We often see customers curious about how metal chassis and brackets can be transformed from flat plates into three-dimensional parts. In fact, the trick lies in this bending. Use a bending machine to apply force accurately to bend the metal plate into a V-shape, U-shape and other angles according to the design.This is the basic craft of sheet metal processing.

From very thin plates to daily steel plates a few millimeters thick, they are all within our processing range. The key is to calculate the inner curvature of the bend and ensure that it is greater than the thickness of the plate, so that the bend will be strong and will not crack.

We mainly rely on various bending machines to work with molds.

According to the requirements of the workpiece and the characteristics of the material,choose different bending methods(such as air bending and V bending). Turn the design on the drawing into a three-dimensional object. Behind this seemingly simple bending and folding is experience and precise calculation.

Summary Of Key Answers:

| Aspect | Describe | Value to you |

| Core principle | Apply external force to the metal sheet to permanently deform it, forming a specific angle and shape (such as V-shaped, U-shaped). |

Efficiently convert 2D sheets into 3D structural components.

|

| Main processes | Press bending is a mainstream method that uses a punch and mold to achieve bending. | Suitable for single piece prototype production until mass production. |

| Common types | Basic bending methods such as V-shaped bending, U-shaped bending, and curled edges. | Can design and manufacture various parts with different structures and functions. |

| Key considerations | Bending radius (affecting strength), rebound (elastic recovery), K factor (calculating unfolded length). | Directly affecting the accuracy and quality reliability of the final product. |

This article will answer your questions:

- This guide will help you understand the meaning of metal bending,

- Analyze the most commonly used metal bending methods,

- Give you some practical design tips,

- The ultimate goal: to help you have a better understanding and do a better job when designing and manufacturing metal parts.

Why Should You Trust This Guide? The Real Experience of JS Sheet Metal Experts Tells You

At JS,bending is the mostthing we deal withon a daily basis, but it isnot justabout being a masterwhooperatesbending machines. We aremore like engineers whocanhelp customers solve structural problems. Over the past decade, we haveproducedthousands of precision sheet metal parts in electronics factories, construction sites, and machinery and equipment.

What makes this guide worthy of your trust? It relies on the real skills we have accumulated in the workshop every day:

- We know: How to calculate the annoying rebound amount accurately so that each 90-degree angle is tightly fitted. This is not written in the book, but the feel of the machine after countless adjustments.

- We know:How to choose the most suitable mold when encountering materials of different thickness and temperament.

The method in the guide is not a theoryquotedfrom a textbook, but a trick we figured out when we were working and solving practical problems every day.In fact,Master Zhang, who hasbeen workinghere for 20 years,alwayssaid that,

"Don't just look at the formulas on the letter paper, the real skills are hidden in the iron filings in the workshop. This guide is what we have summed up in solving practical problems every day. "

The Principle of Metal Bending: The Science of Making Metal "Yield"

"The essence of metal processing is the art of forcing materials to yield within a precisely controlled range. -- James F. Lehr, an authority in the field of precision manufacturing."

As this true knowledge says, we must first understand that bending is not to break the metal abruptly, but to cleverly use its own plasticity. That is, on the premise of ensuring that the material is intact, a large enough force is applied to make it exceed the yield point, resulting in irreversible permanent deformation,thereby shaping the shape we need (such as V-shaped, U-shaped). Ultimately, understanding how the material changes internally when it is bent is the most important thing.

The boundary between elasticity and plasticity:

- Initial stage (elastic deformation):When we start to bend a piece of metal sheet with force, it is initially stiff.Just like when you press a spring lightly with your finger, it will deform, but as soon as the force is removed, the material will completely return to its original shape.

- Critical turning point (yield strength): When the applied bending force continues to increase and exceeds a critical value of the metal (we call this the yield strength), the situation changes.

- Target stage (plastic deformation): After exceeding the yield strength, the metal material begins to deform plastically. At this point, even if the external force is removed, the material cannot completely return to its original shape, but permanently retains some deformation. When we do bending processing, we have to cleverly control the force so that the metal sheet just crosses this critical point andenters the stage of plastic deformation, so that the bent shape will be fixed.

Stretching and compression:

Imagine that you bend a card. At the bend, is the outermost material stretched? And is the innermost material squeezed together and shortened? The same is true when a metal plate is bent: the outer side is stretched and the inner side is compressed.

Then the question is, between the stretched outer side and the compressed inner side, there must be a special middle layer, which we call the neutral axis. This layer is neither really stretched nor really shortened during the bending process, and its length remains basically unchanged. The position of this neutral axis is the key to calculating the actual length of the metal plate after bending!

The key to calculating the unfolded length--K factor:

The neutral axis mentioned above is not necessarily exactly in the middle of the thickness of the metal plate!We use a decimal to represent how much it is offset, which is the K factor. It is a decimal between 0 and 1 (usually 0.3 - 0.5).

This value is crucial for us to calculate the unfolded length of the metal plate after bending. Different materials, different bending methods, and even different molds will affect the size of the K factor. This is a very core parameter in our process.

Dealing with springback after bending:

Elastic recovery: Even if the material is successfully plastically deformed during the bending process, the force of its previous elastic deformation has not completely disappeared. Therefore, when you remove the die that bent it, the metal sheet will rebound slightly, just like a stretched rubber band when you let go! This phenomenon is called springback.

Result: This causes the actual angle you bend to be slightly larger than the angle set by the die. For example, if you bend with a 90-degree die, the actual angle may become 91 or 92 degrees after releasing it.

How does the JS team deal with this situation?

Springback is an inevitable phenomenon, and we have a way to deal with it! The core experience accumulated by our JS team in long-term practice is:

Overbending:

This is the most commonly used method.We pre-set a bending angle smaller than the target angle for processing. For example, if the target is 90 degrees, we may set the die to 88 or 87 degrees for bending. In this way, when the sheet rebounds, the angle just bounces back to the 90 degrees we need.

Custom Compensated Tooling:

For high-volume, high-precision production, we design and manufacture special tooling with special compensation angles. The angle of the tooling itself has taken into account the amount of springback, so that when it is pressed down and released, it will naturally be the target angle.

"Metal bending is both a science and an art of craftsmanship. Are you pursuing the perfect sheet metal bending effect? With professional process knowledge, simulation calculation tools and rich practical experience, the JS team can solve the most complex bending challenges for you. "

Mainstream Metal Bending Methods and Technologies

Press Brake Press Bending - Our Main Weapon

Working Principle: Imagine placing a metal sheet on a V-shaped groove (we call it the lower die) and then using a punch of matching shape (we call it the upper die) to press down from above. The metal sheet is clamped in the middle and, under strong pressure, obediently bends along the V-shaped edge of the lower die.This is the basic principle of press brake processing. We rely on it to complete most precise angle bends.

Three common pressing methods:

(1)Air Bending:

The most flexible and most used! This method allows the upper die to press down, but does not completely press the metal plate to the bottom of the lower die.The bending angle is determined by controlling the depth of the upper die pressed into the lower die.The deeper the pressure, the deeper the angle. The shallower the pressure, the larger the angle.

What are the advantages? A set of molds can be bent into many different angles, with fast exchange speed and high efficiency! Guess which one is used for more than 90% of the processing in our workshop? Yes, it is this one!

(2)Bottoming:

Higher precision and less rebound. This time, the upper die will press the metal plate tightly to the side wall of the lower die.The final bending angle is basically determined by the shape of the mold itself, unlike air bending, which depends on the depth of pressure.

- The advantage is that the pressure is solid, the rebound is less than air bending, and the angle is more stable.

- The disadvantage is that a set of molds can basically only correspond to one angle, and the mold must be changed when the angle is changed.

(3)Coining:

It is very powerful, but it is rarely used. It requires very high pressure (several times greater than the previous two) to completely squeeze the metal sheet into the gap between the upper and lower molds, so that the material can be shaped in the mold. This can almost completely squeeze out the rebound and has extremely high precision.

However! The machine tonnage requirements are too high, the mold wears quickly, and the cost will increase. Now, unless the precision requirements are extremely high or special materials are used, we generally don't use this method.

Comparison of the characteristics and requirements of the three bending processes:

| Characteristics/Requirements | Air Bending | Bottoming | Coining bending |

| Required tonnage | Low (≈ 20-40% of Coining) | Medium (≈ 1.5-2.5x Air Bending) | Extremely high (≈ 4-10x Bottoming, 8-25x Air Bending) |

| Angle accuracy (typical tolerance) | ±0.5° - ±1.5° | ±0.25° - ±0.75° | < ±0.25° |

| Rebound control | High (dependent compensation) | Medium to low (good) | Extremely low (almost eliminated) |

| Mold lifespan | The highest | Medium | Minimum |

| Mold universality | Extremely high (one model for multiple uses) | Low (mainly for single angle use) | Extremely low (dedicated) |

| Application scenario ratio | > 85% | ≈ 10-12% | < 3% |

Core data sources:

- Precision Metalforming Association (PMPA) - Precision Metalforming Association (USA)

- International Journal of Advanced Manufacturing Technology - "International Advanced Manufacturing Technology Magazine"

- Fabricating & Metalworking Magazine - "Fabricating & Metalworking"

Other common bending technologies:

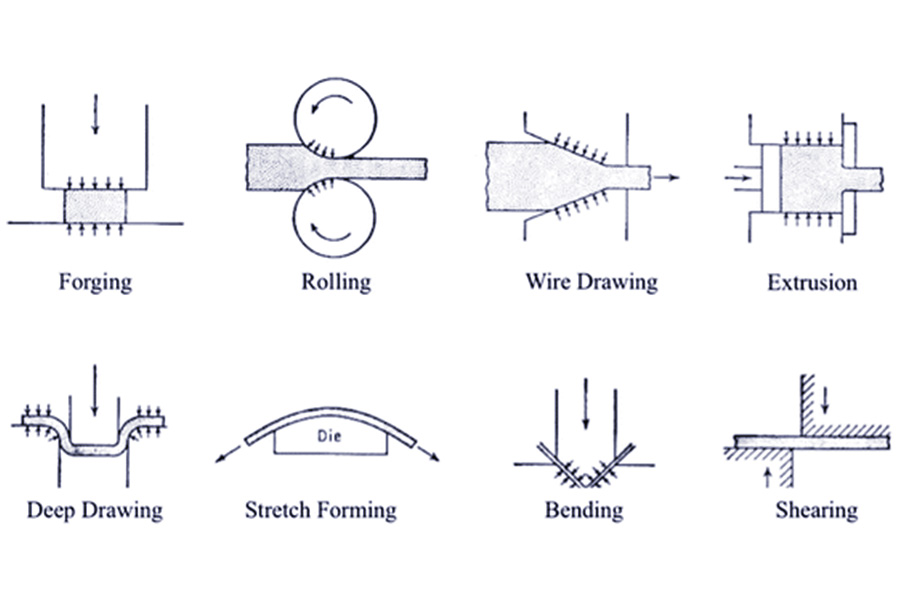

In addition to the press bending (especially air bending) technology commonly used by bending machines, there are several important bending processes suitable for different scenarios:

(1)Rolling:

- Functional characteristics: Specially used to continuously bend metal sheets into large radius arcs or form closed cylindrical components.

- Typical applications:Manufacturing ventilation ducts, large storage tank bodies,curved building roofs, curtain wall panels and other parts that require large curvature radius forming.

- Equipment principle: A rolling machine with a three-roller or four-roller structure is usually used. The sheet passes through the middle of these rollers, and by adjusting the position and pressure of the rollers, the sheet can be smoothly and continuously bent into an arc or a complete cylinder.

- Process advantages: It is suitable for theproduction of large curved or cylindrical sheet metal parts, and is the core process for the manufacture of such products.

(2)Folding:

- Functional characteristics: This method is particularly suitable for bending the edges of large plates, or processing some relatively complex box parts.

- Application scenarios: It is more advantageous when the part size is too large to make the bending machine difficult to operate, or when the part structure involves complex edge folding.

- Equipment principle: Use a folding machine. It is characterized by a "bending beam" (swinging beam) that can be lifted. During operation, first clamp the plate on the table, and then the bending beam moves up or down along the set trajectory to bend the overhanging part of the plate.

- Process advantages: It has good visibility and ease of operation for the edge bending of large plates, andcan efficiently complete more complex edge folding structureswith a relatively high safety factor.

"On the JS production line, the bending machine is the absolute main force, responsible for most of the precise angle bending. Faced with super large plates or complex box structures, the folding machine is the best choice. If you have a metal bending project on hand, please feel free to leave it to our JS team!"

4 Basic Bending Types and Their Applications

Next, we will show youthe four most common basic bending types in sheet metal parts. Knowing these, you can better play the advantages of sheet metal technology when designing. The drawings you draw are not only beautiful, but also easy to make in our workshop and more cost-effective!

4 basic bending types and their applications

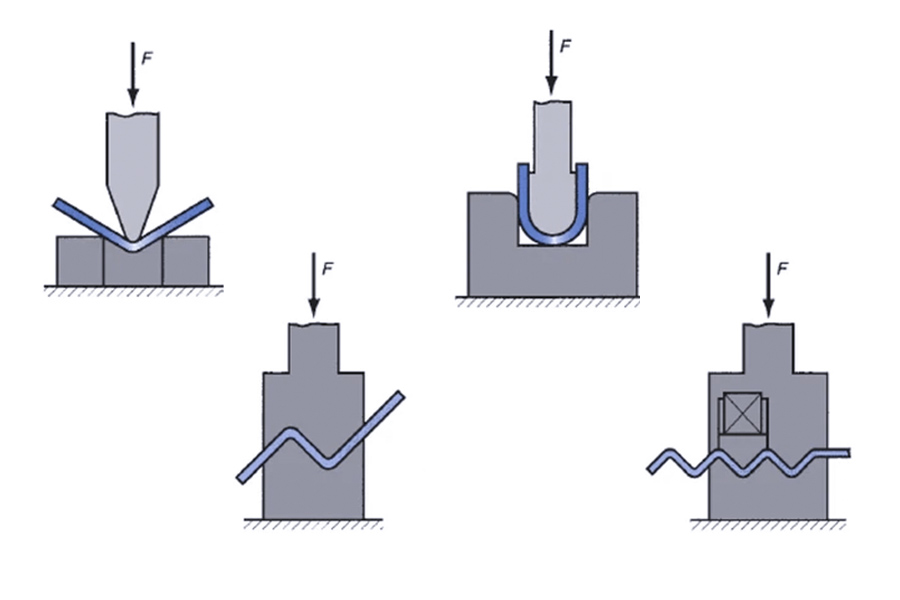

The first type: V-Bend-basic general bending

Process description: Using the V-shaped lower die and matching upper die (punch) of the bending machine, pressure is applied to a specific position of the sheet to form a bend with a specific angle.This is the most basic and widely used bending method.

Typical applications: Applicable to most sheet metal structural parts that need to form an angle.

For example: support angles of various brackets, edge bending of equipment chassis/casings, flanging of mounting panels, etc. Its advantages are mature technology, strong mold versatility, and high efficiency. It is the main process for daily production in the workshop.

Second type: U-Bend - Double bends in one step

Process description: Using a special U-shaped upper die and a corresponding lower die groove, two parallel bends in the same direction are formed on the sheet at the same time through a single stamping stroke, and finally a U-shaped section is obtained.

Typical applications:Mainly used to manufacture parts that require a U-shaped section.

Typical examples include: U-shaped troughs, channels for cable or pipeline routing, slots for sheet metal fixtures, mounting rails in electrical cabinets, etc.

Compared with making two V-shaped bends separately, U-shaped bends can significantly improve production efficiency, ensure the parallelism and dimensional accuracy between the two bends, and areespecially suitable for mass production.

Third type: Z-Bend - Achieve height difference connection

Process description: Completed through two bending operations in opposite directions. First, make the first bend at one end of the sheet (for example, 90° downward), and then make the second bend in the opposite direction (for example, 90° upward) at the appropriate position, finally forming a stepped profile similar to the letter "Z", creating a height offset between the two planes.

Typical applications: The core value lies in solving the connection problem between different planes.

For example: a sheet metal part needs to span and overlap another sheet metal part of different heights. The panel design needs to avoid the raised structure on the back (such as ribs, welds or components), or provide an alignment step for assembly. When your design involves height misalignment, Z-bending is usually an effective structural solution.

The fourth type: Hem Bend

Process description: A special processing process for the edge of the sheet, usually completed in two steps. First, the edge is pre-folded at a small angle (commonly 90°). Subsequently, this pre-folded edge is further flattened to fit tightly back to the sheet body, completely wrapping the original edge.

Typical applications:

- Enhance edge rigidity: By increasing the edge thickness, the overall structural strength and deformation resistance of thin plate parts are significantly improved, especially for edges that are subjected to force or are easily deformed.

- Improve safety and aesthetics:Completely eliminate sharp burrs and edges produced by shearing or laser cutting, provide a smooth and safe touch, and give the edges a neat and professional appearance. Widely used in edges that require user contact (such as cabinet door edges, drawer panels), thin-walled components (such as shell side panels), and products with high requirements for appearance quality.

Key suggestions for designers:

- Basic angle forming:V-shaped bending is the first choice. Efficient and versatile, meeting most corner folding needs.

- U-shaped section components: U-shaped bending is used. Double bending is formed in one step to ensure accuracy and efficiency.

- Spanning plane height connection: Choose Z-shaped bending. Create precise steps to solve assembly misalignment problems.

- Edge reinforcement and protection: Apply hemming (Hem). Improve strength, eliminate burrs, optimize appearance and safety.

"JS engineers suggest that during the design process, clarify the functional requirements and assembly relationships of the parts in order to best select the most appropriate bending type. This will not only optimize the structural performance but also significantly enhance the feasibility and cost-effectiveness of production. Please do not hesitate to discuss specific bending process or design details with our JS team if you have any questions. We shall give you professional help based on our rich engineering experience."

FAQ -- Answer All Your Questions About Metal Bending

Question 1: What can metal bending do?

It simply means that we can make a flat, inexpensive metal plate become a three-dimensional part that bears load and is practically useful using our machines and experience.

From drawing lines to the box, shelf or machine shell in your hand, is this bending process the most fundamental and important step? It makes ideas turn into physical objects quickly, well and economically!

Question 2: Is there a difference between metal bending and sheet metal bending?

Lots of people wonder about this! Metal bending is a generic term. In theory, any metal can be bent-of course, it varies in difficulty. The term sheet metal bending is specific and describes the bending of relatively thin metal sheets or sheets, usually under 6mm in industry practice. These terms are exchanged and generally refer to sheet metal bending in most industrial manufacturing scenarios, especially when they refer to processing thin plates.

Question 3: What martial art is metal bending based on?

This is an interesting question! Metalbending comes from "Avatar: The Last Airbender" and was created by the character Toph Beifang. Its action is based on Hong Jiaquan, a Chinese southern martial art that emphasizes a stable lower body and strong, straight-line attacking skills.

Of course, in the real manufacturing field (such as our JS team), the core of our precise control of metal is not based on martial arts, but high-performance hydraulic bending equipment and engineers' rich practical experience based on materials, but in the precise control of metal forces, there are indeed similar pursuits.

Question 4: How to obtain PDF materials for sheet metal bending processes?

Although there are many common PDF materials on the Internet, it is often easy to fall into traps due to their universality!

What causes this problem?The specific situation of each project is very different, with different materials, thicknesses, angle requirements, and machines. Therefore, the most reliable method is to communicate with experienced engineers.

Our JS team is free for design consulting. Submit your design sketch and our engineers will give you a professional process evaluation and suggestions. If you need a written reference, we can provide you with a practical guide "Sheet Metal Bending Process Core Points Reference" (PDF) summarizing key design parameters. Contact us for a copy.

Summary

Metal bending is much more than just "bending with force". It is a technology that precisely blends material properties, mechanical principles and practical experience. Understanding the core concepts of yield strength, neutral axis, K factor and springback, and mastering basic processes such as V-bend, U-bend, Z-bend, and hemming are the foundation for us to continuously andstably manufacture sheet metal partswith strong structure, precise dimensions and controllable costs. Behind every precise bend is the adherence to scientific principles and the embodiment of countless practical accumulation.

Let the JS team be your solid and reliable manufacturing partner!

When your design drawings need to be transformed into high-quality metal products, it is crucial to choose a partner with deep technical accumulation and rich engineering experience.

If your next project involves metal bending or sheet metal processing, theJS team is ready to provide you with professional support at any time:

Expert team, escort throughout the process: We are not simple operators. From the moment you send the drawings or 3D models, our experienced engineers (such as me) will intervene:

- In-depth analysis of your design intent and functional requirements.

- Evaluate material selection and process feasibility, and identify potential challenges.

- Develop optimal process routes and precise processing parameters, including accurate expansion calculations, K factor application, and springback compensation strategies.

- Advanced equipment, precise execution:JS workshops are equipped with mainstream precision bending machines, laser cutting machines, CNC punching machines and other equipment to ensure that engineering plans are accurately and efficiently transformed into physical objects.

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com