for viewing windows or protective housings that require transparency in addition to high strength. It is, on the other hand, quite demanding when it comes to surface treatment of the insert and the entire injection molding process, requiring special attention.

| Plastic type | Global market share | Heat distortion temperature |

| ABS | 25% | 90°C |

| Nylon (PA) | 30% | 80°C |

| Polycarbonate (PC) | 20% | 130°C |

| PEEK | <5% | 260°C |

| Ultem (PEI) | 8% | 200°C |

| TPE/TPU | 12% | 90°C |

Note: Data is integrated from international industry reports, and market share reflects the global market share of insert molding plastics in 2022-2023. Heat deformation temperature is a typical value based on ISO 75 standard.

High-performance engineering plastics

- PEEK: It can withstand high temperatures of around 300 degrees, chemicals don't affect it, and its mechanical properties are very high. Despite the cost being quite high,it cannot be substituted in fields like aerospace and medical implants.

- Ultem (PEI): Has relatively comparable performance to PEEK, heat-resistant and dimensionally stable, processable a bit more easily, and the cost is a bit lower. They are widely used in medical sterilization parts and electronic connectors operating at high temperatures.

Elastomer materials (TPE/TPU):

Thermoplastic elastomers (TPE/TPU): This compound provides soft touch and elasticity, and is generally utilized in products such as seals and handles.While more common in overmolding, it can also produce excellent surface coating effects in insert molding.

"In insert molding injection, nylon and polycarbonate account for 70% of our applications (nylon accounts for 30%), both of which provide toughness, wear resistance and transparency. Although PEEK/Ultem accounts for less than 5%, it is the savior of extreme environments such as aerospace and medical. The key to success lies in the adhesion between the plastic and the insert interface. If you need customized parts, please contact the JS team to inform the temperature resistance, strength and budget requirements. We will use our practical experience to select the best material for your insert."

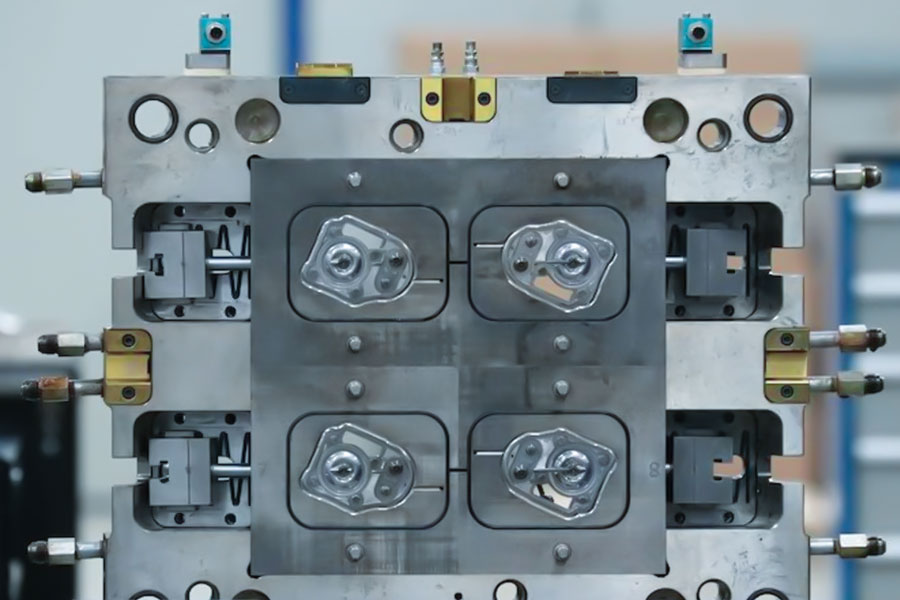

Part 3: Mold Materials - The Foundation of Molding Everything

You asked what materials are usually used for cavities and core inserts. This is a really good question! Because the material you choose is directly related to how long the mold can be used, the production cost, and the quality of the final product. In the end, the material you choose still depends on the specific needs of the project at hand:

Pre-hardened steel: a reliable and economical choice

Representative grade: P20 (such as 1.2738 / P20+Ni).

Why is it the main force?

This is our most commonly used material, especially in medium-volume projects with an estimated production of 50,000 to 500,000 molds. The advantage of P20 is that it has achieved a very good balance between strength, processing performance (easy cutting) and cost.

It has the required hardness (about HRC 30-36) when it leaves the factory, eliminating the subsequent heat treatment process, greatly shortening the mold manufacturing cycle and reducing costs.

For the molding of most general plastics (such as PP, ABS, PS, PE, etc.), P20's wear resistance and toughness are fully sufficient. It can be said that it is the default option when we design standard molds.

Hardened steel: Ultimate durability

Representative grades: H13 (hot work die steel, such as 1.2344), S136 / 420 stainless steel (such as 1.2083 / Stavax)

Why do you need it?

When the project requires a mold life of more than 1 million molds, or the plastic used is highly abrasive, orthe product has extremely high surface gloss requirementsor needs to be used in a corrosive environment, pre-hardened steel P20 is not very suitable.

- H13: After quenching + tempering, the hardness can reach HRC 48-52, and the wear resistance and high impact resistance are extremely excellent. It is the first choice for highly abrasive plastics and mass production. But it is more difficult to process and the cost is higher.

- S136 / 420 stainless steel: In addition to hardness and wear resistance, its biggest advantage is rust resistance. When making molds for medical devices or when the production environment is humid, ordinary steel is prone to rust and affects the surface quality of the product. S136 perfectly solves this problem. Of course, the cost and processing difficulty are also correspondingly higher.

Aluminum alloy: a fast response and prototype tool

Representative grade: 7075-T651 (aerospace aluminum)

The biggest advantage of aluminum alloy is its extremely fast processing speed, which can significantly shorten the mold manufacturing cycle (sometimes by more than 70%), and the cost is much lower than steel. High-strength aluminum alloys such as7075-T651 are sufficient to meet the needs of small-scaletrial production or prototype verification.

Where is it used?

For proofing (prototype verification) or small-scale production (usually less than 10,000 molds). If you are in a hurry to see the real thing, or only need a few thousand parts, using aluminum molds is the fastest and most cost-effective. But! It is not wear-resistant and has a short life. For slightly abrasive plastics or slightly higher production requirements, the dimensional accuracy and surface quality are reduced.

"In insert molding molds, the cavity and core inserts are the core components that withstand high pressure and high temperature, and special mold steels such as H13 (hot work steel) or P20 (pre-hardened steel) must be used. If you are not sure which material is the most suitable, feel free to talk to us. As a professional insert molding solutions inc, we will help you choose the most reliable and cost-effective solution to minimize the risk!"

FAQ - Answer All Your Questions About Material Selection

Question 1: Insert Molding vs. Overmolding: What is the difference in material selection?

The core difference is the different things being covered.

- Insert molding: The part that is inserted, we call it an insert, usually a metal or ceramic part. At this time, what we are most worried about is that when the part undergoes hot and cold changes, the metal/ceramic insert and the plastic injected later have very different degrees of thermal expansion and contraction. If the design is not good, the joint may loosen or crack. Therefore, when designing the insert, you need to use a barb, hole or groove structure so that the subsequent plastic can really hold it.

- Overmolding: It can also be called secondary injection molding. Here, the biggest difference between overmolding and insert molding is that the object being covered is usually another pre-made plastic part (substrate). At this time, the most critical thing is to choose the materials to see if the two plastics match. Can they stick together? Will they separate? Will they weaken each other over time? These must be evaluated. For example, in a soft rubber handle, the hard plastic inside is often ABS or PC, and the outer coating will choose materials such as TPE or TPU that are firmly bonded.

Question 2: How should I choose materials for my insert molding project?

Now, let me answer you the key to material selection for insert molding, which is the basis in our insert molding design guide:

- First, we have to figure out what the role of the insert is? Is it to transmit electricity, bear force, be used as a screw hole, or something else. This directly determines whether you choose metals such as copper, steel, stainless steel, or other special inserts.

- Then, the operating environment of the part is very important. Will it be exposed to chemicals, continuous high temperatures, or require medical-grade biocompatibility? These conditions will limit the choice of plastics and inserts, such as chemical-resistant PPS or medical-grade PEEK.

- Never ignore the output. This determines the investment in mold steel. It is more cost-effective to use H13 steel for high-volume and high-precision projects, and it is more practical to use P20 steel for small-scale trial production.

Question 3: What material is used in molding?

The term "molding material" is a bit unclear. The key depends on what you specifically mean:

- If you are asking about the final molded plastic part itself: there are many choices. It can be said that there are dozens or hundreds of common plastics that may be used. The specific choice depends on the purpose of the product, the required strength, heat resistance, appearance requirements, etc. ABS, PP, PC are all very commonly used types.

- But if you are asking about the mold itself used to make plastic parts: the material is completely different. We mainly use very hard and wear-resistant high-strength steel (such as heat-treated mold steel such as P20 and H13) to make molds, so that they can withstand the high pressure, high temperature and repeated wear of the injection molding process.

Summary

For insert molding, I know one key: if you want to do it well, the right material is the foundation! This is not as simple as understanding the requirements of the parts. The key is that you have to fully predict: what kind of interaction will occur between plastic, insert, and mold? Only bychoosing the right material combinationcan your design be successfully turned into a stable and reliable product. This step of decision-making is really important.

Don't hesitate, take action!

Are you still worried about how to firmly combine metal and plastic, but are afraid of assembly troubles? Don't let complex material selection hold back the project!

JS team does this!We are very experienced in material properties and mold design, and specialize in solving such problems.

Just throw your design drawings, ideas or samples over!Contact us to talk about the challenges you encounter.

We promise: After receiving your information, I will carefully evaluate your needs and tailor a material plan and complete insert molding solutions for you within 1-3 working days.

Ensure that your project has a clear direction from the beginning to avoid later risks. Let’s talk now and let us help you land your project smoothly!

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com