射出成形は、現代の製造業界の革新的なプラスチック成形技術です。 コア原則は、溶融プラスチックを精密金型キャビティに注入し、冷却して固化し、特定の形状のプラスチック製品を取得することです。

従来の処理方法とは異なり、射出成形は一度に複雑な構造成形を完了することができるという独自の利点があります。

射出成形のコアプロセスは何ですか?

射出成形のコアプロセスは、基本的に制御された位相遷移中の熱可塑性材料の空間計画です。 href = "https://jsrpm.com/blog/what-is-injection-molding">噴射により、溶融プラスチックはダイナミクスの挙動を備えたカビの空洞に注入され、粘性状態から固体へのインテリジェントな移行は、プリセットの幾何学的制約の下で完了します。

材料レオロジー、熱力学的伝達、および機械的制約の相乗効果を組み合わせたプロセスは、ポリマーの容器だけではありません。 基本的な製造プロセスから材料特性への射出成形をアップグレードするための動的なカビの温度制御やマルチステージ噴射戦略などの革新的な手段を採用する際に、プロセスを再設計します。

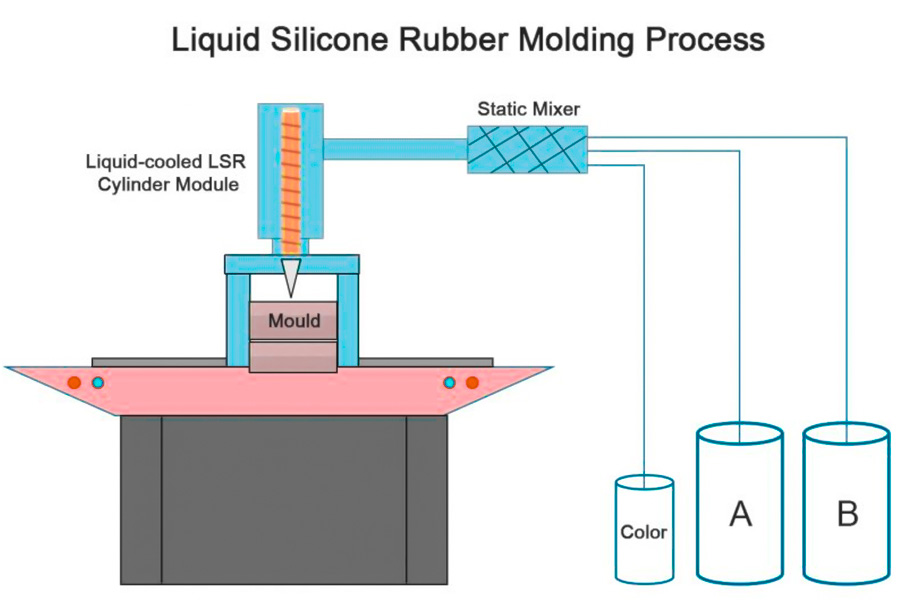

液体シリコン射出成形プロセスの特徴は何ですか?

2。 data-len = "28" data-v-7b79c893 = ""> 自己修復カビの適応

シリコン材料のユニークな弾性メモリ効果は、ダイの低い耐性の欠陥を自動的に補正し、シリコン成形プロセスでのフラッシュ欠陥を減らすことができます。

3。 Data-V-7B79C893 = "" "> 生体適合性の分子プログラミング A/Bグループ比を調整することにより、材料の硬度を注入時にカスタマイズして、医療カテーテルからセイミックシールへのパフォーマンス移行を達成できます。

4。 data-len = "33" data-v-7b79c893 = ""> 逆温度制御ロジック 半治療可能なシリコン製品は、形状記憶の特性を持ち、後期における二次加熱による変形回復を可能にし、新しいメーカーのパラダイグを提供するための新しいパラダイグを提供します。

噴射型技術は、従来の大規模生産ツールの役割を通じて突破し、業界全体の技術革新のコアドライバーになりました: たとえば、特定の企業は、マルチレイヤーCOインジェクションモールディングテクノロジーを使用して、Minus 150°Cへの温度サイクリングテストを実現するために、マルチレイヤーCO注射テクノロジーを使用して、深いスペース探索の製造基準を再定義しました。 href = "https://jsrpm.com/industry/industry-equipment">火星プローブ射出成形の放射抵抗性センサーハウジング 極端な環境での射出成形場で、活動的な防御からシフトされた型材料は、極端な環境での材料をシフトしました。 これらの革新的な材料の共通の特性は次のとおりです。

data-pos = "0" "data-len =" 3 "data-v-7b79c893 =" ""> 2。 data-len = "39" data-v-7b79c893 = ""> 動的温度制御金型 ブレークスルーポイント:ストロー繊維強化プラスチック(最大40%)は、JS特別なネジのデザインを介して直接注入できます。

ブレークスルーポイント:JS特許を組み合わせて、抗菌/抗ウイルスマスターバッチはプラスチック成形中に均等に分散し、長期にわたって表面ミクロガーニズムを効果的に阻害します。

JS Precision Manufacturingのユニークな利点と組み合わされた楽器: Based on various medical-grade polymers in the JS material library (e.g. PEEK, medical silicone, transparent polycarbonate), a material adaptation model for instrument use developed, and special alloys (e.g. molybdenum titanium alloys) that have passed ISO 10993 cytotoxicity testing are prioritized for long-term instrument implantation. 2.Pre treatment of infection-resistant surface modification Combining plasma immersion ion implantation with nano silver, an antibacterial microstructures was established within the cavity of injection moldings to form a long-lasting (>500 cleaning cycles) antimicrobial layer on the instrument surface (Escherichia coli inactivation rate>99.9%). Submicron level precision manufacturing matrix 1.Dynamic tolerance compensation system Using JS patented closed-loop temperature controlled injection molding system (±0.002°C accuracy) combined with real-time pressure sensing (resolution 0.1MPa) in the die cavity, component size stability of 0.1 wall thickness was ±0.003mm, satisfying the assembly requirements of microsurgical instruments. 2.Multi material integrated molding process The development of gradient injection molding technology allows seamless connection between hard metal (e.g. stainless steel) and flexible TPU soft tissues in a single molding process, with shear strength exceeding 25MPa, exceeding the fatigue life limit of traditional bonding processes (a more than 3 increase). Medical grade cleaner production chain 1.100,000 level clean unit cluster The injection molding workshop is equipped with an ISO 7 purification system, AGV material transfer and dust-free packaging workstations with dust concentration less than 0.5 μg/m³, which meets the requirements of the U.S. Food and Drug Administration's QSR sterile instrument production environment control. 2.Closed loop traceability management system Each injection molding piece is equipped with an RFID chip that integrates data from more than 200 dimensions such as raw material volume, injection parameters (pressure/ temperature/ velocity), quality inspection results, and more to support electronic record traceability of FDA 21 CFR Part 11 standards. Extreme working condition verification system 1.Accelerated aging test matrix The reliability of the instrument in cases of extreme emergency surgery was ensured by triple verification of temperature cycling (-40°C to 130°C, 1000 cycles), chemical corrosion (72 hours soaking with 75% ethanol) and mechanical fatigue (100,000 opening and closing tests). 2.Bioburden extreme challenge The most serious contamination conditions (MRSA biofilm loading 10^7 CFU/cm²) were simulated, using JS's self-developed enzymatic cleaning process, the residual protein content on the surface of the instrument is less than 2μg/cm², meeting the EU MDR Class III sterilization standard. Intelligent composite specification output solution 1.One-stop authentication acceleration Kit Provide two-track FDA 510(k) and CE MDR dual track certification consulting services, including a complete set of registration documents such as risk analysis reports (ISO 14971), biocompatibility data package, sterilization validation schemes, etc., reducing the average certification cycle by 40 days. 2.Digital twin delivery system Simultaneously, 3D functional simulation models of the instrument, material microstructure analysis reports and manufacturing process parameter files (derived from MES system) are provided to assist clients quickly complete preclinical validation. Breakthroughs in environmental tolerance technology 1.Ultra-wide temperature range stability 2.Innovation in resistance to medium penetration 3.Dynamic load strengthening Environmental Adaptation verification system JS converts precision machining accuracy (±0.005mm) into micrometer level protective structure control capability that combine with 23 military-specific grades in the materials genome database to form customized solutions across the land, sea, air, and space domains. The company's production base is equipped with a thermostatic ±0.1°C clean workshop and a dust-free 100,000 level dust-free laboratory, which provides comprehensive support for high-reliability components from design simulation to mass production. JS reduced the cost of small-scale injection molding by 30%-50% through professional technology and process optimization. The specific plans are asフォロー: Digital pre-production system 1.Virtual validation replaces physical trial modeling 2.Smart quotation system Flexible Manufacturing System Material Innovation 1.Recycled material plan 2.On-demand synthetic technology Whole life cycle cost control Typical case: A drone customer was supposed to buy 1000 custom antenna covers. Only three prototypes were used for validation and mass production through JS's digital twin pre production and mold technology. Total costs are down 67% compared to traditional model, with distribution times compressed to 12 days (an industry average of 30 days). Injection molding has already surpassed traditional molding meaning, which is not only a simple process of injecting molten plastic into molds, but also a modern technology combining materials science, precision engineering and intelligent manufacturing. From nanoscale medical devices to meters long aircraft, molding plastic is reshaping the manufacturing boundaries of industries with incredible creativity. The real appeal of this technology lies its limitless possibilities. Injection molding always brings amazing solutions when new materials encounter intelligent processes and innovative designs that break through traditional limitations. We are on the cusp of a manufacturing revolution where entrepreneurs, engineers and product designers have the opportunity to realize their innovative vision through this technology. The content on this page is for general reference only. JS Series makes no express or implied warranties regarding the accuracy, timeliness, or applicability of the information provided. Users should not assume that the product specifications, technical parameters, performance indicators, or quality commitments of third-party suppliers are completely consistent with the content displayed on this platform. The specific design feature, material standards, and process requirements of the product should be based on the actual order agreement. It is recommended that the purchaser proactively request a formal quotation and verify product details before the transaction. For further confirmation, please contact our customer service team for professional support. JS is an industry leading provider of customized manufacturing services, dedicated to providing customers with high-precision and high-efficiency one-stop manufacturing solutions. With over 20 years of industry experience, we have successfully provided professional CNC machining, sheet metal manufacturing, 3D printing, injection molding, metal stamping and other services to more than 5000 enterprises, covering multiple fields such as aerospace, medical, automotive, electronics, etc. We have a modern factory certified with ISO 9001:2015, equipped with over 100 advanced five axis machining centers to ensure that every product meets the highest quality standards. Our service network covers over 150 countries worldwide, providing 24-hour rapid response for both small-scale trial production and large-scale production, ensuring efficient progress of your project. Choosing JS Team means choosing manufacturing partners with excellent quality, precise delivery, and trustworthiness. 1.Is injection molding suitable for mass production? Injection molding is very suitable for mass production. A set of molds can produce hundreds of thousands to millions of pieces, high efficiency, low cost, especially suitable for large-scale production of standardized products. 2.Are injection molded parts resistant to high temperatures? The temperature resistance of injection molds depends on the material. Ordinary plastics can withstand temperatures between 60℃ and 100℃, while engineering plastics such as PEEK can withstand temperatures above 260 degrees Celsius. Special formula can further enhance heat resistance. 3.Can injection molded parts be recycled? Thermoplastic injection molding parts can be recycled, but need to be classified, and thermosetting plastics are not recyclable due to chemical crosslinking. Recycled materials are often downgraded for use, leading to a degree of performance degradation. 4.How long is the lifespan of injection moldings? Injection moldings typically last between 100,000 and 1 million weeks, depending on the material, type of plastic and level of maintenance. Precision molds can reach more than 5 million times.

射出成形は?

に使用されます

業界

革新的なシナリオ

jsコアテクノロジー

データインジケーター

aerospace

燃料ノズル、衛星マウント

金属粉末+カーボンファイバー強化射出成形。

300°Cの温度抵抗、60%の減少。

農業機械

インテリジェント灌漑バルブ。

pa12+グラフェン拡張+統合センサーインターフェイス。

塩スプレーに耐性があり、寿命が3倍増加します。

治療

呼吸マスク、インプラント。

lsr silicone+uvオンライン滅菌。

毎日50,000個の生産、99.9%の滅菌効率。

ロボットオートメーション

生体模倣指の関節、エンコーダーハウジング

デュアルカラーシリコンTPU射出成形+モジュラー設計。

グレーズ精度±0.1mm、コストは40%削減されました。

リサイクル可能なエネルギー

風力タービンベアリングカバー、エネルギー貯蔵ハウジング。

海洋プラスチック+PA11バイオベース材料の化学リサイクル。

回収率95%、炭素削減70%。 >

極端な環境で金型設計材料を選択する方法

極端な環境タイプ

マテリアルスキーム

コアテクノロジーブレークスルー

アプリケーションシナリオケース

高温腐食環境

炭化物のタンタルムナノコーティング型

自己生成抗酸化保護層(1800年で失敗しない)。

航空機エンジン用の高温耐性樹脂成分の射出成形。

超低温度環境

高エントロピー合金複合型。

粒界工学は、-200℃。 でタフネスを達成します

液体水素貯蔵タンクのシールの低温形成

強い腐食環境

アモルファス合金型

化学用使用のための蛍光バルブの射出成形

深海高圧環境

勾配多孔質チタン合金型。

3D印刷制御可能な細孔構造は圧力伝達のバランスをとる。 >

潜水艦の圧力耐性シェルは統合され、形成されます。

空間の微小重力

磁気浮揚インテリジェント金型システム。

超伝導磁場は、非接触型の形成を達成します。

宇宙ステーションの精度コンポーネントは軌道で製造されています。

家電製品のケーシングを注入する方法?

家電製品のケーシングを注入する方法?

手術器具の射出成形の要件は何ですか?

What is the environmental tolerance of military injection molded parts?

Test dimension

Testing standards

JS measured indicators

Industry benchmark comparison

High and low temperature cycle

MIL-STD-810H Method 503

-55℃ to 125℃/100 cycles without failure.

The standard requires -40℃ to 85℃.

Salt spray corrosion

ASTM B117

480 hours without red rust.

Ultraviolet aging

ISO 4892-3

1000 hours, color difference ΔE <1.5.

The standard requires 500 hours.

Low pressure simulation

GB/T 2423.21

The sealing performance is intact at 10^-3Pa/24h.

Conventional 10^-1Pa test.

How can JS company reduce costs for small batch injection molding?

Pain points of traditional mode

JS Innovation Solution

Cost impact

Excessive investment in molds

Magnetic detachable insert mold.

Reduce the cost of single cavity molds by 60%.

Changing lines takes a long time

Robot automatic spraying release agent system.

The time for changing lines has been shortened to 8 minutes.

High marginal cost for small batches

Dynamic scheduling algorithm optimizes equipment load.

Cost reduction of 45% for minimum order quantity of 100 pieces.

Summary

免責事項

jsチーム

For more information, please visit the official website: jsrpm.com FAQs

Resources