El principal principal de la fabricación de chapa metálica es la fusión profunda de las características del material y la operación coordinada de los equipos de fabricación avanzado. El sistema tecnológico combina alta eficiencia y adaptabilidad a nivel de nivel de micrómetro y una precisión de nivel complejo y complejos y complejos de niveles y complejos de niveles complejos y complejos de niveles y complejos de niveles complejos y. href = "https://jsrpm.com/contact-us"> Producción en masa de piezas estructurales a gran escala , que cubre la gama completa de aplicaciones desde la electrónica de precisión hasta equipos de maquinaria pesada.

En el sistema de fabricación inteligente moderno, shate metal Fabricación Se está convirtiendo en un motor de tecnología clave para promover el desarrollo de la fabricación inteligente y de Accionamiento a través de la aplicación de materiales de peso ligero, estructural.

. Bend Sheet Metal es uno de sus componentes centrales. This processing technique can be used to manufacture complex three-dimensional structures by precisely controlling the bending angle, curvature and Dimensiones de hojas de metal.

En la producción de varios componentes, es necesario usar los maquinos de la flexión y otros equipos para completar la operación de la lámina de porta, y luego la combinación de la operación de la lámina de bendición, y luego la combinación de los procesos y luego la reducción de los procesos. Para lograr la unidad de la funcionalidad y la estética.

Las herramientas y equipos centrales de la fabricación de chapa metálica incluyen principalmente los siguientes tipos, de los cuales la lámina de curvatura es la clave para la formación compleja:

- máquina de tijera: Se usa para cortar las hojas de metal en contornos rectos del tamaño deseado para proporcionar material básico para la flexión posterior.

- cnc golpeador de puñetazos: puñetazos, ranuras o cortar una forma especial en una placa de metal por medio de un troquel, a menudo usado para agitarse.

- máquina de flexiones: Como uno de los equipos centrales de la lámina de metal, aplica presión a la lámina de metal a través de la muerte hidráulica o eléctrica a moho de flexión: incluye moho superior e inferior, determinar el ángulo de flexión, el radio y la precisión. tipos comunes comunes son tipos de moho vhapedes, v-shaped, mety, puntos de molde vhapedes, son modernos. es necesario seleccionar de acuerdo con el grosor de la placa y los requisitos tecnológicos.

- Press máquina : proporciona una presión de tonelaje alta para estiramiento profundo o formación de superficie compleja, comúnmente utilizada en la producción de componentes estructurales de alta resistencia, como piezas de lámina automotriz.

- máquina de corte láser: un tipo de equipo de corte térmico de alta precisión que puede reemplazar el corte tradicional. Es especialmente adecuado para el procesamiento de contorno de la placa con forma y mejora la eficiencia de la preparación del material antes de doblar.

- Sistema de programación de flexión de CNC: rutas y parámetros de flexión (como secuencia de flexión y valores de compensación) se generan a través del software CAM para garantizar la consistencia de consistencia en masa en la producción en masa.

< Equipo de soldadura : como el arco de argón y la máquina de soldadura por puntos, utilizada para fijar las piezas de flexión y mejorar la resistencia estructural (como las partes de metal de la lámina de marco).

bend metalicias es el que el proceso de la gámar de machaca es el que se conecta el proceso. afectando directamente la precisión y función del producto terminado.

1. Fabricación de chapa vs. fundición

ventaja comparación:

- Costo y ciclo: Procesamiento de metal de hoja no requiere una apertura de moho , adecuada para una pequeña cantidad o producción personalizada, costo de baja unidad, costo de baja unidad.

- tasa de utilización del material: chapa metal después de cortar los materiales restantes se puede reutilizar, la tasa de utilización de más del 90%.

- liviano: la lámina se puede doblar y estirarse para lograr estructuras livianas complejas, como los marcos de drones, mientras que las piezas fundidas generalmente están en estados más pesados.

limitación:

escenarios aplicables:

- Seleccionar chapa metálica: prototipos rápidos, peso ligero, personalización de lotes pequeños (tales como aplicaciones y chasis).

- selección de piezas de fundición: alta resistencia, estructura de cavidad compleja (como engranajes mecánicos, válvulas de tubería, etc.).

2. Fabricación de chapa vs. soldadura

ventaja comparación:

- Integración: la lámina de metal forma directamente una estructura tridimensional (como los marcos de un cuerpo de automóvil) mediante la flexión, reduciendo los puntos de soldadura y el aumento de la fuerza general.

- Control de precisión: la máquina de inclinación de CNC puede lograr ± 0.1mm tolerance , sin soldadura en la superficie. Welding is easily affected by operation and needs to be polished in Procesamiento posterior.

- Eficiencia: la lámina de metal es adecuada para la producción en masa estandarizada, mientras que la soldadura es más adecuada para reparar o refuerzo parcial de piezas de chapa.

limitaciones:

La soldadura puede conectar materiales diferentes (como metal y plástico), mientras que la chapa se limita a láminas de metal similar.

escenarios aplicables:

- Selección de placa: producción estandarizada de piezas de placa (como soportes eléctricos, estantes, etc.).

- Elija soldadura: reparar defectos, conectar materiales diferentes o reforzar temporalmente (como el acero de construcción).

Fabricación

- iteración rápida: la etapa de desarrollo de nuevos productos no requiere inversión en moho, acortando en gran medida el ciclo de I+D (como la impresión 3D+fabricación híbrida de chapa).

- Lightweight design: Optimization of structural weight through bending, stretching and other processes (e.g. reduction of weight aerospace components components by more than 30%).

- Producción a gran escala: el equipo CNC admite una capacidad de producción diaria de decenas de miles de piezas (como líneas de estampado de metal de teléfono móvil).

- Amigante ambiental: la tasa de reciclaje de residuos excede el 95% y las emisiones de carbono son más bajas que las piezas de fundición (fuente de datos: Informe Internacional de la Asociación de Metalworking).

Datos Comparación

indicador

sheet metal casting

soldadura

costo unitario

bajo (sin costo de moho).

alto (dependiente de los moldes).

medio (dependiendo del trabajo manual).

ciclo de producción

corto (1-7 días).

largo (2-8 semanas).

medio (basado en la complejidad).

tasa de utilización de material

90%-95%

70%-80%

85%-90%

precisión típica

± 0.1 mm

± 0.5 mm

± 0.2 mm

adecuado para la producción de lotes

de lote pequeño a gran escala.

a gran escala.

lote pequeño a mediano.

La fabricación de chapa se ha convertido en una opción ideal para la producción de lotes de tamaño pequeño y mediano , lo que requiere alta precisión.

">"> ">" SECHE SEATO SEATO SEACE METAL Materiales de fabricación?

en la hoja de metal Fabricación , la selección de material razonable es la clave para garantizar el equilibrio entre el rendimiento del producto y el costo. gráfico de medidor de chapa y parámetros relacionados para proporcionarle una guía de selección sistemática:

1. Aclarar los requisitos de la aplicación

- Requisitos funcionales: de acuerdo con la capacidad de carga, resistencia a la corrosión y conductividad eléctrica del material, elija diferentes materiales.

- Limitaciones del proceso: para los materiales complejos de curva metálica, se debe dar prioridad a los materiales con buena ductilidad (por ejemplo, aluminio lámina de metal), mientras que para las estructuras soldadas, los puntos de fusión de materiales (por ejemplo, acero sin soporte con requisitos de calor más altos) se deben considerar.

2.seference shateale Gráfico

The larger the Gauge value, the smaller the actual thickness of the board (such as 16GA ≈1.5 mm, 24ga ≈0.5 mm):

material

16ga (mm)

20ga (mm)

24ga (mm)

spcc hoja de rodilla en frío

1.5

0.9

0.6

aleación de aluminio 5052

1.6

1.0

0.7

3. Características del material común

type

ventaja

aplicaciones típicas

hoja de acero galvanizado

Resistencia a la corrosión, bajo costo.

caja de computadora al aire libre, caja de electrodomésticos (debe cumplir con los estándares de prueba de spray de sal).

aleación de magnesio de aluminio

liviano, buena conductividad.

disipadores de calor electrónico, componentes aeroespaciales (seleccionados según los requisitos de la dureza).

acero inoxidable

antioxidante, resistente al calor, antibacteriano.

Equipo químico y médico (necesidad de equilibrar los costos y los requisitos de higiene).

4. Adaptación de parámetros de proceso

- Proceso de curva de chapa: las placas delgadas (por ejemplo, 24GA) requieren moldes con ranuras V más pequeñas para evitar grietas, mientras que las placas gruesas (por ejemplo, 16GA) requieren presión adicional.

- Compatibilidad de soldadura: las placas de aluminio requieren protección de gas inerte para la soldadura, y la soldadura por arco de argón se recomienda para acero inoxidable (los parámetros deben ajustarse al espesor del material).

- Surface treatment: Galvanized sheet metal can be sprayed directly, while aluminum sheet metal require anodic oxidation pretreatment (process cost differences need to be taken into account in selection).

What fields does sheet metal fabrication mainly serve?

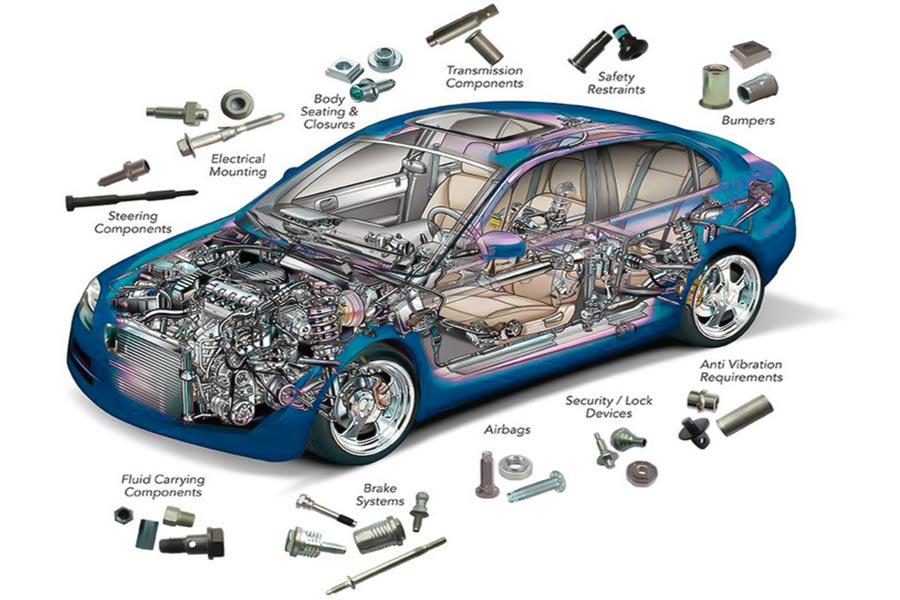

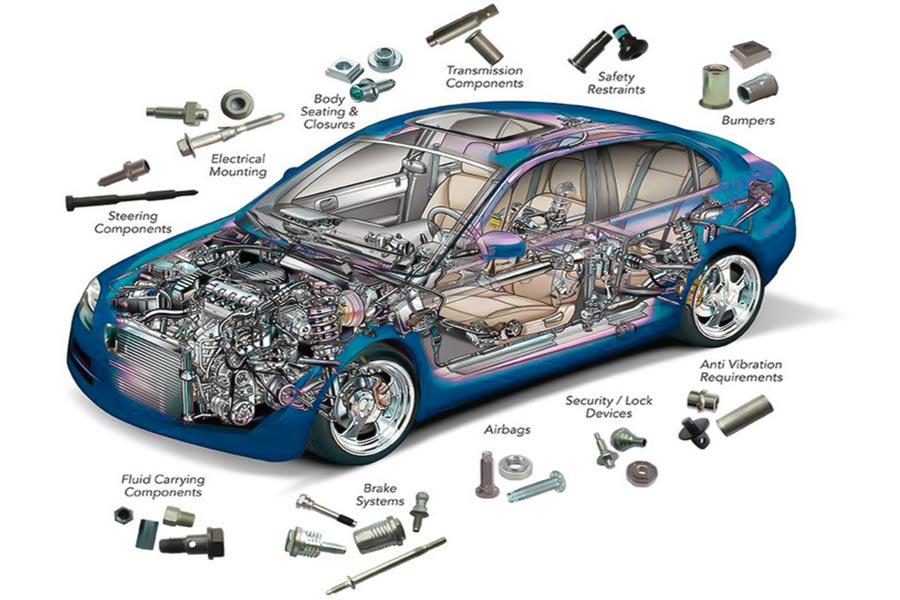

1.Automotive industry

- Application scenarios: Hidden door hinge structure, internal support frame of dashboard, exhaust system, explosion-proof pressure relief valve of battery pack, etc.

- CNC machining processing and 1-2 weeks delivery capability capacity, JS has reduced the automotive company's prototype development cycle by 40%, achieved a 99.2% pass rate with single-use component molding, and strictly adhered to the ASME Y14.5 automotive component tolerance standard.

2.Consumer electronics industry

- Application scenarios: Projector lens focusing mechanism gear set, computer keyboard light guide plate bracket, intelligent hardware structural components, etc.

- In response to the lightweight requirements of electronic products, we have been able to reduce the weight of complex structures by 35% to conventional steel) by innovative use of aviation aluminum, magnesium alloy materials, and laser welding technology

3.Medical equipment industry

- Application scenarios: Surgical robot joint drive plate, CT machine collimator blade, portable ventilator valve assembly, etc.

- JS customizes precision sheet metal components for high-end medical imaging equipment manufacturer, using 304 stainless steel for medical use. By polishing and passivation treatment, antibacterial properties improved by 90% and delivery times is 15% shorter than the original 21 days, helping customers seize market opportunities.

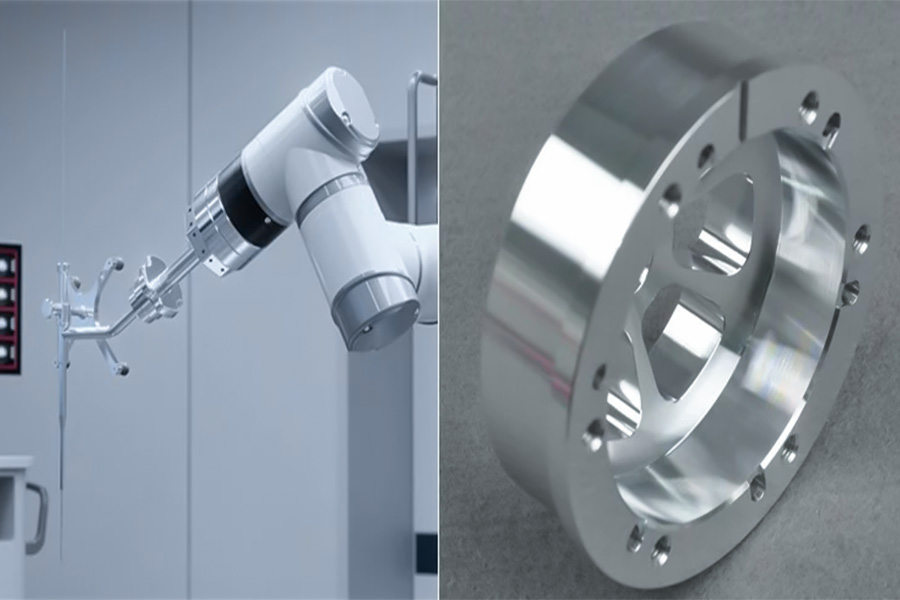

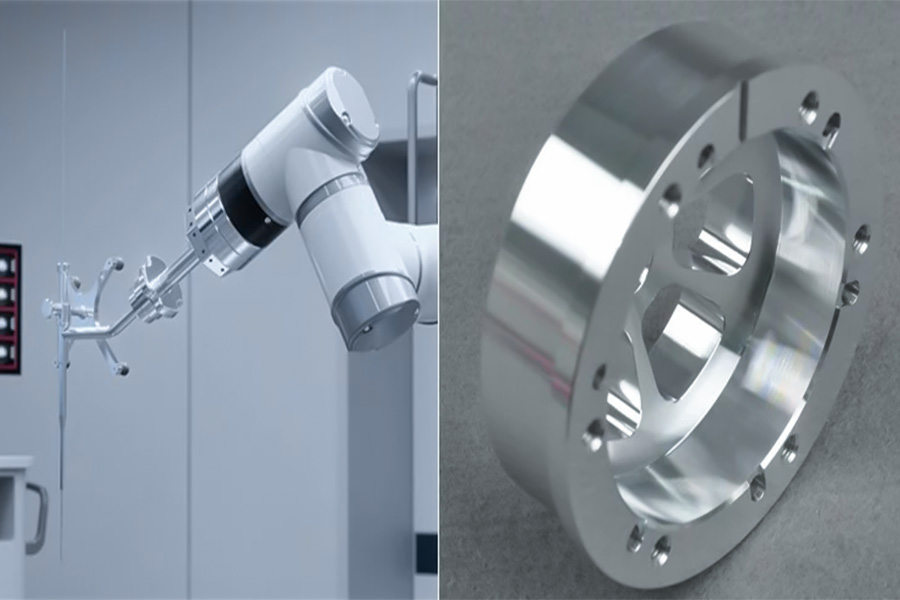

4.Industrial automation equipment

- Application scenarios: Collaborative robot joint protective cover, high-speed surface mount machine feeder shrapnel, etc.

- JS customized high-strength sheet metal structures for an industrial robot manufacturerusing Q355B carbon steel laser cutting. Through intelligent nesting layout technology, the material utilization rate increased to 92% and the overall engineering efficiency increased by 20%.

5.Recyclable energy

- Application scenarios: Wind power variable pitch system guide cover, solar bracket, flow battery electrode plate, etc.

- In a new energy project, JS uses weatherproof steel to process large sheet metal parts, combining laser cutting and bending to ensure stability in harsh environments. Its sustainable manufacturing practices, such as waste recycling, help customers meet environmental goals and reduce carbon emissions.

What are the sterilization requirements for surgical robot sheet metal components?

1.Adaptability requirements for sterilization methods

Material compatibility screening

- Stainless steel components (e.g. 304/316L): Suitable for high temperature, high pressure steam sterilization. JS provides a high temperature resistant scaffold for surgical robots with accuracy of ±0.005mm after more than 300 sterilization cycles.

- Aluminum alloy components: Ethylene oxide is recommended for sterilization to avoid high-temperature deformation. After ETO sterilization, the torque performance of a JS joint module remains unchanged.

- Plastics/composites: Radiation sterilization is preferred, and the JS sensor housing is made of PEEK material with a a tensile strength retention rate greater than 95% after irradiation.

Surface treatment strengthening: Sheet metal parts need polishing Ra<0.8μm and passivation (e.g. anodic oxidation). JS cases shows that the process can reduce sterilization residue by 80%.

2.Verification and compliance management

Biocompatibility verification

These ingredients are subject to ISO 10993 series tests (cytotoxicity, allergies, etc.), and JS's needle holder components are sourced from a manufacturer and approved by FDA 510(k).

Sterilization Verification Report

Data on sterilization process parameters (e.g. ETO concentration, irradiation dose) and material performance were provided to shorten the sterilization cycle by 20% without affecting the assurance level of sterilization (SAL 10^-6).

3.Integration of production processes

JS has very strict control over the workshop and the dust-free workshop complies with ISO 7 standards. After sheet metal processing, use ion air, reduce particle residue, combined with automatic packaging and sealing, reduce the risk of secondary contamination.

4.Cost and productivity

- Modular design: JS splits the surgical arm into three separate sterilization units, saving 40% of time compared to traditional holistic disinfection, while meeting the requirement for an emergency delivery within a week.

- Material substitution solution: For high-value components, titanium alloy are recommended in place of stainless steel. While costs increases by 15%, sterilisation life tripled and the comprehensive TCO decreased by 22%.

5.JS typical cases

In the total hip replacement surgery robot project of an international medical giant, JS provided acetabular polishing components using:

- Material: Ti6Al4V titanium alloy sheet (5mm).

- Sterilization plan: Plasma sterilization (to prevent gamma rays from titanium discoloration).

- Performance: After 10 sterilization cycles, the surface roughness was stable at Ra=0.4μm with precision error of less than 0.01mm, helping clients shorten the clinical trial cycle by 3 months.

How to replace stainless steel with galvanized sheet metal to achieve the same strength?

1.Choose high-strength alternatives

- High-strength galvanized sheet: Choose high-strength low-alloy steel as the base, its tensile strength can be over 600MPa, close to ordinary stainless steel (such as 304 stainless steel, a tensile strength is about 515MPa).

- Double layer galvanizing process: Aluminum zinc plating is adopted on the surface of cold rolled steel plates to improve corrosion resistance while maintaining the high strength characteristics of substitute material.

2.Sheet metal fabrication technology

- Cold rolling reinforcement: The yield strength of galvanized sheet is increased by cold rolling (When the cold rolling deformation exceeds 30%, the strength can be increased by 20%-30%).

- Annealing control: Use incomplete annealing (such as recrystallization annealing) to balance strength and ductility and avoid excessive softening.

- Surface treatment strengthening: Passivation or phosphorylation of the galvanized layer to reduce the risk of microcracks during sheet metal bending.

3.Structural design

- Ribs/flanges: Design of reinforcement or flange structures in key stress areas of sheet metal parts to enhance bearing capacity through geometric shapes (e.g. car chassis parts).

- Bending angle optimization: Using stair bending (Z bend) instead of right angle bending, scattered stress concentration, improve overall stiffness.

- Curling process: The edges of thin sheets (e.g. 5mm thick galvanized sheet metal with a curl radius ≤1t) are curled to prevent sheet metal bending and enhance bending strength.

4.Welding and connection process

- Resistance welding in place of riveting: On the basis of good galvanized sheet conductivity, spot welding or seam welding can reach more than 80% of the strength of the substrate (welding current needs to be controlled to avoid evaporation of the zinc layer).

- Laser welding: High energy laser welding can reduce the heat effect area, avoid strength attenuation caused by zinc coating melting, and reach joint strength close to stainless steel.

5.Verification and testing

- Tensile test: The yield strength of galvanized sheet ≥355MPa (Equivalent to one-third of the strength of 304 stainless steel).

- Cyclic load test: Simulation of actual working conditions (such as vibration, impact, etc.) to verify that the fatigue life of galvanized sheet metal meets the standards.

- Sheet metal bending rebound compensation: Through die prebending or angle correction, to ensure that the dimensions of the bending accuracy and stainless steel parts.

Key preventive measures

- Avoid excessive bending: Galvanized sheet metal are less malleable than stainless steel and should have a bending radius ≥1.5 times thickness (stainless steel generally ≥1 times).

- corrosion reinforcement: In humid environments, epoxy resin is required to be partially sprayed or coated with an increased thickness (e.g., Dacromet treatment).

How can JS optimize your sheet metal project?

JS as a professional sheet metal fabricators, through the following methods to optimize your sheet metal project:

- High precision machining guarantee: Adopt advanced CNC machining technology, achieve tolerance ±0.005mm, guarantee the dimension precision of sheet metal parts, reduce the need for subsequent assembly and debugging.

- Custom Material Selection: We offer more than 50 metals and composites (such as stainless steel, aluminum sheet metal, copper alloy, etc.) and recommend the best materials based on project requirements, balance strength, corrosion resistance and cost to meet a variety of scenarios from lightweight to heat resistant.

- Efficient production process: Through the intelligent scheduling system, the average sheet metal project delivery cycle will be reduced by 15%. Emergency orders can be quickly responded to within 24 hours while maintaining a 98% on-time delivery rate, helping businesses respond quickly to demand.

- Cost control solutions: Through waste reduction, batch layout, application of automation equipment, sheet metal processing costs can be reduced by less than 20%, and provide a transparent quotation system to help customers allocate budgets.

- Green manufacturing practices: Low energy consumption technology such as laser cutting, combined with 15% energy saving measures, can reduce the carbon emissions during sheet metal fabrication, provide recyclable material choices, in line with sustainable development goals.

Comparison between JS and other sheet metal fabricators

Optimize dimensions

JS Precision Manufacturing

Peer manufacturer A

Peer manufacturer B

Processing accuracy

±0.005mm

±0.01mm

±0.02mm

Plate utilization rate

92%

85%

80%

Standard delivery cycle

1-2 weeks.

3-4 weeks.

4-6 weeks.

tipo de material

More than 50 types.

20 types.

15 types.

Cost saving rate

On average 20%.

≤8%.

Equipment depreciation optimization only.

Sustainability certification

ISO 14001

Not have

Partial Process Environmental Declaration.

Summary

Sheet metal fabrication, as the cornerstone of modern manufacturing, plays an irreplaceable role in automotive, electronics, aerospace and other fields, from instrument casings to complex structural components, sheet metal parts through bending sheet metal technology has become a key support for innovation in many industries.

Under the trend of customization, choosing a professional partner is the key to complete sheet metal processing efficiently. With 20 years of industry experience and eco-friendly processes, JS has helped clients around the world shorten project cycles by 15% and costs by 20%. Click on the link for exclusive quotes and professional sheet metal solutions to help you seize market opportunities.

descargo de responsabilidad

The content on this page is for general reference only. JS Series makes no express or implied warranties regarding the accuracy, timeliness, or applicability of the information provided. Users should not assume that the product specifications, technical parameters, performance indicators, or quality commitments of third-party suppliers are completely consistent with the content displayed on this platform. The specific design feature, material standards, and process requirements of the product should be based on the actual order agreement. It is recommended that the purchaser proactively request a formal quotation and verify product details before the transaction. For further confirmation, please contact our customer service team for professional support.

JS Team

JS is an industry leading provider of customized manufacturing services, dedicated to providing customers with high-precision and high-efficiency one-stop manufacturing solutions. With over 20 years of industry experience, we have successfully provided professional CNC machining, sheet metal manufacturing, 3D printing, injection molding, metal stamping and other services to more than 5000 enterprises, covering multiple fields such as aerospace, medical, automotive, electronics, etc.

We have a modern factory certified with ISO 9001:2015, equipped with over 100 advanced five axis machining centers to ensure that every product meets the highest quality standards. Our service network covers over 150 countries worldwide, providing 24-hour rapid response for both small-scale trial production and large-scale production, ensuring efficient progress of your project.

Choosing JS Team means choosing manufacturing partners with excellent quality, precise delivery, and trustworthiness.

For more information, please visit the official website: jsrpm.com

FAQs

1.What are the characteristics of aerospace sheet metal parts?

Highly accurate and lightweight, titanium/aluminum alloy alloy is often used to meet complex structural requirements through bending forming process, meet airworthiness certification standards, and ensure strength and fatigue resistance performance.

2.What materials are commonly used in sheet metal fabrication?

Common materials are steel (stainless steel, carbon steel), aluminum alloy, copper and galvanized/aluminium steel, which balance strength, weight and corrosion resistance.

3.What are the technical advantages of sheet metal bending?

Sheet metal bending technology can effectively form complex geometric shapes, maintain the ductility and strength of materials, meet high precision design requirements, balance mass production efficiency and cost controllability.

4.What are the production processes for customized sheet metal parts?

Design sampling → Material selection and Cutting → Bending formation → Welding/assembly → Quality inspection → Surface treatment → Delivery.

Resources

ventaja comparación:

- Costo y ciclo: Procesamiento de metal de hoja no requiere una apertura de moho , adecuada para una pequeña cantidad o producción personalizada, costo de baja unidad, costo de baja unidad.

- tasa de utilización del material: chapa metal después de cortar los materiales restantes se puede reutilizar, la tasa de utilización de más del 90%.

- liviano: la lámina se puede doblar y estirarse para lograr estructuras livianas complejas, como los marcos de drones, mientras que las piezas fundidas generalmente están en estados más pesados.

limitación:

escenarios aplicables:

- Seleccionar chapa metálica: prototipos rápidos, peso ligero, personalización de lotes pequeños (tales como aplicaciones y chasis).

- selección de piezas de fundición: alta resistencia, estructura de cavidad compleja (como engranajes mecánicos, válvulas de tubería, etc.).

2. Fabricación de chapa vs. soldadura

ventaja comparación:

- Integración: la lámina de metal forma directamente una estructura tridimensional (como los marcos de un cuerpo de automóvil) mediante la flexión, reduciendo los puntos de soldadura y el aumento de la fuerza general.

- Control de precisión: la máquina de inclinación de CNC puede lograr ± 0.1mm tolerance , sin soldadura en la superficie. Welding is easily affected by operation and needs to be polished in Procesamiento posterior.

- Eficiencia: la lámina de metal es adecuada para la producción en masa estandarizada, mientras que la soldadura es más adecuada para reparar o refuerzo parcial de piezas de chapa.

limitaciones:

La soldadura puede conectar materiales diferentes (como metal y plástico), mientras que la chapa se limita a láminas de metal similar.

escenarios aplicables:

- Selección de placa: producción estandarizada de piezas de placa (como soportes eléctricos, estantes, etc.).

- Elija soldadura: reparar defectos, conectar materiales diferentes o reforzar temporalmente (como el acero de construcción).

Fabricación

- iteración rápida: la etapa de desarrollo de nuevos productos no requiere inversión en moho, acortando en gran medida el ciclo de I+D (como la impresión 3D+fabricación híbrida de chapa).

- Lightweight design: Optimization of structural weight through bending, stretching and other processes (e.g. reduction of weight aerospace components components by more than 30%).

- Producción a gran escala: el equipo CNC admite una capacidad de producción diaria de decenas de miles de piezas (como líneas de estampado de metal de teléfono móvil).

- Amigante ambiental: la tasa de reciclaje de residuos excede el 95% y las emisiones de carbono son más bajas que las piezas de fundición (fuente de datos: Informe Internacional de la Asociación de Metalworking).

Datos Comparación

For more information, please visit the official website: jsrpm.com