Materials determine the fate of a part. Imagine the turbine blades of a jet engine, which are subjected to over 1000°C at a high speed of several thousand revolutions. If the wrong material is chosen, no matter how beautiful the shape is, the result may be catastrophic failure.

In the field of investment casting,90% of whether a part will work in the end depends on one question: Is the material chosen right? The materials here refer not only to the metal that is finally formed, but also to the wax mold from inside to outside and the ceramic shell that wraps it.

That is why in our workshop, choosing the right material is absolutely the core. If the right material is chosen, the hard indicators such as strength, heat resistance and corrosion resistance of the parts can be met, and it can also help you save money and materials,reduce the problems such as shrinkage holes and cracks that are easy to appear during casting, and save a lot of trouble in subsequent secondary processing.

This process is really powerful. From small precision pipe joints to key components of aircraft engines, they can all be made with smooth surfaces and precise dimensions, relying on this set of material systems as the foundation.

From the projects I have handled, mistakes in material selection can lead to substandard performance at best, or even batch scrapping and delayed delivery at worst. Accurate material selection can optimize costs, reduce defects, and simplify post-processing. At the same time, whether it is steel or metals such as aluminum and copper, the final performance is inseparable fromthe key heat treatment process. Therefore, a deep understanding of the characteristics of various materials is as important as understanding the casting process itself.

Summary of The Core Answer:

| Material category | Major role | Examples of commonly used materials |

| Model material (Pattern) | Copying the geometric shape of a part can be melted or burned out. | Investment Casting Wax, SLA UV curable resin, nylon powder (3D printing). |

| Shell material | Create a sturdy and high-temperature resistant casting cavity, and replicate the details of the model. | Silica sol/water glass (adhesive), zircon sand/mullite powder (refractory aggregate). |

| Casting Metal Alloy | The body that constitutes the final component determines its mechanical and chemical properties. | Stainless steel, carbon steel, aluminum alloy, copper alloy, titanium alloy, nickel based superalloys (Inconel). |

Now, I will explain the core materials of investment casting:

- I will explain in detail the role of each key material in the process.

- Introduce how 3D printing can revolutionize model manufacturing.

- And combine a real case to show how choosing the right material can significantly improve part performance.

- I believe this guide can provide you with practical reference.

Why Trust This Guide? Real Experience From JS Material Science and Manufacturing Experts

Simply put, we at JS are not just foundries, butmore like partners who help you solve material problems. We deeply understand the core differences in material selection: medical titanium alloys for human bodies and stainless steel for factory valves have completely different material selection ideas. If the formula is not right,even the most expensive super alloy castings will be scrapped.We have really experienced this situation.

- To be honest: I once helped a customer who made aircraft. They used nickel-based super alloys to make parts, and they always had small surface cracks. We didn’t guess blindly, but studied it carefully, and finally found that the formula of the ceramic shell that wrapped the casting was not suitable. After adjustment, the problem was completely solved.

- There is also a startup company that wants to make complex prototypes, and the cost is frighteningly high. We helped themuse 3D printing wax for investment casting, which cut costs by 70% at once! These are all real experiences.

The content in this guide is not empty talk of theory, but we wrote it based on countless experiments and truly understood how to match materials and materials and processes.

"As the famous metallurgist Harry Brearley (the inventor of stainless steel) said: Discovery often comes from the persistent pursuit of the root cause of failure."

The challenges we encountered and the solutions to them are all integrated into this guide. It embodies our practical experience in materials and manufacturing on the front line, just to help you avoid risks and increase the probability of success.

The Cornerstone of The First Step: Pattern Materials

Let me tell youthe key to the first step in investment casting, that is model material selection. This is how we make the original template.Accuracy and surface finish of the final casting are decidedquite strongly when we choose this material.

Traditional main force: investment casting wax

Why wax?It is a tried and true old friend that we have used for many decadesbecause it has several key characteristics:

- Good fluidity: When melted and heated, it flows into the tiny corners and crevices of the mold like water, precisely duplicating the fine details of the pattern.

- Clean burning: It has a relatively low melting point (often softening or melting at around 60°C to 80°C), and importantly, it can be burned completely and cleanly in the subsequent high-temperature sintering of the ceramic shell (we call as "dewaxing" since the wax melts during this process), and very little ash residue is left behind so that the inside ofthe ceramic shell is very cleanand there will be no problem when pouring molten metal.

- Moderate strengh: The wax is hard enough at room temperature, so when we assemble some wax molds manually or mechanically in a "wax tree", it is hard to bend or break, and the entire shape after assembling is stable and trustworthy.

Modern innovation: 3D printing model materials

Technology keeps developing, specifically how 3D printing investment casting has evolved, and it presents us with more powerful and diversified solutions,especially for complex design or rapid prototyping:

Castable resin:

- For example, specific photosensitive resin materials for casting. Their biggest advantage is that they can print extremely smooth surface and super-fine detailsusing SLA technologybeyond the ordinary which can be done by conventional wax models.

- Also, like special wax, the special resins can be burnt completely out of the dewaxing furnace with no residue. It is a tool specifically designed to make parts such as medical device parts and engine blades with complex patterns.

SLS Nylon laser sintered powder:

- Whenever we have some large-size prototypes that should have some structural strength, theSLS technology-printed modelsof nylon powder are very useful. Though its surface finish is usually not that smooth as castable resin, it is good in terms of strength.

- The key is that this nylon material can also be completely incinerated with high temperature, meeting investment casting's minimum demands, and providing a practicable method of the rapid production of large and complex prototypes.

Proper model material selection is the backbone of investment casting.Traditional wax remains a reliable choice for most traditional applications. 3D printing model materials, especially light-curing resins, have enabled us to create complex designs, rapid iterations, and nanotech-level precision manufacturing with full revolution in the way wemake prototypes and small batches of parts.

"Whether you are researching traditional processes or exploring the possibility of 3D printing investment casting, it is crucial that you get to know the nature of these materials. JS has deep experience to help you determine the requirements and choose the best materials and technical paths. If you have a specific part project, please by all means contact us and help you bring your ideas to reality!"

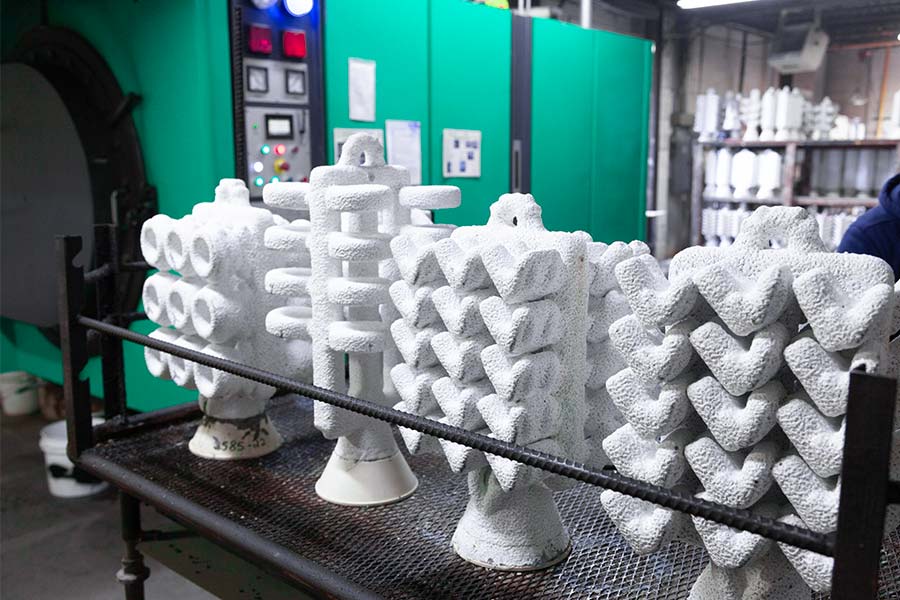

Invisible Fortress: Shell Materials

In investment casting, there is an unsung but crucial role,the shell material.You can think of it as a protective shell or precision mold for the final casting. Its mission is extremely difficult: when it is subjected to the erosion of molten metal up to 1600°C or even higher, it must maintain the fine shape of the original model exactly, and at the same time it must be strong and stable enough not to crack or deform. This is not something that can be done by a single material, but a carefully designedcomposite ceramic system.

Key components of this ceramic system:

Glue - Binder:

(1) Silica Sol: This is the glue we trust most when making high-end castings.

It has several hard-core advantages:

- First,Itpossesses goodhigh-temperaturestrength.

- Second, it has good chemical stability when facing high-temperature molten metal and is not easy to react with alloys.

The inner surface of the shell made of it is usually very smooth and delicate, and it is not easy to crack. Therefore, for projects with extremely high requirements, such asaircraft engine blades, titanium alloys for medical implants, and nickel-based high-temperature alloys, silica sol is our first choice.

(2) Sodium Silicate:

This choice has more advantages in terms of cost. Its high-temperature performance and dimensional stability are slightly weaker than those of silica sol. However, for some castings with relatively mild materials that are not particularly demanding in terms of precision,such asgeneralcarbon steel parts, thesodium silicateshellmold issufficiently capableanda cheap andviable option.

Skeleton - Refractory Grains:

(1) Zircon powder/sand (Zircon):It is used in the first layer of slurry that directly contacts the wax mold or resin mold.

Zircon sand has two special skills:

- One is that it has super high refractoriness and can withstand the hottest molten metal.

- The second is that it is chemically inert and hardly reacts with the precious metal you are pouring.

These two points combined allow it to perfectly replicate the finest textures and details on the surface of the model, which is the key to ensuring the surface accuracy of the casting.

(2) Mullite/Alumina:

- Zircon sand is the pioneer, and mullite or corundum sand is the "main force" supporting the whole situation. They are mainly used in the reinforcement layer after the first layer.

- Their role is to provide strong overall structural strength to the entire mold shell, just like a solid skeleton, so that the mold shell is not easy to collapse or crack under the huge thermal shock of handling, high-temperature baking and pouring. They ensure that the mold shell remains strong under extreme conditions.

The mold shell, this invisible protective shell, its performance directly determines the success or failure of the casting. Silica sol and water glass act as binders with high requirements and economy alternatives respectively. Zircon sand guards the critical first layer surface details with its refractoriness and chemical inertness. Mullite/corundum sand builds a solid skeleton to support the entire mold shell.

"At JS, we are well aware of the impact of different material combinations on the quality of the final casting. No matter what alloy and precision requirements you face, we have mature technology and rich experience to design and prepare the most suitable mold shell system for you. Don’t let the mold shell become the shortcoming of your project. Feel free to contact us and let us cast your perfect parts!"

The Ultimate Sublimation: Castable Metals and Alloys

As a casting engineer who has worked at JS for more than ten years, I deal with investment casting every day. Customers often ask us: What materials can be used for investment casting? Simply put, we can find a way to use almost any metal you can melt to cast it!

"Professor John Campbell of the University of Birmingham said in "Castings": The freedom that investment casting gives to designers is largely due to its almost unparalleled tolerance for engineering alloys."

This is the most powerful part of investment casting,the range of material selection is too wide. Here I will introduce to you some of the materials we use most often:

Steel: Main structural material

- Stainless steel (such as 304, 316, 17-4PH): Excellent corrosion resistance, suitable for food processing equipment parts, surgical instruments, marine valves and other environments that require hygiene or salt spray resistance.

- Carbon steel & alloy steel: High strength, good wear resistance, high cost performance.Widely used in engineering machinery connectors, automotive gears, construction equipment wear parts and other places with high stress or wear.

Aluminum alloy: The first choice for lightweight

Low density, good thermal conductivity and electrical conductivity, corrosion resistance. Commonly used in aircraft parts, automobile engine hoods,electronic product housingsand other precision castings that are sensitive to weight and require a certain strength. Demand is growing rapidly.

Superalloy: Extreme working condition material

- Nickel-based (such as Inconel 718): Excellent high temperature strength and corrosion resistance. Applied to extremely high temperature environments such as jet engine turbine blades and gas turbine hot end parts.

- Cobalt-based: Wear-resistant, corrosion-resistant, and biocompatible. Used in artificial joints (hip joint ball heads) and high-demand valves in harsh working conditions.

Copper alloy: Multifunctional

Including brass, bronze, etc., good conductivity, wear resistance, and a bit of classical beauty. Faucet cores, water pipe joints, bearing bushings, and those exquisite artistic castings are all their stages.

Titanium alloy: High-performance material

High strength, low density, excellent corrosion resistance, and good biocompatibility. Used in key areas such as fighter structural parts, rocket engine parts, andhigh-end artificial bone joints (knee joints). The material and processing costs are relatively high.

Weathervane of aviation casting material selection:

| Material category | Proportion of aircraft engine applications | Application proportion of aviation structural components | Main driving factors | Data sources |

| Nickel-based superalloy | 65-75% | <5% | High temperature strength, creep resistance, and oxidation resistance. | ICAAS Annual Report |

| Titanium alloy | 15-20% | 40-50% | High specific strength, corrosion resistance, and weight reduction. | SMR (Stratview Research) |

| Aluminum alloy | <5% | 30-40% | Cost effectiveness, good overall performance, and easy processing. | ICAAS Annual Report |

| Steel | 5-10% (mainly made of special stainless steel). | 5-10% | High strength, wear resistance, and economy in specific areas. | SMR (Stratview Research) |

Note: ICAAS data is based on supply chain analysis of major engine manufacturers. SMR data is based on global aerospace OEM procurement reports.

You see, from steel and aluminum alloys that are everywhere, to superalloys for extreme environments, to titanium alloys that pursue extreme performance,investment casting covers almost all important engineering metals. This flexibility is the key to its becoming the preferred process for complex and precision parts.

"At JS, we study how to use these materials every day to turn customers' designs into high-performance parts. Come to us with your part needs and challenges to talk about which castable metal is best for your battlefield, and let's make it happen together!"

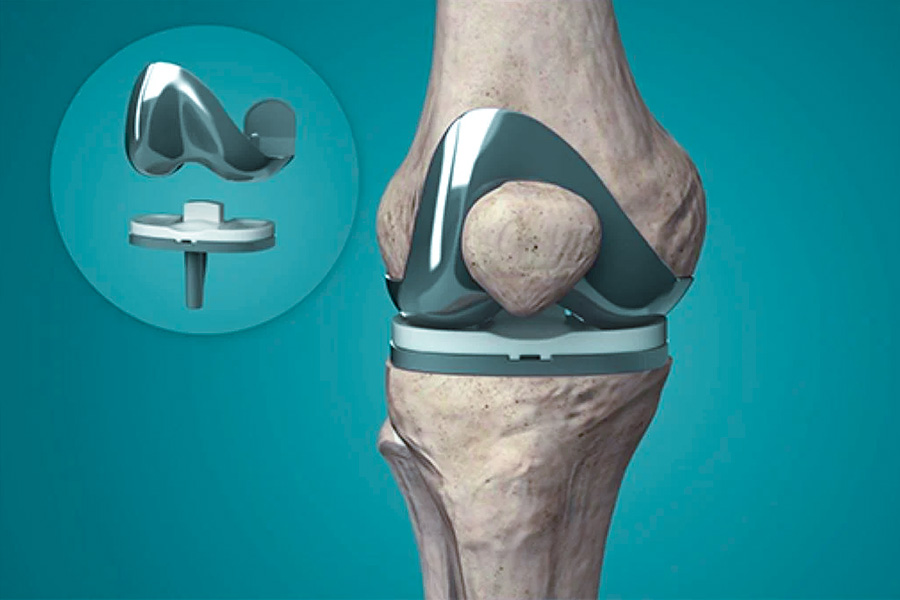

Actual Combat Case Analysis: Customized Titanium Alloy Knee Implants For Surgeons

When customizing knee implants for surgeons, I know that choosing the right material is life-saving. This is not just as simple as meeting technical parameters. It is related to whether the patient can walk smoothly after surgery and whether he can return to normal life.We have a vital responsibility for the selection of materials and processes.

The problem encountered by the customer: Meeting the needs of knee replacements with special bone structures

A medical technology company found us. They had a patient whose knee was seriously injured in an accident. The bone structure was very special and the standard knee prosthesis on the market could not be adapted.

What was the customer worried about at the time?

(1) Limitations of CNC machining:

They thought aboutusing a machine tool (CNC) to mill a knee out of a titanium alloy block. However, titanium alloy machining is difficult and expensive. For complex surfaces and internal structures, integrated CNC machining is almost impossible and the cost is unbearable.

(2) Strict requirements for materials:

Implants that need to enter the human body must meet the following requirements at the same time:

- Biocompatibility: Ensure that there is no rejection reaction in human tissue.

- High strength and low weight: Reliably support the load of human activities.

- Excellent fatigue resistance: Withstand long-term repeated stress without failure. Although stainless steel has a lower cost, its biocompatibility and strength-to-weight ratio are not as good as titanium alloy.

JS solution: Material synergy of model, mold shell, and metal

- Customized model: Directly use the high-precision CT data of the patient's bones provided by the hospital and use a medical-grade 3D printer! Light-cured resin can replicate a perfectly matched bone model prototype. Save the trouble of traditional mold making!

- Mold shell: We use ultra-high purity zircon powder + special silica sol to make the shell. The formation of a highly chemically inert ceramic mold shell ensures the purity of the titanium liquid and the surface integrity of the casting.

- Metal: What is used for the skeleton substitute? The industry's top player Ti-6Al-4V (Gr5) titanium alloy is our core weapon! The body does not reject it, it is strong and light, and it is particularly durable. It is an ideal choice for long-term implants.

Final results:

We successfully cast a titanium alloy knee implant that meets all requirements:

- 100% fit with the patient's bone anatomy.

- The casting has a high surface finish and no internal defects.

- 100% passed rigorous medical tests such as biocompatibility, static strength and fatigue life.

Benefit comparison:

| Key indicators | Traditional CNC machining solutions | JS Precision Casting Solution | Comparative advantage |

| Manufacturing cost | Benchmark. | Reduce by 60%. | Significant cost optimization. |

| Personalized fit | Unable to meet the demand. | 100% match. | Realize anatomical level adaptation. |

| Postoperative recovery potential | Relative standard cycle. | Expected shortening. | Promote faster recovery. |

"This case proves that precision casting combined with rigorous material science is a reliable path for extremely individualized medical needs. With a deep understanding and precise application of medical 3D printing models, ceramic molds and medical-grade titanium alloys, the JS team successfully transformed complex challenges into practical solutions, significantly reduced costs and improved clinical adaptability, and ultimately helped patients regain freedom of movement."

FAQ - Answer More Questions AboutInvestment Casting Materials

Question 1: Investment casting vs sand casting: what are the main differences in material selection?

Sand casting vs investment casting, mainly depends on two points:

(1) Precision and material requirements:

- Investment casting uses precise, high-temperature resistant inert ceramic molds, which are suitable for manufacturing parts with precise dimensions and smooth surfaces, and can cast materials with active chemical properties or extremely high melting points such as titanium alloys and high-temperature alloys to ensure purity.

- The sand molds of sand casting have low precision and temperature resistance and are easy to react with metals.

(2) Applicability and efficiency:

- Investment casting excels in processing high-performance alloys with high requirements.

- Sand casting is more economical and efficient, and is suitable for conventional and large castings such as cast iron, carbon steel, and aluminum.

Question 2: What are the advantages and disadvantages of investment casting?

Advantages:

- Wide selection of materials: Almost any metal can be cast, especially those precious metals that are difficult to handle.

- Ability to make complex parts: Even parts with tricky shapes can be made with high precision.

- Save expensive materials: The utilization rate of expensive metals is particularly high, with less waste.

Disadvantages:

- Many consumables: A large amount of wax and ceramic shell materials are required in the process.

- Long cycle: From wax model to finished product, there are many steps and it takes a long time.

- Expensive price per piece: If you make one or two pieces or small batches, the cost is too high and it is not cost-effective.

Question 3: What is investment casting process?

It is to make the desired part model with wax, and then assemble multiple wax models on a wax stick to form a "wax tree". The wax tree is coated over and over again with a special ceramic slurry and covered with sand, and then topped with a shell of ceramics. Then melt the wax until completely molten and pour it out to achieve a hollow shell of ceramic mold. At this time, pour the molten metal into this hot mold shell. After the metal cools, knock off the ceramic shell, cut the part from the "tree", and then polish and clean it.

Summary

What is the power of investment casting?The key is that it can handle a variety of powerful materials!From precise wax molds, to high-temperature resistant ceramic shells, to the final high-performance metal. This entire process is essentially a material matching game.Choosing the right material combination for each step, especially the metal used for your final part, is absolutely the basis for the success of the project.

Is your project facing these challenges?

- The design is complex, but it is difficult to determine the most suitable metal material?

- It is necessary to meet stringent performance requirements (strength, corrosion resistance, etc.) while controlling the overall budget?

Don't struggle with these professional problems alone! At JS,our material engineers work closely with manufacturing experts to focus on solving such problems. You only need to provide design goals, performance requirements and budget framework, and we will do the rest:

- In-depth analysis: Which metal material can best meet your performance indicators?

- Comprehensive evaluation: The cost and feasibility of different solutions, recommend the most cost-effective path.

Want to get professional material solutions?

👉Please feel free to contact us and send us your project requirements(such as CAD files, performance specifications, budget range). Let us check for you from the source of material selection to ensure the final part is strong and reliable.

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

Resource