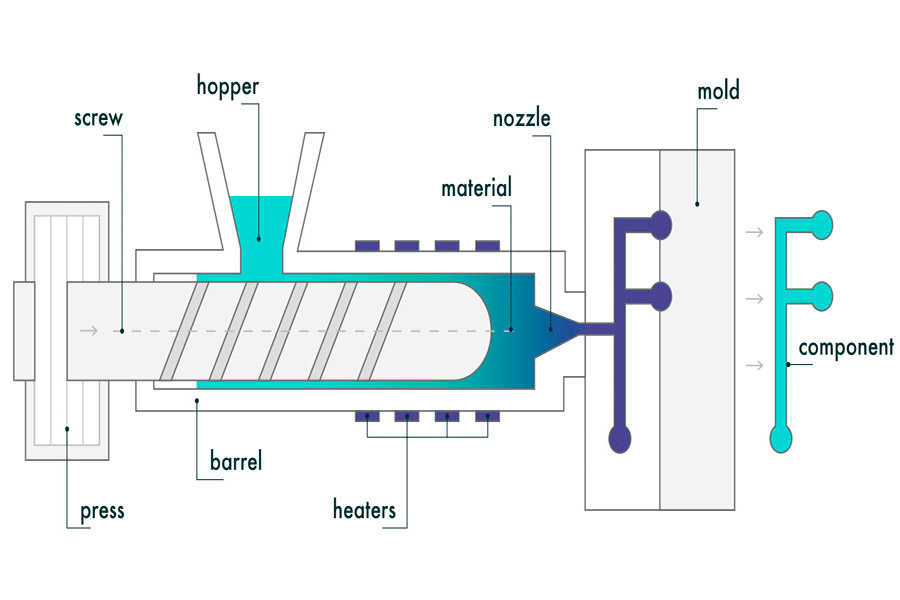

Plastic injection moldingis one of the most basic and commonly used processes for manufacturing plastic products. It heats and melts the plastic raw materials in the injection molding machine to make it flowable. Then, under high pressure, the molten plastic is injected into a specific shape space in a tightly closed steel mold through the nozzle of the machine at high speed. After the plastic fills the cavity, it solidifies with the help of the cooling system inside the mold. Finally, when the mold is opened, a plastic part with the exact shape of the cavity can be obtained.

The power of this process lies in its ability to efficiently and accurately shape extremely complex geometric shapes. Many of these shapes are either costly, inefficient, or simply impossible to achieve using other manufacturing methods.

So, before you evaluate whetheryour project is suitable for plastic injection molding service, it will be helpful to understand the following key points.

What is plastic injection molding?

Plastic injection molding is the core method for manufacturing a variety of customized plastic parts, whether it is daily necessities or high-end industrial products.

Theplastic injection molding processfirst heats and melts small plastic particles, and then forces them into the cavity of a metal mold. After the plastic is cooled and hardened inside and has been shaped, open the mold, take out the molded parts, and they are basically ready for use.

Its biggest advantage is that it is particularly suitable for mass production. First, there is less material waste, and second, the cost of each part can be kept very low. Because of this, industries such as medical devices, daily consumer goods, and automotive parts are particularly fond of using it.

JS is an industry-leading plastic injection molding company. If you need plastic injection molding services, we can do it here. Whether it is proofing and prototyping, or the final parts of formal production, we can handle it. The parts can be delivered to you in as fast as 1 day.

How does plastic injection molding make products step by step?

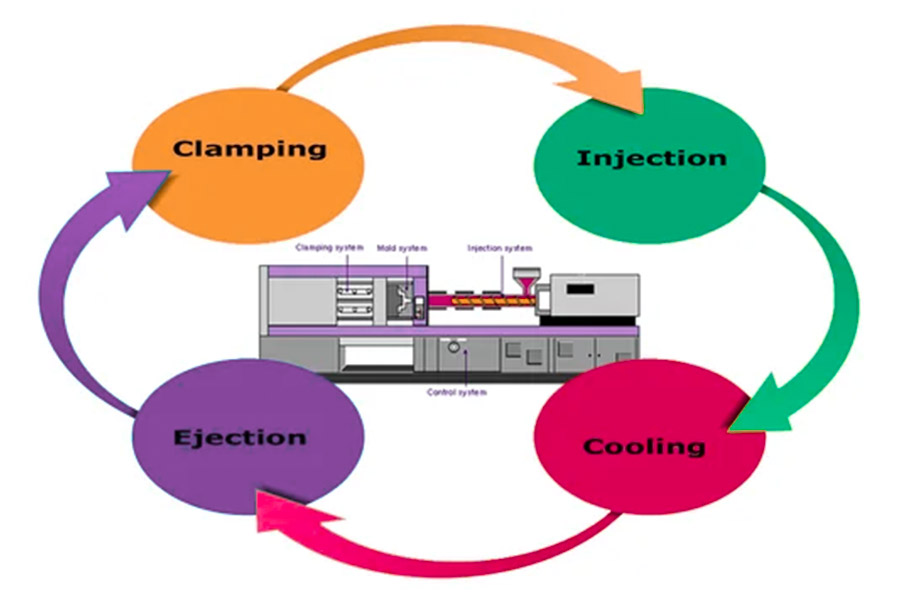

1. Mold closing

The first step of plastic injection molding jobs is to close the mold tightly. There are usually two halves of the mold in the injection molding machine. This step is to move the lower half of the mold forward and fit it tightly with the upper half of the mold.

When the two halves of the mold are completely closed, the raised and recessed parts inside them (professionally called cores and cavities) will leave a space in the middle. The shape of this space is the shape of the plastic product we want to make in the end.

At this time, the injection molding machine uses a lot of force to lock the mold tightly. Ensure that the upper and lower molds can always stick together in the subsequent steps, even in the face of strong injection pressure. This step is particularly critical to whether a good product can be made later.

2. Injection/filling

After the mold is firmly locked, the next step is toinject the molten plastic into the mold cavity.

Plastic pellets fall from the hopper into the heated barrel. The rotating screw in the barrel transports the pellets forward, while using external heating and its own friction to melt them into a fluid called melt.

The molten plastic is pushed to the front end of the screw and gathered. After reaching the preset injection volume, the screw stops.

The critical injection stage follows: The hydraulic system strongly pushes the screw forward at high speed, injecting the molten plastic through the nozzle and into the mold at high pressure. The plastic flows through the mold's runner system (including the main runner and the branch runner) and eventually fills the cavity formed by the closed mold.

The core goal of this step is to quickly, evenly and completely fill the entire cavity under high pressure. Only in this way can all the details of the mold be accurately replicated toensure the accuracy of the product shape and size.

3. Holding pressure

Afterthe plastic melt quickly fills the mold cavity under high pressure, the work is not done. At this time, the machine will not unload the force immediately, but continue to maintain a certain injection pressure. We call this stage holding pressure.

When the plastic cools from a hot liquid to a solid, the volume will naturally shrink (just like thermal expansion and contraction). If the pressure is not continued, the plastic that is cooling and solidifying will shrink and form a cavity inside the product or make the size smaller and the shape distorted.

At this time, continue to support the plastic from the back so that more molten plastic can be added to the cavity to make up for the part of the volume that is vacated due to cooling and shrinkage. Make the final product full, dense, and accurate in size.

Common plastic holding pressure classification references are as follows:

| Pressure holding range (MPa) | Difficulty of operation |

| 80 - 100 | Ideal |

| 100 - 120 | More difficult |

| >120 - 150 | very high |

If it exceeds 120-150 MPa, the requirements for machines, molds and process control will be very high.

4. Cooling and solidification

After the molten plastic fills the mold cavity, the mold needs to be kept closed to allow the plastic to cool and solidify, changing from liquid to solid. This process is accompanied by the natural shrinkage of the plastic.

Mold temperature control is the key:

- Mold temperature directly affects product quality(such as deformation, surface, and size).

- Usually, the mold is heated by hot oil circulation, or quickly cooled by cold water circulation.

- A few precision products require alternating heating/cooling in the same cycle and precise temperature control.

Cooling time is critical:

Plastics must be cooled in the mold for a sufficient time before they can completely harden and set. If the period is too brief, the product can easily be deformed and the size is unstable. If the period is too long, it will create inefficiency. It is necessary to find the right time point to allow the product to be completely set and the size is the most stable.

After the plastic parts are fully cooled and solidified and hard enough, you can proceed to the next step.

5. Mold opening and ejection of parts

The next step is to open the mold and take out the molded plastic product.

Unlike the initial mold closing process, the bottom mold will return and release from the top mold. Conveniently, a piece called an ejector within the mold shall push the newly molded and cooled product away from the lower mold.

These ejectors are particularly important, especially when making products with complex shapes or thick walls that are not easy to demold. Without the ejector, some products may be stuck in the mold, and it is almost impossible to take them out intact.

Another key issue is to ensure that the product will not stick to the top mold. Because the top mold normally does not equip with an ejector device. Therefore,designing a good ejector systemso that the product can fall smoothly every time is particularly important for the smoothness of the entire production process and product quality.

What factors should be considered when designing plastic injection molding molds?

1. Uniform wall thickness

This is the top priority! Uneven thickness will lead to different cooling speeds of parts. The thin parts will harden first and the thick parts will harden later. It is easy to shrink, deform, and even produce internal stress cracking.

2. Handle the raised parts

Where the roots of these places connect to the main wall, a rounded transition must be made. But the key fact is: this rounded corner must not thicken the root! The root gets thickened, the cooling is retarded, and it is easy to shrink and form pits.When designing, the root rounded corners should be naturally transitionedwithout increasing the local thickness.

3. Make good use of ribs

Insert ribs in thin areas or weak points of the part. The size of the rib must be held to a minimum (typically 50%-60% of critical wall thickness), and roots must be filleted also, and these must be given a light demoulding taper, otherwise they will get scratched or even jam on ejection.

4. Choice of gate position

The gate is the door for the plastic melt to enter the cavity, and it is very important where to put it! If the gate is opened on a prominent outer surface,it will leave an ugly gate mark. Try to hide it in an inconspicuous place (such as the inner side, under the rib, and the place covered after assembly).

Second, gate position will affect the flow direction of the plastic. Steer clear of having the weld line in a location of high stress or high prominence and making it capable of flowing the entire cavity smoothly.

5. Choose a suitable parting surface

The more intricate the structure of the mold, the larger the precision requirements, and the higher the quality material used, the lower the cost of the mold itself.

When selecting the parting surface, consider: How can the part be demolded in the simplest way possible? Where to locate the parting line so that its effect on appearance will be reduced?Multi-sided parts may have more than one parting surface.

6. Cost considerations

The more complex the mold structure, the higher the precision requirements, and the better the material used, the more expensive the mold itself will be.

When designing, try to make the mold structure simple, reliable, easy to process, and easy to maintain, while meeting the product requirements. If it can be achieved with a simple structure, don't make it too complicated.

What are theplastic injection moldingmachine types?

In a plastic injection molding factory, choosing the right machine is the first step. Nowadays, there are three mainstream machine types: hydraulic, electric and hybrid, and each of them has its own characteristics.

1. Hydraulic injection molding machine

This type of machine is the oldest.It was the only choice until the Japanese companyinventedthe first electric machine in the 1980s. The advantages of hydraulic presses are very real:

- Low price: It is the cheapest to buy and suitable for factories with tight budgets.

- Parts saving: In case the parts are broken or need to be replaced after years of use, the accessories are not only cheaper, but also easier to buy.

- Durable: Its hydraulic parts are strong and wear-resistant, with a long service life, usually up to ten years.

- Powerful: It can provide extremely high clamping force, which is very suitable for products with large molding size or high clamping force requirements.

2. Electric injection molding machine

After its birth in the 1980s, electric injection molding machines quickly became popular. The advantages are in front of us:

- High energy efficiency: The motor only works when executing the action, and it does as much work as it uses electricity, unlike the hydraulic press that keeps the pump running all day and wastes electricity.

- Easy maintenance: The biggest advantage is that hydraulic oil is not used! There is no risk of oil leakage, and there is no need to change oil and filter frequently, which reduces the cost of consumables and maintenance workload.

- Fast speed and high precision: All actions are driven by servo motors, with digital control, extremely high repetition accuracy, and the molding cycle is usually shorter, and basically no human supervision is required.

- Clean and environmentally friendly: The feature of no oil is too critical! It is especially suitable for fields with high requirements for the cleanliness of the production environment,such as the production of medical parts, and it is particularly safe to use it in a clean room.

3. Hybrid injection molding machine

Many people think that the mixer absorbs the strengths of hydraulic and electric, mainly to complement each other. This is indeed the case:

- Combination of strengths: Combining the power saving and precision of the motor with the advantages of the hydraulic press to provide a large clamping force.

- High-efficiency hydraulic system: The old fixed-speed oil pump motor is replaced with an adjustable-speed variable-frequency motor. The oil pump only works when needed, greatly improving the energy utilization rate of the hydraulic system.

- Easier maintenance: The possibility of downtime is less than that of pure hydraulic or pure electric, and maintenance is easier.

- Outstanding cost-effectiveness: It is cheaper than full electric and more expensive than full hydraulic. It is an economical and practical choice,especially for medical device manufacturerswho pay attention to cost-effectiveness.

Comparison of three types of injection molding machines:

| Characteristic | Hydraulic injection molding machine | Electric injection molding machine | Hybrid injection molding machine |

| Price level | ★★★ (Low) | ★ (High) | ★★ (Middle) |

| Power consumption level | ★ (High) | ★★★ (Low) | ★★ (Middle) |

| Maintenance difficulty /consumables cost | ★ (Need to change oil/filter element) | ★★★ (Very little maintenance) | ★★ (Moderate) |

| Operating speed and accuracy | ★★ (acceptable) | ★★★ (High) | ★★★ (High) |

| Cleanliness level | ★ (Attention should be paid to oil stains) | ★★★ (No oil pollution) | ★★ (Less oil pollution) |

| Locking force strength | ★★★ (Strong) | ★★ (Medium) | ★★★ (Strong) |

| Typical application | Limited budget, large items, and average cleanliness requirements. | High precision components, medical clean environment, pursuit of efficiency and precision. | Balancing electricity cost savings with strong capabilities and high cost-effectiveness requirements. |

Therefore, when choosing processing equipment, plastic injection molding companies need to comprehensively consider the specific needs and conditions of production, not just the price of the machine.

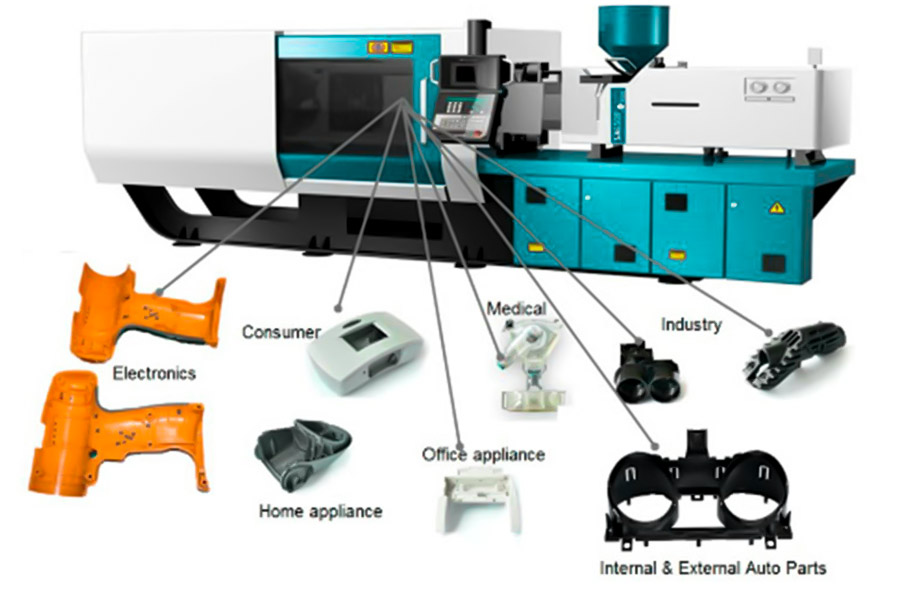

What are the key applications of plastic injection molding?

1. Medical industry

The medical field has extremely high requirements for product quality, which is directly related to patient safety. Plastic injection molding is widely used here, such as various medical equipment, disposable consumables commonly used in hospitals, many key components and eventhe entire product are completed by injection molding.

Plastic is particularly suitable for medical environments. First, it has good tolerance to various strong disinfectants commonly used in hospitals and can withstand repeated and strict disinfection procedures. Second, the surface of some special plastics is extremely dense and has no small holes, which is not easy to hide and breed bacteria, which helps to control the spread of germs in the hospital environment.

2. Electronics industry

The most common is to make shells for various devices, such as mobile phones, TV remote controls, and car key shells, which are basically tailor-made by injection molding machines. Plastics are suitable for electronic products because they can withstand some harsh environments, such as high temperature or chemical corrosion. Moreover, when making the shell, holes need to be opened on it to install buttons, switches, etc. Injection molding can be done directly in one step, which is very convenient.

3. Automobile industry

Many plastic parts on cars are produced by it. For example, the bumpers, pedals, wiper covers on the outside, as well as the dashboard, buttons, switches, cup holders inside, many of which are made of plastic injection molding.

Automotive companies often use plastic injection molding process, which makes things fast, accurate and strong. For large-scale production of cars, automotive plastic injection molding can ensure that parts with exactly the same specifications are repeatedly made, which is particularly important. Secondly, plastic is much lighter than metal, which can make the car lighter but also very durable, so that the car is more fuel-efficient.

4. Aerospace industry

Plastic injection molding is also used in many places on airplanes and rockets. Its biggest advantage is lightness! Andit can make parts with complex shapes, and can also meet places with high precision requirements. For example, the blades of jet engines, buttons in the cockpit, joystick parts, etc.

In this safety-conscious industry, injection molding can ensure that every part meets strict safety standards and is very consistent.

Summary

The core of the entire cycle of plastic injection molding lies in the four key stages of change that the plastic undergoes inside the mold: heating and melting, injection, pressure holding, and cooling and shaping. The entire process relies on the close cooperation of highly automated injection molding machines and well-made molds.

To master this efficient technology, three elements need to be precisely controlled at the same time: temperature, pressure, and time. This is the core advantage ofJS in providing high-quality custom plastic injection molding services. If you need to know more about plastic injection molding services, please contact us and we will respond to you quickly!

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

FAQs

1. What are the core components of the injection molding machine?

Barrel and screw, clamping cylinder and template, ejector mechanism, hydraulic/electric system, and control system.

2. What is the role of pressure in molding?

Pressure drives the plastic melt to quickly fill the mold, maintain pressure to prevent shrinkage, and ensure that the clamping is tight and does not overflow, which directly determines the product dimensional accuracy and appearance quality.

3. Why is clamping force so important?

The clamping force must be greater than the injection pressure to hold the mold tightly. Otherwise, when the molten plastic is pushed in with high pressure, the mold will be stretched open, and the plastic will be squeezed out to form flash, or even damage the equipment.

4. What are the main advantages of plastic injection molding?

Plastic injection molding can produce complex parts quickly and in large quantities, with high precision and excellent consistency, a wide range of material choices and highly automated processes, which is very suitable for cost-saving large-scale manufacturing.