CNC-Machining은 복잡한 구조를위한 기술입니다. 성공적인 데이터 -v-7b79c89 3 =" "" "" "데이터 -v-7b79c83 =" "" 재료 선택 공차 제어 및 기하학적 구조 최적화와 같은 몇 가지 차원. 변형 위험 및 다감성 처리는 효율성을 향상시키기 위해 도구 경로와 일치해야합니다.

고급 다축 축 기계 도구를 AI 구동 프로세스 최적화와 결합하여 JS는 95mm의 정확도를 95mm의 정확도로 생산 비용을 20% 줄입니다. 구성 요소 또는 의료 등급의 플라스틱 구성 요소, JS의 엔지니어링 팀 (평균 20 년 이상의 경험) 문서 검토 (단계, Iges, STL 등과 같은 지원 형식)에서 전체 프로세스를 지원할 수 있습니다.

.CNC 가공의 정의는 무엇입니까?

< "> <">

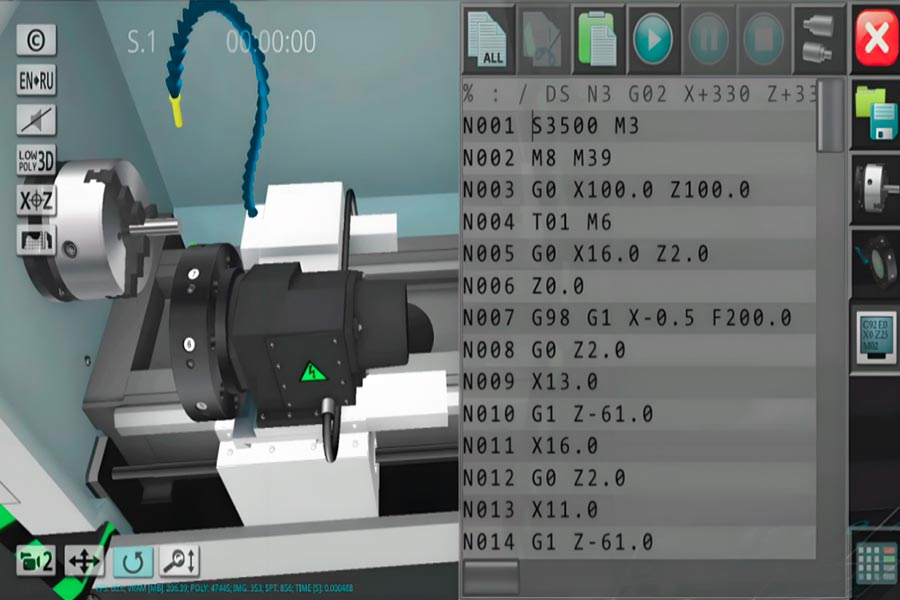

CNC 프로그래밍에 필요한 기술은 무엇입니까?

CNC 프로그래밍은 다음 핵심 기술의 숙달이 필요합니다.

1. 벽 두께는 변형을 피하기 위해 균일합니다.

벽 두께 설계의 예방 조치는 무엇입니까?

벽 두께 설계의 예방 조치는 무엇입니까?

밀 가공에서 고르지 않은 벽 두께는 밀링 후 응력 집중력과 뒤틀림 또는 균열을 유발할 수 있습니다. href = "https://jsrpm.com/blog/how-does-cnc-machining-work"> 설계 프로세스 중에 벽의 두께를 일관성있게 유지하려는 노력 또는 필요한 경우지지 구조를 추가하기 위해 노력해야합니다.

.

- 선반 가공에는 얇은 벽 부품의 경우 높은 동심 정도가 필요합니다. 최소 벽 두께 ≥0.5mm가 일반적으로 권장됩니다.

- 그라인딩 가공은 휠의 마모에 의해 영향을받습니다. 얇은 벽은 변형이 쉽고, 최소 0.3mm의 간격을 예약해야합니다. .

3. 힘줄을 강화하고 전환 코너를 최적화하고 전환 코너를 최적화합니다.

- 밀 가공에 보강재를 추가하면 국부 강성을 향상시킬 수 있지만 칩을 제거하기가 어려워서 과도하게 설계를 피해야합니다. .

- 내부 및 외벽에 r = 0.5mm 이상의 둥근 모서리를 추가하여 연삭 가공 중에 공구 응력 농도를 줄입니다. >.

티타늄 합금과 같은 고강도 재료는 5. Shrinkage rate and fanclerance 예약

캐스팅 또는 분사 성형 부품은 수축률이 필요하지만 정밀한 CNC 부품 (의료 구성 요소와 같은 의료 구성 요소) (예 : 그린딩 마치) 및 ghinding machining)를 통해 크기 오류를 보상해야합니다. 0.02-0.05mm는 설계를 위해 예약되어 있어야합니다.

.

복잡한 벽 두께 구조는 밀링 가공 공구 경로 빈번한 공구 교체를 피하기 위해. CNC에 대한 기하학적 복잡성의 영향은 무엇입니까?

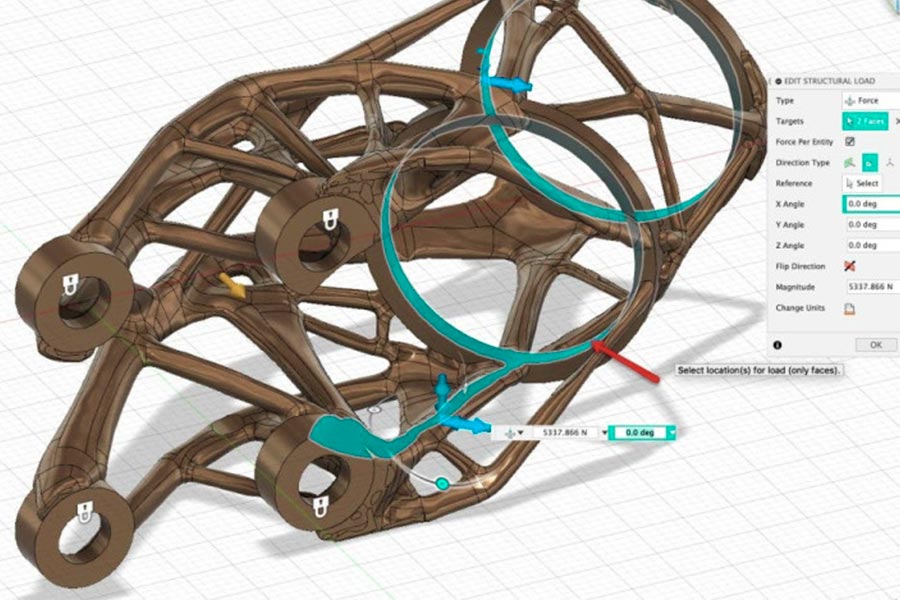

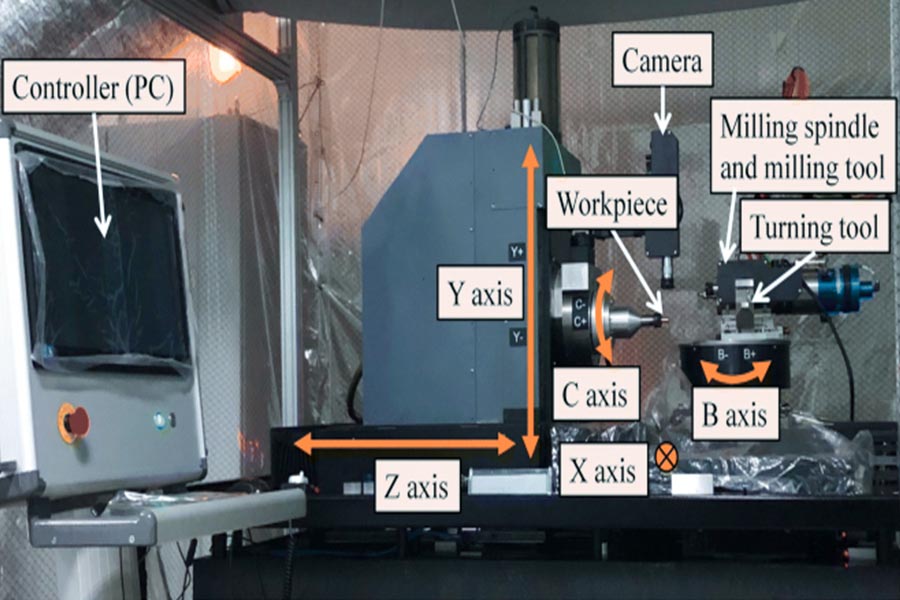

기하학적 복잡성은 CNC 가공, 특히 밀링 가공 및 가공 레터에 큰 영향을 미칩니다. 다음과 같은 차이점과 과제를 강조해야합니다. 1. data-len = "43"data-v-7b79c893 = "" "> 도구 경로 계획 및 가공 효율성 도구 선택 및 마모 제어 3. data-len = "39"data-v-7b79c893 = "" "> 처리 정확도 및 표면 품질 4. data-len = "31"data-v-7b79c893 = "" "> 처리 비용 및 타당성 5. data-pos = "3"data-len = "35"data-v-7b79c893 = ""> 재 처리 및 품질 관리 전통적인 CAD 모델링 및 AI 디자인 비교 생성 알고리즘은 특히 엔지니어의 경험을 완전히 대체 할 수 없습니다. CNC, 두 사람은 서로를 보완해야합니다. 산업 관행 : 1. data-v-7b79c893 = ""> 핵심 역량 비교 2. data-v-7b79c893 = "" "> 생성 ai의 한계 3.The manifestation of collaborative value Algorithms are tools, experience is irreplaceable The practical logic of JS: Using generative AI for initial design exploration (such as quickly generating multi version shell structures), followed by engineers screening and optimizing based on CNC process constraints (such as JS's ±0.005mm tolerance), material properties (such as titanium alloy processing temperature), and customer case experience (such as batch consistency of automotive molds). Generative AI can improve design efficiency, but the core of machining CNC experience and quality control-still needs to be led by senior engineers. The success of JS demonstrates that the human-machine collaboration model (AI assisted+manual verification) is the most optimal solution for current manufacturing. 1.Minimize empty motion 2.Optimization of dynamic cutting parameters 3.Tool load and life management 4.Machine tool kinematic adaptation 5.Optimization of material removal rate 6.Process constraints and tolerance control 7.Sustainable manufacturing integration Processing difficulties 1.Treatment of complex irregular structures 2.Characteristics of high-temperature alloy materials 3.Cleanliness and consistency of internal flow channels 4.Thermal deformation control JS company's core advantages Typical cases JS company uses nickel-based superalloy to forge blank in integral, processing a new type of rocket engine shaped cooling cavity. Through CNC multiaxial machining and electrolytic polishing, the uniform cooling channel with 0.3mm wall thickness is achieved, and the thermal conductivity efficiency improved by 40% and engine thrust by 15%. 1.Special cutting tools and cutting techniques Using diamond coated tools or cubic boron nitride (CBN) and other ultra-hard tool materials to optimized cutting parameters, such as speed and feed speed, can effectively solve the problem of high hardness of ceramics and cemented carbide, reduce tool wear and improve machining efficiency. 2.High precision CNC machine tools and control systems With ±0.005mm level ultra high precision machine tools and advanced CNC systems, the processing requirements of complex shapes and strict tolerances such as micrometer level are ensured, satisfying the application requirements of superhard materials in precision components. 3.Customized process plan Design specialized machining strategies based on material characteristics (such as brittle ceramics vs. high-toughness hard alloys), such as using micro lubrication (MQL) or dry cutting techniques to optimize surface smoothness and avoid material cracking or thermal damage. 4.Integrated cross-material processing experience Based on the experience of dealing with multiple materials in the past year, the mechanical models and parameters of metal and composite materials processing were transferred to the field of superhard materials, and the processing risks predicted by finite element analysis. 5.Support green manufacturing systems Energy recovery system and environmentally-friendly coolant circulation technology can reduce energy consumption and pollution in superhard materials processing. At the same time, it can be used automatically to reduce material loss to a minimum, in line with its sustainable improvement target of 20%. In CNC machining, the core of design and engineering considerations lies balance precision, material properties and process feasibility. From the structure optimization of machining mill to tool path planning of CNC machining, every step needs to be focused on tolerance control, material strength and machining efficiency. JS Precision Manufacturing integrates multi-axis coupling technology, specialized cutting tools and AI-driven process optimization to successfully solve the processing challenges of superhard materials such as ceramics and cemented carbide. Its ±0.005mm level accuracy and 98% on-time delivery rate confirm the importance of design, engineering and manufacturing integration. The content on this page is for general reference only. JS Series makes no express or implied warranties regarding the accuracy, timeliness, or applicability of the information provided. Users should not assume that the product specifications, technical parameters, performance indicators, or quality commitments of third-party suppliers are completely consistent with the content displayed on this platform. The specific design feature, material standards, and process requirements of the product should be based on the actual order agreement. It is recommended that the purchaser proactively request a formal quotation and verify product details before the transaction. For further confirmation, please contact our customer service team for professional support. JS is an industry leading provider of customized manufacturing services, dedicated to providing customers with high-precision and high-efficiency one-stop manufacturing solutions. With over 20 years of industry experience, we have successfully provided professional CNC machining, sheet metal manufacturing, 3D printing, injection molding, metal stamping and other services to more than 5000 enterprises, covering multiple fields such as aerospace, medical, automotive, electronics, etc. We have a modern factory certified with ISO 9001:2015, equipped with over 100 advanced five axis machining centers to ensure that every product meets the highest quality standards. Our service network covers over 150 countries worldwide, providing 24-hour rapid response for both small-scale trial production and large-scale production, ensuring efficient progress of your project. Choosing JS Team means choosing manufacturing partners with excellent quality, precise delivery, and trustworthiness. 1.How to optimize tool path and reduce vibration? The tool path is optimized by increasing the step distance, using spiral/cycloid cutting, adjusting the cutting direction to disperse the cutting force, maintaining the cutting load the same, avoiding the concentration of resonance point, and using axial layered cutting to reduce vibration. 2.What should I do if thin-walled parts are prone to deformation? When thin-walled parts are easy to deform during processing, the cutting force and vibration can be reduced by segmental cutting, decreasing feed speed, increasing support fixtures or vacuum suction clamping fixture, and optimizing tool paths to maintain uniform force distribution. 3.What are the key points of daily maintenance for CNC machine tools? Clean and lubricate machine tool daily, regularly calibrate coordinate system and tools, check coolant and fixture status, ensure system stability and machining accuracy. 4.Do complex surfaces require multi axis machine tools? Multi-axis machine tools are needed for complex surface machining because they can be used for multi-angle connecting rod cutting to ensure accuracy and efficiency and avoid multiple clamping errors.

전통적인 CAD 모델링 대 생성 AI 설계 : 알고리즘이 엔지니어 경험을 대체 할 수 있습니까?

치수

전통적인 CAD 모델링

생성 AI 디자인

JS Company Practice

디자인 논리

엔지니어 모델은 물리학 및 경험의 법칙에 따라 손으로 모델입니다. .

인공 지능은 알고리즘을 통해 설계를 생성하고 패턴 일치를위한 교육 데이터에 의존합니다. .

JS 엔지니어는 CAD 경험을 활용하여 AI 출력 솔루션을 최적화합니다.

정밀 제어

± 0.005mm의 공차 (JS 사례의 95%).

인공 지능은 알고리즘을 통해 설계를 생성하고 패턴 일치를위한 교육 데이터에 의존합니다. .

JS는 엔지니어링 경험을 통해 AI 생성 설계의 처리 위험을 보상합니다.

효율성 개선

복잡한 구조에는 더 긴 반복이 필요합니다.

여러 디자인을 빠르게 생성합니다 (예 : JS는주기를 15%단축합니다). .

인공 지능은 엔지니어가 키 노드를 제어하는 초기 설계를 단축시킵니다.

비용 최적화

경험 중심 자료 및 프로세스 선택 (JS의 20% 비용 절감).

자동 저비용 솔루션의 자동화 된 생성, 확인할 가능성.

JS는 AI 권장 사항과 엔지니어 경험을 결합하여 비용과 품질의 균형을 유지합니다. .

산업 적응성

항공 우주, 자동차 및 기타 고정밀 필드에서 널리 사용됩니다.

범용 부품과 같은 표준화 된 구성 요소에서 미결제. .

JS는 산업 로봇 구성 요소를 사용자 정의하는 두 가지 접근 방식을 통합합니다. .

Step by Step

The role of AI

The role of engineers

JS case results

Conceptual design

Generate multiple solutions to shorten the cycle (e.g. JS reduces design time by 15%).

Choose a solution that meets the processing logic.

Client projects were completed an average of 15% ahead of schedule.

Optimization

The combination of cutting parameters is recommended.

Adjust parameters according to machine performance and material characteristics.

Precision ±0.005mm (95% JS compliance rate).

Cost control

Provide lightweight design advice.

Verify manufacturability and balance costs.

Help customers reduce manufacturing costs by 20%.

Innovation breakthrough

Explore the possibilities of non-traditional structures.

Evaluate the feasibility of mass production and improve the design.

Develop multiple patented precision components.

What is the core logic of tool path optimization in CNC multi axis machining?

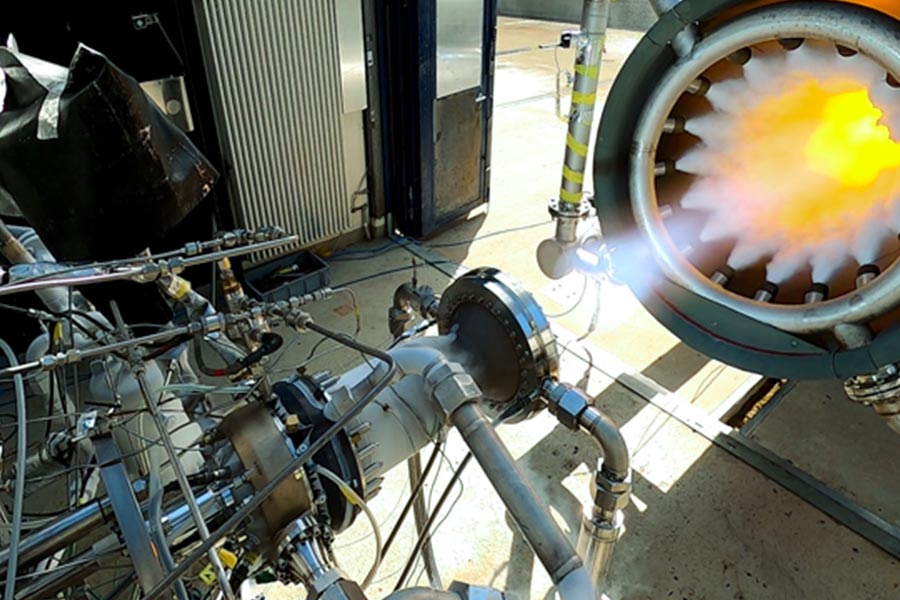

What are the difficulties in processing the irregular cooling chamber of rocket nozzle?

Technical capabilities

Specific measures

Application effect

Multi axis precision machining

Five axis coupled CNC system to support complex surface machining.

The cooling chamber channel is formed in one go to reduce clamping errors.

Special material processing

Experience in working with high temperature materials, such as Inconel and titanium alloys, with CBN cutting tools.

Surface roughness ≤0.8μm, strength loss<3%.

Digital quality control

Comparison and verification between CMM and CAD.

The pass rate is over 98% and the rework rate is down by 70%.

Efficient production process

Modular programming, automated loading and unloading system.

Average distribution cycle reduced to 10-14 working days.

Aerospace grade certification

Certified by 9001 and AS9100D aerospace quality management system certification.

We supply components for SpaceX, Blue Arrow Aerospace and others.

How does JS process superhard materials?

Summary

Disclaimer

JS Team

For more information, please visit the official website: jsrpm.comFAQs

Resources