You spent a lot of time designing and printing the shell of the drone, and the finished product looks perfect with clear details. However, when you flew it out for the first time for testing, the arms began to soften and deform under the summer sun. This is a typical consequence of the wrong material selection. PLA's performance in hot environments teaches us an important lesson.

In daily3D printingprojects,PLA and ABS filament are definitely the two most commonly used and easiest to buy basic printing consumables.They are not expensive and are also very friendly to novices. Many users' first printing experience is them. But don't be misled by popularity: these two materials have significant differences in core performance.

If you choose the wrong one, it will affect the life of the parts at the least (such as PLA's insufficient heat resistance), or it will be easy to warp and deform when printing like ABS filament (it usually requires a closed printing environment).

Therefore, when planning new parts, the key question is: do you value easy printing and beautiful appearance more (PLA often has the advantage), or do you need the parts to be strong and resistant to falling and withstand a little temperature (ABS may be more suitable at this time)? Understanding the essential differences between PLA and ABS can help you avoid potential risks at the beginning of the design.

Core Answer Summary:

| Comparing dimensions | PLA (Polylactic Acid) | ABS filament (acrylonitrile butadiene styrene) |

| Core Features | Easy to print, environmentally friendly, and highly rigid. | Durable, heat-resistant, and flexible. |

| Printing difficulty | Simple (no need for a hot bed, not prone to warping). | Difficulty (requiring a closed hot bed, prone to warping). |

| Strength and toughness | Good rigidity, but relatively brittle (PLA vs ABS has lower strength). | High impact strength, more flexible and durable. |

| Temperature resistance | Low (softening starts at around 60 ° C). | High (softening starts at around 100 ° C). |

| Odor and Safety | Non toxic, with a slightly sweet odor. | There is a noticeable plastic odor and ventilation is required. |

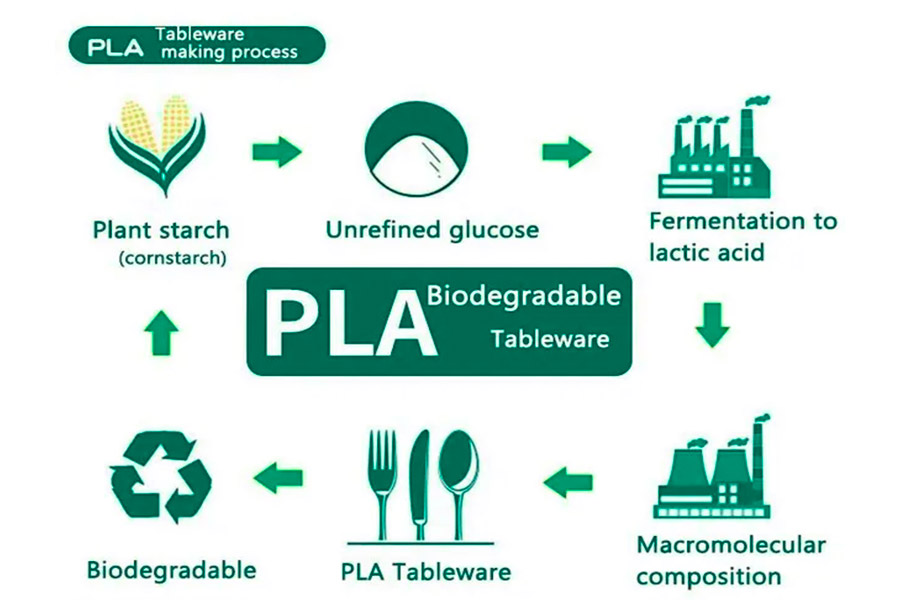

| Environmental friendliness | Biodegradable, derived from renewable resources. | Petroleum based plastics are non degradable. |

This article will answer your questions:

- In this guide, let's get straight to the point: Thoroughly understand the difference between PLA and ABS 3D printing.

- I will start with the most basic material properties and talk about the practical difficulties encountered when printing.

- Use a real example to compare, such as making a drone bracket that needs to withstand high temperatures and a display model on a table, and you will immediately understand how to choose the material.

- Finally, let's focus on the most frequently asked questions: which material is stronger, more heat-resistant, and environmentally friendly. Help you have a better idea of the next material selection.

Why Is This Guide Worth Your Reference? JS's Daily Material Decision

At JS, we handle dozens of kilograms of3D printing materialsevery day. PLA or abs filament? This is almost the starting point when we evaluate every customer project. Our judgment is not empty talk, but comes from real experience - we have printed thousands of parts for the aviation, automotive, medical and consumer electronics industries.

We have personally experienced how different abs filaments warp when printing large-size planes, and have also tested how various modified PLAs find a balance between being easy to hit and being strong. The views in this guide are extracted from these successes and failures: for example, we have used Aabs filament to make test fixtures for customers that can withstand the high temperature of the engine compartment, and we have also used high-gloss PLA to print exquisite display models required by architects.

"Scott Crump often said: Understanding materials is half of the success of 3D printing."

What we share are these practical experiences that can help you avoid pitfalls and choose the right materials.

Understanding PLA: The First Choice For Rapid Prototyping And Visual Presentation

In JS's daily printing,PLA, the full name of Polylactic Acid, is definitely the starting point we recommend to novices, andit is also the "main force" for model display and rapid design verification. It is made of renewable materials such as corn starch, with a low entry threshold and a high printing success rate. It is the first material for many users to contact 3D printing.

What are the core advantages of PLA?

- Print-friendly:PLA can be melted well at relatively low temperatures (usually 190-220°C), and does not require high heating of the printing platform. It shrinks very little when cooling, and there is almost no need to worry about warping, which greatly improves the success rate of printing, especially suitable for beginners and projects that pursue efficiency.

- Good details:PLA's fluidity in the molten state is not so "thin", which allows it to restore the sharp edges, fine textures and small logos of your design, and the appearance of the printed model is usually very good.

- Safer and environmentally friendly:The raw materials are derived from plants, and there is basically no pungent smell when printing (a bit like the light sweetness of boiled corn), and it can be decomposed in a specific industrial composting environment. It is also safer to use in daily contact.

- Rich appearance options:There are many PLA styles on the market, from basic matte, glossy, silk texture, to special effect filaments that imitate wood, stone and even metal, which can be found to meet different visual needs.

The main limitation of PLA: environmental adaptability needs attention

- Heat fear is a hard flaw:This is the most important thing about PLA.Its softening temperature is only about 60°C. This means that PLA parts are easily deformed or even collapsed when placed in a car under the sun, near heating appliances (such as routers and lamps), or when they need to withstand a certain operating temperature (such as parts near the engine compartment), and are completely incapable of doing so.

- Limited strength, afraid of falling and collision: PLA itself is relatively hard and brittle. Although it can bear static loads, it is easy to crack once it is impacted, hit, or needs to be bent repeatedly. Therefore, PLA is usually not a good choice for functional parts that need to withstand force or frequent collisions.

- Difficult grinding and polishing: Thesurface of PLAprints is very hard, and manual grinding is difficult. Moreover, it has basically no reaction to common solvents, and it is difficult to obtain a mirror-like surface effect through chemical methods, and the options for post-processing are limited.

"As a JS engineer, I know that PLA is an ideal partner for rapid proofing, display models, and educational projects. It is easy to use and beautiful. But when planning, be sure to confirm two points: Will the parts be exposed to high temperatures? Do they need to be impact-resistant? If "yes", PLA may not be enough. This is where JS's value lies. Let us immediately recommend more suitable professional materials to you based on your specific needs to ensure the success of your project."

Understanding ABS: The Choice For Reliable And Durable Functional Parts

At JS, when we receive a request for parts that need to withstand the test of actual working environments,ABS filament (acrylonitrile-butadiene-styrene) is often the material of choice.This "veteran" in making Lego bricks has become a reliable cornerstone for making truly functional3D printing partswith its excellent strength, toughness and heat resistance.

ABS's core advantage: Withstanding the test of actual combat

- Toughness is the trump card: The "butadiene" in the material is a master of impact resistance. Unlike PLA, which breaks at the first drop, ABS parts can absorb energy and are not easy to break under repeated force, vibration or accidental impact, making them more suitable for moving parts or environments that may be bumped.

- More reliable heat resistance: The softening point (glass transition temperature Tg) of ABS is usually around 100°C, which is much higher than PLA. This means that it can maintain its shape and function in the mild heat environment of summer car interiors, electronic equipment housings, and even some non-core engine areas, and will not easily soften and deform.

- Post-processingis the highlight: The surface ofABS prints is relatively softand easy to polish and drill. The most important thing is that it is sensitive to acetone. Through acetone vapor fumigation, a smooth surface close to the injection molding level can be achieved, greatly improving the professional feel and feel, which is something that PLA cannot do.

ABS vs. PLA: Comparison of actual performance and process depth

| Performance dimension | Typical Performance of PLA | Typical performance of ABS (FDM process) | JS Experience&Key Process Leverage |

| Stability in high temperature environment | >Significant softening at 60 ° C. | Maintain function at<100 ° C. | Chamber insulation above 45 ° C can improve tolerance to 5-10 ° C. |

| Anti drop impact (1m) | Fragile and prone to cracking (3-5 times). | Impact resistance (10-20+cycles). | Increasing the filling rate (+20%) or using modified ABS significantly increases the gain. |

| Post processing glossiness | Difficult to polish, mainly matte. | Acetone fumigation can achieve>90 Gloss. | The control of fumigation time/concentration is crucial, as excessive exposure can dissolve details. |

| Long term oil contact | Easy to be corroded by engine oil. | Excellent oil/grease resistance. | Fumigation or annealing treatment can seal surface micropores and improve resistance by over 30%. |

| Success rate of large-sized printing | High (low warpage). | Medium to low (high risk of warping). | The combination of a closed printer and platform adhesive is the key to success or failure. |

Data source: UL iQ™ certified impact test data, BYK-Gardner gloss meter measurement.

Get ABS printing done: Three unavoidable thresholds

- High temperature is the ticket: If the nozzle is not 230-260°C and the hot bed is less than 90-110°C, ABS basically cannot be printed. The first layer cannot stick to the big problem, and stable platform heating is the key.

- Warping is the number one public enemy:ABS filamentshrinks when it cools, and large flat surfaces or sharp corners will curl up. A closed printing chamber (maintained >45°C) is a rigid demand, which can suppress temperature difference stress.

"Sanjay Mortimer, founder of E3D, once said: When printing ABS, environmental control is more important than extruder accuracy."

- Odor management should be taken seriously: ABS heating will release odor (including styrene). Ventilation must be in place, either open the window for convection, or use a closed machine with HEPA+activated carbon filtration,don't joke with your health.

ABS is indeed a hardcore choice for making functional partsthat are impact-resistant, high-temperature-resistant, or pursue a professional appearance! But before you start, talk to JS first: Is your printing environment hot and closed enough? Is the ventilation in place? If you can pass these two tests, the durability of ABS is absolutely amazing. Let us help you evaluate the equipment conditions andmaterial matchingimmediately to ensure that you use ABS to print truly strong parts!

Actual Combat Case Analysis: Desktop Hand-Made vs. Drone Landing Gear

In daily work, it is important to help customers choose the most suitable 3D printing material. Let me use two real projects that have just been completed to talk to you abouthow to choose between PLA and ABS, a pair of "brother" materials. The difference is really big. The core is just one point: Is your part for "looking" or for "using"?

Case 1: Anime hand-made - PLA is the first choice for detail control

What does the customer want?

Print a 20cm high anime character that looks good on the table. The details must be clear (hair and clothing folds must be visible), the surface must be smooth and textured, the color must be positive, and the price cannot be too high.

Project Features: Pure decorations! No need to bear force, no need to toss, but the appearance must be exquisite, and the customer's budget is also tight.

JS material decision: PLA (silk white)

Why must PLA be used?

- Detail magnifying glass: PLA is particularly good at handling those ultra-fine and suspended structures when printing. The flowing hair and layered folds of the characters are printed with clear lines and not blurred at all with PLA, and the little thoughts on the design draft are all restored.

- Save worry and effort and one-time molding: The structure of the hand-made figures is winding and easy to warp and deform. PLA material has good properties and small shrinkage. Theone-time moldingrate on ordinary printers is very high. There is no need to toss repeatedly,saving materials and time, and customers also save money.

- Exquisite appearance: Silk white PLA comes out with a high-grade gloss, and there is no need to work hard on polishing. When the customer gets it, we basically don’t need to do any surface beauty. It is beautiful enough to put it on the table directly.

- Friendly printing in the office area: Printing is done right next to the open office area. PLA has basically no smell and is safe and secure.

Final result:The delivered figures have high details and stunning visual effects, and the customer is particularly satisfied. The entire 3D printing process is fast and economical, and it is completely within the customer's budget and time.

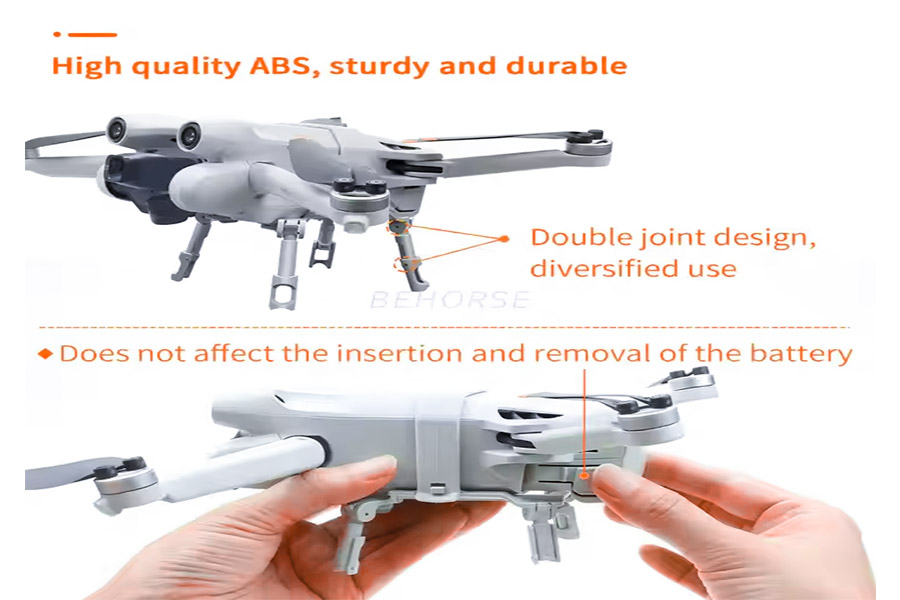

Case 2: Agricultural UAV landing gear - Engineering application of ABS

Customer needs:Urgent customization to replace thelanding gear partsof agricultural plant protection drones, which need to withstand the impact of take-off and landing and adapt to the outdoor high temperature environment, and require rapid delivery for on-site maintenance.

Project difficulties:This functional component must withstand the violent impact during landing, and may work in high temperatures outdoors, requiring rapid availability.

JS material decision: ABS (black)

Why choose ABS?

- Anti-fall and impact resistance is the bottom line:The core function of the landing gear is to absorb impact! This is the absolute priority for material selection.ABS is naturally toughand can effectively absorb the impact energy of the drone when it lands, and will not break into slag like PLA. In terms of strength, ABS wins.

See the following table for the most critical performance comparison:

| Property | ABS (typical value) | PLA (typical value) | The importance of landing gear |

| Impact strength (Izod, kJ/m ²) | 20 - 40 | 1.5 - 4 | Extremely high - able to withstand landing impact. |

| Tensile strength (MPa) | 30 - 50 | 50 - 70 | High load-bearing capacity and structural forces. |

| Tensile elongation at break (%) | 10 - 50 | 3 - 8 | Extremely high - good toughness, not easy to break. |

| Hot deformation temperature (° C @ 0.45MPa) | 90 - 105 | 55 - 65 | Extremely high - resistant to outdoor high temperatures. |

| Elastic modulus (GPa) | 1.8 - 3.1 | 2.7 - 4.0 | Medium - rigid support. |

- Stability under high temperature:During field operation, the cabin temperature can easily reach 40-50℃ in summer, and even higher near the motor and battery. The heat deformation temperature (HDT) of ABS is close to or even exceeds 100°C (depending on the specific formula), which is much higher than the 60°C of PLA. It can maintain its shape and strength without deformation under these conditions.PLA softenstoo easily under such conditions.

- Easy to repair and adjust:The landing gear needs to be precisely connected and fixed to the main body of the drone. After ABS printing, we can perform slight grinding, hole expansion and other machining treatments on the key connection holes. Its material properties (toughness, strength) can ensure that these post-processing operations are completed smoothly and the connectors are not easy to crack.

Results & JS Custom Advantages: It only took 3 hours from receiving the demand to delivery.This black ABS landing gear, which wascustom 3D printingmanufactured for harsh working conditions, resumed drone operation that afternoon. It has completely withstood the test of field conditions.

PLA is an ideal choice for achieving high-precision visual models, especially in the presentation of complex details and ease of use. ABS is a reliable material for creating impact-resistant and temperature-resistant functional engineering parts. The key to material selection is to clarify the core mission of the parts, whether it is to display aesthetics or to carry functions.

"Want to find the most suitable material for your project? Bring your requirements map and contactJS's engineers. We have professional engineers and customized solutions that have been verified in actual combat to help you steadily turn your ideas into reality."

FAQ - End Your Final Doubt on PLA and ABS

PLA vs ABS: Which material is stronger?

It is relative to how you define "strong".

- If you compare the tensile strength (unbreakable) and stiffness (not easily bendable), PLA will tend to have better numbers and the parts will feel "harder".

- But comparing to resist falling, impact resistance (to resist sudden impact of force) and toughness (unbreakable bending), ABS definitely wins. It will absorb more energy before it's completely broken, and it will bend much more instead of being broken immediately.

Simple summary: PLA is used to resist static loads, and ABS is used to resist impact and collision. Static load and dynamic load, requirement determines the selection.

Is ABS better for the environment than PLA?

ABS is not better for the environment than PLA in my opinion.

- PLA is produced from renewable resources such as corn or sugar cane that can be industrially biodegraded, thus reducing the load on resources. ABS is a petroleum-based plastic that taps fossil fuels during its production and does not biodegrade significantly in the environment, adding to the footprint even more.

- But do not fret, both materials are recyclable and reusable but there must be a complementary recycling system.

Which material should I choose to get started?

My suggestion is:Starting with PLA is the most reliable. It is very friendly, almost not picky about printers, and has a high success rate. It allows you to quickly print decent works and build confidence in operation. When you can stably output high-quality PLA parts and start to need to make heat-resistant and impact-resistant functional parts, it will be smoother to try ABS.

ABS is like your promotion challenge. It requires higher printing skills, but when you master it, you can make practical parts that are indestructible and resistant to high temperatures. Lay a solid foundation in PLA, and then master ABS. This is a solid growth path.

How about PETG? Is it a perfect combination of the two?

PETG is indeed a very practical intermediate option between PLA and ABS.In terms of strength and performance at high temperatures, it is much stronger than PLA, but it is much easier to print than ABS, not too delicate, and it also meets the safety standards for food contact.

However, it also has its own minor shortcomings, such as it is easier to hang silk when printing, and the surface is softer than ABS, which is easy to be scratched by things like keys. Therefore, it is not the ultimate material that perfectly replaces all situations, but more like a good tool in our toolbox, which can play a better role in specific occasions.

Summary

Having said so much, the core is one point:PLA and ABSare not absolutely "good" or "bad" in 3D printing, only "suitable" or "unsuitable". Why do you say that? Because your project needs determine the direction, PLA is easier to print, beautiful and easy to use, but ABS is more durable and suitable for load-bearing parts. If you choose the wrong material, not only will your careful design efforts be wasted, but it will also slow down the project progress. Isn't this a pity?Understanding these core differences is the starting point for your success.

So how can you choose the right material quickly and accurately?

- Don't think about it yourself! Our team does material selection every day and has rich experience. Upload your model file directly to our platform.

- Tell us your specific needs. Do you want to make a display model? Or do you want parts that are force-bearing and high-temperature resistant? The clearer the details, the more accurate our judgment.

- Professional advice is coming soon! In addition to PLA and ABS, JS has dozens of engineering plastics. Our intelligent system, combined with the experience of engineers, will pick out the most suitable material for you according to your specific needs.

- After helping youselect the right material, a clear3D printing pricecan be generated for you immediately, and the process is transparent and not hidden.

Take action!Upload your design and experience our professional online 3D printing services. Let us work together to use the right materials to turn your ideas into reality! The upload channel is ready!

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsrpm.com