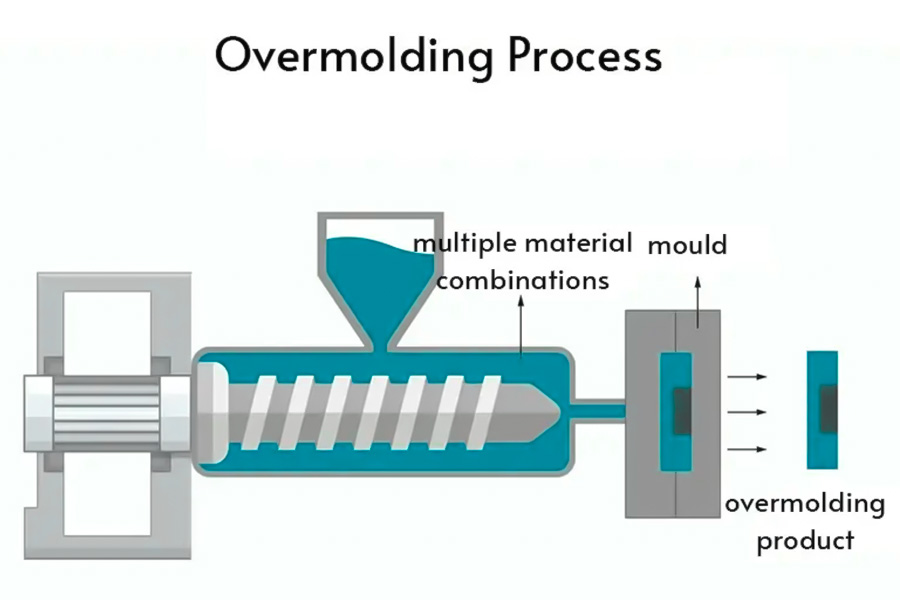

When I see plastic products, I wonder how the soft glue on the hard plastic body comes from? This is not simply glued on, but behindit is a delicate process, overmolding.This is a special injection molding method we often use, which can really melt different materials into an integral part.

How to do it specifically? We first use hard plastic to make the core skeleton (substrate) of the product, and then, in the preset specific area, through the overmolding process, wrap a thin layer of elastic soft material where needed. The two layers of material are tightly combined under high temperature and high pressure, and finally merged into one part.

In JS's product design, the application value of overmolding technology significantly exceeds the simple touch optimization and appearance improvement. It improves product performance:

- Adding a layer of soft glue to power tools and handles is non-slip and labor-saving, and it is not easy to get tired after using it for a long time.

- In some places where sealing is required,this layer of wrapping can directly replace the traditional rubber gasket, with a simpler structure and a more reliable sealing effect.

- The overall strength is stronger and lasting, and the waterproof and fall-resistance performance are also upgraded.

Because overmolding can improve functions, optimize feel and upgrade appearance at the same time, more and more good products, such as our common daily necessities, precision medical equipment, and portable electronic devices that everyone cannot do without, are beginning to use it. Next time you get a product that feels particularly comfortable to hold, maybe it contains the ingenuity ofour JS engineers using overmolding!

Core answer summary:

| Aspect | Describe | Regarding your values/core characteristics |

| Core Definition | The manufacturing process of injecting a different layer of material (usually soft glue) onto an existing (hard plastic or metal) substrate. | Improve product grip, sealing, aesthetics, and brand recognition. |

| Key processes | Two step method: First, manufacture the substrate. Then place the substrate into the second set of molds for secondary injection molding and encapsulation. | Realize the perfect combination of hard plastic and soft rubber/plastic. |

| Main applications | Consumer electronics, medical devices, manual tools, automotive interior parts, etc. | Any product that requires improved human-machine interaction experience and functional sealing. |

| Core difference |

Secondary injection molding: Usually plastic wrap (one type of plastic covers another type of plastic, with the substrate being an injection molded part). Insert injection molding: Plastic wrapped metal parts (with prefabricated metal inserts as the base material). |

The two technologies are similar, but the focus on substrate types and application scenarios is different. |

In this article, you will learn:

- In the following chapters, I will systematically analyze what is overmolding.

- The injection molding workflow is explained in detail step by step, showing how materials can be firmly combined.

- And we will explore the differences in characteristics and application scenarios between plastic overmolding and silicone overmolding, so as to make wise design decisions for your products.

Mastering these contents, you will know how to use overmolding to optimize your product design and make decisions that meet your needs!

Why is This Guide Worth Trusting? Because It Comes FromThe Practical FrontLine of JS

At JS, the overmolding plastic process is not simply pressing the button of the injection molding machine. This is one of our core technologies, which really helps customers solve key problems and improves product competitiveness.Why doI mention this? Because we deal withchemical and physical problems of this process every day:

What are the material problems?We are not only facing the injection molding machine, but also the chemical issues of whether the materials can cooperate with each other.

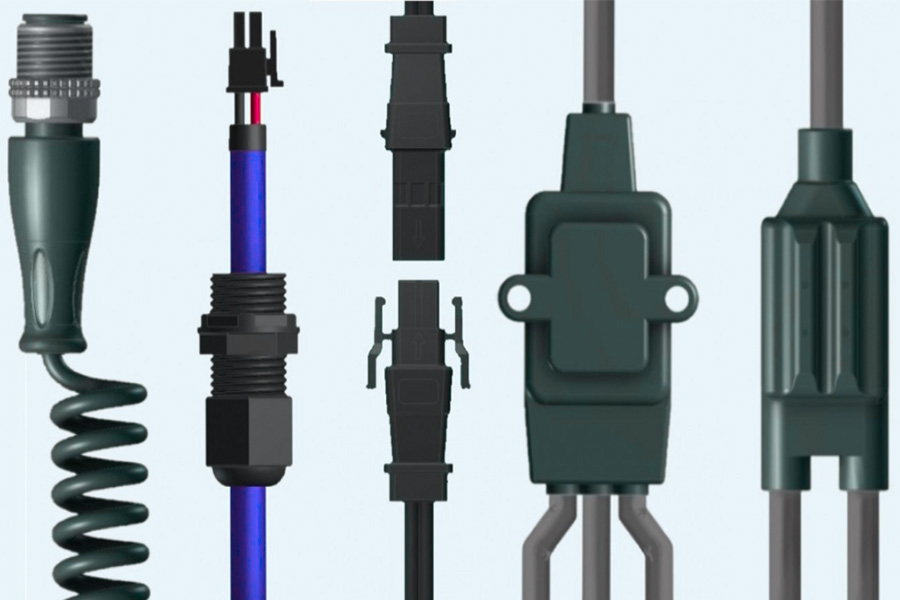

For example: We have developed precision seals for silicone overmolding for medical device customers, and have alsohelped consumer electronics customers realize reinforced joints for cable overmolding.These successes are based on our proven experience.For example, we know which specific TPE (a soft material) can form a really strong chemical bond with ABS plastic.

How to ensure that the hard base part molded in the first injection molding does not deform or melt under high temperature and pressure during the second injection molding? This is a test of the real skills of mold design. We have accumulated a lot of practical skills and know how to design mold structures to avoid these risks.

"As the senior experts in our team often say: the core of overmolding is the art and science of making two materials truly become one."

This guide shares the practical experience accumulated from solving this core problem day by day, not theory on paper. What you see is the insights we have gained from our experience in actual projects.

How is Overmolding Done? - Step-by-Step Explanation

In simple terms,this process is like putting a customized soft coat on a hard plastic partto make it feel better or function better. Take the manufacture of a screwdriver handle with a soft rubber grip as an example.The whole process can actually be divided into two steps:

Step 1: Make the hard skeleton inside (substrate)

- Prepare the mold: We will first prepare a set of very precise steel molds. When this set of molds is put together, the shape of the cavity in the middle is the shape of the hard plastic core in the final handle.

- First injection molding: Pour the hard plastic particles (such as the commonly used PP or ABS) into the injection molding machine and heat it to melt it into a viscous liquid state. Then use high pressure to "beat" the molten hard plastic into the mold cavity just prepared to fill it up.

- Cooling and extraction: Turn off the injection molding machine and let the hard plastic in the mold cool and harden. When you open the mold, we can extract the finished, solid hard plastic core.This is the core component that we will wrap with soft rubber later.

Step 2: Perform overmolding

- Transfer the base part: Put the hard plastic substrate just made into the second set of molds with a robot or manually. This new mold is a little bigger than the first one because the shape of the cavity inside it is the complete shape of the final product. The substrate is placed in the mold and stuck exactly where it should be, leaving space around it to be filled with soft glue.

- Second injection molding:This time, we heat and melt the soft rubber particles (TPE or TPU). Again, injecting high-pressure molten soft glue into the second mold. Here comes the key point: the soft glue does not fill the entire mold, but is precisely injected into the reserved space around the hard plastic substrate to wrap it.

- Bonding and cooling: In the mold, under high temperature and pressure,the melted soft glue will react with the surface of the hard plastic substrate.It may be a slight chemical reaction that sticks together, or the soft glue flows into the tiny bumps on the hard plastic surface, forming a bite. Then, turn off the injection molding and wait for the soft glue to cool, solidify and harden while wrapping the hard core.

- Final product: Finally, open the second mold and we can get a complete screwdriver handle! It has a solid hard plastic core and is perfectly covered with a soft, non-slip rubber grip. The two materials have been firmly combined into a whole. This is a typical plastic overmolding product.

"Overmolding is essentially a two-step process: first make a hard substrate, and then precisely cover the soft rubber layer in a second mold. The key lies in material pairing and precise positioning of the substrate. If your product requires the integration of different materials, I will immediately integrate JS resources to deliver you overmolded parts with stable quality, from material selection, mold coordination to strict production control."

Key Comparison: Overmolding vs. Insert Molding

We often need to explain these two key injection molding processes to customers and internal teams.Insert molding and overmoldinghave basically the same name and are very easy to confuse. The core difference between them is what the object is and where the object comes from.Let me analyze the key points and differences between the two:

(1)Overmolding - Plastic over plastic

Object to be wrapped (substrate): Another plastic part. This part is usually made in advance on the injection molding machine.

Process core:

- Step 1 (making substrate): On injection molding machine A, make the internal hard plastic parts.

- Step 2: Place the hard plastic substrate just formed in the previous step (usually still keeping a certain residual temperature) accurately into the second set of molds. Then, inject the second molten plastic (usually soft glue such as TPE) around the substrate or in a specific area. This new layer of plastic is firmly bonded to the substrate after cooling.The second step is what we call plastic overmolding.

What for? Largely to improve the function or feel. For example:

- Place a layer of soft glue grip on the plastic toothbrush handle, which is comfortable to hold and will not slip.

- On the hard ABS power tool case, a soft TPE is molded in the gripped portion, which is non-slip and shock-absorbing.

Process features: Performed in phases, based on correct mold matching (especially the second pair of molds alignment on the substrate), in a bid to achieve good bonding of the two plastics.

(2)Insert injection molding - plastic encapsulation of non-plastic

Wrapped object (insert): prefabricated non-plastic component.The inserts are not produced together in the injection moldingmachine but are added after they have been manufactured elsewhere.

Typical material: metal (screws, nuts, pins of connectors, heat sinks), circuit boards (PCBs), ceramic components, etc.

How is it done? The procedure is surprisingly effective:

- Step 1: Place metal or other material inserts into the mold in predetermined positions by workers or automatic devices in advance.

- Step 2:Close the mold and feed the plastic melt into it once.The melt flows in the mold, wraps and holds the insert closely, and becomes an integral part after cooling.

Core purpose:

- It is mainly utilized to fasten mixed material components securely, enable subsequent assembly to be easier, or introduce special functionality to plastic parts. For instance:

- Plastic knob of the door handle is cast with a brass nut, so that the screw can be screwed in directly, which is very strong.

- The electronic product PCB is well wrapped and encapsulated by a plastic cover (also encapsulation), whichprotects the circuit, insulates, and provides structural strength. One-molding reduces assembly cost.

Overmolding and insert injection molding process: global typical application field distribution

| Application Fields | Overmolding | Insert Molding |

| Consumer Electronics | ≈40% | ≈30% |

| Automotive Electronics/Whole Vehicle | ≈15% | ≈35% |

| Tools&Hardware | ≈25% | ≈10% |

| Personal care products | ≈20% | <5% |

| Medical equipment/devices | ≈10% | ≈10% |

| Industrial equipment/machinery | <5% | ≈20% |

| Other fields | <5% | <5% |

Data source:

- Grand View Research - Global Injection Molding Market Analysis Report (2023).

- Statista - Market Data & Outlook for Advanced Molding Technologies (2023 Synthesized Projections).

Key points of difference between the two:

- Overmolding always has two plastics involved (substrate + coating), and the process is separated into two steps (first make the substrate, second make the coating).

- Insert injection molding solves the problem of the relationship between non-plastic and plastic inserts. The process is a one-stage process. The secret is to carefully position the pre-fabricated non-plastic inserts in the mold in advance, and then bind and cover them with plastic at once.

"At JS, we choose the best process based on the product design needed: if having certain functions or tactility layers applied to plastic parts is necessary, use overmolding. When non-plastic parts such as metal parts and circuits must be deeply integrated into plastic parts' ends, insert injection molding is used. Understanding this basic difference is where the correct decision starts."

Applications and CasesInfinite: Possibilities of Overmolding

Overmolding injection molding is a process that simply combines materials with different properties(such as hard plastic and soft rubber) in one or more injection molding processes. It can bring great improvements to products. Here are a few examples to illustrate its capabilities:

"True design wisdom is to make materials and processes a silent solution. Overmolding is the perfect tool to achieve this goal. -Paul N. Gardiner Injection Molding Handbook"

Case 1: Improving Hand Feel and Control - Rubber Coating First

Common Products: The handles of electric drills, frying pans, and toothbrushes you are familiar with.

Core Value:

The key is the hand feel! A layer of soft rubber is wrapped around the hard plastic, which is comfortable to hold and non-slip. The benefits are so real: when doing things, your hands are not easily tired, and it is not easy to slip and fall out of your hands. It can also greatly reduce the vibration of the machine (so that your hands are not numb), and the overall use is safe and labor-saving.

Case 2: Waterproof and dustproof - protect circuits and electronic devices

Common products: the small interface part of the mobile phone charging head, the environmental monitoring equipment hanging outdoors, andthe portable inspection instrument in the hands of doctors.

Core value:

- The essence of this trick is the word "sealing". Wrap a layer of plastic or rubber directly on the outside of the fragile electronic parts or the joint of the entire shell. This is like wearing a seamless raincoat for the device, effectively blocking the invasion of water vapor and dust.

- At the same time, this layer of wrapping can also buffer the impact caused by bumps and greatly extend the life and reliability of electronic products. Outdoor equipment and medical equipment especially need this kind of protection.

Case 3: Appearance is strength - multi-color overmolding injection molding

Common products: the two-color function keys on the keyboard, the delicate powder box lid or lipstick tube, and the conspicuous brand logo on the product.

Core value:

- Through precise control, plastics of different colors and even different materials can be easily combined in a one-time molding process, with clear and neat lines, and will not fall off or fade as easily as sticking them on later.

- The patterns and logos made will always remain clear and bright, and the overall look is more upscale. This advantage is of great help in shaping the brand image, improving the texture of the product, or making the key components more eye-catching, so that people can recognize your products at a glance on the shelf.

Overmolding is not just a manufacturing step,it actually solves three key problems of the product: improving grip comfort and safety, ensuring the sturdy protection of electronic components, and enhancing product appearance and brand recognition. This process makes the product both easy to use and good-looking.

FAQ--Answer All Your Questions about Secondary Injection Molding

Question 1: What is the key to overmolding design?

- Material selection: The first layer of material (substrate) and the second layer of material (coating) must be able to really stick together, which is chemical bonding. For example, the PC plastic and TPU rubber we often use are a good match.

- Physical connection: If the material itself does not have enough adhesion. We design some grooves, small holes or barbs on the surface of the substrate. In this way, the second layer of material can be stuck to the first layer when injected, forming a reliable physical connection.

- Uniform thickness:The wall thickness of the two layers of material should be kept uniform as much as possible. The most feared thing is that the thickness difference is large, and the uneven cooling shrinkage will cause deformation, dents or bending.

- Contact us: The most reliable thing is to send us your ideas during the design stage to chat! We have a detailed "Secondary Injection Design Guide PDF" to share, and we can also give direct and practical suggestions for your specific design to help you avoid problems.

Question 2: What is the rubber overmolding process?

- Process essence: Rubber secondary injection molding or rubber overmolding, which is often referred to in the industry, is the core of coating soft materials such as thermoplastic elastomers (TPE/TPV) orliquid silicone rubber (LSR)on a hard substrate by injection molding. Its basic process flow is the same as the general secondary injection molding mentioned above.

- Material selection is the key: Whether TPE/TPV or LSR is used as the soft rubber layer, the most important success factor is that the soft material must be compatible with the underlying hard substrate.

- Special attention to LSR: If liquid silicone rubber (LSR) is used for coating, it is important to note that its molding process has its own characteristics: it is injected into the mold in a liquid state, and then vulcanized (cured) into the final elastomer by heating.It usually works well in soft rubber applications with high precision requirementsor thin-wall molding.

Question 3: Can plastic overmolding be performed on metal?

Absolutely feasible! We often do plastic overmolding on metal parts. This is definitely a mature and reliable process.

The core method is similar to insert injection molding. In actual operation, we will put the pre-processed metal parts as "inserts" into a special mold, and then directly inject plastic outside it. The biggest advantage of doing this is that it can perfectly combine the strength and rigidity of metal with the lightweight and insulation of plastic.

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

Summary

Overmolding is far more than just wrapping a shell around the outside of the part! What really makes it powerful is that it combines hard and soft materials together to create a performance combination that cannot be achieved by a single material. Tool grips that feel great, electronic interfaces that are waterproof and dustproof, and medical parts that are comfortable and easy to clean are all advantages brought by this process.

Why choose the JS team to help you with your overmolding project?

- Intervention in the design stage: Evaluate your design as early as possible to optimize the structure, material selection and bonding area.

- Material science support:Use our processing experience of more than 100 materialsto help you choose the best material combination.

- Precision molds and processes: With high-precision molds and strict control, ensure that every injection molding is perfectly combined.

- Complex insert experts: Whether it is metal parts, electronic components or other inserts, accurate positioning and reliable coating can be achieved.

Act now to accelerate the implementation of your ideas:

If you are conceiving or designing a product that needs to combine the advantages of multiple materials, please contact us now!

Even if it is a preliminary idea, we are happy to discuss the possibilities with you. Talk directly to our senior engineers. Let us understand your product goals in depth.We will provide professional feasibility assessments and preliminary solutions based on your needs.