Modern manufacturing often requires precise processing of hard materials,which places very high demands on cutting technology. Laser cutting technology can meet this challenge.Its core principle is to use a highly concentrated powerful laser beam, like an extremely precise light knife, to cut various plates.Whether it is wood, steel, or a variety of plastics, it can handle it.

You are likely to have encountered the troubles caused by traditional cutting:the cut is not smooth, there are many burrs, the workpiece is easy to deform and bend, or the size is not accurate enough,which is a headache. But now, laser cutting has brought new possibilities.This technology can achieve surgical scalpel-like cutting on metal or wood, with an accuracy of up to micron level. It goes beyond the simple segmentation action and truly realizes an art of precision manufacturing.

Summary of the Core Answer:

| Aspect | Describe | Value to you |

| Core principle | Instantly melt, vaporize, and burn materials using highly concentrated and powerful lasers. | Accurate and precise, without touching the workpiece or tool wear. |

| Main advantages | Extremely high precision, fast speed, extremely narrow cutting seam, and minimal thermal impact. | Complex design is easy to implement with minimal material waste. |

| Application Fields | From thick steel plates to wood and transparent acrylic. | Almost covering all manufacturing industries. |

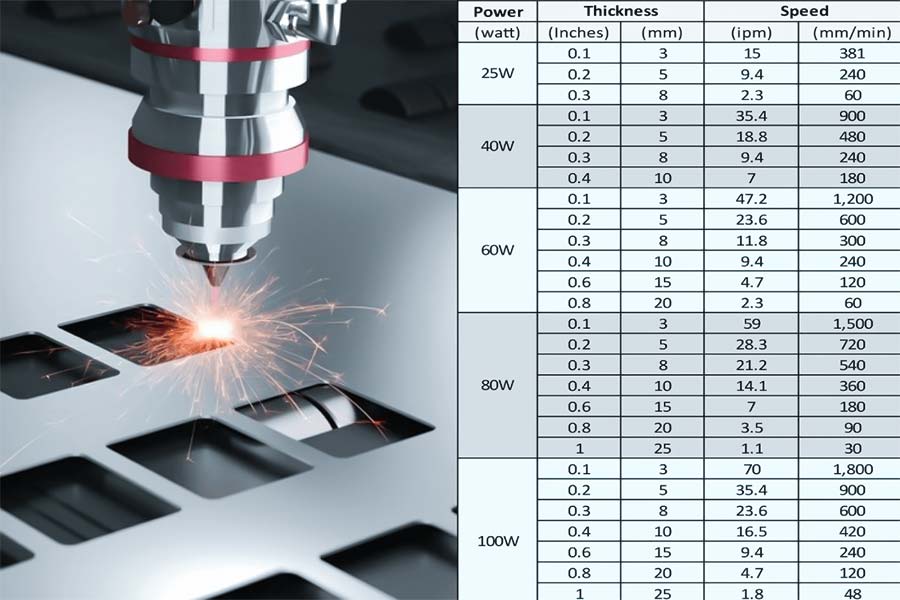

| Key parameters | Power level, cutting speed, polishing frequency, and kerf width. | It directly determines the cutting effect and production cost of your workpiece. |

This Article Will Answer Your Questions:

- This guide will explain in detail how laser cutting works,

- analyze its different forms and principal advantages (Advantages),

- and provide some useful advice (like: how to calculate the kerf of laser cutting),

- help you evaluate whether this technology is suitable for your project.

Why is This Guide Worth Your Trust? Practical Experience From JS Laser Cutting Experts

In the field of laser cutting, there is often a gap between book knowledge and actual operation. What makes this guide different is that it is completely rootedin the practical experience of the JS team for many years.

In the past decade, we have handled countless cutting projects, from precision aerospace components,complex custom equipment parts, to creative art design works. Behind these thousands of parts is our deep understanding of the properties of various materials.

For example, we are naturally not a problem with commonly used steel and acrylic, but more importantly, we have successfully mastered the hard bones that are recognized as difficult to chew, such as 3mm brass. They are highly reflective and heat-conductive in laser laser cutting, and cutting failure is easy if you are not careful. It is through countless debugging of CO2 and fiber laser parameters and solving countless practical production problems that we have accumulated this real experience.

"Every successful cutting is the result of a perfect dialogue between parameters, experience and material properties."

This guide is to share with you the key experience that we have repeatedly verified in actual combat without reservation. It embodies the wisdom of the JS team in the front line of laser cutting.

Working Principle of Laser Cutting: How a Beam of Light Creates Miracles

As an engineer of the JS team, I will explain the working principle of laser cutting to you clearly.It is essentially to turn a beam of light into an ultra-strong and ultra-fine thermal energy knife. The whole process can be divided into three steps:

In fact, the core of laser cutting is the synergy of these three key links: generating strong laser -> precise focusing -> instant melting of materials and clearing with gas.

Step 1: Generate a laser beam

The most significant work is to generate a strong laser beam.There are two mainstream industrial equipments at present:

(1)CO2 laser cutter:

The laser used in this cutting method is excited by electrifying a mixed gas (mainly carbon dioxide). This is the earliest laser and is still commonly used. This mixed gas contains not only carbon dioxide, but also nitrogen, hydrogen, xenon and helium.

Why add other gases? It is in order to stabilize the laser and enhance the efficiency.

When using it to cut things, you have to choose an auxiliary gas to spray on the cutting point:either oxygen or nitrogen.

- Oxygen is suitable for cutting thicker materials:

However, there is a small trouble: oxygen will react with metal at high temperature, leaving a black oxide layer on the cutting edge.If the subsequent process requires a clean surface (such as painting or welding), we will deal with this oxide layer first.

- Nitrogen is more suited to cutting slender boards:

It is essentially tasked with "blowing away" the melted metal and protecting the cut, so that the cutting edge is very clean with minimal oxide layer, with the work of follow-up polishing preserved.

(2)Fiber laser:

This cutting method is distinct.It utilizes high-power diodes in exciting special optical fibers, and the beam of light is amplified and enhanced inside the optical fiber before being output. This laser's energy is extremely concentrated, and it can melt and cut a 1 cm thick stainless steel plate with ease.

During cutting, high airflow (typically nitrogen or compressed air) will follow the laser beam and blow onto the material.

Its task is very critical: over time, remove the molten metal slag, so the cut will be clean and the edge smooth.

Cutting efficiency is higher with this technology for metal materials and more visible benefits,especially in cutting highly reflective and highly thermal conductive metals(such as copper and aluminum).

Step 2: Focus the laser beam

The divergent laser beam formed initially is then concentrated through an exact optical lens system into a highly thin point (usually less than 0.2 mm in diameter). Focusing in this manner is extremely crucial as it allows the spot to possess a highly high energy density. The combination of laser cutting and precision focusing forms the fundamental foundation for achieving fine and high-accuracy cutting.

Step 3: Melt and remove the material

What happens when the ultra-high-energy laser is applied?

When the incredibly powerful laser focused into a very small region of focus illuminates the surface of the material,the temperature there will rapidly heat the materialwith so much energy that the metal will melt straight away and some materials will vaporize.

High-pressure gas toassist:

Melting by laser only is not enough. To create a clean cut, the molten metal material should be removed from the cutting gap. While this is being done, a high-pressure gas (usually compressed air, oxygen or nitrogen) will spray downwards near the laser beam.

Key points of metal cutting:

While cutting metal, the auxiliary gas selected will have a direct influence on the effect:

(1)Use oxygen:

- Not only does it remove the molten material, but also undergoes an oxidation reaction (combustion) with hot metal.

- The heat produced by this reactionhelps in cutting thicker metal sheets.

- But an oxide layer is usually formed on the cut edge.

(2)Use nitrogen (N2) or inert gas:

- If youwant a shiny, non-oxidized cut surface,then you have to use an inert gas such as nitrogen, which essentially protects the material against oxidation at elevated temperatures.

- Nitrogen becomes chemically inert at elevated temperatures and does not readily react with molten metal.

"Laser cutting, using a good lens to press the laser into a super strong light spot, melts the material in seconds! Paired with high-pressure air, it quickly blows away the slag and affects the cutting effect, which is the core process of transforming a beam of light into a thermal knife. Do you want to cut it quickly and beautifully? Contact the JS technical team anytime!"

The Great Advantages and Potential Challenges of Laser Cutting

At JS, we deeply apply and trust laser cutting technology because it perfectly matches our pursuit of precision, efficiency and flexible manufacturing.

Why do we prefer laser cutting?

- King of precision, stable and reliable:Laser cutting can easily achieve micron-level tolerances(thinner than a hair) and ensure that the size of each part in mass production is highly consistent, which is the cornerstone of precision manufacturing.

- Free and unrestrained design: Good news for engineers and designers! No matter how complex the geometry, fine internal hollowing, or sharp corners, as long as they can be drawn with CAD, the laser can basically cut them accurately,breaking through the limitations of traditional cutting.

- Narrow incision, small material damage: The cutting slit formed by the laser is extremely narrow, and the material utilization rate is high. The heat-affected zone it produces is very small, which canretain the original properties of the material to the greatest extent,which is crucial for subsequent processing or product performance.

- Non-contact processing High-energy beam action, no physical contact. This means no tool wear (reducing maintenance costs) and no mechanical stress (perfect for thin and brittle materials such as thin metal sheets, special plastics, and ceramics).

- High speed and high degree of automation: After the program is set, it can run continuously at high speed, with a high degree of automation, which is particularly suitable for mass production, and its efficiency far exceeds traditional processes such as sawing and stamping.

"As Taiichi Ohno, a pioneer of lean production, emphasized: the essence of manufacturing is to eliminate waste."

What should I pay attention to when using laser cutting?

(1)There is an upper limit to thickness

- Phenomenon: When cutting metal with laser, if it cuts very thick steel plates, the speed of cutting will be significantly decreased and the energy consumption will be increased.

- Essence: The efficiency of laser cutting is not high and the cost is not worthy at this point.

- Recommended solution: In the case of such ultra-thick parts, processes likeplasma cutting or water jet cuttingare most realistic and cost-effective options.

(2)Highly reflective metal is a challenge

- Phenomenon:Cutting highly reflective metals like copper, brass, or bright surface (bare aluminum) is a technological challenge in laser cutting.

- Essence: The metallic surface is too reflective, easy reflection of the laser beam, not allowing efficient cutting of the material.

- Requirements to respond: This requires specialist equipment capabilities (e.g., fiber lasers with high power), as well as very precise process parameter setup, everything depending on the extensive experience gain of the operator. This is the advantage of our JS team in day-to-day working with such problematic materials.

(3)High threshold for equipment investment

- Phenomenon: Most companies need laser cutting machines and would prefer to have their whole set of industrial hardware (the machine itself + related chillers, air compressors, and dust collection systems). Initial investment cost is extremely high.

- Essence: A high portion of initial investment is a costly hurdle.

- Flexible solution: For this reason, companies generally avoid buying it themselves,but instead work together with specialized laser cutting service providers like us. This is a more flexible strategy with much lower initial investment and better cost effectiveness.

(4)Smoke and exhaust gas need professional treatment

- Phenomenon: Burning materials with lasers will definitely produce smoke and exhaust gas, and some materials may also release toxic gases.

- Essence: These waste materials must be removed in an immediate and safe process.

- Measures required: Thus, with the performance of laser cutting, a robust exhaust filtration system is a necessary setting (such as industrial dust collectors and directed filtration units).

- Importance: This has a direct bearing on the health and safety of individuals andthe factory environment's compliance. It is an obligatory running investment, and this segment is an obligatory running expenditure.

"Laser cutting is a powerful technology, but it is not omnipotent. Encountering headaches due to thick material reflection? We have a trick! Experienced JS team+high-performance equipment, specializing in treating various cutting difficulties and miscellaneous problems."

Practical Tips: How to Prepare for Your Laser Cutting Project

Cleardesign documents are the starting point for efficient processing. Do the following points well, our communication will be smoother, and you can get high-quality cut products faster.

Tip 1: Prepare for laser cutting projects-get kerf

Want the cut parts to fit perfectly? Understanding and compensating for the kerf is an inevitable step. Let me explain it to you, especially how to find your kerf for laser cutting width:

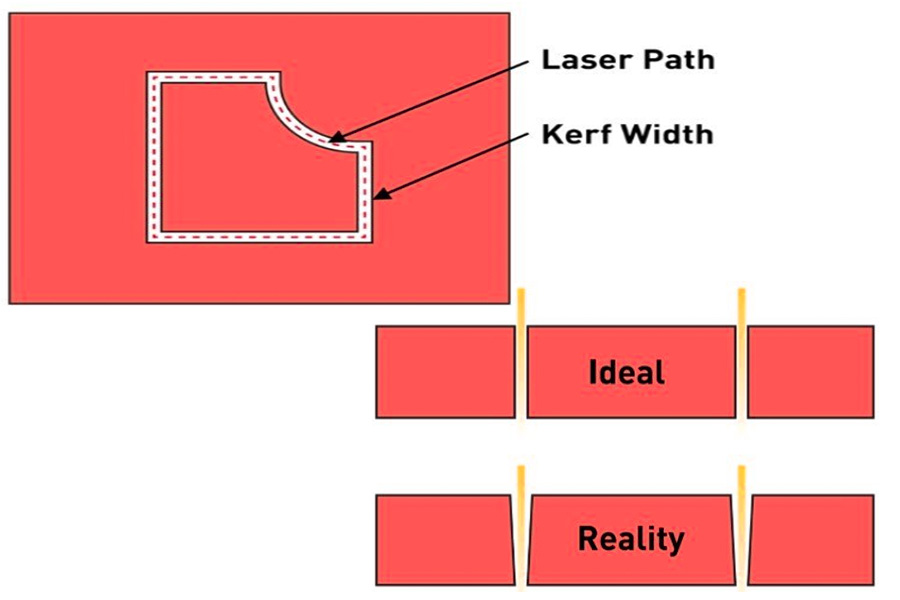

What is the kerf?

The laser beam itself has a certain width. When it cuts through the material, the width of the small strip of material burned is the kerf. It is not zero, but a real size.This is the cut of laser cutting.

Why is it so important?

Imagine that you want to cut two parts that need to be inserted together (card slot structure). If you design exactly according to the final required size and ignore the existence of the laser kerf, the actual cut parts will be loose when assembled (too big a gap) or can't be inserted at all (too tight). Compensating the kerf is to make the parts fit just right in the end.

How to find and compensate the kerf?

- The most reliable way is to measure it yourself: Design a simple 10mm x 10mm square (solid inside), and then let us cut it for you with the same material and thickness.

- Measure the result: Use a precise caliper to carefully measure the actual size of the cut square. For example, you measure that the side length is only 9.8mm.

- Calculate the kerf: Knife = (design size - actual size) / 2. Here it is (10mm - 9.8mm) / 2 = 0.1mm. This means that the laser burned about 0.1mm of material on this piece of material.

- Compensate when designing: When you design a slot or hole that needs to fit precisely, remember to offset the edge of the slot inward by the kerf value (such as 0.1mm here). The actual size of the groove cut in this way is just enough to accommodate the parts of the designed size.

Reference range of cutting width:

| Material type | Material thickness (mm) | Laser cutting incision width (mm) | Key points |

| Mild steel | 1 - 3 | 0.15 - 0.25 | Use oxygen assistance. |

| Stainless steel | 1 - 3 | 0.10 - 0.20 | Use nitrogen assistance. |

| Aluminum alloy | 1 - 3 | 0.15 - 0.30 |

Highly reflective materials require specialized parameters.

|

| Acrylic | 3 - 10 | 0.05 - 0.15 | CO2 laser. |

| Wood | 3 - 6 | 0.20 - 0.40 |

The key factors affecting the kerf width are the laser spot diameter and the laser power.

|

Data source: International Laser Association (ILA), 2023 Technical Report.

My suggestion:

Although literal measurements and comparison charts are convenient, the easiest and most accurate method is to contact us directly! Here in JS laser cutting services,we have accumulated a massive amount of actual combat experience. We possess an accurate slit database for the identical material type, thickness, equipment parameters and optimized processes utilized on your project.

Inform us in advance about your material and accuracy requirements, and we can provide you with the optimal corresponding remuneration value, saving you the trouble of multiple trials and ensuring your design is a hit on the first attempt.

Tip 2: Optimize your design file

"Industrial design master principle: impeccable quality comes from impeccable preparation."

(1)Select vector file format

Please provide vector format fileslike DXF/DWG/AI/SVG. Such a file maintains the precise line direction and coordinate points, which can directly determine the motion trajectory of the laser head and avoid dimensional deviation caused by bitmap conversion.

(2)The cutting path is completely closed

All cutting contours need to create a closed connected shape. Open paths may cause laser position failure, and hence cut misalignment or interrupted processing, which directly affects the accuracy of the end product.

(3)Remove redundant repeated line segments

Eliminate duplicate or redundant lines from the design file. Duplicate paths will cause the material to burn or burn through, or widen the slits to turn into waste. It not only will cause processing to take longer (↑ cost), but also a high likelihood of leading to material overheating and deformation (↓ quality).

Tip 3: Typical application analysis --- 3mm brass laser cutting settings CO2

You must have encountered materials such as brass during processing. Today I will share a specific case that our JS team often handles:the key points of cutting 3mm thick brass plates.

Technical premise clarification:

It is really not a good idea to use CO₂ laser to cut 3mm brass. The high reflection characteristics of brass to 10.6μm wavelength (reflectivity>90%) will cause serious attenuation of laser energy. Cutting efficiency and molding quality cannot meet industrial standards. Fiber laser technology is required.

Fiber laser process solution (based on JS high-power equipment):

| Parameter | Technical indicators | Mechanism of action |

| Laser power | 3000-4000W | Breakthrough the material reflection threshold and maintain the stability of the melt pool. |

| Auxiliary gas | 99.5% purity O₂ | Improve energy utilization efficiency through exothermic oxidation reactions. |

| Gas pressure | 1.8-2.2MPa | Remove slag to ensure the quality of cutting. |

| Cutting speed | 0.8-1.2m/min | Control heat input to ensure full thickness penetration. |

Our verification conclusion:

"This combination has beenproven effective in JS mass production practice, with a cut taper of ≤0.05° and a surface roughness of Ra<12.5μm. Case proof: For highly reflective materials, choosing a service provider with fiber laser equipment and a mature process database can avoid technical risks."

FAQ -- Answer All Your Questions About Laser Cutting

Question 1: What is laser cutting used for?

- Metal processing (sheet metal parts/electrical enclosures).

- Advertising logos (hollow precision letters/three-dimensional signs).

- Crafts production (laser cutting wood/leather cutting).

- Architectural modeling (proportional structural components).

- Medical equipment (surgical guides/implant templates).

Core value: Achieve complex plane cutting with millimeter-level precision, replacing traditional stamping/sawing processes.

Question 2: How does laser cutting differ from laser processing?

In actual operation and utilization of equipment of our JS, laser cutting is really a professional application mode of laser processing. Laser processing is a more general professional term that includes a lot of other techniques such as laser engraving, laser marking, laser welding, laser drilling, etc. which are achieved by our machine.

Question 3: What laser cutting near me?

When you look for laser cutting services nearby. JuSheng is nearby! We are located in Dongguan and focus on providing rapid and convenient laser cutting services to local consumers. From sample design to mass production, you can enjoy the local advantages of timely response, same-day quotation, and same-day delivery.

Of course, we also ship to customers nationwide with fast logistics to ensure excellent delivery. Just upload the drawing online and get an accurate quote within 1 minute! Save one step of your project.

Question 4: What is laser haircut?

Laser haircut, maybe a terminological error. The proper term is laser hair removal (Laser Hair Removal).

Differences in key:

- Technology and objects: Laser hair removal aims the hair follicles in the skin with a specific wavelength, low-energy laser, which destroys the roots of the hair using heat energy in order to gain a permanent effect of growth reduction. It is part of medical beauty or body care.

- Industrial laser cutting: The laser cutting service provided here utilizes a high-density energy laser beam (e.g. CO2, Fiber laser) as a cutting tool to melt or vaporize engineering materials such as metal, acrylic, and wood. It is an accuracy industrial processing technology.

Summary

The power oflaser cutting technologylies in its rare combination of speed, accuracy, and flexibility. It not only cuts the material, but also "prints" the drawings you carefully designed in the computer onto the real material without any error. It is a precise bridge connecting the digital world and the physical world.

Want to try what laser cutting can do for you?

Whether you want to make:

- Acomplex metal part(such as a bracket, a shell),

- or a beautiful decorative piece (acrylic sign, wooden crafts),

- or any plate project that requires precision processing...

The JS team has the confidence and ability to help you: Our accumulated experience, professional equipment, and control of details are to ensure that the parts you get are exactly the same as you imagined.

The next step is super easy:

Don’t hesitate! Feel free to talk to us about your project ideas, or just send us your design files. We’ll quickly evaluate and give you a clear, competitive quote, so you can experience what professional, worry-free laser cutting services are like.

Contact us or upload your files now to get a quote!

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com