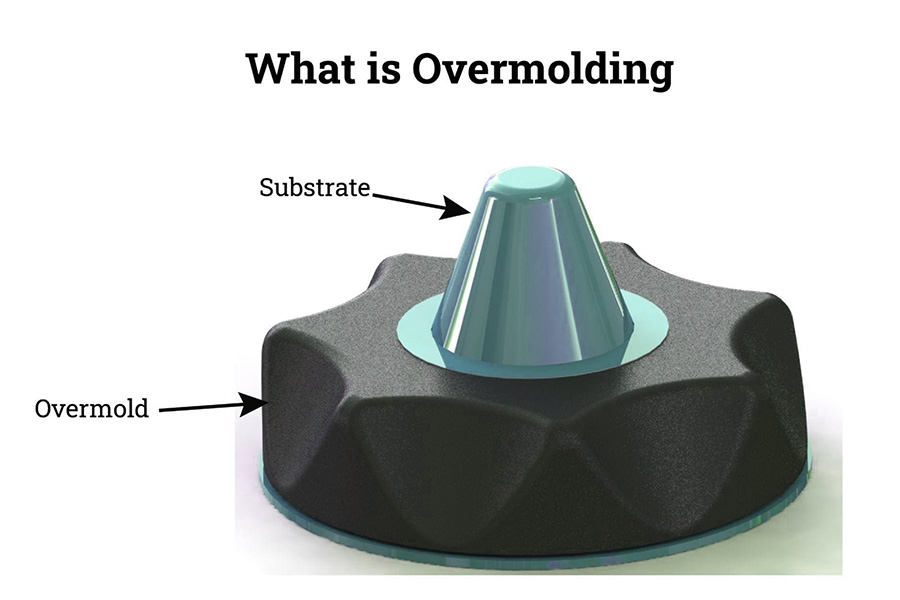

Overmolding, in simple terms, is a process of injection molding where a plastic (usually a rubber-like TPE) is injected on top of another existing part (substrate) directly. The most common substrate is a hard plastic part, but it could also be metal or otherwise.

The biggest advantage of doing this is that it can perfectly combine the advantages of the two materials into an integral part, which not only saves the trouble of subsequent assembly, but also can produce richer surface effects and improve the overall quality and practicality of the product. Because of these advantages,overmolding technologyis widely used in various industries.

What is overmolding?

The most common way to make plastic parts is injection molding: inject molten plastic into the mold, and you can get a solid part after cooling. But if you want to make a more complex and functional product, engineers need to use some advanced techniques when injecting. Among them, overmolding is a very common and critical technology.

The core of the overmolding process is to directly coat a layer of new material on the outside of a pre-made part (called a substrate, usually hard plastic or metal). The outer layer of material is usually soft, which not only provides better hand feel or anti-slip properties, but also can change color as needed, and even make elastic foam materials.

The biggest advantage ofthis process is one-time molding: it can tightly combine the strength of the hard substrate and the special properties of the soft coating layer (such as soft touch, elasticity, etc.) into an integral part.

What key stages are required to achieve overmolding?

1. Prepare the mold andpositionthe substrate

A set of special molds is required. The core functions of this set of molds are twofold:

- Fix the base part (substrate) firmly: usually hard plastic or metal parts.

- Leave a molding cavity: the shape of this cavity is the shape of the new layer of material that will be coated on the outside of the substrate in the future.

2. Treat the substrate

In order to make the newly coated material and the substrate tightly bonded and not fall off,the substrate surface must be treated in advance.

Common treatment methods include: thoroughly cleaning to remove oil and dust, applying a special adhesion promoter, or performing special surface treatment (such as slight etching) to increase bonding strength.

3. Injection of coating material

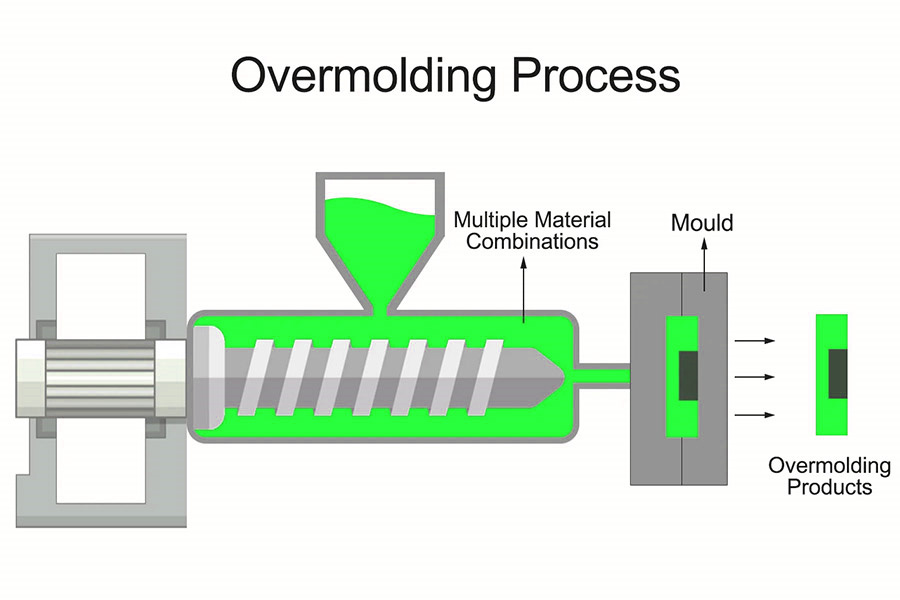

This is the core molding step of overmolding, which is to accurately place the processed substrate into the mold and fix it in place.

The key step is here: heat and melt the selected coating material (usually soft materials such as thermoplastic elastomers).

Then,through the overmolding injection molding process, the molten coating material is quickly injected into the cavity reserved in the mold under high pressure. Of course, other methods such as insert molding, transfer molding, casting or compression molding are sometimes used according to product needs.

4. Cooling and shaping/heating and curing

After the injection is completed, the material needs to be shaped in the mold.

If common plastics (thermoplastic materials) are used, cooling is mainly used to harden the coating layer and firmly adhere to the substrate.

If special materials (thermosetting materials) are used, the mold needs to be heated first to make the material undergo a chemical reaction and solidify, and then cooled to demold. The core is to make the two bond into one.

5. Demolding and post-processing

After the parts are completely cooled and solidified, the mold can be opened and the molded parts can be taken out.

At this point, there may be some excess plastic edges (also called flash or burrs) on the part that need to be trimmed off.

Finally, the necessary surface treatment is performed according to the product requirements, such asadding specific texture effects or polishingto make the final product look and feel as required.

What are the different overmolding methods?

1. Two-Shot Molding

Core process:

This method uses an injection molding machinewith two independent injection units and a special mold. First, the first part, which is usually made of hard plastic, is injection molded in the mold. The mold is then automatically rotated or moved to another position, and the second material is injected directly on the specific area where the first part has been molded.The second materialcan bea softonesuch as TPE or silicone.

Main purpose:

Its advantage is the efficient manufacture of tightly integrated dual-material one-piece parts. This can achieve aesthetic effects, functional zoning (hard main structure with soft grip area) or sealing functions. This method is very applicable whether it is overmolding plastic, which uses a second plastic to cover the first plastic, or silicone overmolding, which uses silicone to cover plastic parts.

2. Insert Molding

Core Process:

The first step of this method is to place the pre-made parts (called inserts) into the mold and fix them accurately. These inserts can be metal parts, such as screws, electrodes or connectors, or plastic parts.After closing the mold, moltenplasticorrubberis poured into the mold cavity. These products willsurroundthe designatedareaof the insert and willbecome securelybonded to the insertwhen cooledone.

Main purpose:

Createareliable metal-plastic or rubberbond. Doing so cansignificantly enhance the structural strengthof the final part, provide electrical insulation performance, achieve effective sealing, or greatly simplify subsequent assembly processes. Rubber overmolding often uses this method to form the required sealing ring on the outside of the metal part or provide a grip part that provides a comfortable grip.

3. Co-injection (sandwich molding)

Co-injection uses a special injection device to inject two materials into the same mold cavity sequentially or simultaneously in a tight process to form a core-skin layered structure. The core advantages are:

- Optimize costs: The core layer uses cost-effective materials, and the skin layer uses high-performance, beautiful or tactile materials. For example, plastic overmolding can use recycled PP core and TPE skin to make tool handles, taking into account strength, cost and anti-slip properties. Similarly, cable overmolding also adopts this low-cost core + high-performance skin combination strategy.

- Improve appearance and function:The skin layer determines the appearance and touch of the part, and can achieve high-end surface effects. Design freedom supports two-color or gradient.

- Enhance functionality: The core-skin combination can achieve specific functions, such as foamed core to reduce weight/sound insulation + dense skin sealing, or high-barrier core to extend shelf life + easy-to-print skin.

Overmolding vs insert molding: How to distinguish?

Overmolding and insert molding are both advanced processescommonly used in the manufacturing industry. They can cleverly combine different materials into a single part at one time, eliminating subsequent assembly, bonding and other steps, thereby improving production efficiency and the performance and reliability of the final product. Although the goals are similar, both methods are to achieve multi-material combination, but the implementation principles, cost structure and applicable scenarios of these two methods are significantly different. Let's compare them in detail:

1. Process principle:

Overmolding:

- First step of injection molding: First use hard plastic (called substrate or base) to make the first part in the mold.

- Second step of injection molding: Wait for the first part to cool in the mold or take it out while hot and immediately put it into the second mold, or in another cavity of the same mold, inject the second material (usually soft material such as TPE, rubber) to cover the specific area of the first part.

- Combination: After cooling, the two materials are physically or chemically combined on the contact surface to form a solid integrated part.

Insert molding:

- Insert placement: Before plastic injection, a pre-manufactured part (called an insert) is accurately placed in a specific position of the mold and fixed.

- One-shot injection: After the mold is closed,plastic melt isinjectedstraightinto the mold cavity tocoverthe specifiedsectionof the insert.

- Fixed: After the plastic cools and shrinks, it will tightly wrap and lock the insert to form a mechanically combined or physically integrated one-piece.

2. Production speed:

Single molding time: If you only compare the action time of molding in the injection molding machine, insert molding usually has an advantage. Becauseit only requires one plastic injection and cooling cycle.

Overall process time:

- Overmolding requires two complete injection molding cycles (two mold closing, injection, pressure holding, cooling, mold opening), so the machine occupancy time is usually longer.

- But the speed advantage of insert molding depends on the availability of ready-made metal inserts. If thesemetal inserts need to be customized, the pre-processing/procurement time of the customized metal parts must be included in the overall production cycle. In this case, the total manufacturing time may not be shorter than overmolding.

- Insert placement is usually manual or requires special equipment. This operation also takes time and needs to be accelerated through automation in mass production.

3. Cost considerations

Both processes avoid subsequent assembly and bonding costs, can significantly improve production efficiency and yield, and can effectively reduce costs and increase profits in mass production.

Comparison of the costs of the two molding processes:

| Cost project | Overmolding | Insert Molding | Explain |

| Mold cost | Higher (usually requiring two sets of molds). | Relatively low (usually requiring only one set of molds). | Encapsulation molding requires substrate molds and encapsulation molds. The insert mold only requires a plastic molding mold. |

| The cost of the insert itself | No (using plastic substrate). | There may be significant costs involved. | The cost of purchasing or customizing metal inserts needs to be included. |

| Equipment and Operation | Two injection molding machines or complex mold transfer mechanisms are required. | Generally, an injection molding machine with an insert placement device. | The investment in wrapping equipment is usually higher. |

| Suitable for bulk production | More suitable for medium to large quantities. | Suitable for both small and large quantities. | When it comes to small batches, the cost of coating molds is high. The cost of inserts can be amortized in large quantities. |

| Single piece material cost | It depends on the amount of two types of plastic used. | It depends on the amount of plastic used and the cost of the embedded parts. | The cost of embedded parts is often much higher than that of plastic parts themselves. |

Core differences:

- Overmolding: The initial mold investment cost is high, especially inthe sample making and small batch trial production stages, the mold cost allocated to each part will be considerable.

- Insert molding: The mold cost is relatively low, but the processing or procurement cost of the insert itself becomes the main influencing factor. If the insert is complex or requires precision processing, its cost may be high, especially in small batches. In large-scale production, the insert cost has the opportunity to be diluted.

4. Typical application scenarios

(1) Overmolding: Its core value lies in creating parts that combine soft and hard and integrate functions.

- Enhancegrip/comfort: Toothbrush handles (soft rubber anti-slipsurface), power tool handles (shock-absorbing anti-slip area), medical equipment grips, razorhandles.

- Improve sealing: Waterproof sealing ring ofelectronic device housing(TPE coated on hard shell).

- Enhance protection/appearance: Mobile phone protective case (hard back shell + soft frame), kitchen utensil handles with anti-slip strips.

- Protect electronic components: USB connector packaging, sensor encapsulation (protecting internal circuit boards or components).

- Multifunctional integration: Integrate buttons, gaskets, etc. into the housing at one time.

(2) Insert molding: The core goal is to integrate reinforcement and increase functionality.

- Provide structural reinforcement/connection: Plastic nuts with metal threaded inserts, metal parts embedded in wrench heads, metal reinforcements at tool handle connections.

- Provide conductive contacts/connections: Metal contacts on electronic switch buttons, conductive terminals onautomotive connectors.

- Embed precision components: Embed small circuit boards (such as antenna boards), sensor components, bearings, guide columns, etc. into the plastic matrix.

- Replace metal parts/reduce weight: Embed metal sheets in plastic to provide local strength (such as automotive interior buckles).

What aspects of overmolding design need to be focused on?

1. Material bonding strength

This is the most critical! The upper layer of coating material must be firmly bonded to the underlying base material. The ideal state is to form a chemical bond, but this depends on the compatibility of the materials. When the viscosity is not strong, physical interlocking design is required:

- Mechanical method: Design grooves, holes, undercuts or rough surfaces on the substrate to allow the coating material to flow in, and form physical anchors after cooling and solidification.

- Chemical method: Select a combination of materials that are naturally attracted to each other and let them combine at the molecular level. This combination is usually tighter, especiallysuitable for parts that require waterproofing and shockproofing.

- Hybrid method: Combining physical interlocking design with chemically compatible materials is a common strategy for the highest reliability, especially for parts that require waterproofing, shockproofing or impact resistance.

2. Temperature resistance

The coating material must be melted at high temperature to form. Both the substrate and the coating material must withstand the processing temperature and cannot deform or deteriorate in performance.

When selecting a material, you must consider how hot the environment it will encounter when it is actually used (such as parts in the engine compartment). Choose a material with a high heat deformation temperature and that is not prone to thermal expansion and contraction.

3. Surface properties and friction

The roughness of the coating surface (friction coefficient) affects the feel and anti-slip effect, and also indirectly affects the adhesion. For example, tool handles and car steering wheels have slightly rough or textured surfaces, which are more stable, comfortable and safer to hold. Materials such as TPE and silicone have good hand feel and strong anti-slip properties.

4. Material selection and thickness design

Choosing the right material combination is the core. It is necessary to balance the strength, toughness, environmental tolerance, special requirements and cost required for the final product. At the same time, the thickness of the coating layer should be designed according to the functional requirements:

- Shock absorption, sound insulation or providing a soft touch usually requires a thicker elastomer layer.

- Too thick a coating layer will extend the production cycle, increase costs and may affect dimensional accuracy. It is necessary to find the best balance between functional requirements and manufacturing efficiency.

Common materials for overmolding:

| Type of wrapping material | Typical materials | Main application scenarios |

| Rigid plastics | PP, ABS, PC, PA | Structural components, shell frame. |

| Soft elastic material | TPE, TPU | Anti slip grip, soft touch surface, cushioned seal. |

| Silicon rubber | LSR | High demand seals, medical components, and high-temperature resistant parts. |

| Metal | commonly used as substrate. | Tools and high load-bearing structural components. |

5. Material hardness

The hardness of the material(usually expressed by Shore hardness A or D) is very important. If it is too hard, it may hurt your hands and be easy to wear. If it is too soft, it may not support and be easy to deform. For example:

- Applications that require shock absorption and comfortable touch: it is advisable to use a lower hardness (Shore A 50-80).

- Parts that need to provide support, wear resistance or withstand pressure: require a higher hardness (Shore A 80+ or Shore D).

Why choose JS as your partner?

1. Ultra-high precision

The tolerance control capability of ±0.005mmis stable in 95% of the projects. Last month, the three-dimensional inspection of titanium alloy joint parts of medical equipment fell into the green zone, and the customer inspection was directly exempted from inspection.

2. Emergency response

When the production line of the automotive customer was out of material, the team took the order at 23:00 and completed the full process delivery of 300 aluminum alloy shells from drawings to finished products within 56 hours, 8 hours ahead of the agreed time.

3. Cost-effective

For injection molded parts processed by old customers, we proactively optimized the wall thickness to 0.8mm (original design 1.5mm). Under the premise of ensuring the pass rate of the drop test, the cost per piece was reduced by $1.2, and the annual material cost was saved by more than $300,000.

Summary

Overmolding is to directly inject a layer of soft glue on a hard plastic part. The parts produced in this way have both hardware support and the comfort, anti-slip or sealing functions of soft glue.

Although the process is more complicated and costly than ordinary injection molding, it can improve the feel, enhance durability, and save assembly steps. Therefore, many industries will consider it when making high-quality products. Knowing thesecan help you determine whether it is suitable for your project.

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

FAQs

1. Which parts can be overmolded?

Parts that can be overmolded include tool handles, electronic device housings, medical instrument grips, toothbrush handles, kitchen utensils, and other functional parts or ergonomic parts that require the combination of multiple material properties.

2. How does overmolding work?

Overmolding is divided into two steps: first, the hard base part is injected, and then it is placed in the mold after cooling, and then the molten soft glue is injected to cover the surface, and the integrated component is formed after thermal bonding and cooling.

3. What are the benefits of overmolding?

Enhance grip and anti-slip properties, improve product sealing and shock absorption performance, achieve seamless combination of materials, reduce assembly costs, and improve durability and aesthetics.

4. Why is overmolding popular?

Overmolding is popular because it efficiently integrates different material properties, reduces assembly steps, saves costs, improves product anti-slip, shock absorption and aesthetics, and enhances durability and sealing.