How can an ordinary piece of metal plate be turned into a server chassis supporting key components, a seamless equipment shell, or a sturdy structural bracket? In the eyes of our JS, this is not a simple folding.Metal bendingmeans that we use precise force to make the metal plate permanently deform along a set line, turning it from a straight plate into the angle or shape we need, such as a V-shaped groove or a U-shaped bend.

It sounds like bending with force, but it is far from that simple. It is definitely a science to do this well. What our team thinks about every day is how to understand the characteristics of metal materials, how to choose the right method and use those advanced, computer-controlled equipment according to the thickness of the metal plate and the desired bending angle.

Why is it so particular?Because the accuracy and quality of the final bending angle all depend on whether these details are made in place.

It is precisely because of thisinsistence on precision controlthat we can turn seemingly ordinary metal plates into key parts that support various industries. From inconspicuous small brackets to large structural parts, the engineering wisdom of metal bending is condensed behind them.

Core Answer Summary:

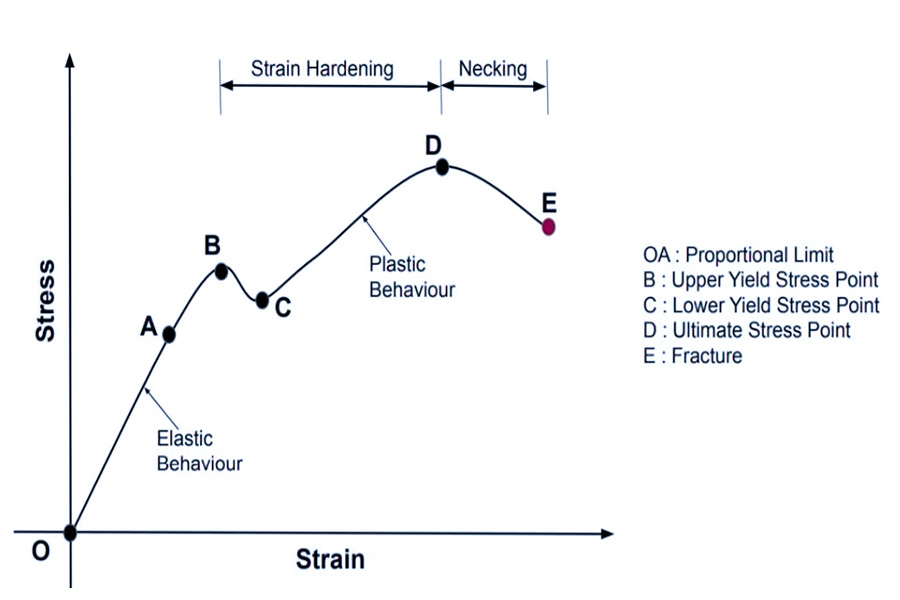

| Stage | Core principle | Result |

| Initial stage of force application | Elastic deformation. | The material is temporarily bent and can fully return to its original state after releasing force. |

| Exceeding the yield point | Plastic deformation. | Permanent deformation occurs, causing slippage and irreversible changes in the internal crystal structure of the metal. |

| After releasing the force | Springback. | Partial elastic deformation is restored, resulting in a final bending angle greater than during unloading (slight opening). |

| Engineering compensation | Overbending. | Pre calculate the rebound amount and bend to an angle smaller than the target angle to counteract the rebound. |

This article will answer your questions:

- In this guide, I will tell you about the physics of metal bending and explain in detail how a press brake works.

- Then compare several commonly used bending methods.

- Then share a practical example of a problem we have solved.

- Finally, I will answer all the common questions you care about.

Why Should You Trust This Guide? Frontline Manufacturing Insights from JS

This guide comes from our JS workshop every day. We are "talking" to metal every day and giving precise instructions with the press brake.

Take a simple 90-degree bend as an example.Do you think it's simple?

But in actual operation, the rebound of the material, the choice of the bending radius, and the release of internal stress all require precise calculations. Every suggestion in this guide is the real experience we have accumulated after processing thousands of sheet metal parts by hand.

We at JS provide more than just onlinemetal bending processing services. We have been deeply involved in the entire manufacturing process of our customers and solved difficult practical problems.

For example, in the workshop, we have encountered a situation where the parts could not be assembled and formed in the end because the bending sequence was not arranged correctly. By optimizing the bending solution, we successfully avoided the risk of material cracking at the bend. We hope to be your engineering partner on the road from drawing to physical product.

"As Dr. Joseph Juran, a leader in the field of quality, emphasized: Experience is not what happens to you, it's what you do with what happens to you."

The content of our guide is the result of our repeated thinking and refinement of massive workshop practices, challenges encountered and successful solutions. It comes from the real production line and condenses our understanding of sheet metal forming process, which is why you can trust it.

The Science of Metal Bending: The Art of Plastic Deformation

If you want a flat sheet of metal to bend into the angle you want, you can't just apply strong pressure. The key is to understand the two core deformation characteristics of metal:elastic deformation and plastic deformation.Only when you apply enough force to make the metal sheet enterthe plastic deformationzone can the metal maintain the set bend angle.

Stage 1: Elastic Deformation

Imagine that you gently bend a plastic ruler with your hands. It will bend, but as soon as you let go, it will bounce back to its original shape. The same is true for metals when the force is small at the beginning. It will deform a little, but as long as you let go, it will immediately return to its original shape without leaving any trace. This stage is like the instantaneous response of the material, and no permanent changes will occur.

The key turning point: Yield Strength

Every metal has a "stubborn point", which is professionally calledyield strength. When the force you use becomes greater and greater, so great that the "muscles and bones" inside the metal begin to fail, move and dislocate, it exceeds this point. Once it exceeds this point, the metal can no longer completely return to its original shape. It marks the beginning of permanent deformation.

The ultimate goal: Plastic Deformation

When the applied force steadily exceeds the yield strength, the metal enters the plastic deformation stage we want. The bending that occurs at this time is permanent! The metal sheet has been transformed into a new shape. The core work of our bending machine is to bring the metal into this stage accurately and controllably and keep it there.

A reality that cannot be ignored: Springback

Even after the metal is bent, it undergoes permanent deformation (plastic deformation), and a part of the elastic force that tries to restore its original shape is stored inside. Just like a spring that has been bent wants to bounce back. So when the bending pressure is released, this external force will make the bending angle rebound a little bit, which isthe springback effect.

Don't underestimate this springback, it will directly make the angle of the finished product inaccurate! In order to offset it, both experienced workshop masters and intelligent CNC bending systems must calculate and reserve this springback amount in advance.

The specific operation is:in order to obtain an accurate 90-degree bending angle, the actual bending may have to be deliberately pressed to 87 or 88 degrees, and then rely on the material's own rebound force to bounce back to exactly 90 degrees! This angle difference that is pre-pressed deeper is the overbend angle.

So you see, metal bending is not a brute force job, but a science ofprecisely controlling elasticity and plasticity.From understanding the yield strength of the material, to plastic deformation, to springback compensation, each step is related to whether the finished product is qualified.

"In the JS workshop, I think about these details every day. Next time you encounter bending problems in designing sheet metal parts, or want to ensure that the bends are accurate, feel free to talk to us. With my experience, I can help you turn the lines on the drawings into real objects that are exactly the same."

Core Process and Equipment: Analysis of Main Bending Technologies

After understanding the basic principles of bending, the next step is to rely on key equipment to achieve it. In the field of sheet metal processing,CNC Press Brakeis definitely the main force in achieving metal bending.It mainly completes the bending task through several different working modes:

Main force: CNC Press Brake

How does it work?

In short, it relies on the cooperation between the upper and lower parts. There is a punch on the top of the machine, and a die with a V-shaped opening below. We put the metal sheet between them. Then, the punch presses down hard, pressing the sheet into the V-groove below, and the angle is formed. This is the basic operation of our daily metal bending.

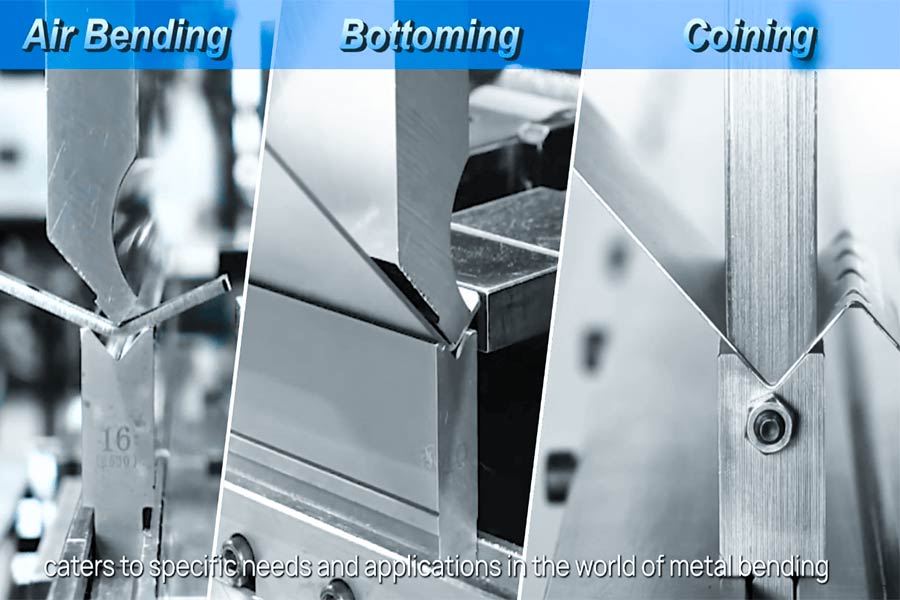

Comparison of three core bending methods

"Prof. Peter Ulintz emphasized: Understanding and selecting the bending method that matches the application is the key to achieving a triangular balance between cost, precision and production efficiency. "

The working method of CNC bending machines is not static, and there are mainly threebending methods:

(1) Air Bending (Most commonly used):

- Principle: The punch presses the sheet down, but does not completely press the sheet to the bottom of the mold, which is equivalent to letting the sheet bend in the air above the mold.

- Advantages: Flexibility is its biggest highlight. You can make many different angles by using a mold, which is very convenient. Moreover, it has the lowest equipment tonnage requirement among the three, with fast production preparation and high cost-effectiveness.

- Limitations: The forming angle is greatly affected by material rebound. Because after releasing the material, it will rebound a little, and the angle of the bend may be slightly different from the setting. So it depends on the experience of the operator and the control accuracy of the machine.

(2) Bottoming (More accurate):

- Principle: This time the punch presses the sheet to the bottom, tightly againstthe V-shaped surfaceof the mold, and the bending angle is completely determined by the shape of the mold.

- Advantages: Higher precision! Because the pressure is solid, the space for the material to rebound is smaller, and the angle control is more accurate.

- Limitations: Requires 30%-50% higher equipment tonnage than air bending. More importantly, a set of molds can only make the specific angle it is designed for. To change the angle, the mold must be replaced, and the flexibility is a bit poor.

(3) Coining (High precision, but rarely used):

- Principle: Use extremely high tonnage (usually 5-8 times that of air bending) to force the tip of the punch into the material like a stamp, so that the material deforms and completely eliminates rebound.

- Advantages: Theoretically, it can achieve the highest forming accuracy and angle consistency.

- Limitations: It takes too much time for machines and molds, the machine is burdened, and the mold is easily damaged. It can usually only be used for softer materials or specific occasions. Because of the high investment and many restrictions, it is now used less and less in production, unless the precision requirements are particularly stringent.

Comparison of core data of commonly used bending methods:

| Bending method | Application penetration rate (estimated) | Typical angle accuracy range | Required tonnage (relative air bending) | Main applicable material thickness range |

| Air bending | 85% - 95% | ±0.5° - ±1.0° | Benchmark (100%) | Thin plate medium thick plate (universally applicable). |

| Bottom bending | 10% - 30% | ±0.1° - ±0.5° | 130% - 150% | Thin Plate - Medium Plate. |

| Coining | < 3% | ± 0.1 ° (theoretically optimal) | 500% - 800% | Thin sheet (mainly made of soft materials). |

Source: ASM Handbook, FABTECH report.

Bending curves and cylinders: Roll Bending

When is it best to use it?

When you need to make arcs, cones or cylinders with continuous curves, CNC bending machines can't do it. This is when theroll bending machinecomes into play.

How does it work?

Usually it relies on three or four rotating rollers, and the metal plate passes through them. By adjusting the position and angle of the rollers, the plate is bent little by little, and finally forms the arc we want or rolls into a cylinder. This is a special tool for curved surface modeling.

To summarize briefly: Air bending is flexible and labor-saving, and is the main force of daily metal bending. Bottoming bending is more accurate but not flexible enough. Imprinting bending pursues extreme accuracy but is expensive, and is rarely used now. To make curved cylinders, you have to rely on roll bending machines. Each method has the most suitable processing for it.

"At JS, we know that choosing the right bending process is critical to part quality and cost. If you have sheet metal parts that need processing, especially those that require precision, efficiency or complex shapes, don't hesitate to talk to us at any time. Our team is experienced and well-equipped to help you choose the most suitable metal bending solution."

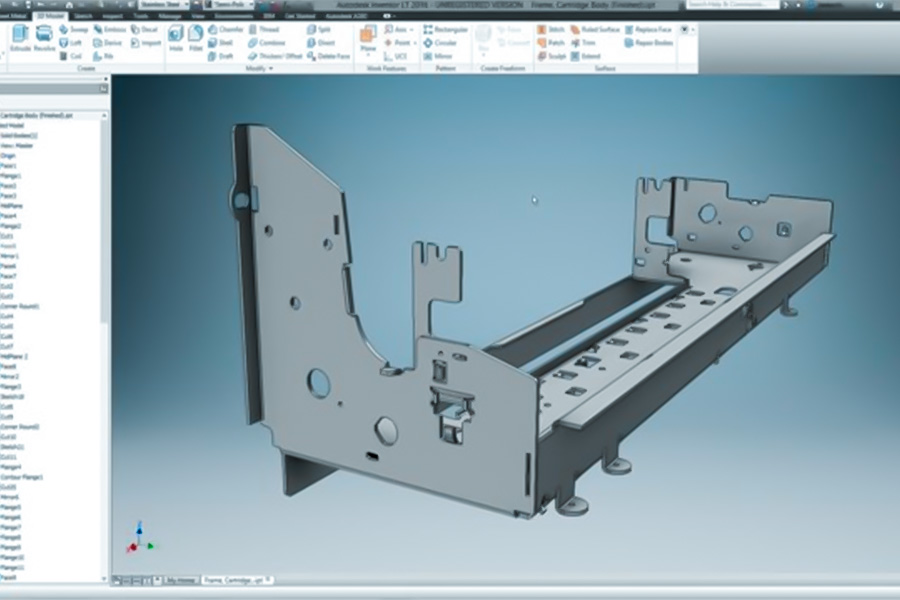

Actual Combat Case Analysis: Building a Precision Console Shell for a Drone Ground Station

I just finished a very interesting project, which is just right to use as an example to tell you how metal bending plays a key role in actual products. This time, it is to help a company that makes drone ground stations to build aprecision console shell.

Customer challenge: A complex shell that needs perfect alignment

Project background:The customer is a startup with ideas and designed a portable drone ground console. The shell is made of 2mm thick 5052 aluminum alloy plate, and holes are required to be opened on it to install the screen, joystick and various interfaces.The bent corners add up to more than 12!The most important thing is that the positions of all openings and corners must be accurate, and even a little difference will not work.

Potential risks:

As soon as we got the initial design, we knew the risk points of this project. What is the problem? Two places:

- First, the bending radius is insufficient: the design of the inner bending radius of some parts is only 0.5mm, which is much smaller thanthe minimum bending radiusrecommended for the material (usually 1 times the material thickness, e.g 2mm).

- Second, the bending spacing is too small: if this design is followed and the bending machine is directly used, the material will either crack directly when bending, or the parts will be deformed and scrapped because the mold cannot be inserted or interferes. The danger is not insignificant!

JS's engineering fix: Manufacturability and process optimization design

(1) Root cause analysis (DFM):

During the project quotation and feasibility analysis stage, we used specialized software to conduct a thorough analysis of the customer's3D modeland rapidly identify the aforementioned risk points.

(2) Sophisticated customer modification:

Finding the issue is not the purpose, but resolving the issue is. We contacted the customer in a timely manner and provided some optimization suggestions:

- Increase the bend radius: It is extremely recommended to increase the minimum bend radius from the unsafe 0.5mm to 2mm (thickness of the material) appropriate to the material characteristics. In this way it is safe to bend and won't shatter.

- Make adjustments in the flange height: Somewhere the two bends become too heavy. Make an adjustment in the height of one of the flanges so there is enough space for the bending mold to work in so that it will not conflict.

(3) Proper process planning:

For complex components with more than 12 bends, bending sequence is very important. The wrong sequence will render the parts unable to meet following operations due to structural locking in bending.Our engineershave always concluded and set up best bending steps in a bid to have an easy ride.

(4) Accurate unfolding calculation:

To ensure the final size is accurate, the unfolded flat plate size must be calculated to the millimeter. We use software to accurately calculate the bend deduction of each corner to ensure that accurate margins are reserved for subsequent bending when cutting and cutting.

Comparison of key points of process optimization:

| Design risk points | Customer initial design | JS optimization plan | Optimization purpose |

| Minimum bend radius | 0.5mm | 2mm (1 times the material thickness). | Avoid bending and cracking to ensure material safety. |

| Key flange height | 15mm | Adjust to 18mm. | Reserve sufficient mold operation space to prevent bending interference. |

| Bending sequence | Unclear | Detailed step planning. | Prevent parts from self-locking and ensure that all bends can be completed. |

Final results and value

- Results: Design optimization is in place, process planning is clear, and the master of our workshop has excellent operating skills. The sample was bent successfully at one time! All hole positions, interface positions, and bending angles meet the design accuracy requirements.

- Value: The most important thing is that our professional DFM analysis in the early stage directly helped the customer avoid a trial production that was bound to fail. It not only saved a few thousand dollars in proofing fees, but more importantly, it saved at least one week of precious R&D time!

- Core inspiration: To handle a complex metal bending part, it is not enough to have a topCNC bending machine. The real value lies in the practical experience of our engineers who can foresee risks in advance, optimize product design, and plan perfect processes. Equipment is dead, experience is alive!

"This case fully illustrates that for precision sheet metal processing, especially complex bending parts, in-depth engineering analysis and process planning in the early stage are crucial. At JS, we not only have advanced equipment, but also an experienced team of engineers who focus on helping you transform your design into products that can be efficiently manufactured."

FAQ - All bending issues you concerned about

What is the most commonly used sheet metal bending method? Why?

Regarding the most commonly used bending method,the answer is clear: air bending.

Why is it the most popular?

- The key is two words: flexibility! A set of standard V-shaped lower dies with a suitable punch can be bent into a variety of different angles by precisely controlling the depth of the punch's downward pressure. This means that the number of times the die needs to be changed during production is greatly reduced, and efficiency is naturally improved.

- It is especially suitable for production scenarios with a large variety of products and a small single batch volume, which saves time and controls costs. In the metal bending projects we come into contact with on a daily basis, it is conservatively estimated that more than 90% of the work will be the first choice for air bending.

What is "springback"? How to solve it?

Springback is a key issue that cannot be avoided. It refers to the natural phenomenon that the metal sheet rebounds a little after the bending pressure is removed. You can imagine bending a steel ruler, and it will always rebound a part when you let go.

How to solve it?

- The core idea is overbending compensation.Simply put, it is to deliberately bend the angle a little smaller than the target value (for example, if it is to be 90 degrees, it may actually be pressed to 88 degrees), leaving space for rebound so that it can just rebound to the angle we need.

- But this compensation amount is not guessed, it must be calculated by empirical formula, or fine-tuned by trying to bend it several times. In our workshop, experienced masters can control the rebound very accurately with the machine compensation function.

What is the most important consideration when designing bending parts?

As a first-line bending engineer of JS company,these three factors are the most critical for uswhen designing sheet metal bending parts:

- Minimum bending radius: This is the bottom line! The inner radius of the bend must not be less than the limit that the material can bear, otherwise it will crack when it is folded. Usually, the minimum radius must be at least equal to the material thickness (1t), and the safe point is 1.5t or 2t, depending on the hardness of the material.

- Minimum flange height: It is the height of the "edge" that is folded. If it is too short, the mold cannot be clamped or pressed steadily, and the size of the bent part is inaccurate or even slips. In experience, the height of this edge must be at least 4 times the material thickness (4t) to be reliable.

- Safe distance between holes and slots and the bending line: If the hole or slot is too close to the line to be bent, it is easy to deform or flatten the hole when it is bent. Sufficient safety distance must be reserved during design. This distance is also related to the material thickness and hole diameter, and needs to be calculated or referenced by standards.

Controlling these three points well can avoid most of the manufacturing troubles and the risk of parts scrapping in advance.

Summary

Metal bending is not a simple "bend", it is a technology that integrates material science, mechanical calculation and precision technology. Behind every precise bend is the strict control of details and the experience accumulated from countless practices. Whether your project is a sturdy industrial cabinet or a delicate electronic equipment housing, its quality and reliability cannot be separated from the support ofprecise metal bending technology.

At JS, we offer more than just competitive prices:

From design feasibility analysis (DFM) to help you avoid risks, to precise calculations and process planning to ensure perfect dimensions, to final high-quality delivery.

Act now!

Upload your CAD file(supports STEP, IGES, Solidworks and other formats)and let JS's professional team evaluate it for you!

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsrpm.com

Resource