Imagine you designed a turbine blade with a labyrinth of cooling channels and aerodynamic textures on the surface. CNC machining? The tool can't reach into those twists and turns. Ordinary sand casting? The surface is too rough and all the details are lost. How to solve this dilemma?The answer lies in a 4,000-year-old but timeless process: investment casting.

Its core secret is to perfectly replicate a wax model.We first use wax to accurately make all the details of the part ("investment casting" originally means "wrapping"). Then, the wax model is repeatedly coated with a special ceramic slurry, which is dried and hardened layer by layer to form a solid ceramic shell to wrap it.

Here comes the key step: heating the shell, the wax inside melts and flows out, leaving a cavity in the shell that is exactly the same as the original wax model. Finally, pour molten metal into the cavity, knock off the ceramic shell after cooling, and a metal part that replicates all the complex details is born.

This is why it is the preferred process for manufacturing extremely complex parts with fine cavities or curved surfaces such as turbine blades. Combined with modern CAD design,3D printing wax for investment castingand control technology, we can efficiently produce high-quality parts with precise dimensions, smooth surfaces and small machining allowances. In our workshop, investment casting is a powerful tool for those impossible tasks.

Core Answer Summary:

| Comparison items | Investment Casting | Sand Casting | CNC Machining |

| Core principle | The "lost wax method" uses a meltable model to manufacture disposable ceramic molds. | Use reusable molds to press out the mold cavity in sand. | Cut off excess material from solid metal blocks. |

| The most suitable | Complex geometric shapes, high surface finish, thin-walled parts. | Large, simple parts with low tolerance requirements. | High precision, prototyping, and simple geometric shapes. |

| Main limitations | High initial cost and long process cycle. | Low dimensional accuracy and rough surface. | Difficult to process complex internal structures and material waste. |

In this guide, I will introduce in detail:

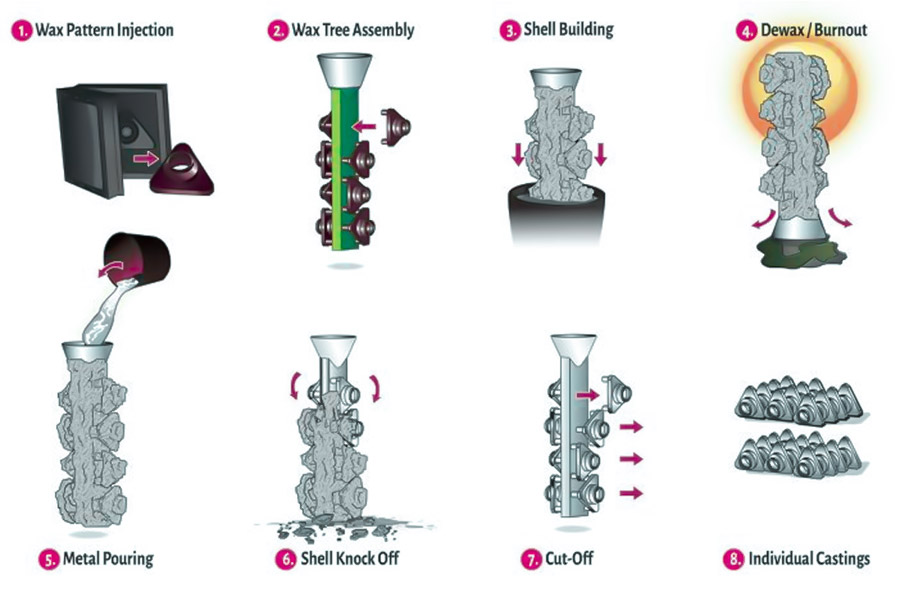

- The seven complete steps of the investment casting process, and use an investment casting diagram to visually present the process.

- Then, I will compare the advantages and disadvantages of sand casting vs investment casting.

- Finally, through a real case, I will prove its unique value and help you easily master the core advantages of this technology.

Why Should You Trust This Guide? Comprehensive Perspective From JS Manufacturing Experts

At JS,helping customers find the best part manufacturing solutions is our daily work. We are not just experts in operating CNC machine tools, but more like manufacturing consultants for customers. After working in this industry for a long time, you will understand one thing: not all parts are suitable forCNC cutting (that is, "subtractive manufacturing"). Sometimes, additive manufacturing ideas such as investment casting are smarter and more economical solutions.

- Let me give you an example: Previously,an aviation customer brought a complex bracket to consult. If it is made by CNC, it will be divided into three parts for processing and welding. Not only are there many processes, but the weight and strength are also affected. After careful evaluation, our team strongly promoted investment casting. What is the result? An integrally formed part is lighter and stronger, and it also saves the cost and hidden dangers of welding.

- Another time, wehelped an art client to replicate extremely fine sculpture details. Traditional methods simply could not achieve that effect, so we used 3D printing investment casting to perfectly restore the details of the original.

"Just as the manufacturing master Henry Ford emphasized: quality means adhering to standards when no one is supervising."

This guide is condensed with the experience and judgment criteria accumulated by our JS team in countless project practices. It is not an empty theory, but our actual experience after repeatedly comparing different processes (especially CNC and investment casting) after facing the key factors such as cost, performance, and design complexity. Our goal is simple: to help you avoid detours, use the right method, and make the right parts. After all, we are not cold machine operators,but partners who really understand manufacturing.

What Exactly is Investment Casting?

In terms of the way we work in our workshop,investment casting is a process of making an identical model with wax, then wrapping it with ceramic, and finally melting the wax and pouring metal into it to obtain a replica of a precision part. It also has a more vivid name, the lost wax method.

Making wax models:

Most critical step! First, there has to bemade a wax model of precisely the same form and size as the ultimate metal piece. How precise this wax model is determines how excellent the ultimate piece is going to be.

Ceramic shell:

A special ceramic slurry is applied layer upon layer onto the wax model surface. Fine sand should be added to each layer. It is applied when completely dry and hardened. Done many times, a hard ceramic shell forms on the outside of the wax model, completely encasing it inside.

Why is it called "Investment Casting"?Because in this Invest! Investment, in casting parlance, refers to covering or wrapping layer, which accurately describes the fundamental process of encasing the wax model snugly in ceramic slurry.

Melting wax, pouring metal, shelling:

- Lost wax melting: After the hardening of the ceramic shell, it is placed in a furnace heated. The wax model inside melts and pours out, and the cavity with the shape,size and details of the wax model precisely replicated in the shell.This is the main lost wax process.

- Metal pouring: Fill the cavity with molten metal at a particular temperature.

- Shelling and cooling: Once hardened and cooled through, remove the outer ceramic shell by vibration or high-pressure water jet. The exposed metal part is your designed blank.Through cleaning, a very accurate part is formed.

"What is investment casting then? It is the way that fusible wax models are employed to replicate fine metal parts. From precision aircraft engine blades, medical devices, to unique artwork, it cannot be replaced. Here at JS, we utilize this ancient art in combination with modern technology (such as 3D printed wax) on a regular basis to help customers bring seemingly impossible designs to life. If you find that you have a complex metal piece on your hands and are wondering if investment casting is your best friend, please don't hesitate to get in touch with us. You are always free to visit around our workshop and see the process of processing for yourselves."

8 Key Steps of Investment Casting

As an engineer responsible for the investment casting production line at JS,I will break down the seven core steps of this precision process, just as clearly as taking you on a tour of our workshop process:

Step 1: Make a precision wax model

It all starts with investment casting wax. We heat and melt the special wax material, inject it into a precision metal mold, and cool it to get a wax model that is exactly the same as the final part you designed. This is the source of precision. Forsmall batch trial production or extremely complex parts, we will directly use 3D printing technology to make wax models, saving the cost and time of opening metal molds, which is very flexible.

Step 2: Wax Tree Assembly

To improve efficiency, we will not do it one by one. Instead, we will carefully weld multiple wax models to a central runner and branch runners made of the same wax, just like building blocks, to form an inverted "tree". Imagine that the trunk and branches of this tree are the channels for the molten metal to flow into each wax model, sothat multiple parts can be cast at one time.

Step 3: Build a ceramic shell

This is the origin of the name of investment casting (Investment means wrapping). We immerse the entire wax tree in a special ceramic slurry, evenly coat it with slurry, and immediately sprinkle a layer of very fine refractory sand on the wet surface. After this layer dries and hardens, repeat the process, immerse it in a coarser slurry, sprinkle slightly coarser sand, and dry it again. Repeat this 5-9 times until a sufficiently thick and strong ceramic shell is formed outside the wax tree. Each step of drying is crucial and determines the final strength of the shell.

Step 4: Dewaxing

We put the entire shell into a high-pressure steam dewaxing kettle (like a pressure cooker for casting). The high-temperature and high-pressure steam willquickly melt and flush out the investment casting wax inside, and discharge it through the reserved channels. At this time, a cavity network that perfectly replicates the shape of the original wax model tree is left inside the solid ceramic shell.

Step 5: Metal Pouring

The dewaxed ceramic shell is sent to a high-temperature furnace for baking.

There are three purposes:

- Burn off the remaining trace wax, completely remove moisture, increase the shell strength and preheat it to a temperature close to the molten metal.

- At the same time, we melt and refine the selected metal in the melting furnace to the best state.

- Then molten metal is slowly and smoothly cast into the preheated ceramic shell cavity to fill each part cavity at the end of a branch.

Step 6: Shelling

After pouring, let the shell cool in a controlled environment to ensure that metal inside is solidified completely. After cooling, the ceramic shell covering outward is shaken off and shattered by vibration table vibration or high-velocity water jet to expose the tree of metal inside.

Step 7: Cutting

Then, the formed metal pieces are cut and removed from middle runner and branch runner by band saw,grinding wheel cutting or laser.

Step 8: Finishing and inspection

After cutting, we remove these scratches by grinding,polishing and other methods to get a flat surface. Depending upon your requirements for the part, sandblasting, heat treatment, precision machining or surface treatment are also requested. Finally, X-ray flaw inspection is utilized to confirm internal defects, and the three-coordinate measuring machine (CMM) precisely measures all vital dimensions to ensure every part shipped relentlessly meets specification on your drawings.

All these seven investment casting processes are interrelated closely. The key thing is to employ accurateinvestment casting wax to create the model replica, and then, following wrapping and transformation of the ceramic shell, finally achieve high-precision shaping of complex metal parts.

"At JS, we understand the know-how in every step of processing and quality check points and are very well capable of using 3D printing wax model technology to penetrate complex structures with difficulty in obtaining with traditional methods. When you plan to manufacture metal parts with interior cavities and critical surface requirements, investment casting could be your best option. Please do not hesitate to approach the JS team with your samples or design drawings and let us collaborate to create the most effective manufacturing plan."

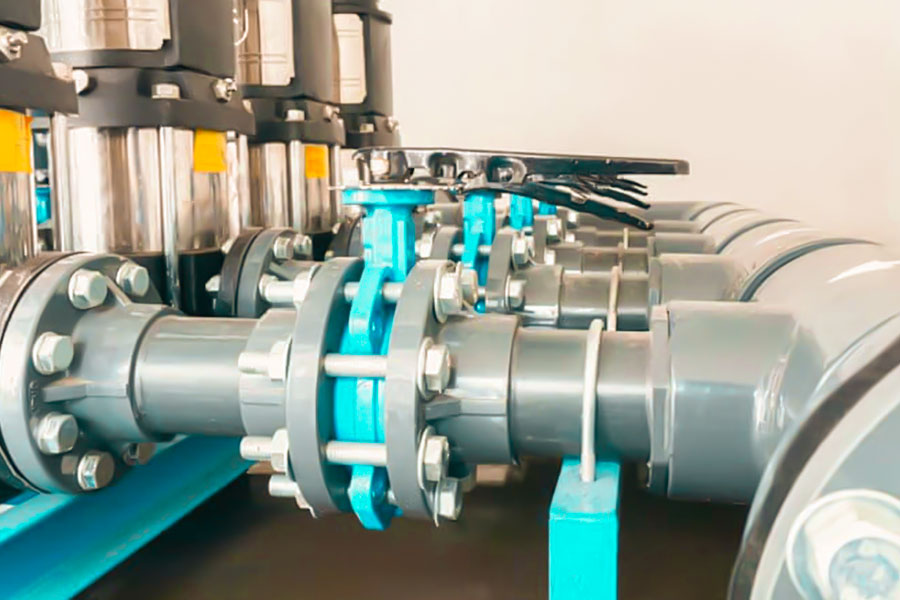

Real-life Case Analysis: Manufacturing One-piece Stainless Steel Valve Bodies For the Oil Industry

Now, let me share a real case of how we use investment casting to solve a difficult problem in the oil industry. This is not just a theory, but a real turning of the impossible into reality.

An oil equipment giant came to us and they wanted a one-piece 316 stainless steel valve body for high-pressure pipelines. The design drawing showed the difficulty: the valve body has several winding fluid channels, which is like a metal maze. The most terrible thing is that the customer requires absolutely zero leakage, which means that the entire valve body must be a whole, and there must not be any welds, because welds are potential leakage risks under high pressure.

Two solutions they considered before:

- CNC processing solution: Engineers thought about disassembling the valve body into several pieces, processing them separately,and then welding them together. After cost accounting, it was beyond their tolerance. More importantly, each weld is a time bomb-like leakage hazard. On high-pressure oil and gas pipelines, who can afford this risk?

- Sand casting solution: Tried it, butthe surface of the internal channel is too rough, like sandpaper,the fluid resistance is large, affecting efficiency. Moreover, the dimensional accuracy of the key sealing surface does not meet the requirements, and the sealing is not guaranteed.

The core contradiction is nakedly laid out: extremely complex internal geometry VS strict requirements for structural integrity and sealing. Traditional processes hit a wall here.

JS's solution: Investment casting, perfect combination of complex internal organs and seamlessness

Faced with this challenge, our team immediately thought of investment casting (lost wax method).

Why? Because it is naturally suitable, perfectly replicating complex shapes, one-piece molding without seams.

- Precision shaping:We first use a high-precision mold(combined with CAD design and precision machining) to inject a complete wax mold. This wax mold, which makes the intricate internal flow channels in the customer's design drawings, is made exactly as a whole.

- Ceramic cloning: Put on multiple layers of special ceramic "coats" on this wax mold, harden layer by layer, and form a solid ceramic shell. Then, the key step is here: heating! The wax melts and flows away, leaving a complete cavity with all the complex flow channels inside the ceramic shell.

- Metal rebirth: Pour moltenhigh-quality 316 stainless steelinto this seamless ceramic mold cavity. The metal fills every corner, and after cooling and solidification, knock off the ceramic shell, and a stainless steel valve body with extremely complex internal flow channels and no welds is born!

Results landed: performance exceeded expectations, and costs were reduced

What was the result?After the customer received the finished product, the effect was amazing:

- Zero leakage guarantee: The entire valve body is a whole piece of metal, completely eliminating the biggest risk point of the weld, the structural integrity is impeccable, and the high-pressure sealing is perfectly up to standard.

- Performance improvement:The internal flow channel surface of the investment castingis extremely smooth, which greatly reduces fluid resistance, improves flow and efficiency, and even exceeds design expectations.

Cost surprise:

- Number of parts: From the original CNC solution required 5 parts to be welded, it is directly changed to 1 integral part.

- Potential failure points: The number of welds was reduced from 4 (high-risk points) to 0.

- After final calculation, the manufacturing cost of a single valve body was nearly 30% lower than the original CNC machining + welding solution!

"This case vividly demonstrates the core value of investment casting: it can directly transform the designer's complex design into a structurally reliable integrated metal part, while also bringing surprises in terms of cost and efficiency. Investment casting is the guarantor of this inherent quality, especially for parts with complex inner cavities and absolute sealing requirements, its advantages are difficult to replace by other processes. If you are having a headache for complex metal parts, don't hesitate! Please contact JS. A disruptive solution can be found in the time it takes to have a cup of coffee."

FAQ - Answer More Questions About Investment Casting

Question 1: investment casting vs sand casting: How should I choose?

They are different in many ways, and the choice depends on what you are making: if the shape is complex or requires high precision, investment casting may be more suitable. If the thing is simple or you want to save money, sand casting is better. Below I have listed the core features in a table, which is clear and you can know which one is more suitable for your situation by comparing them.

| Comparison aspect | Investment Casting | Sand Casting |

| The ability to make complex productions | Very strong, capable of producing various fine shapes and cavities. | Relatively weak, suitable for designs with simple structures. |

| Surface quality | Very good, almost no additional polishing required. | It is relatively rough and usually requires subsequent processing (such as grinding, cutting). |

| Accuracy level | High, with small dimensional errors (e.g. approximately ±0.1mm per 25mm). | The error is relatively large (e.g. about ±0.8mm per 25mm). |

| Mold cost | High (requiring the production of precision wax molds). | Low cost sand mold material. |

| Unit cost | Moderate to high (affected by materials and processes). | Low (especially with significant cost advantages in large quantities). |

| Suitable for production volume | Medium to large quantities (economies of scale can reduce unit costs). | Flexible application: Suitable for small batches/individual items (such as large parts), as well as large quantities. |

Question 2: What are the disadvantages of investment casting?

- Large initial investment (especially for metal molds): To make high-precision wax molds, you usually have to make a set of precision metal molds first. The cost of this set of molds is not low, so it will be uneconomical for small-scale production. Of course, there is now 3D printing wax mold technology to alleviate this problem.

- Long production cycle: There are many steps in this process, including making wax molds, assembling trees, repeatedly coating shells, dewaxing, roasting, pouring, cleaning... Each step takes time, and the overall process is slower than many other casting methods. For urgent projects, you have to plan in advance.

- Size is limited: Making particularly large and heavy parts is not its strong point. Due to the difficulty of shell making, dewaxing and pouring, the upper limit of the size and weight of parts it can handle is lower than that of sand casting.

Question 3: How are investment casting molds made?

Let me disassemble the key point of molds in investment casting. In fact, there are two completely different molds involved here:

Wax mold mold (reusable):

This mold is usually made of aluminum or steel through precision CNC machining (CNC). It determines the shape and precision of the wax mold, and can be used repeatedly tens of thousands of times to inject exactly the same wax mold parts.

Ceramic shell for pouring metal (disposable consumables):

This is the mold used to pour metal. It repeatedly immerses the wax mold in ceramic slurry, dries and hardens layer by layer to form a high-temperature resistant shell. Each part needs to be made separately. After heating and dewaxing, the cavity inside is where the metal is poured.

Summary

The essence of investment casting is that it uses fusible wax molds to provide a unique solution for manufacturing metal parts with complex structures, fine details and excellent surface quality.It is one of the key processes for transforming difficult designs into reliable metal entities.

Do you often encounter this situation?

- You have a great design, but you are worried that it will be difficult to manufacture because the structure is too complicated?

- Are you struggling between investment casting, sand casting, and CNC machining, and are you unsure which one is the most suitable? You need to consider whether the design can be realized, and weigh the budget and performance requirements...

Don't worry, this is exactly the problem our team solves every day!At JS, our engineers focus on this: according to your design drawings, budget range and part performance requirements, we will help you analyze and compare to find the best and most cost-effective manufacturing solution.

Want to know the answer quickly? It's easy!

Upload your CAD file now.Let our professional team of engineers help you evaluate clearly, provide professional advice, and turn your impossible and wonderful designs into reality steadily!

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com