cnc maquining redefine los límites de los límites de la fabricación de componentes con sus componentes de fabricación con sus componentes de componentes. mecanizado juega un papel irreplacable en los rodamientos de precisión, las herramientas de carbohidratos contenidas y así con su material único con su material único de material. mecanismo.

¿Qué es el mecanizado CNC?

mecanizar CNC es la piedra angular de la fabricación moderna. Controla principalmente la herramienta de la herramienta de máquinas herramientas mediante el programa de computadora y da forma a la pieza de trabajo al eliminar físicamente el material. Micrometry Level Precisión y consistencia con superficies complejas .

¿Qué equipo se requiere para el mecanizado CNC?

1. CNC Machining Center

Equipado con un sistema de enlace de eje multi-eje , admite un mecanismo de efectos de efectos complejos y es irregular. js empleados a los algados a los algados a los algados a los high. con un sistema de gestión de herramientas inteligente con precisión ± 0.005 mm y un aumento de hasta un 20% en la eficiencia de producción.

2. CNC mecanizado de torno

El torno CNC de JS está especialmente diseñado para el procesamiento de partes rotativas del cuerpo. Integra un sistema de monitoreo en tiempo real para completar el mecanizado preciso del círculo exterior, el agujero interno y el hilo. 3. máquina herramienta de corte de cable

, y mantiene la tasa de entrega a tiempo de pedido de más de 98%.

4. Sistema de transferencia de material automático

equipado con robots AGV y unidades de almacenamiento inteligentes de almacenamiento, js de fábrica de fábrica de los materiales de prima hasta los productos de los primeros materiales terminados

5. Equipo de inspección tridimensional

El producto de la verificación del tamaño de los productos mecanizados CNC por el instrumento de medición de la precisión de Zeiss y otras marcas.

Cómo procesar aleación de aluminio de alta resistencia con CNC?

1. Tecnología de selección de herramientas y recubrimiento (proceso de núcleo de mecanizado CNC)

- Adaptación de herramientas especializadas: las aleaciones de aluminio de alta resistencia (como aluminio de la serie 7, aluminio 2024, etc.) están hechas de aleaciones duras o cortadores de cerámica importados con bordes geométricos especiales diseñados para reducir la resistencia de corte.

- mejora de recubrimiento: tialn o diamond se aplica a la superficie de la herramienta para mejorar la resistencia de alta temperatura de la herramienta de la herramienta y la adaptación a la fricción y el calor durante la velocidad de alta velocidad del aluminio de la superficie de la herramienta para mejorar la resistencia de la alta temperatura de la herramienta de la herramienta y la adaptación a la fricción y el calor de la alta velocidad de la velocidad de la velocidad del aluminio. aleaciones.

- Estrategia de alta velocidad de alta velocidad: eficiencia de equilibrio y masa superficial con una combinación de alta velocidad (8,000-1,500 rpm) y pequeños volúmenes de alimentación. Estrategia de capas axiales: las piezas complejas de paredes delgadas se cortan en capas para evitar la deformación y la tolerancia se controla a ± 0.02 mm para cumplir con los requisitos de precisión de grado aeroespacial.

3. sistema de eliminación de enfriamiento y chips (para abordar los puntos doloridos en el procesamiento de aleaciones de aluminio)

- Tecnología de micro lubricación: reemplaza el enfriamiento de fundición tradicional MQL, reduce el riesgo de cuchillo adhesivo de chips de aluminio, reduce el consumo de energía. aspiradora de presión negativa: puede limpiar las virutas de aluminio en tiempo real, evitar la superficie del segundo rasguño de la pieza de trabajo, especialmente para el espejo de polish Partes.

4. Control de estabilidad del proceso (sistema de gestión de calidad JS)

- Compensación de deformación térmica: a través del taller de temperatura constante de la máquina herramienta (± 0.01 ° C) y el algoritmo de compensación de temperatura en tiempo real, elimina el impacto de la expansión térmica y el retroceso de los materiales, Asegurar la consistencia de la producción en masa .

- En el sistema de inspección de la máquina: las sondas Renishaw integradas pueden detectar automáticamente dimensiones críticas por cada 50 piezas procesadas, con una tasa de defectos de menos de 0.3%.

5. adaptación de propiedad de material (soluciones de diversificación JS)

- Coordinación del tratamiento de endurecimiento del tiempo: para las aleaciones que requieren endurecimiento por tiempo, como 6061-t6, se ha desarrollado un proceso colaborativo de tratamiento y tratamiento térmico para evitar microcracks causadas por la concentración de estrés.

- Pretratamiento de piezas refractarias: para cavidades profundas y estructuras de agujeros cruzados, descarga o corte de cables se usa para el pretratamiento, seguido de un acabado de CNC para mejorar la producción total.

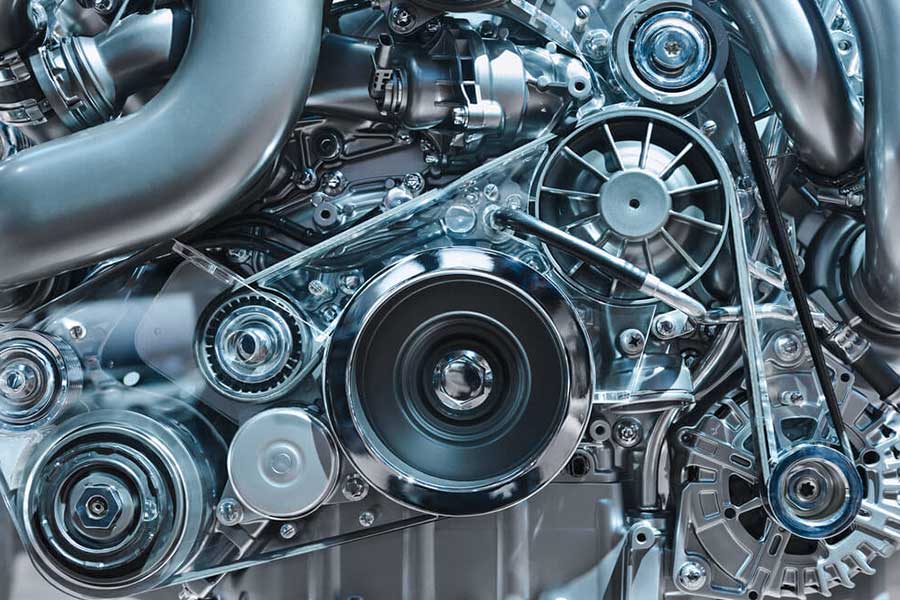

¿Cómo puede el mecanizado de CNC mejorar la precisión de los componentes del motor automotriz?

1. El mecanizado de alta precisión garantiza el rendimiento de los componentes clave

- Technical implementation: JS company adopts CNC mill machining and lathe machining technology, can achieve ±0.005mm ultra-high tolerance accuracy, far exceeding industry Estándar.

- Caso de aplicación: un cliente del automóvil necesita producir cuchillas de turbocompresor, y los métodos de procesamiento tradicionales son propensos a la distorsión. 2. 2. 2. Precio de complejo de complejo de complejo de complejo de complejo de complejo de complejo de complejo de complejo de complejo de complejo de complejo de complejo de complejo de complejo de complejo de complejo de complejo de complejo de complejo de complejo de complejo. Estructuras

- colaboración de procesos múltiples: los componentes del motor a menudo contienen superficies complejas como tuberías de admisión y pasajes de aceite. JS combina el giro de CNC con fresado de eje múltiple para lograr mecanizado de procesos multi

- Case reference: In the process of cylinder block hybrid automobile engine, JS synchronously completed the precision machining of the crankshaft hole, cooling channel and locating pin hole, and the an overall coaxiality error controlled to be less than 0.01mm, which extends the engine service Life.

3. adaptabilidad de material e innovación ligera

- Rango de material: JS admite el procesamiento de más de 50 materiales como aluminio, aleación de titanio y acero de alta resistencia.

- CNC Piezas de aluminio: el uso del diseño liviano del pistón, la reducción de peso del 30%, mientras mantiene la resistencia.

- fresado de aleaciones resistentes a alta temperatura: mecanizado de hojas de turbina que pueden soportar condiciones de trabajo por encima de 1000 ° C.

- colaboración de procesos múltiples: los componentes del motor a menudo contienen superficies complejas como tuberías de admisión y pasajes de aceite. JS combina el giro de CNC con fresado de eje múltiple para lograr mecanizado de procesos multi

- Efficiency improvement: One customer used castings for multiple mold repairs, but JS used CNC precision machining directly, shortening the prototype production cycle by 60% and reducing the cost by 40%.

4. Manufactura y optimización de costos sostenibles

- Tecnología verde: JS reduce el desgaste de la herramienta al optimizar los parámetros de corte, aumentar la tasa de utilización de materiales de la ingeniería del cabezal del cilindro del motor diesel al 92% y ahorrar más de 10 toneladas de acero anual.

- Costo de costo: Personalizar el ensamblaje del cuerpo del acelerador electrónico con CNC Alredilado de alta velocidad en lugar de la reducción tradicional de alambre, con un costo de 25% en el costo de la unidad y una reducción de la derecha de la derecha de la unidad y un reductor de la derecha de la unidad y un reductor de la derecha de 3 semanas de remo. días.

5. JS El respaldo técnico de la empresa

como a Provider de servicio de fabricación de precisión con 20 años de experiencia , JS proporciona:

- cigüeñal del motor v8: después del proceso compuesto de giro y molienda de CNC, el error de redondez es de solo 0.001 mm.

- Placa bipolar de celda de combustible de hidrógeno: utilizando la tecnología de fresado de espejo una rugosidad de la superficie RA <0.1 μm, ayuda a los clientes a romper el cuello de botella de producción de vehículos de energía de hidrógeno.

Si necesita saber más sobre las necesidades de procesamiento de los componentes del motor, el equipo JS puede proporcionar asesoramiento técnico gratuito y servicios de preparación de muestras.

cómo procesar componentes estructurales de aviación de aleación de titanio con CNC?

Proceso central del mecanizado CNC de estructuras aeroespaciales

"Span Data-V-7B79C893 =" "> Pretratamiento de material

- La aleación de titanio en blanco debe formarse forjando o fundición para reducir los márgenes de corte posteriores.

- JS Company usa tecnología de tratamiento térmico de vacío para eliminar el estrés dentro del material y reducir el riesgo de deformación de procesamiento.

Tools and parameter optimization

- Use a hard alloy or coating tool (such as TiAlN coating) to improve abrasion resistance and cutting efficiency.

- Cutting speed is controlled at 60-80m/min and feed speed is controlled at 0.05-0.15mm/r to avoid cutting tool wear due to high temperature.

3.Process path planning

- High-speed milling (HSM) technology used to layered cutting to reduce cutting force fluctuations.

- JS company simulates the cutting process through simulation software and optimizes the tool path to reduce residual stress.

4.Thermal deformation control

- Layered cooling (such as intermittent injection of cutting fluid) suppresses thermal expansion and ensures size stability.

- Complex structures are handled separately, welded/riveted to reduce the probability of overall deformation.

5.Surface treatment and testing

- Anodized or pelleted treatment to improve corrosion resistance.

- Coordinate Measuring Machine (CMM) detects key dimensions to ensure compliance with AS9100D aviation standards.

Technical advantages of JS in aerostructures processing of titanium alloy

| Key indicators | JS Company Capability | Industry benchmark | Advantages reflected |

| Processing accuracy | ±0.005mm (over 95% of projects meet the standard). | ±0.01 ~ 0.02mm. | To meet the strict tolerance requirements of aviation precision parts. | adaptabilidad del material | We have processed more than 50 materials, including titanium alloys such as TC4 and TA15. | Conventional material coverage. | Transferring cross-industry experience to the aviation industry. | Production efficiency | 98% of orders were delivered on time, with an average lead time of 1-2 weeks. | The industry average is 2-3 weeks. | Respond quickly to urgent aviation order. |

| Cost control | Reduce manufacturing costs by 20% through process optimization. | Standard cost. | Improve the profitability of customer projects. |

| Quality certification | ISO 9001 and aviation special process certification. | AS9100D | Ensure products pass the airworthiness review. |

Case study: Processing of titanium alloy wing beams of a certain type of UAV

JS worked on titanium alloy wing beams (3m in length and 2mm wall thickness) for an aviation enterprise:

Challenge: The wing beam requires a high aerodynamic load, wall thickness uniformity ≤0.02mm, and no microcracks on the surface.

JS solution:

- Five axis coupling machine tool is used for regional processing to reduce clamping deformation.

- The coolant constant temperature system controls the temperature of the cutting area at 20 ± 2℃.

- After heat treatment, vibration aging is carried out to eliminate residual stress.

Results: 99.2% product qualification rate, 15% reduction in client project lead times and 18% reduction in costs.

What is the CNC machining process for orthopedic implants?

1.Design modeling and documentation

- Customers must provide a 3D CAD model of the implant (e.g. STEP, IGES format) or engineering drawings (PDF/STL). JS company supports uploading multi-format files and makes optimization suggestions (e.g. wall thickness uniformity, structural strength, etc.) through its team's review of design feasibility.

- Advantages of JS: Its engineers have 20 years of experience and are skilled in complex geometric structures. They assist clients improve design iteration efficiency by 15%.

2.Material selection

- Biocompatible materials such as titanium alloy (Ti6Al4V), cobalt chromium molybdenum (CoCrMo) or PEEK were selected based on the intended use of the implant, such as hip and knee joints. JS supports a wide range of materials and can be customized to meet mechanical requirements.

- Case study: Hip implants are made of titanium alloy and are finely machined by JS achieve surface roughness Ra<0.8μm to meet long-term implant requirements.

3.CNC programming and processing

- Use software such as Mastercam to generate tool paths and select high-speed machining centers,such as five-axis linkage equipment, for cutting. JS's machine tool is ±0.005mm accurate, ensuring implant size tolerance.

- Data shows that the processing efficiency of crystalline titanium alloys was 20% higher than the industry average, and the processing cycle of complex structures such as porous titanium implants is shortened to 1-2 weeks.

4.Post-treatment and surface treatment

- Including burr removal, electrolytic polishing, sandblasting, etc., to improve the surface smoothness and biocompatibility of implants. JS uses automatic cleaning equipment to reduce pollution risks.

- Advantages: In custom bone plate project, surface roughness can be reduced by 40% by optimized polishing process, and postoperative bone integration can be promoted after operation.

5.Quality inspection

- Dimensions, orifices, and internal structures were verified by CMM, X-ray, or CT scans. The pass rate of JS quality inspection is 98%, far exceeding industry standard.

- Advantages: Small cracks were discovered in a batch of acetabular cup blanks, avoiding batch rework and reflecting strict quality control.

6.Packaging and delivery

Aseptic packaging or customization, with global logistics network to ensure timely delivery. JS has an average delivery time of 1-2 weeks, and emergency orders can be delivered quickly.

Case Study of Orthopedic Implant Processing in JS company

Case 1: Hip replacement

- Material: Ti6Al4V titanium alloy.

- Challenge: Porous structures need to balance lightweight and mechanical strength.

- JS solution: Five axis machining + electrolytic polishing with tolerances within ±0.01mm and standard surface porosity (50-150μm).

- Results: Customer project cycle was 20% shorter and the implant was FDA approved.

Case 2: Customized bone plate

- Material: Medical grade stainless steel 316L.

- Challenge: Complex surfaces conform complex fracture shapes.

- JS solution: Reverse engineering reconstructs CT data and CAM programming optimizes cutting path to reduce material waste by 25%.

- Results: After delivery, the clinical feedback adaptation rate was 95% and the rate of customer repeat purchase rate increased.

What challenges does JS CNC machining face in various industries?

1.Aerospace industry: Balance between extreme precision and material strength

- Challenges: Aerospace components require tolerances of ±0.001mm, while refractory materials such as titanium alloys and superalloys are frequently used, requiring high wear and process stability for cutters.

- Solutions: Stable machining can be and coated cemented carbide tool combined with adaptive cutting parameter optimization algorithms. Its five-axis coupling technology can form complex surfaces (such as engine blades) at once, reduce clamping errors, achieve 92% material removal rate and improve processing efficiency by 40%.

2.Medical devices: Miniaturization and biocompatibility

- Challenges: Orthopedic implants, dental prosthetics, etc., need to balance micrometer level precision (e.g. hip joint ball head surface roughness Ra< 0.4μm) with processing of biocompatible materials such as titanium alloys and PEEK.

- Solutions: The micro machining center are equipped with optical measurement system to compensate for tool wear in real time, ensuring a 0.01mm positional tolerance. Its patented coolant filtration technology has extended the tool life by three times and successfully completed mass production of 0.3mm diameter bone nails with a yield rate of 99.5%.

3.Automotive manufacturing: Lightweighting and mass production efficiency

- Challenge: Parts such as battery pack shell and lightweight brackets for new energy vehicles need to take into account the high strength characteristics of aluminum alloy and the speed of production (for example, 500 pieces per day), as traditional processing is prone to thermal deformation.

- Solutions: By using high-speed dry cutting technique (24,000rpm) combined with a 3D thermal deformation prediction model, the flatness error of aluminum parts is controlled to within 0.005mm. Its flexible production line can quickly switch mold cavity processing and component assembly processes, changeover time reduced by 80%.

4.Consumer electronics: Precision microstructure and surface treatment

- Challenge: The micro holes (diameter 0.1mm) and logo relief of mobile smart wearable devices need to achieve a mirror effect of Ra< 0.05μm, and be compatible with brittle materials such as stainless steel and ceramics.

- Solutions: The nanoscale precision machining center is equipped with a force feedback system, which can adjust the feed speed in real time and avoid ceramic processing edge breakage. Its independently developed composite machining path algorithm can form angle microstructures at once, and efficiency is 5 times higher than the traditional method.

5.Energy industry: Heavy components and long-term stability

- Challenges: Large workpieces such as wind turbine gearboxes, planetary carriers and nuclear power sealing rings (weighing more than 1 tonne) require continuous processing over long periods of time, posing extreme tests of machine stiffness and tool tool durability.

- Solutions: The heavy-duty gantry machining center is equipped with a two-drive system, which eliminates large cutting vibration, and acubic boron nitride tool to achieve 24 hours of continuous stable processing. The self-developed tool life management system can reduce the processing cost by 28%.

The technological differences between JS and traditional suppliers

| Indicator | JS Precision Manufacturing | Traditional suppliers | Increase amplitude | Minimum machining tolerance | ±0.005mm | ±0.02mm | ↑ 75% | Complex surface machining capability | Five axis linkage, R angle ≤0.5mm. | Three axis machining, R angle ≥1.5mm. | ↑ 200% | Material utilization rate | 80% | 65% | ↑ 23% | Tool wear rate | 0.03mm³/minute. | 0.12mm³/minute. | ↓ 75% | Typical delivery time | 7-10 days | 14-21 days | Shorten by 50% |

With its comprehensive technical advantages, JS has solved processing problems in multiple fields. One aerospace customer almost doubled the processing time to 3.5 hours per piece after adopting a five-axis titanium alloy impeller processing plan, with the pass rate jumping to 98% and an annual cost reduction of over $500,000. This technical barrier builds a moat and made the first choice to break through into high-end manufacturing.

Summary

CNC machining (including lathe machining, milling machining , grinding machining , etc.) has become an intelligent manufacturing center of modern industry. Through computer program, the machine tool movements is precisely controlled, and the leapfrogging process from aerospace titanium alloy components to scale surfaces of medical implants is realized. Especially in the field of machining mill, the complex surface forming can be effectively accomplished by the five axis linkage machining centers, and the material removal rate can be increased to more than three times the traditional process by the adaptive feed algorithm.

The core benefits are in three areas:

- Precision rotation: ±0.005mm tolerance control to meet the ultimate requirements of semiconductor packaging carrier, aircraft engine blades, etc.

- Efficiency leap: Automated systems increase batch production efficiency by 40% and reduce tool wear by 75%.

- Greener transformation: Cutting liquid circulation technology could promote energy consumption consumption by 20%, in line with carbon neutrality goals.

JS Precision Manufacturing seamlessly integrates aerospace impellers five-axis processing with automotive cover flexible grinding by means of a self-developed composite process matrix. The entire process can be traced back through artificial intelligence quality inspection, reshaping the competitive landscape of high-end manufacturing with a single machine as an innovative production line.

descargo de responsabilidad

The content on this page is for general reference only. JS Series makes no express or implied warranties regarding the accuracy, timeliness, or applicability of the information provided. Users should not assume that the product specifications, technical parameters, performance indicators, or quality commitments of third-party suppliers are completely consistent with the content displayed on this platform. The specific design feature, material standards, and process requirements of the product should be based on the actual order agreement. It is recommended that the purchaser proactively request a formal quotation and verify product details before the transaction. For further confirmation, please contact our customer service team for professional support.

JS Team

JS is an industry leading provider of customized manufacturing services, dedicated to providing customers with high-precision and high-efficiency one-stop manufacturing solutions. With over 20 years of industry experience, we have successfully provided professional CNC machining, sheet metal manufacturing, 3D printing, injection molding, metal stamping and other services to more than 5000 enterprises, covering multiple fields such as aerospace, medical, automotive, electronics, etc.

We have a modern factory certified with ISO 9001:2015, equipped with over 100 advanced five axis machining centers to ensure that every product meets the highest quality standards. Our service network covers over 150 countries worldwide, providing 24-hour rapid response for both small-scale trial production and large-scale production, ensuring efficient progress of your project.

Choosing JS Team means choosing manufacturing partners with excellent quality, precise delivery, and trustworthiness.

For more information, please visit the official website: jsrpm.com

FAQs

1.How to improve the efficiency of CNC machining?

By means of automatic equipment, intelligent path planning and adaptive feed algorithms, processing parameters are optimized, idling and waste are reduced, material utilization is improved, and processing time is reduced by more than 30%.

2.What are the advantages of CNC machining?

High accuracy, high efficiency, material utilization rate more than 85%, can process complex surfaces and irregular structures, support 24 hours of unmanned production, significantly reduce costs and improve efficiency.

3.What is the typical process of CNC machining?

CAD modeling generates machining path, CNC system controls automatic cutting of machine tools, and cooperates with detection adjustment and post-processing to complete production.

4.What is the development trend of CNC machining?

Intelligent (AI+IoT), green manufacturing (energy-efficient processes), composite processing (multi-axis coupling + hybrid technologies), Industry 4.0 is deeply integrated with digital technologies.