Imagine a beam of light that can cut steel more accurately than the sharpest knife. This is not science fiction, but a reality that happens every day in our workshop! Have you ever wondered how those intricate hollow patterns on metal plates or the precision parts that fit together perfectly are made? No knife marks, no burrs, only clean edges. The answer lies in thisbeam of highly focused light.

Modern manufacturing has too demanding requirements for the processing of hard materials. It requires both speed and precision, and traditional methods are really a bit powerless. This has made new technologies such as laser cutting popular and used in all walks of life.

In our JS, laser cutting is not just a cold machine. Every day, watchingthe customer's design, whether it is wood, acrylic or metal sheet, is turned into a real finished product by this magical beam of light, which feels great! It is this possibility that makes me think that I should talk about how it works.

Simply put, it relies on concentrating huge energy into a light spot thinner than a hair, and wandering on the material like the most stable carving knife. Whether you are cutting metal, plastic or our popular laser plywood, it can cut complex patterns cleanly and neatly. Want to know how this beam of light is generated and how it completes the cutting task? Let me break it down for you.

Summary of the Core Answer:

| Characteristics | Laser Cutting | Plasma Cutting | Waterjet Cutting |

| Accuracy | Very high | General | Higher |

| Speed | Quick (Thin Plate) | Very fast (medium thick plate) | Slower |

| Heat affected zone (HAZ) | Very small | Big | None |

| Scope of Materials | Widely (metal/non-metal) | Only applicable to conductive metals | Almost all materials |

This article will answer your questions:

- In this guide, I will take you through the entire process of laser cutting.

- Focus on analyzing how it can accurately cut metal.

- We will compare the differences between common lasers (such as CO2 and fiber) and demonstrate how to calculate a key parameter: the width of the kerf.

- Finally, through a real project case, you will see how this technology can efficiently turn complex designs into reality.

Knowing this, you will have a deeper understanding of the core value of laser cutting in modern manufacturing.

Why Trust This Guide? Practical Experience from JS Laser Workshop

For us, thelaser cutting machineis far more than just a piece of equipment. It is our "brush" to realize the customer's ideas. Every day, we do one thing: convert the drawings sent by the customer into execution instructions that the machine can understand, that is, set the key parameters such as power, speed, frequency and gas pressure.

We know clearly that cutting different materials, different thicknesses, and even using different types of lasers (such as CO2 or fiber) requires completely different settings. Take the 3mm brass laser cutting settings co 2 for example. The power, speed, focus position, auxiliary gas (usually nitrogen) pressure, each parameter must be adjusted just right to cut cleanly and quickly without blackening the edges. This is completely different from cutting a 10mm thick acrylic sheet.

There was a project that particularly illustrates the problem. An architectural design firm sent us a CAD drawing of a particularly complex Islamic-style window pane, requiring us to cut a decorative screen out of stainless steel within 24 hours, and the accuracy must becontrolled within ±0.1 mm. We did it. This ability to quickly and accurately turn difficult designs into physical objects is a microcosm of our daily work.

"Professor Jean-Pierre Kruth, an expert in the field of laser processing, has a very accurate saying: Those who truly master laser cutting know how to make light talk to materials."

This guide is a summary of the experience accumulated by our team day after day, "talking" with various materials and laser beams. What is described in it are all stable process paths that we have verified in the workshop.

Core Principle: a Super Magnifying Glass and a Powerful Airflow

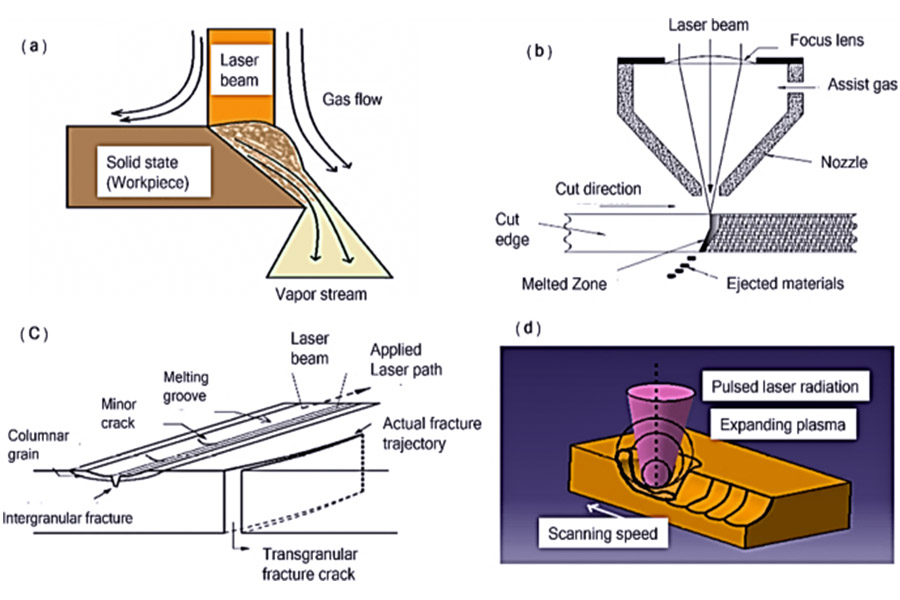

It relies onthe perfect combination of a super magnifying glass and a precise airflow. Let me explain step by step how our equipment works:

Step 1: Create and focus an ultra-high-intensity "light knife"

- Produce pure color strong light: There is a core component in the machine, which is like a "light generator" (professionally called a laser source). It can produce a beam of extremely strong and pure color light, which is the raw material of the "light knife" we use for cutting.

- Transmitting the light beam: This beam of light will not run around by itself. It is relayed by several precise mirrors in the machine (this is the optical path system) and is steadily sent to the cutting head all the way.

- Focusing the energy beam: There is a key component in the cutting head, which works just like you use a magnifying glass to focus on a piece of paper in the sun (it is the focusing mirror). It can instantly compress a beam of several millimeters in diameter into a tiny point (usually less than 0.2 mm in diameter).This focusing processis very critical, and the energy density instantly soars thousands of times!

Imagine that the originally scattered light energy is concentrated on a small needle tip, and the temperature is so high that it can melt or even vaporize metal instantly when it touches it. This is the sharp tip of our "light knife".

Step 2: Remove the molten material to form a clean incision

The light knife starts working: When the ultra-high energy focused light spot hits the material (such as a steel plate), the contact point temperature is extremely high, and the material melts immediately, and even part of it directly turns into gas (gasification).

High-pressure airflowcomes into play: It is not enough to just melt or vaporize, the melted waste slag must be cleaned up before the incision can be formed. At this time, the cutting head will also spray out a high-speed, high-pressure airflow (this is the auxiliary gas), which just sprays down along the axis of the light spot, like a powerful hair dryer.

Dual role of gas:

(1) Main task: blow away the slag

The main task of this airflow is to blow away and clean the metal liquid or gas that has just been melted by the laser from the cut. In this way, the incision can be neat and will not be stuck together. Finally, the cut we need is formed, which is also the key step of how to find your kerf for laser cutting.

(2) Additional effect: help or protection

What gas we choose depends on the material being cut:

- When cutting ordinary steel plates, we often use oxygen. Oxygen not only blows away the slag, but also reacts violently with the high-temperature iron, which is equivalent to adding an extra fire, making the cutting speed faster and more efficient.

- In cutting stainless steel, aluminum alloy and other materials, "protective gases" such as nitrogen or argon are utilized. Their principal uses are to shield the air, avoid oxidation of the cut and its becoming black, and maintain the cleanliness of the cut edge, as well as blow off the slag from the cut area. This is the crux of laserlaser cutting precision processing.

The underlying principle of laser cutting is very simple: using a super powerful focused beam (super magnifying glass) to briefly melt/gasify the material locally, and at the same time using a high-pressure airflow (powerful hair dryer) to blow away the molten material to form a slit. It is fast, accurate, and has a good cut, and can handle complex shape cutting.

"We at JS are proficient in this technology and provide efficient laser cutting service. Whether it is metal plates or pipes, please feel free to come and talk to us and let us use this beam of light to solve your problems!"

Step by Step: From Digital Files to Physical Parts

As a laser engineer at JS. Dealing with these sophisticated equipment every day, I am happy to disassemble for you step by step how laser cutting turns the drawings in the computer into physical parts in your hands. The whole process is efficient and accurate, and it is the perfect bridge between digital and reality.

Step 1: Design import and path planning

Everything starts with the design drawing in your computer (usually in formats such as DXF or DWG). We will import this file into the dedicated control software of the laser cutting machine.

The next step of significance for the software is layout.The software will automatically or manually operate by the engineer to arrange multiple part shapes closely on the entire sheet. There is only one goal: maximize the use of materials and reduce waste. Once the plan is determined, the cutting path is also planned.

Step 2: Machine parameter setting

The operator places the to-be-cut material(e.g. stainless steel plate, aluminum plate, or even cutting wood using a laser) flat on the machine workbench and clamps it.

The most crucial step is here: cutting parameter setting. It is like commanding the machine. Depending on the type of material and its thickness, we enter or call the pre-verified recipe from the control panel:

- Laser power: Energy size, cutting thick pieces requires strong firepower (high power).

- Cutting speed: Adjust the motion speed of the laser head to balance the efficiency and cut quality.

- Auxiliary gas typeand pressure: Use oxygen to "burn" to cut carbon steel? Or use nitrogen to "shield" stainless steel? The type of gas pressure also directly affects the slag blowing effect and cutting quality.

Step 3: Precision machining under CNC control

All is set, pull the start switch! Official laser cutting operation.

This laser cutting and execution process is completely controlled by a computer. After receiving the instruction ofthe CNC system, the cutting head moves along the path traced by the software with high speed. The high-energy laser beam is ignited at once, and the high-pressure auxiliary gas is released synchronously.

The high temperature generated from the laser focus vaporizes or melts the material immediately, and the coaxially swept high-speed air removes the slag to form a clean and neat cut. The machine precisionedly "draws" all lines and curves on the drawing with phenomenal speed.

Step 4: Unloading and quality confirmation

The cutting is completed and the laser goes out. The operator removes the cut sheet skeleton, and the cut parts can be easily removed.

The last step is quality control.The quality inspector will carefully check the size of the parts (using calipers, projectors and other tools) and the quality of the cuts (to see if they are smooth, burrs, slag or overburning). Ensure that every part strictly meets the requirements of the design drawings and meetsthe accuracy standardswe promise.

From digital files to perfect parts, laser cutting achieves fast andhigh-precision materialprocessing through careful design layout, precise parameter setting, efficient execution process and strict quality inspection. It can not only process metals, but also a variety of materials such as wood and acrylic. It is an indispensable tool for the manufacturing industry.

"Our JS company is deeply involved in the field of laser cutting cutting, with advanced equipment and an experienced team. Whether your project is a complex and precise metal part or a creative and unique non-metal product, we are committed to providing reliable processing solutions."

Actual Combat Case Analysis: Manufacturing Precise Front Panels for High-End Audio Brands

Those who play audio know that the first thing you see is the panel. A finely made andhigh-end metal panelis the silent spokesperson for product quality and the first feeling of users. Whether it is well done is directly related to the brand image.

Customer challenge: Make an aluminum panel with brushed texture, complex logo and tiny holes

Background: A well-known Hi-Fi audio factory found us, and their newly designed amplifier needed a front panel.

Difficulties faced:

- The design is too complicated: The panel must have multiple knob holes and long slits for heat dissipation, and a particularly fine brand logo (the logo is composed of many fine lines).

- The trouble with CNC milling machines: The precision ofCNC milling machinesis enough, but the milling cutter will leave scratches on the surface of the beautiful brushed aluminum plate, destroying the overall texture. Moreover, using it to cut the fine logo bit by bit is too inefficient and the cost is increased.

- Stamping is not feasible: The shape of the logo and the heat dissipation slit is too complicated. If a special stamping mold is opened, the cost and time (especially when they are still in the small batch trial production stage) are not worth it.

JS's laser cutting solution: accurate, lossless and efficient

Core question: What does the customer need most?That is, without destroying the delicate brushed effect on the surface of the panel, we can cut out those complex shapes with high precision, and we must be able to respond quickly to theirsmall batch needs.

Our solution:

- Process selection: After analysis, we found that fiber laser cutting is the only process that can simultaneously meet the requirements of 100% protection of the brushed surface and easily meet the micron-level requirements of precision.

- Gas selection: In order to ensure that the cutting edge is clean and beautiful, and matches the brushed surface, I chose high-purity nitrogen as the auxiliary gas. The aluminum cut edge in this way is bright and not black, and has no ugly oxidation.

- Parameter adjustment: My team members and I tested the machine repeatedly several times and finely adjusted the laser power and cutting speed. We found an optimal combination point: the cutting speed is fast enough, and the heat generated has very little impact, so that the Logo part can still be cut clearly and sharply.

- Speed is the advantage:It took us only 48 hoursfrom receiving the final drawing file (DXF format) sent by the customer to delivering the first batch of 50 finished panels to the customer. The customers were shocked!

Final result: a "work of art" panel that makes customers give a thumbs up

Customer feedback: After getting the finished panel, they were very satisfied, especially the presentation of the logo and the cleanliness of all the cuts. The big problems they worried about before did not appear at all.

Final benefits:

- A large cost saving: Compared with the CNC solution originally considered, the unit cost was directly reduced by almost 60%.

- Fast speed: The delivery time was shortened from the original estimated 2 weeks to 2 days, which accelerated the pace of their new amplifier to the market.

- Save time and effort: The panel is a finished product after cutting, and there isno need to grind burrsor do surface repairs. It can really be used after it is finished.

Comparison of laser cutting with other processes:

| Key indicators | CNC milling (aluminum) | Stamping (aluminum) | Laser cutting (aluminum) |

| Cost of small batch complex parts | Extremely high. | Medium to high (including molds). | Low. |

| Prototype/small batch delivery cycle | Days to weeks. | Several weeks (including mold making). | Hours to days. |

| Surface integrity protection | Poor (contact damage). | Good. | Excellent (non-contact). |

| Feasibility of complex geometry | Tall. | Low. | Extremely high. |

| Precision of fine features | ±0.05mm. | ±0.1mm. | ±0.03mm. |

Note: The data is based on the typical value of 1-2mm thick aluminum alloy processing, and the specific project may fluctuate.

"This cooperation makes me more convinced that laser cutting is not just as simple as cutting metal. It breaks many limitations of traditional processing methods. If you are also worried about the processing of complex metal parts, especially small-scale production that requires both high appearance and high efficiency, JS's laser cutting capabilities are the solution you need. Contact our engineering experts immediately and let us help you improve your market competitiveness!"

FAQ - Answer More Questions about Laser Cutting

What are the advantages and disadvantages of laser cutting?

- The advantages are very prominent: It has extremely high precision (easily ±0.1mm or even higher), fast speed, and little thermal impact on the material. Because it is "light" that is cutting, there is no physical contact, so there is no problem of tool wear, and it is extremely flexible.

- Of course, there are limitations: the cutting capacity is limited by the thickness of the material, and the efficiency and quality of cutting too thick boards will decrease. The investment threshold of the equipment itself is relatively high, and the process needs to be specially adjusted when cutting highly reflective materials such as copper and brass, otherwise the effect will be unstable. Smoke and dust will be generated during processing, so a good exhaust and dust removal system must be equipped.

What is "kerf" and how to find it?

The kerf is the material thickness that the beam "burns" when laser cutting. Although it is small, it must be taken into account when designing parts that require precise assembly (such as plug-in and mortise and tenon structures), otherwise the parts may not fit or be too loose.

Want to know the kerf value of your machine under specific materials and parameters? The most practical way is: cut a square of precise size (such as 20mm). Then use a precision caliper to measure:

- The actual size of the cut square (such as 19.9mm).

- The size of the square hole cut out of the plate (such as 20.1mm).

- Kerf ≈ (hole size - square size) / 2.

According to this example, it is (20.1 - 19.9)/2 = 0.1mm. This 0.1mm is the value you need to compensate, which is a key step to ensure the accuracy of the fit.

What is the difference between CO₂ laser andfiberlaser?

This is mainly because they produce different laser wavelengths:

- Fiber laser: The wavelength is shorter, and metal materials absorb it very efficiently. This makes it the first choice for cutting all kinds of metals, with fast speed and usually better energy consumption performance.

- CO₂ laser: The wavelength is longer and can be easily absorbed by most non-metal materials. Therefore, it's better to cut wood, acrylic, plastic and other materials. Which one to use mainly depends on the material you want to process.

Summary

Laser cutting is no longer an unattainable "black technology". It has become a powerful and easy-to-use tool in the hands of our engineers. It turns drawings into physical objects instantly with the speed of light and digital precision. Whether it israpid proofingto verify ideas or mass production of personalized parts, the efficiency and possibilities it brings are revolutionary.

- Are you still worried about the implementation of your design?

- Do you have an exquisite design, but you are worried that you can't find a process that can achieve high precision, protect the surface, and respond quickly to small batches?

- Or, are you looking for a truly reliable laser cutting services partner who understands your needs?

Choose JSand let your creativity shine immediately!

Don't bother searching for laser cutting near me! We are equipped with top-notch fiber laser and CO₂ laser equipment. More importantly, our team of engineers is well versed in material properties and process essence, and can provide you withthe best cutting solution.

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsrpm.com

Resource