Since the time 3D printing technology was invented, it has changed the traditional manufacturing process. It has the ability to print part prototypes and physical models quickly and compress product development time. The principle of this technology is building material layer by layer from computer files to eventually produce visible and tangible three-dimensional objects. People are usually puzzled to know how it is done step by step. In the following, we will describe its actual operation, typical forms, and actual application scenarios.

What is 3D printing?

3D printing magic lies in cutting computer models into hundreds of cross-section layers and solid forming by building up materials. It is just a dimension-reduction blow to the manufacturing industry! Traditional processing at times entails cutting through the entire raw material, resulting in as much as 80% waste, while 3dprinting saves the mold development cost directly! It is very simple to accomplish with only one machine, and the utilization rate of material has risen to 95%!

What do you think is the most disruptive? Conventional subtractive manufacturing requires several weeks to tailor parts, but now uploading just CAD files is sufficient, and it can be held in hand for 48 hours. The 3D printing services solution can effectively accomplish this.

What do we need to know about the history of 3D printing?

History of 3D printing is not as old as you can imagine!

They conceived this concept at the end of World War II, but it took them until 1980 to implement it! That was when Japanese scientist Dr. Hideo Kodama invented the prototype of rapid prototyping technology, which shocked the manufacturing community.

But in 1986, there was an American named Charles Hull who invented the three-dimensional lithography technology capable of milled three-dimensional objects through liquid resin and ultraviolet light. In their heels, two University of Texas professors came up with a new trick by coming up with a technology utilizing laser sintering to sinter material powder, which is commonly used in industry today as the SLS process.

In the late 1990s, personal computers began going mainstream, design software became user-friendly, and open source environments became lively. Compelling engineers to make 3D printers small to around the same dimensions as standard ink jet printing devices, since 3D design software began appearing on university campuses.

In 2006, desktop 3D printers became available for consumers officially, with prices dropping from tens of thousands of dollars to the two thousand dollar range.

The COVID-19 has unintentionally been a push for technology advancement. In 2020, while hospitals across the world were racing to get ventilator accessories, engineers used 3D printers to print overtime to deliver the parts overnight, and some of them even utilized 3D printers to print transparent protective face shields. This directly urges the process of updating industry standards, and now medical grade 3dprinting materials have to be subject to biocompatibility testing, with discrepancies in accuracy measured at 0.1 millimeters regulated.

3D printing is no longer a lab device. It has entered the manufacturing process in big and small factories too.

Conductive metal inks and biodegradable bioplastics have been invented by materials scientists, and these, in turn, are driving the advancement of printing technology. It's amusing that these two fields always progress hand in hand in a race against one another.

Simply put, how does 3D printing work?

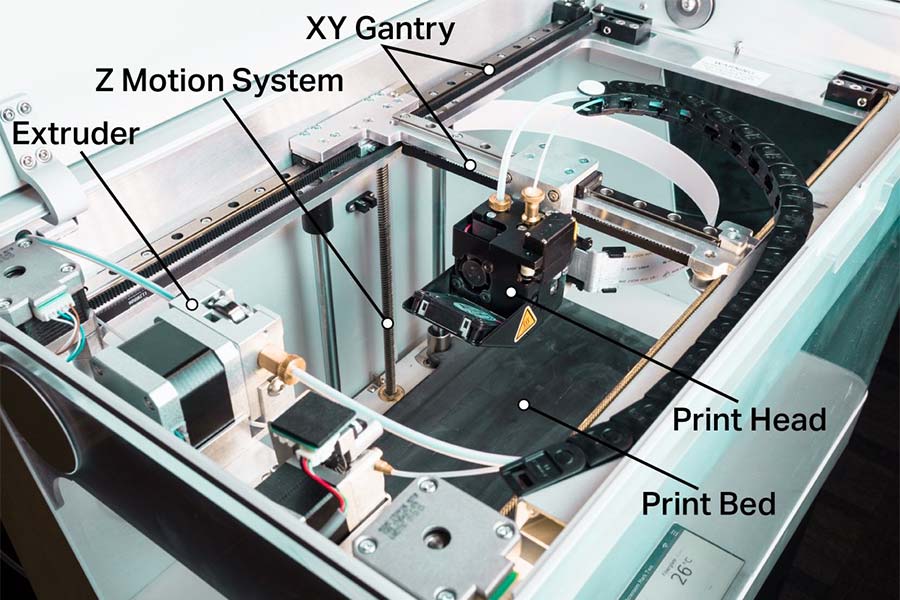

The workflow of 3D printing can be broken down into four key steps, Realize precise production from drawings to finished products.

Step 1: Need to build a digital model

You can use CAD software to design from scratch, or use a 3D scanner to accurately replicate the physical object. This stage is particularly interesting, as designers can repeatedly adjust the 3D printing model in virtual space, such as reducing the wall thickness of mechanical parts from 5 millimeters to 3 millimeters, to avoid wasting materials during printing.

Step 2: Enter the format conversion stage

There is a technical detail worth noting here, the STL format will decompose the surface of the model into countless triangular meshes, just like using mosaic puzzles to restore three-dimensional shapes. But advanced players have already started using the AMF format, which can record more information such as color and material, just like adding attribute labels to 3D printing models. At this point, we need to adjust the placement angle and imagine printing a suspended arm model. A reasonable tilt angle can reduce the support structure by 60%.

Step 3: Slicing software

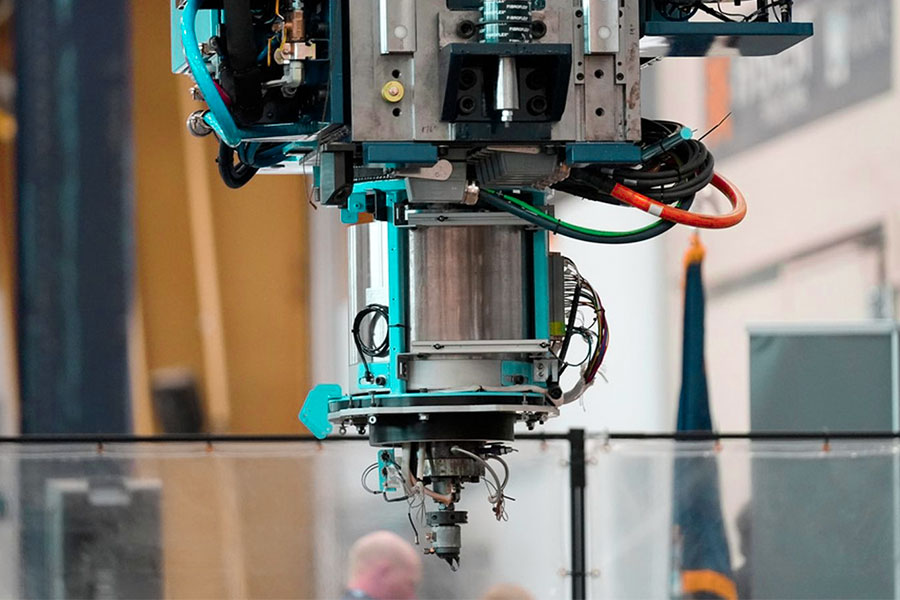

It cuts the 3D model into hundreds of layers of 2D profiles, with each layer being as thick as a hair diameter (0.05-0.3 millimeters). The printer starts working according to this setting. The FDM process is commonly used at the desktop level, and the nozzle heats the plastic wire to 220 ℃ and extrudes it into shape. Industrial grade equipment uses laser to instantly melt metal powder, achieving micrometer level accuracy.

Step 4: The crucial post-processing step

Dismantling the supporting structure requires careful removal of the auxiliary frame and sanding of the joints with sandpaper. Aerospace parts also need to undergo hot isostatic pressing treatment, and the final quality inspection requires using a laser scanner to check if the dimensional error is within 0.1 millimeters. This is a crucial standard for medical implants such as artificial joints.

What are the common types of 3D printing?

There are four main technologies that play an important role in 3D printing service:

1.SLA

It was born in 1986 and remains the ace of precision manufacturing to this day. Its secret weapon is ultraviolet laser, which is like using light as a carving knife to solidify liquid resin layer by layer, with an accuracy of up to one tenth of a human hair! From invisible braces in dental clinics to micro carved models in jewelry design, SLA firmly holds the top spot in the medical and precision manufacturing fields with its silky surface treatment capabilities.

2.FDM

It is the king of cost-effectiveness in 3D printing service, and its working principle is like an upgraded hot melt glue gun, heating PLA or ABS plastic wire to 220 ℃ and extruding it into shape. Although the layering is visible to the naked eye, the advantage is that the equipment is cheap, and you can buy a desktop level machine for two thousand yuan, which is particularly suitable for college students to do course design or for makers to DIY personalized ornaments. However, to print load-bearing structural components, industrial grade FDM must be used, which can handle carbon fiber reinforced nylon, and of course, the price also goes straight to six figures.

3. SLS

It is directly laser sintered on nylon powder. Wherever the 400 watt laser beam goes, the powder instantly melts into a dense structure, and even better, the unmelted powder naturally forms a support, making it possible to print complex geometries such as hollow structures and serpentine pipes. Adidas' Futurecraft 4D sports shoe midsole is a honeycomb structure printed with TPU powder using SLS technology, which is both lightweight and has excellent cushioning.

4. MJF

It can be regarded as an artist with micrometer level precision, capable of simultaneously spraying 6 types of materials, and its 16 micrometer layer thickness precision makes it difficult for the naked eye to distinguish layer marks. What's even more amazing is that some industrial models can directly print conductive lines inside the parts, such as the precision shell of hearing aids integrating electronic components, which is disrupting the traditional process of electronic manufacturing.

In the medical field, it is used to create surgical guides with colored vascular markers, allowing surgeons to clearly see the spatial relationship between tumors and blood vessels.

Comparison of Four Types of 3D Printing Technologies

| Technical type | Accuracy (mm) | Core materials | Printing speed (cm ³/h) | Typical application scenarios | Price range (10000 yuan) |

| SLA | 0.05 | Medical grade photosensitive resin. | 30-60 | Invisible braces/precision casting molds. | 50,000-500,000 |

| FDM | 0.1-0.3 | PLA/Carbon Fiber Nylon. | 50-150 | Educational prototype/load-bearing structural component. | 2,000-300,000 |

| SLS | 0.08 | Nylon 12 powder/TPU elastomer. |

20-40

|

Space bracket/sports shoe midsole. | 400,000-2 million |

| MJF | 0.016 |

Mixed photosensitive resin+conductive material.

|

10-25 | Surgical guide plate/embedded electronic components. | 600,000-3 million |

Which industries often use 3D printing technology?

1.Healthcare

3D models printing technology is bringing revolutionary changes to the medical industry. From tailor-made bone implants to simulation models for auxiliary surgery, this technology makes treatment more accurate, cheaper and faster to recover. Specific applications include:

- Customized dental implants: Through computer design models and patient CT scan data, print out implants that fit the mouth perfectly, which not only improves comfort but also enhances functionality.

- Personalized prostheses: Prostheses customized according to personal body data are not only more convenient to use, but also look closer to real limbs, making prosthetic production a qualitative leap.

- Surgical simulation props: Doctors can use 3D replicas of patients' organs to practice surgical plans in advance, which is equivalent to adding a rehearsal to complex surgeries, greatly improving the success rate.

- Precise drug delivery tools: Specially designed 3D printing devices can accurately control drug dosages, such as small-dose medicine boxes customized for children, making medication safer.

2.Aircraft manufacturing

Aircraft manufacturers use 3D printing technology to solve two core problems:

- Quickly make prototype samples of new parts, eliminating the long process of traditional mold opening.

- Reproduce discontinued accessories of old models, such as using 3D printing to restore the ventilation parts of aircraft 30 years ago.

- This method not only ensures quality and meets special needs, but also saves a lot of production costs.

3.Automobile manufacturing

From concept car design to parts production, 3D printing is changing every aspect of automobile manufacturing:

- Using SLS technology of laser sintering powder, engine prototypes can be made in 48 hours.

- Test parts printed by FDM technology allow the design team to quickly verify new structures.

- Porsche has used 3D printing technology to reproduce discontinued parts of classic models, giving classic cars a new life.

4.Education and scientific research

Schools are making knowledge visible and tangible through 3D printing:

- Printing bronze models in history classes, students can touch the details of the patterns with their own hands.

- Biology classes use transparent human organ models to show the internal structure.

Scientific research institutions are exploring cutting-edge fields:

- Cornell University is trying to print artificial heart tissue with biomaterials.

- MIT is developing printable microelectronic components.

5.Daily consumer goods industry

3D printing brings personalized products into life:

- Opticians can scan face shapes on site to print exclusive frames.

- Jewelry designers use resin to print pendants with complex shapes.

- Clothing brands launch 3D woven breathable sports shoes.

Products that require molds in traditional manufacturing can now be produced in small batches through 3D printing, which is particularly suitable for customized needs.

Why use 3D printing?

1.Customization has great advantages

Traditional factories need to first open a mold to make a new object, and the mold cost alone can easily reach tens of thousands of yuan. 3D printing is different, you can directly start working by building a model on the computer.

Three visible benefits:

1.The precision is comparable to embroidery: Hearing aids printed using JS's light curing (SLA) technology have an error control of less than half a hair thread thickness (<50 microns), and they will not hurt the ears at all when worn.

2.Colors and materials can be chosen freely: now customize birthday gifts for children, mix pink, blue, and transparent plastic for printing, and make a gradient toy car.

3.Same day delivery: A certain dental clinic prints invisible braces based on the patient's dental data. After the patient takes dental photos in the morning, they can receive exclusive orthodontic appliances in the afternoon.

Technical support:

- SLA (Stereolithography): Highprecision detail (such as jewelry molds, hearing aids) capable of printing errors of less than 50 μm.

- Multi material spraying: Supports color and material mixing for customized consumer goods (phones, toys).

Case in point: JS uses SLA technology to assist dental clinics print personalized orthodontic appliances based on patient dental data.

2.Sustainability of 3D Printing

3D printing requires only the amount of material needed and reduces waste generation compared to traditional subtractive manufacturing, i.e., cutting, and is therefore particularly well-suited for expensive materials such as titanium alloys and carbon fiber composites.

Comparison of data:

Traditional process: Wastage rate of up to 70% when cutting aviation aluminum.

3D printing: It is possible to reuse powder with a waste rate of below 10%.

Example: JS provides lightweight structural components to drone producers with 50% material usage gain.

3.Speed advantage

3D printing eliminates need for mold development and multi-process coordination, greatly shortens the product development cycle, and is especially suitable for rapid prototyping and small batch production.

Technology efficiency comparison:

| Technique | Prototype production time (complex gearbox) | Applicable scenarios |

| Traditional Casting | 2-4 weeks (including mold making) | Large number, standard pieces. |

| FDM | 12-24 hours | Rapid validation of design feasibility. |

| SLA | 6-8 hours (high precision) | Functional prototypes, transparent components. |

What are the advantages of JS's 3D printing technology?

Unlike traditional printing shops, JS offers differentiated solutions with industrial-grade equipment and expertise:

1.Ultra-high precision and complex structure

Support ±0.005mm tolerances, much higher than industry standards, for precision part manufacturing (e.g. medical devices, aerospace components, etc.). Complex geometries without pressure, hollow structures, irregular surfaces and other shapes can be achieved mold-free.

2.Material diversity

We offer more than 50 material options from metals (aluminum, titanium, stainless steel), engineering plastics (PEEK), biocompatible materials, and more to meet the needs of the automotive, electronics, and healthcare sectors.

3.Efficient production and on-time delivery

With automated production lines and smart scheduling systems, 98% of orders were delivered on time and the average project cycle was 15% shorter.

Allow easy transition between small small batch customization (e.g. single piece trials) and mass production.

4.Cost optimization

- Material utilization algorithm optimization can reduce waste and overall cost by 20%.

- Free design review services are provided to avoid pre-printing defects and reduce rework costs.

5.Sustainable manufacturing

Through the use of green materials and energy-efficient equipment, carbon emissions decreased by 15% and the waste recycling rate achieved up to 20%, aligning with the orientation of green manufacturing.

Summary

3D printing redefines the potential of manufacturing as it converts digital models into physical objects. With the layered stacking by FDM, precise solidification by SLA, or powdery fusion by SLS, 3D printing has been driving industries to overcome traditional limitations with its agile design, high material efficiency, and fast iteration.

Facilitated by 3D printing service, the manufacturing of complex structures becomes possible, from bespoke medical implants to the rapid prototyping of lightweight aerospace components. As technology spreads and service ecosystem develops, not only does 3D printing lower the barrier of innovation, but also it shifts customization production from niche applications to mass applications.

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy, completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features,material quality and type or workmanship that the third-party supplier or manufacturer will provide through the jusheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers,we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it's low-volume production or mass customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

FAQs

1.Why do some 3D printed models require support structures?

In 3D printing, if the model has a suspension or a tilt angle too high (for example, more than 45°), the material can easily collapse under gravity as it piles on top of each other. The supporting structure serves as a temporary framework to support the suspension section, ensuring accuracy and completeness of printing.

2.Why is industrial-grade printing more expensive than desktop printing?

The high cost of industrial printing is due to higher requirements for materials such as titanium alloys and engineering plastics, maintenance of precision equipment such as laser calibration and high temperature systems, and technical support costs. At the same time, high accuracy, stability and mass production efficiency must be ensured, while desktop printing focuses on low cost and ease of use.

3.What's the difference between metal 3D printing and plastic printing?

Metal printing requires high-temperature molten powder (such as SLS), which makes the the finished product stronger, but the equipment is expensive and mainly used in high-end areas such as aerospace and medical implants. Plastic printing is formed by molten deposition or photosynthesis. It is low-cost, simple to operate, suitable for prototypes and everyday products, and lightweight and economical.

4.What are the key steps in 3D printing reprocessing?

Post-processing for 3D printing involves removal of support structures, surface polishing to remove layer marks, heat treatment to enhance strength, and beautification steps such as surface spraying or polishing to ensure the the finished product is smooth, durable, and meets design requirements.