Having been engagedin laser processingat JS for many years, I know a key link: designers often get entangled in material selection after completing exquisite designs. Will this structure be easy to break if it is made of acrylic? Can choosing wood avoid edge burns? In particular, can this CO₂ laser machine at hand cut a 3mm thick brass plate? The material selection step directly determines the quality, cost-effectiveness, and even operational safety of the finished product, which is by no means a trivial matter.

Why is laser cutting technology so popular here?

- The core advantage is its excellent material adaptability. Cardboard, wood, acrylic, and even various metal plates can be effectively processed by our machines. But it does not mean that it can do everything.

- Some materials seem feasible, but they will cause problems during actual processing. Poor results are a small matter, and it is more likely to damage the equipment or produce dangerous fumes. This is a lesson I have seen with my own eyes in the workshop.

I found that sometimes, both my peers and our own operators are not very clear about which materials are suitable for laser processing, or underestimate theimportance of material selection. If you want a project to succeed once, understanding the compatibility of materials and lasers is definitely a key step. Although it is collectively called laser cutting machine, we actually use it for three types of processing: cutting, engraving, and marking.

Of course, the machine capabilities vary, and matching materials is the core. Different materials react differently to lasers: some cut smoothly and efficiently, while others may melt or produce harmful fumes. Fortunately, technology continues to advance, and even the parameters of 3mm brass laser cutting settings CO₂ can achieve good cutting.

Core Answer Summary:

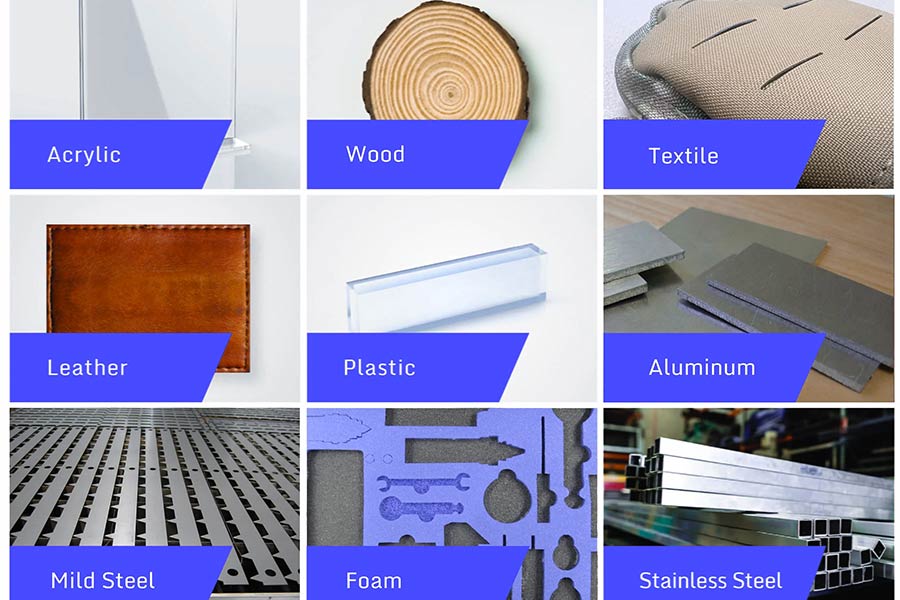

| Material category | Can Be Laser Cut | Can Be Engraved/Marked | Never Cut |

| Plastics | Acrylic, Delrin (POM), PETG. | Acrylic, Delrin (POM), PETG. | PVC (Vinyl), ABS, Polycarbonate (PC). |

| Wood | Plywood, MDF, solid wood, cork. | Plywood, MDF, solid wood, cork. |

Pressure treated wood (containing chemicals).

|

| Metal | Steel, stainless steel, aluminum, brass (fiber laser required). | Anodized aluminum oxide, coated metal. | Pure chromium (high reflectivity). |

| Other | Leather, cloth, paper, foam. | Glass, stone, ceramic. | Glass fiber, carbon fiber composite materials. |

This article will answer your questions:

- This guide will show you which materials are best suited for laser cutting.

- Talk about which laser cutting machine parameters need to be adjusted for different materials.

- Finally, a practical example will be used to illustrate how we choose materials.

Why Should You Trust This Guide? Daily Practice from JS Laser Technology Experts

I deal with CO₂ lasers and fiber lasers every day. These devices have huge energy. We cut far more than metal sheets, acrylic or wood, but also key components of customer-designedproduct prototypes, architectural models, or parts of precision equipment. Behind each project is a specific demand.

- Last week, I helped an architect use a laser cutting machine to process a batch of high-precision wooden components for his architectural model. The day before yesterday, I was cutting steel plates with a thickness of more than 20mm, which are key components of large equipment. This daily routine made me deeply realize that materials such as stainless steel, aluminum, and titanium alloys have different ways of absorbing lasers, the difficulty of cutting, and the characteristics of edge forming.

- We have encountered many situations. I remember one time, a customer wanted to use our CO₂ laser to cut brass parts. We immediately stopped this operation. Because the zinc element in brass is very easy to vaporize and produce highly reflective melts at the wavelength of CO₂ lasers, which will definitely damage the expensive laser head. That time we helped him adjust the process to avoid equipment damage.

- Another time, when we were cutting a special composite material, the customer reported that the cutting edge always had burrs or burns. We spent a whole afternoon repeatedly adjusting key parameters such as power, speed, and air pressure, and finally achieved a smooth and precise cutting edge. In order to ensure that the cut parts can be assembled, we accurately calculate andcontrol the kerf, which is one of the core skills of our daily work.

"As Arthur Schawlow, a pioneer in the field of lasers, emphasized: Lasers are not magic, you must understand light and you must understand your materials."

This guidebook is a summary of our experience in the field based on this comprehensive knowledge, connecting material properties and laser technology. It is formulated from real problems and solutions, and its purpose is to assist you in mastering laser cutting more efficiently and safely.

Basic Principle: Why are Lasers Able to Cut Materials?

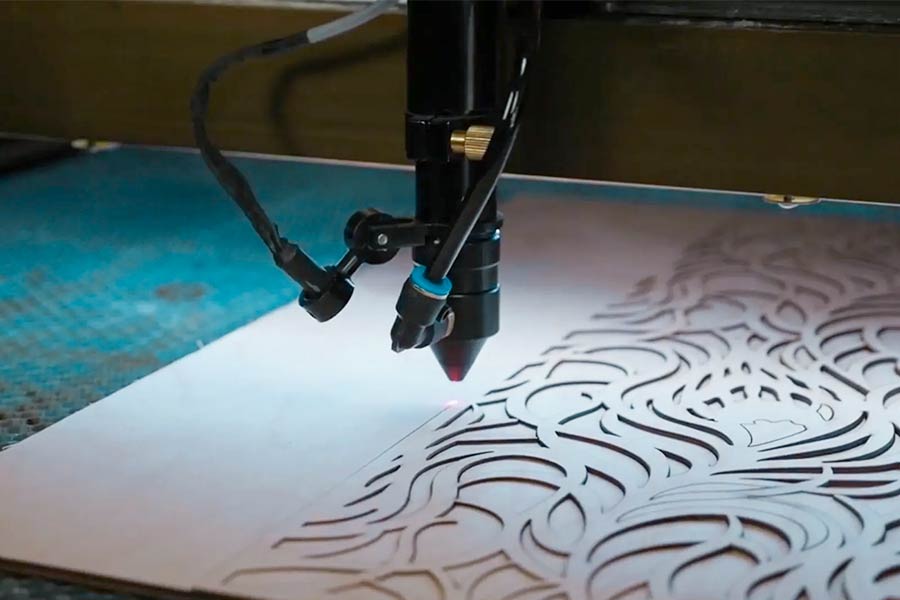

Theprinciple of laser cuttingis to concentrate enormous energy in a very small point. Let us assume that we utilize a unique instrument (laser) to create a very powerful and pure beam of light. Then, by the lens, this light beam is focused into a spot of light very small compared to a needle tip.

- Ultra-high heat: The energy is very high at this very small focal point. This ultra-high heat can cause instant extreme changes in the material, melt it, burn it, or even evaporate it instantly.

- Blow away the residue: Incomplete burning with a hole is not good enough, we need a clean cut. High-pressure auxiliary gas (compressed air, oxygen or nitrogen) is useful here. It is like a high-pressure air knife, which blows the melted or burned material residue off the cut.

- Movements to make a cut: The core motion of laser cutting in JS's production workshop is precise movement. Have this light spot with ultra-high energy move over the material along the intended route. It moves along, burning or evaporating the material in the process, and the high-pressure gas cleans it along the process. This process reveals how to find your kerf for laser cutting, and what is left in the end is aclean and precise cut. This is the process of laser cutting and material forming.

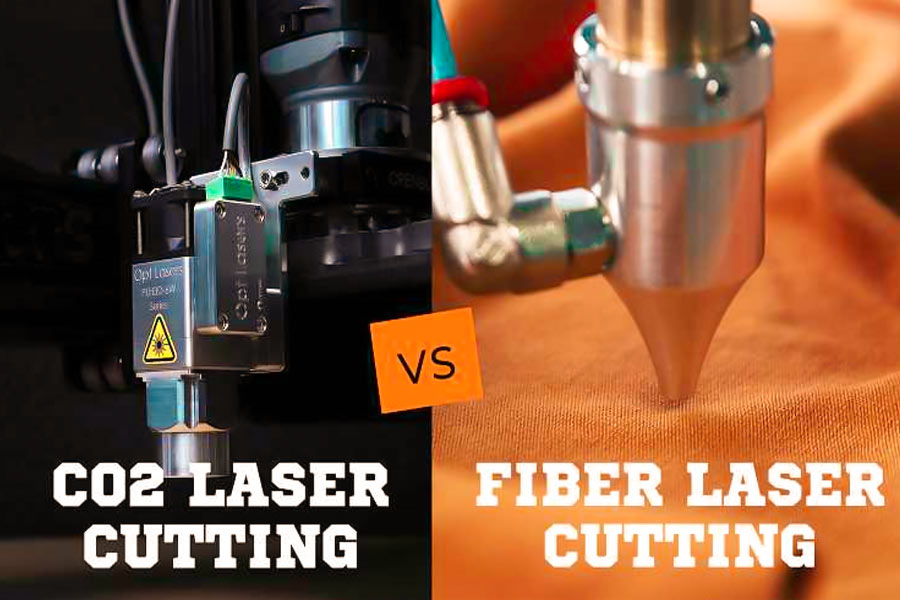

Key difference: CO₂ laser vs. fiber laser

Choosing the right type of laser is as critical as choosing the right material itself!They work on different principles and specialize in different areas:

CO2 laser (non-metal expert):

- Wavelength: Longer, approximately 10.6µm.

- Impresses with cutting ability: Organic materials and non-metals! Wood, acrylic, leather, paper, certain stones and plastics (such as ABS). These can accept the light energy of this wavelength efficiently, thus the cutting action is usually swift and good, and the cut is nice and smooth.

- Features: The technology is very mature and it is the classic workhorse forprocessing non-metallic materials.

Fiber laser (metal cutting king):

- Wavelength: Very short, about 1.06µm.

- Specialize in metal: Light of this wavelength is particularly efficient for metal materials to absorb.

- Here comes the point: The metal surface is usually very reflective like a mirror, and most of the energy of ordinary light (including CO₂ laser) is bounced away. But this specific wavelength of fiber laser can overcome the high reflectivity of metal and allow energy to effectively enter the metal to heat it.

- Core advantages: Cutting metal extremely fast, with extremely high precision, relatively lower energy consumption, and narrower cutting kerf. It is the undisputed first choice for laser cutting of metal parts that require precision processing.

Important revelation:The matching of wavelength and material absorption is the basis for successful cutting. This is why you can never useordinary CO₂ lasersto cut brass even if it is only 3mm thick! Brass has a very high reflectivity to CO₂ laser wavelength, and most of the laser energy is reflected back. Not only can it not be cut, but the reflected energy may also rush directly back into the laser and damage the laser head!

The essence of laser cutting is to focus ultra-high energy precisely on one point, change the state of the material instantly, and then use auxiliary high-pressure gas to remove the slag and achieve precise separation.

"The core of choosing CO₂ or fiber laser depends on the absorption characteristics of the material to the laser wavelength. If you have a project on hand and are not sure about the material or process, don't hesitate, feel free to contact our JS engineers to chat, we use tens of thousands of hours of practical experience to help you achieve it!"

Laser Cutting Material List: Feasibility and Precautions

I work with various laser materials every day. This material list is my experience from actual combat. It tells you which materials are suitable for cutting, how to cut, and what to pay special attention to:

Plastics & Polymers: The effect is very different

- Acrylic (PMMA): This is the "star player" of laser cutting! The cut edge is smooth and transparent, just like it has beenspecially polished, and the effect is very beautiful. It is the right choice for making signs, display stands, and crafts.

- Delrin (POM / acetal resin): It is an engineering plastic. After laser cutting, the edge is clean and sharp, and the size is almost not deformed. It is especially suitable for functional parts that require precise matching, such as gears, buckles, and fixtures.

⚠️ Absolutely forbidden area - PVC (polyvinyl chloride):Never! Do not use laser to cut PVC!It will release highly toxic chlorine gas at high temperature, which is not only extremely harmful to the human body, but also forms hydrochloric acid inside the machine, which seriously corrodes your laser system and is expensive to repair. If you see PVC materials, please go straight away!

Wood & composite boards: Economical and practical, with different effects

(1) Plywood & MDF (Medium Density Fiberboard):

- These two materials are economical and practical, and the laser cutting effect is generally good. They are common choices for making models, furniture parts, and decorations.

- But be aware that the cut edges will turn black due to high-temperature carbonization (especially MDF). The cutting quality of plywood is affected by the glue used inside and the layers of wood themselves, and sometimes there will be slight differences. They are very common forlaser cutting wood models.

(2) Solid wood:

If you are looking for a more natural texture and grain? Solid wood is a good choice. But the effect varies greatly:

- Low-density and low-resin woods such as basswood and cherry wood are smoother to cut and have relatively clean edges.

- However, woods with high density or high oil and fat content (such as some hardwoods) are prone to more smoke and scorch marks when cutting, and require more fine-tuning of parameters.

Metal: The main battlefield of fiber lasers

(1) Steel & stainless steel: This is the material that fiber lasers are best at!

- When cutting carbon steel, oxygen is usually used to assist, which can speed up the reaction like a "combustion aid", allowing you to cut thicker plates.

- When cutting stainless steel, in order to get a perfect edge without oxidation, you have to use an inert gas such as nitrogen to protect the cutting surface.

(2) Aluminum & Brass: A big challenge!

- These two metals are very reflective (like a mirror), which is a challenge for laser cutting.

- You must use a high-poweredfiber laserto cut them effectively.

Directly answer the key question:Can 3mm brass be cut with a CO₂ laser? The answer is clear, no! The wavelength of the CO₂ laser will be greatly reflected by the brass, and it will not be able to cut it at all, and the reflected laser energy will most likely damage the internal optical components of your laser!

Other common materials: each has its own characteristics

- Leather: Laser cutting leather is very fast and can cut very fine and complex patterns. However, the smell is relatively strong when cutting, and strong ventilation and exhaust must be ensured in the workplace.

- Cloth & Paper: Laser cutting these thin materials is very fast. There is an additional benefit: when cutting synthetic fiber fabrics (such as nylon and polyester), the high temperature will seal the edges at the same time, effectively preventing the threads from unraveling and saving the trouble ofsubsequent processing.

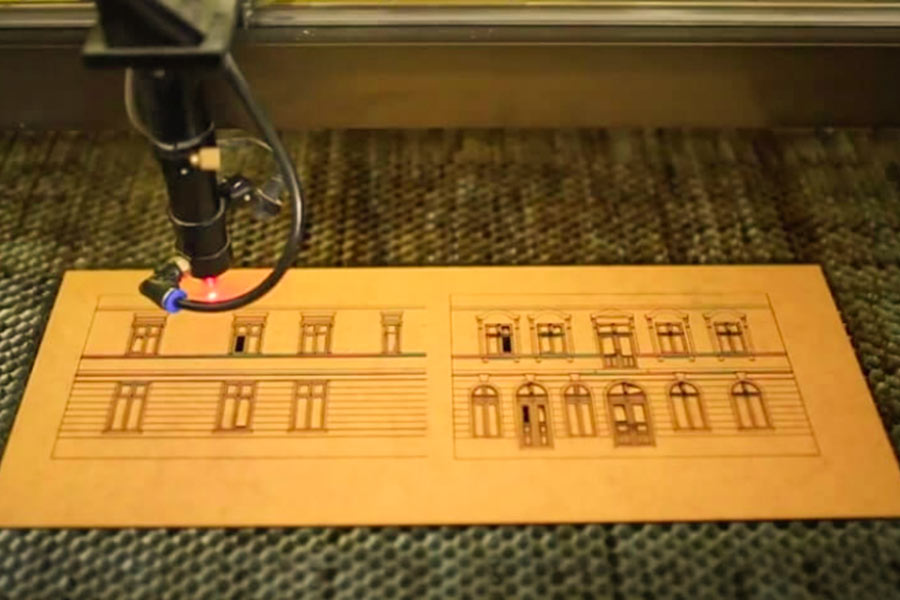

Actual Combat Case Analysis: Building a City Planning Model for an Architectural Firm

Next, I will share this tense and exciting project experience and see how we use laser cutting to help customers win a key battle:

Customer challenge: Make a city model with hundreds of fine building outlines within 7 days

Background: A top architectural firm found us with an urgent task: within 7 days, make a large 2m x 2m city planning model with hundreds of fine building outlines on it. This is the key prop for them to win important project reports. The model must be rich in details, precise in lines, and clear in layers.

Customer's dilemma: time is tight and traditional methods don't work

- 3D printing limitations:There is simply not enough time! Printing such a large and fine building cannot be completed in 7 days. Moreover, the surface of the printed part has layers, which will destroy the exquisiteness required by the model.

- Manual cutting is not feasible: It is difficult to cut hundreds of complex building outlines by hand within 7 days and ensure accuracy.

JS's solution: Layered laser cutting materials to build depth

We carefully analyzed thatthe customer's core needs are three: speed, accuracy, and expressiveness.A single material or method cannot solve this problem. The solution we provide is: use different materials to make them in layers, and laser cutting them in parallel!

Base layer:

The model base plate and terrain contours are made of 6mm medium-density fiberboard (MDF). Why choose it? It is cheap, the base plate is easy to color after cutting, and it is thick enough to support the entire model.

Building body:

For all the walls of the building, we use 1.5mm thick birch plywood to cut. This choice is critical:

- Thin and strong: The thickness is thin enough to reflect the architectural details, and the strength is enough to support the model structure.

- Good cutting effect: The edges cut by laser are relatively clean, the color is lighter, and it has a warm wood texture, which is visually comfortable.

- High efficiency: Fast cutting speed for thin plates.

Window details:

We used0.5mm transparent acrylicsheets to cut the glass curtain walls of the iconic buildings designed by customers. After cutting, we embedded them into the reserved position of the plywood wall, and instantly had a realistic glass reflection effect!

Final result: Delivery ahead of schedule, amazing the audience

We split the design drawings into cutting files for different materials, and three laser cutting machines were fully fired to cut different parts at the same time. This efficiency improvement is not a little bit:

| Efficiency indicators | Traditional single material approach | JS hierarchical parallel scheme | Lifting effect |

| Time required to complete cutting | Estimated duration>5 days. | Actual 2.5 days. | Production efficiency increased by 300%. |

| Overall project cycle | Tight card for 7 days limit. | Completed on the 5th day. | 2 days in advance. |

On the 5th day, all parts were cut and assembled,two days ahead of the 7 days required by the customer!They were given enough time to check and adjust.

How did the final model look?

The customer team was very satisfied when they saw the finished product. The fine architectural outline, clear layers, and acrylic glass embellishment had a strong visual impact, far exceeding their expectations. They said that this model helped a lot in the report and helped them successfully win the project!

Core revelation:This experience profoundly illustrates that the truly valuablelaser cutting serviceis not just about starting the machine to cut materials. It tests how to intelligently combine the characteristics of different materials according to the project goals and use laser cutting technology to provide a complete and optimal solution.

"The core value of laser cutting is to transform complex designs into high-quality entities. JS engineers are good at scientifically matching material characteristics and processing technology according to project requirements to develop the best solution. If you have high requirements or urgent model, prototype or parts manufacturing needs, please contact the JS team immediately and let us help you achieve your goals."

FAQ - Answers to More of Your Laser Cutting Material Questions

What is the difference between the best materials for laser engraving and laser cutting?

Engraving can be used on a wider range of materials. Almost any material that can be cut can be engraved, and materials such as glass, marble, granite, coated aluminum, and coated metals that are not suitable for cutting through can be laser marked or surface treated very well. This is mainly because of engraving: it precisely removes a thin layer of the surface of the material, rather than cutting through the entire material. Therein lies the key difference.

How do I find the laser cutting machine settings for different materials?

This is a common question, but there is no universal settings table, and the right settings depend on a few key factors: whether you are using a CO2 or fiber laser, how powerful the laser is, how fast it is cutting, what specific material it is, and how thick it is.

Our advice is to first refer to the recommended range given by the material manufacturer, and then test it on a piece of scrap material. This little test will help you find the best combination that will give you the smoothest cut with the least amount of scorch marks on the edges. The key is to try more and find the set of numbers that best suits the materials and equipment you have.

Why use laser cutting materials?

- First, it has super high precision and the cuts are almost identical every time, which is especially important for jobs that require a perfect fit.

- Second, it can easily handle very complex designs, such as those with fine patterns or small sharp corners, which are difficult to achieve with traditional tools.

- Most importantly, the laser head does not have to touch the material at all, which avoids the material being deformed by pressure and does not need to be clamped tightly, so it is particularly suitable for cutting thin and brittle materials and is not easy to damage.

Summary

The most powerful thing about laser cutting is that it can accurately turn the design drawings in your computer into the physical parts in your hands, almost exactly. And if you want the final effect to be perfect,choosing the right materialis definitely a key step. Understanding the matching characteristics of materials and lasers is the key to improving processing level.

Have you encountered these challenges in your project progress?

- Not sure which material (such as stainless steel, acrylic or specialty wood) best suits your needs?

- Worried about wasting materials while exploring cutting parameters?

- Need reliable laser cutting services support?

Leave these problems to us JS!We specialize in solving them. You only need to:

- Submit your design files online.

- Get a transparent instant quote.

- Our engineerswill review the design and recommend the best material for your implementation based on your goals.

No need to search for laser cutting near me service providers. Submit online, and our professional team will optimize material and process selection for you to ensure efficiency and reliability.

Upload your design nowand let us help you realize your creativity accurately!

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsrpm.com

Resource