Having been dealing withsheet metal componentsin the JS workshop for so long, I have seen too many such experiences: the components that I designed so carefully went wrong as soon as they reached the metal bending process, the corners were destroyed, or the angles were not able to achieve the standard. In this situation, people are likely to suspect the machine parameters or operation procedures firstly, but actually the original cause is mostly the first one: improper choice of materials.

Whether metal can be bent and formed smoothly depends on its plastic deformation ability, which is what we often call ductility. This refers to how much permanent deformation the material can withstand before breaking. Another key factor is work hardening, the degree to which the material becomes harder and more brittle during the bending process.

That is, whenmetal being, we would want the grains in the material to slide and deform along with each other, rather than cracking at the point of local stress concentration. Like low-carbon steel (such as SPCC), its yield point isn't very high, and the internal lattice structure has a greater likelihood to slide compliantly, bending smoothly without a tendency to crack.

The reason why the popular 304 stainless steel or 5052 aluminum alloy is utilized as a general material for bending is that they possess fine ductility and work hardening properties that can be controlled, smooth sliding grain, and are difficult to crack or wrinkle.

If you choose the right material, the bending process will be smooth and accurate, and the quality of the parts will be reliable. If you choose the wrong one, it will take time to rework at best, or even the parts will be scrapped. So, which material can withstand bending?This question is definitely one of the key decisions when starting a project, which is directly related to the efficiency and cost of subsequent production.

A Brief Summary of The Core Answer:

| Material category | Formability | Key advantages | Typical applications |

| Low carbon steel | ⭐⭐⭐⭐⭐ (Excellent) | Low cost, easy to form and weld. | Universal bracket, chassis, shell. |

| Stainless steel | ⭐⭐⭐⭐ (Good) | Corrosion resistant and aesthetically pleasing. | Kitchen equipment, medical equipment, and building decoration. |

| Aluminum alloy | ⭐⭐⭐⭐ (Good) | Lightweight, corrosion-resistant, good thermal conductivity. | Aerospace, electronic product casings, automotive panels. |

| Copper/brass | ⭐⭐⭐⭐⭐ (Excellent) | Excellent conductivity and beautiful appearance. | Electrical contacts, decorations, pipeline fittings. |

This article will answer your questions:

- This guide will first take you through the core science behind metal "bendability".

- Next, I will systematically compare the performance and key considerations of commonly used metal materials in bending.

- Then, I will share a real case study of the choice between lightness and strength, and analyze how material selection is a decisive factor.

- Finally, I have sorted out the most common thorny issues you encounter about material selection, and use our accumulated experience to provide you with decision-making references.

Why Should You Trust This Guide? The Truth from The JS Workshop

In our JS workshop, metal is our daily partner. I have witnessed how materials like A36 carbon steel deform smoothly under thebending machine, and I have also personally handled many problems where the material became harder and harder during metal bending and almost cracked because of the wrong stainless steel model (such as some 304 variants).

We know too well that choosing materials is not just as simple as "can it be bent", it is directly related to whether the things you make are easy to use and how long they can last.

JS provides more than justonline bending services. We want to be your engineering partner on the road to product development. From the early stages of design, we help you find the best balance between performance and cost. Every suggestion in this guide is a valuable insight that we have verified with real projects and even paid for.

"As Dr. Robert Cahn, a pioneer in materials science and engineering, emphasized: Understanding the behavior of materials does not come from the first chapter of the textbook, but from first-hand experience in the manufacturing field."

This guide is the result of our repeated practice, observation, and refinement of thousands of bending operations in the workshop, various challenges encountered, and solutions found. It is not a theoretical deduction, but the practical wisdom I have accumulated every day beside the roar of machines and testing instruments.

The "Genetic Code" of Bending Performance: What Determines The Bendability of Materials?

Want to predict whether a piece of metal is easy to bend? Don't guess, just look at its inherent properties. Understanding the following key points will give you a clear idea when you choose materials and design.

Key indicator 1: Ductility

Ductility is the degree ofpermanent deformation(such as stretching and becoming longer or compressing and becoming thinner) that a material can withstand before it completely breaks.This is definitely the most crucial indicator for determining whether it is easy to bend!

Imagine it: a rubber band is stretched a great distance before it breaks (good ductility), while dry noodles break when bent (bad ductility). It is the same with metals. Materials with high ductility, such as some of the softer aluminum or low-carbon steel (like A36), are easily bent and are difficult to break. This is the basis for good bending.

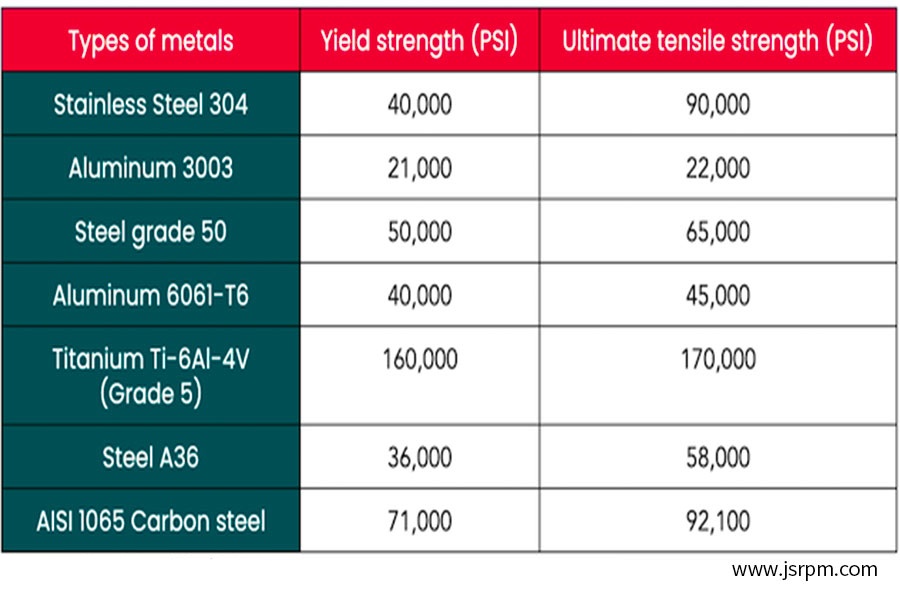

Key indicator 2: Yield strength-tensile strength gap

Yield strength: This is at what stress the material begins to deform permanently (it can never return once it has been bent). It is the material's "first line of defense" against deformation cracking.

Tensile strength: This is the maximum stress that the material can withstand before it fractures, and it is its "ultimate limit.".

When you're bending material, you'd like it to deform rather than crack immediately. Therefore the greater the tensile to yield strength difference, the better! The higher the difference, the greater the "safe zone" between when the material starts to deform and is about to break.Bending inside this "safe zone", the material has more buffer space to deform without cracking and is much easier to metal bending and shape.

Key consideration: Be careful that the material is getting harder

Some metals, especiallyaustenitic stainless steelssuch as 304 and 316, have a very strange property. When cold-processed at room temperature such as bending and stamping, they become harder and more brittle.This is called work hardening.

What is the impact?

For example, if you design a part that needs to be bent several times in a row, the first bend may be fine, but because of work hardening, the material becomes hard and brittle. If you bend the same place again for the second time, it is likely to crack directly! Therefore, when making multiple bends or complex shapes, this strange property must be taken into account in advance, otherwise the subsequent steps will easily fail.

The ductility of the material is the basis.The difference between the yield strength and the tensile strength provides space for safe operation, while the work hardening property warns us of the risks of multiple metal bending. By understanding these three points, the selection and design of bending parts can avoid cracking and scrapping.

"Please bring your needs to JS to talk. Our team of engineers is proficient in the prices of various metal materials and can help you avoid risks from the source of material selection and process design."

The Spectrum of Bendable Materials: From Ordinary Steel to Special Alloys

Now that we understand the "genetic code" of materials that are easy to bend, let's take a look at several commonly used metal materials in our workshop. Their bending characteristics and applicable scenarios are different.

Carbon steel

- Common grades: Low-carbon steels such as A36 and 1018 have very good bending performance. Medium and high carbon steels have high hardness and are more difficult to bend.

- Bending performance: If you choose the right grade (such as 5052), it will be very smooth to bend. If you choose the wrong one (such as 6061-T6 is not processed well), it will be a disaster.

- Advantages: Huge cost advantage,good welding performance, easy processing, and a reliable choice for structural parts.

- Disadvantages: Easy to rust, usually requires surface treatment (such as painting) after processing.

Stainless steel

- Common grades: 304 is the most commonly used, and 316 is used when higher corrosion resistance is required (such as in harsh environments).

- Bending performance: It can be bent, but it requires greater force than low-carbon steel.It has a characteristic called work hardening, which makes it harder and harder during the bending process. Pay attention to this when designing the processing flow to avoid cracking.

- Advantages: Excellent corrosion resistance, good appearance, and no subsequent protective treatment is required.

- Disadvantages: Higher material cost, slightly more difficult processing (cutting, bending), and faster tool wear.

Aluminum alloy

Common grades: 5052 has the best bending performance. 3003 is also good. But 6061-T6 is very hard and brittle, and it is very easy to crack when bending at a small angle or a small corner, and a largebending radiusmust be used.

Is it easy to bend? The brand and state are the key!

- Choose the right brand (such as 5052), and the bending will be smooth.

- Choose the wrong brand or state (such as 6061-T6), it is very easy to crack, and a very large bending radius must be used.

Advantages: The biggest killer is light! Intrinsically corrosion-resistant.

Disadvantages:The unit price is usually higher than ordinary carbon steel, and welding is more complicated than steel, requiring special technology and equipment.

Typical aluminum alloy minimum bending radius:

| Aluminum alloy grade and condition | Minimum bending radius (inner R) | Key points |

| 5052-H32 | 0.5T - 1T | Excellent bending performance, preferred. |

| 3003-H14 | 0.5T - 1T | Good bending performance. |

| 6061-T6 | 2T - 4T+ | Easy to crack, requires large rounded corners, not recommended. |

Source: ASM International - Key to Metals AG.

Copper and brass

- Bending performance: Very soft and easy to form.

- Advantages: Top electrical and thermal conductivity, unique and textured appearance.

- Disadvantages: Relatively low strength and high cost.

"There is no absolute best material selection. The key is to see what the core needs of your product are. Don't let the material selection problem slow down your project! If you are looking for the most suitable bending material for a new design or product, or have questions about complex metal bending processes, feel free to contact JS. Our team of engineers has been rooted in the workshop for many years and can help you accurately match materials and needs."

Practical Case Analysis: Material Trade-Offs for Portable Medical Device Shells

No matter how good the theory is, it is not as practical as getting a real project done. Our experience in making aportable diagnostic devicehousing for a medical technology company fully demonstrated how our engineers can find the most suitable material in complex requirements.

Customer Challenge: Durability, Lightweight and EMI Shielding

Project background:We recently worked with a medical technology company that developed a new portable diagnostic device and put forward three core requirements for the housing: strong structure, light weight and effective EMI shielding.

The customer initially considered using 1.5mm thick 304 stainless steel, valuing its excellent strength and corrosion resistance, which indeed meets the basic requirements of the medical environment.

JS's Analysis and Solution

We evaluated the feasibility of the stainless steel solution and found that there were key challenges:

- Weight Excess: 304 stainless steel has a density of about 8.0 g/cm³. My calculations show that the weight of the complete housing will exceed 1.2kg, which significantly exceeds the customer's actual expectations for portability.

- Cost Pressure: Stainless steel raw materials are expensive, and the processing of complex shapes (especially metal bending) is relatively difficult and costly.

- Does the shielding capability meet the requirements? Although stainless steel has excellent shielding performance, considering the need to reduce weight and cost, there may be abetter comprehensive solution.

Looking for alternatives:Based on the above analysis, we turned our attention to aluminum alloy materials. After a systematic comparison, we finally recommended theuse of 5052-H32 aluminum alloy.

Why choose 5052?

Among the commonly used aluminum alloys, 5052 is particularly easy to process and shape, and it is very easy to make complex shell shapes. It is also very corrosion-resistant and can fully withstand the test of the medical environment.

Why is it H32 state?

This "H32" means that the material has undergone a specific hardening and stabilization treatment. Simply put, this state maintainsgood bending properties. At the same time, it provides higher strength than the fully annealed state (O state) to meet the structural requirements of the shell.

Key performance data comparison:

| Characteristic | 304 stainless steel (1.5mm) | 5052-H32 aluminum alloy (1.5mm) | Change/Advantage |

| Density | 7.9 - 8.0 g/cm³ | 2.67 - 2.68 g/cm³ | Reduce by approximately 66.5%. |

| Calculate the weight of the shell | >1.2 kg | Approximately 0.4 kg | Reduce>65% (approximately 0.8 kg). |

| Relative manufacturing cost | Higher | Significantly reduced | Reduce unit cost by approximately 15%. |

| Fundamentals of Electromagnetic Shielding | Good (high conductivity) | Good (high conductivity) | Meet project requirements. |

| Corrosion resistance | Excellent | Excellent (especially after anodizing) | Meet the requirements of medical environment. |

Source: ASM Handbook, Vol. 2 (ASM International), IEEE Std 299 (Basics of Shielding Effectiveness Evaluation).

Final Result: Win-win of Performance Compliance and Cost Optimization

The customer adopted our 5052-H32 aluminum alloy solution.Final product:

- Fully met the requirements for structural strength and internal component protection.

- The weight was significantly reduced to about 0.4kg, which improved the user's carrying and use experience.

- The electromagnetic shielding performance was tested to meet the equipment operation requirements.

- Through material and process optimization, the manufacturing cost per piece was reduced by about 15%.

"The key to the optimal material solution is not to pursue the ultimate in a single performance, but to accurately match the comprehensive requirements of the project (performance, weight, cost, and processability). This is the core value of JS's professionalcustomized metal bendingmanufacturing. Welcome to communicate with us about your specific needs."

FAQ - All Material Bending Issues You Care About

Which material is recognized as the easiest to bend?

In terms of the difficulty of bending, low-carbon steel and soft copper in the annealed state are generally recognized as the easiest to bend. When bending, they require less force, are easy to control in shape, and have less rebound. But in actual work, "good bending" is just the starting point.

We must consider all aspects when selecting materials: How strong does the product need to be in the end? Is there any weight limit? What is the cost budget? And rust resistance, etc. Good materials must find the best balance between good bending and these practical requirements.

Why is 6061-T6 aluminum alloy not suitable for complex bending?

The key lies in its "T6" state. This state is obtained through enhanced heat treatment. The advantage is that 6061 becomes very hard and strong, but the disadvantage is that its ductility is greatly reduced.

Imagine that when bending, the material needs a little "deformation space" to adapt. 6061 in the T6 state has almost no such space, especially on the outside of the bend, it is extremely easy to crack directly.

Therefore, we do not recommend it for processing projects with complex shapes and small angles or small radius bends. If you must use 6061 for bending, you can only use a very large bending radius, or soften a specific area before bending (local annealing) to increase toughness.

Can I bend metal at home? What do I need?

For very thin and very soft metal sheets, you can indeed clamp them with a bench vise and slowly knock out simple bends with a mallet or rubber hammer. But! If you want to bend accurately and cleanly, especially for slightly thicker steel or aluminum plates, you must rely on professional equipment, the most common of which is a press brake (also called a press brake). For safety and quality, complex metal bending work really needs to be completed by professional equipment.

Summary

Our engineers all know that the basis of metal bending is material selection. If you want to bend metal well and in place, it is not enough to have a design drawing.The key is to understand the performanceof the material and think clearly aboutyour specific needs. The strength of the part, the complexity of the shape, and the use environment are all crucial. If you choose the wrong material, no matter how fine the process is, it will be difficult to achieve the desired effect.

Don't let material selection become a bottleneck for your project.This is exactly where our JS engineering team specializes!

Pleasesend us your design sketchor file now!You will get more than just a simple bending quote, but a complete solution that combines our professional material recommendations and manufacturing feasibility. Let us use our experience to pave the way for your manufacturing.

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsrpm.com