Think about the very sturdy screwdriver in your hand. Why are its metal rod and plastic handle so solid as if they were born together? No glue or screws are needed?The key is the insert molding injection technology we use every day.

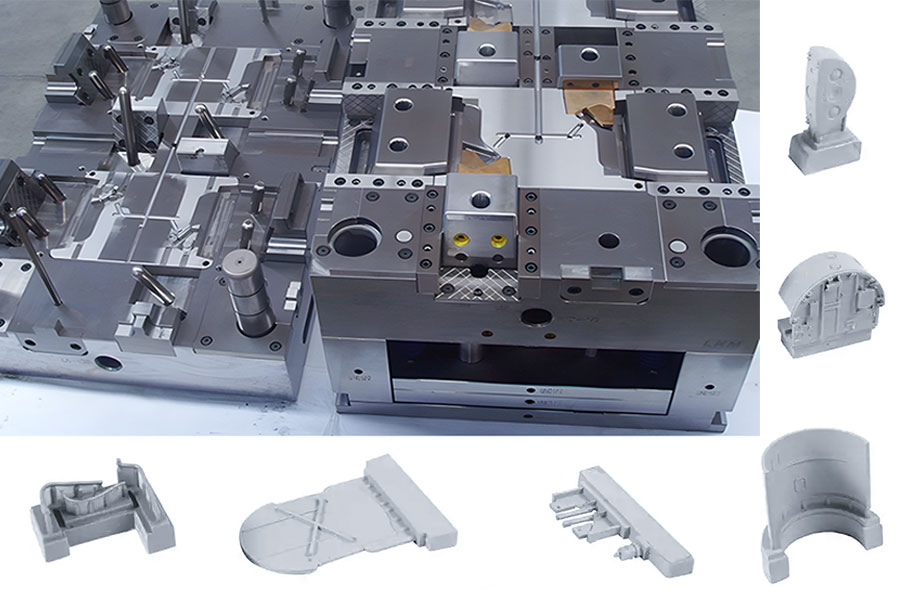

Simply put, it is to put the finished metal parts (or other inserts) into the mold accurately. Then, like ordinary injection molding, inject the molten plastic into it. The plastic will tightly wrap the insert during the cooling process, and finally form a strong and light integral part.

We often use this technology because it really solves the problem: making the parts more durable (especially the stress-bearing parts), completely saving the trouble of assembling screws later, and effectively controlling costs. Plastic shells that require metal threads, durable handles, and precision instrument parts are all typical application scenarios of insert molding.

If you also want to make plastic parts stronger, perfectly integrate metal and plastic, or simplify the process to reduce costs,insert molding is definitely worth considering.

Core Summary of Key Answers:

| Aspect | Describe | Value to you |

| Core Definition | The process of placing a pre manufactured part (insert) into a mold and then injecting plastic to wrap it up. | Create integrated parts that are high-strength, multifunctional, and do not require secondary assembly. |

| Key steps | Place the insert ->close the mold ->inject plastic ->cool and remove. | Perfectly combining the strength of metal with the lightweight and design freedom of plastic. |

| Common inserts | Nuts, screws, bushings, contacts, circuit boards, surgical blades. | Any prefabricated component that needs to be wrapped in plastic to increase functionality or strength. |

| Application Fields | Automotive, medical, electronics, aerospace, consumer goods. | Greatly reducing assembly time and cost, and improving product reliability. |

Next, I will explain in detail:

- Astep-by-step descriptionof the insert molding process.

- A simple step-by-step guide to explain how it works

- An explanation of insert molding vs. overmolding.

- Practical tips for becoming a design expert.

Why is This Guide Reliable? Practical Expertise of JS Insert Molding Professionals

At JS, insert molding is more than just turning on the machine. It is the key technology that helps our customers solve the core challenge of "how to make parts stronger and more reliable."

- I have personally practiced it: I have embedded stainless steel sensors intohigh-performance PEEK special engineering plastic housings for aviation customers.I have also encapsulated dozens of brass terminals in connector bodies at one time for electronics companies.

- This is all real experience: We know how to design the mold so that the molten plastic will not distort or damage the metal insert inside. We also mastered the key technology of insert preheating to reduce the stress inside the finished product.

This guide is a collection of our valuable experience inproviding reliable insert molding solutionsto turn thousands of discrete parts into strong and reliable integrated components.

"As James Hendry, an authority in the field of injection molding, said: Excellent injection molding is 30% in equipment and 70% in process wisdom. Our experience is the embodiment of this process wisdom."

How Does The Insert Molding Process Work? - Four-Step Explanation

Imagine putting a blueberry in an ice tray and then pouring water into it to freeze it into ice cubes. The insert molding we do is very similar to this. The difference is that the ice tray is replaced by a metal mold, the blueberry is replaced by the metal part (insert) that needs to be wrapped, and the water poured in is the plastic we are going to mold.

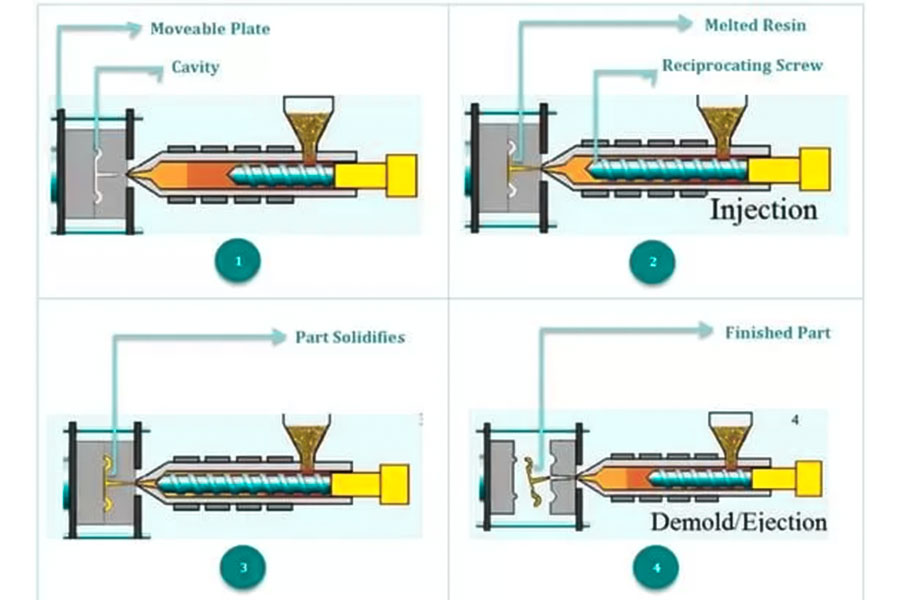

It isbasicallythe process ofcombiningthe prefabricatedcomponentsof metal or other materials with plasticintheprocess ofplastic insert molding.The four main steps are described below:

Step 1: Accurate positioning of the insert

- We want to make a plastic knob with metal threads. The first step is to prepare the small metal part (such as a brass nut, which is the insert).

- At this time,the mold of the injection molding machine is open and divided into two halves. My task is to place the insert into the designated position in the mold, either by skilled workers or by using a flexible robotic arm.

- The mold is designed with precise positioning structures (such as pins, slots or vacuum adsorption) to prevent the insert from being distorted during the subsequent high-pressure injection process. The accuracy of this step directly determines the quality and function of the final product, so it is particularly critical.

Step 2: Mold Closing

- After the insert is in place, the injection molding machine is started. The fixed mold half and movable mold half will close extremely accurately and forcefully.

- The purpose of this stepis to firmly lock theinsert in the predetermined cavity and form a closed, complete cavity space to be filled. The mold is closed tightly to ensure that the plastic injected with high pressure later will not leak out.

Step 3: Plastic Injection

- The highlight is here!Plastic raw materials(such as nylon, ABS or engineering plastic particles) are heated in the barrel of the injection molding machine and become a molten state like sticky syrup.

- Next, the screw or plunger of the injection molding machine will applyimmensepressure topush molten plastic into the tightly closed mold cavity.

- The plastic melt quickly fills all the gaps in the cavity, and flows tightly and wraps around the insert to achieve physical bonding. The control of this pressure and temperature is a big deal, which directly affects the wrapping effect and part strength.

Step 4: Cooling and Ejection

- After the hot plastic is injected within, it cannot be opened at once.Upon completion of injection, the cooling mechanism within the mold starts working, and the plastic material within solidifies very quickly by cooling down.

- The process of plastic cooling and hardening is also the process of it and the small copper nut really tightly combined and becoming one. When the temperature drops to the right level and the plastic is hard enough, the mold will open again.

- At this time, the built-in ejector in the mold will move to smoothly push the new part that has been fully solidified and integrated with the insert out of the mold. An insert part is born!

"Theinsert molding processcan achieve a pass rate of over 95% for insert wrapping, reducing costs by 30% compared to traditional assembly. JS's multi-level positioning system (error ±0.003mm) and closed-loop temperature control technology (±1℃) have served 400+ industrial customers, with a yield rate of 99.2%. Submit your part drawings now, get free samples and technical solutions, and let us work together to transform your design ideas into durable products."

Main Comparison: Overmolding vs Insert Molding

In my daily work, I am often asked what the difference is between insert molding and secondary injection molding? To be honest, these two words are actually quite different and are indeed easy to confuse. They both involve wrapping an object with a layer of plastic,but the most fundamental difference lies in what the "wrapped object" itself is.

Help you distinguish at a glance: see this table for the core differences:

| Key features | Insert Molding | Overmolding |

| Basic component material | Usually non plastic (metal, ceramic, electronic components, etc.). | Usually it is a pre formed plastic part. |

| Technological process | Single injection molding completed (insert pre placed in the mold). | Two independent injection molding processes are required (first make the base part, and then wrap it). |

| Main goal | Enhance functionality and structural strength. | Improve human-computer interaction, sealing or aesthetic effects. |

| Typical product examples | Knob with metal shaft, plastic encapsulated electronic module, enhanced handle. | Soft rubber handle toothbrush, dual color buttons, lid with sealing ring. |

1. Insert molding:

The base part here, whichwe usually call an insert, is not a plastic part itself.It may be metal (screws, shaft cores, circuit board connectors), ceramic, or other pre-made non-plastic parts.

How to do it specifically?

The operation is quite direct. I put the metal or ceramic insert into the mold cavity, close the mold, and directly inject plastic to overmold it in one go. When the plastic cools and forms, what I get is a composite part that combines non-plastic inserts with plastic.

Typical applications include:

- Embedding metal threaded inserts (more durable than molding threads directly on plastic).

- Encapsulatingelectronic components in plastic to provide insulation and protection.

- Embedding metal skeletons or inserts inside plastic structures greatly improves overall strength and rigidity (such as tool handles, structural parts).

- Integrating bearings, bushings, etc. directly into plastic parts.

2. Overmolding:

The first step is to make a basic part out of ordinary plastic(this part is called a substrate or insert), which itself is also an injection molded plastic part.

How to do it specifically?

This is divided into two steps:

- Step 1: We first make the first basic plastic part (such as the handle of a toothbrush) in another set of molds.

- Step 2: Take this first plastic part out and put it in another set of special molds to fix the position.Then, inject a different, usually softer or more sticky plastic(such as TPE, TPU, etc., which is a soft glue or plastic with good adhesion) for the second time, and let it wrap or adhere to the specific area of the basic plastic part.

Why use it? Mainly to improve the product's user experience, appearance or increase functionality:

- More comfortable and stable to hold: Just like the screwdriver handle or razor grip made in our workshop, the hard plastic is covered with a layer of soft glue.

- Good sealing effect: In some places that need to be sealed, a layer of soft plastic is wrappedto make it more tightly in contact and leak-proof.

- Color matching is better: For example, for those two-color keys, one color is used as the base, and the other color is injected, and the pattern comes out. This is how the keyboard keys made by our company for American customers were processed.

3. Actual examples:

- Insert molding: If the power tool in your hand has a metal structure firmly embedded inside its plastic handle to withstand high loads, this is a typical application of insert molding.

- Overmolding: The soft rubber layer wrapped on the outer layer of the same tool handle that provides a comfortable grip and shock absorption is achieved through secondary injection molding (overmolding on a hard plastic substrate).

A quick judgment rule:

When you hear about plastic coating on metal (or ceramics, circuit boards), this basically refers to insert molding.The core of overmolding is to mold another plastic on a plastic part.

"In the projects handled by our JS, these two processes are widely used. Simply put, insert molding accounts for about 65% of the demand for multi-material combination, and the core is to solve functional integration. Overmolding accounts for about 35%, which is mainly used to improve human-computer interaction and appearance. If the product you are designing needs to combine different material properties, please feel free to contact our JS team. We will definitely find the best and most cost-effective manufacturing solution."

Why Can Insert Molding Reduce Costs and Improve Quality?

In product development,we often recommend insert moldingbecause it can optimize the cost structure and improve the quality of the final product. The core advantages are reflected in the following key aspects:

(1) Simplify the assembly process and eliminate the risk of loosening:

Pain point:In the past, if you wanted to add a metal part to a plastic part, you had to make the plastic part first, and then install it by pressing it in, applying glue, or ultrasonic welding. Not to mention the time and labor, these places are easy to loosen over time or when the machine vibrates, and become failure points.

How do we solve it?

- We directly put the metal inserts (such as nuts, bushings, and sensor metal shells) into the mold in advance,and then overmold the plastic in one injection. One step!All subsequent assembly steps are eliminated, and labor hours and costs are naturally reduced.

- The key is that the plastic wraps the metal parts tightly in the molten state, and forms a tight covering force after cooling. There is no need to worry about it loosening due to vibration or hard use, and the reliability increases sharply.

The sealed housing of automotive sensors and the key bearing seats in power tools rely on this process.

(2) Integrate material advantages to enhance part strength:

Pain point:It is often difficult to take both into account with a single material. All metal is bulky and expensive, while all plastic is insufficient in strength.

The best solution:

- Insert injection molding combines the strength of metal with the lightweight ability of plastic.In the key stress area, place the metal parts in advance, and then wrap them with plastic injection molding in one go. In this way, the hardness and strength of the metal are achieved while maintaining lightness and design freedom.

- The plastic handles with stainless steel blades in medical devices and the plastic levers with metal frames in industrial equipment are all due to the performance leap brought about by this composite structure.

(3) Free design to improve functionality and aesthetics:

Directly hit the pain point:

- Embedding slender electronic components (sensors, terminals, PCB) or exquisite decorative strips (metal bright strips, textured parts) into plastic shells requires both slimness and sturdiness and reliability?

- The complex manual wiring, step-by-step assembly, and post-sealing processes in traditional processes are time-consuming and labor-intensive?

- Is it difficult to compress the space occupancy to the extreme, and the finished product structure is fragile and easy to damage?

Innovative solution:

- We put electronic components or decorative inserts directly into the mold as inserts. When plastic is injected, they are firmly wrapped inside toform a sealed and insulating protective layer.One-time molding, the structure, electrical connection and appearance are done! The design can be made more compact and integrated, saving space and improving reliability.

- Following the insert molding design guide is the key.Think about the router shells with integrated antennas, electronic connectors, and RV insert molding decorative strips that make the RV look cooler, and you will know how powerful it is!

"According to McKinsey's analysis report on automotive parts manufacturing, the insert molding process can reduce the assembly process cost by more than 25% on average. At the same time, test data from the Society of Plastics Engineers (SPE) shows that in vibration application scenarios (such as power tools and automotive parts), the fatigue life of parts using insert molding can be increased by 30-50%."

If your design faces challenges in cost, reliability or integration,please contact the JS technical team. Provide your requirements in detail, and we will tailor the most competitive insert molding solutions for you based on real project data and engineering experience.

FAQ - Answer All Your Questions about Insert Molding

Question 1: What materials are used in insert molding?

- In our daily insert molding production,the most commonly used inserts are various metal parts,such as brass, stainless steel or aluminum, because they are strong enough. We can also make special parts such as ceramics and circuit boards.

- As for the outer plastic shell, ABS, nylon (PA), polycarbonate (PC) and other high-performance plastics such as PBT and PEEK are also used.

The specific plastic we choose mainly depends on how much pressure resistance and temperature resistance your parts need, as well as cost control. The goal is to make reliable and cost-effective electronic or industrial parts for you.

Question 2: What is film insert molding?

This process is what we oftencall in-mold decoration (IMD),which is quite special:

- Film as insert: We put film sheets with exquisite patterns, textures and even conductive lines pre-printed into the mold.

- Injection molding: Inject molten plastic (such as ABS, PC) on the back of the film. The film is tightly and firmly combined with the plastic matrix.

- Applications and advantages: Many of the patterned parts on the surface of the car center console button panel and the home appliance control panel are made using this technology, which makes the final parts functionally integrated, beautiful in appearance and wear-resistant.

Question 3: What is the customs code (HS Code) for "insert mold"?

Combined with our actual shipping experience, let me tell you about this customs code:

The general customs code forthe insert injection molds we export is usually 8480.71, which is classified as a special mold for plastics or rubber.

However, we would like to remind you that there may be adjustments or additional information required when declaring to a specific country. The safest way is to confirm with the customs broker we cooperate with before shipping. They will get the most accurate code according to the requirements of the destination country to avoid customs clearance problems.

Question 4: What is Inset Molding?

In our industry, Inset Molding is actually a common slip of the tongue or spelling deviation of Insert Molding. The two refer to exactly the same process. First put the part (insert) into the mold, and then inject plastic to overmold it. The correct term commonly used in the industry is Insert Molding. It is recommended that you use this name in formal documents or technical communications to avoid confusion.

Summary

As an engineer in the JS team, I feel more and more that insert molding is not a simple processing step, it is an upgrade of design ideas!It breaks away from the traditional processof making parts first and then assembling, and directly completes the ultimate combination of different materials in the mold.

Let insert molding detonate the potential of your product!

Still worrying about how to reliably combine metal functional parts and plastic shells? Do you think traditional assembly methods limit the design? Insert molding may be the answer you are looking for!

Take action now to unlock new product possibilities!

As insert molding solutions inc, the JS team is by your side!If you are designing a product that needs to combine heterogeneous materials and plastic structures:

- Send us your design concept, drawings or sample information immediately.

- Make an appointment for a quick assessment: Talk to me about your needs and challenges.

- Get a dedicated plan: Within 1-3 working days, you will receive a preliminary feasibility analysis and value enhancement suggestions. See how insert molding can transform your product!

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com