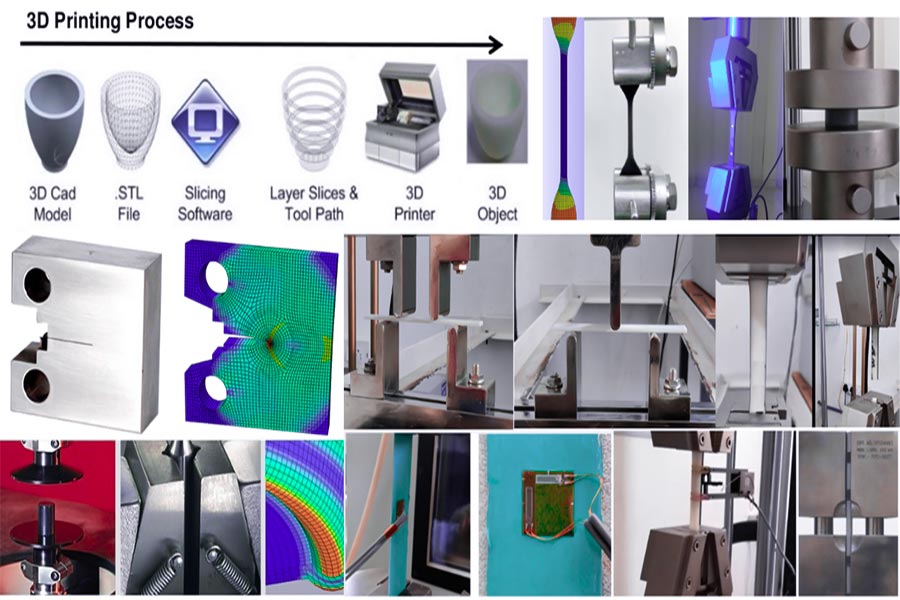

3D printing has surpassed the technological boundaries of traditional manufacturing and become a revolution that reshapes the industry paradigm. It uses layer by layer additive logic to transform 3D printing models into complex functional entities, from lattice structures in the aerospace field to biomedical fluid channels. The disruptive nature of the technology has long surpassed the limitations of shape replication. However, true industry disruptors are well aware that the potential of 3dprinting lies not only in manufacturing complexity, but also in data-driven design to reconstruct material behavior.

In this article, the JS team will analyze from multiple dimensions and redefine the full chain logic of complex models from virtual conception to physical formation.

Why do more and more industries need 3D printing technology?

3D printing was originally used in medical devices, industrial components and design prototypes. Today, it has expanded into every aspect of everyday life, from custom-made toys to fine jewelry to teaching tools.Despite the growing popularity of 3dprinting, the cost-effectiveness of buying specialized printing equipment alone remains limited. Considering that different materials require specialized equipment and that complex models still require specialized designers to operate, these factors significantly increase overall printing costs. As a result, many companies work with specialist 3D printing shops.

JS, as one of the professional printing service providers, we have a variety of high-end printers, a rich library of materials, and a team of experts with more than 20 years of practical experience. Whether it's the rapid verification of product prototypes or the creation of exquisite models for educational presentations, we are able to efficiently help you to create a full-chain solution from concept to finished product.

How to design a 3D model of an overhanging structure?

3D printing is like building a house with blocks layer by layer, the new layer must be placed securely on the layer below and cannot be deposited directly in the air, which is why overhanging structures are a bit of a challenge in a 3D printing model.

Most printers have an angle of about 45 degrees, below which the model can be stacked in layers. But beyond that angle, the printer needs support material to hold up the overhang. However, the support structure is like scaffolding, and removing it often leaves rough marks that affect the aesthetics and accuracy of the finished product.

1.45° Principle

Try to make the inclination angle of the overhanging parts ≤45°, so that they can naturally support the previous layer and can save additional supporting materials to drag the overhanging parts.

2.Conversion of large overhanging structures to assemblies

If the design must have large overhangs (e.g. bridges or extended arms), consider printing the model in multiple parts and assembling them later to avoid the hassle of support materials.

3.Preferably use rounded transitions

The use of right-angle transitions is often prone to the formation of invisible overhangs, even if they do not appear to be clearly protruding, the actual printing of each layer of the edge will be slightly flared, which can easily lead to edge curling or collapsing. Rounded corners are designed to spread the force through the curve, so that the print is more resistant to drop, deformation, while eliminating the risk of curling or collapsing this risk, so that each layer can be stable to take on the previous layer.

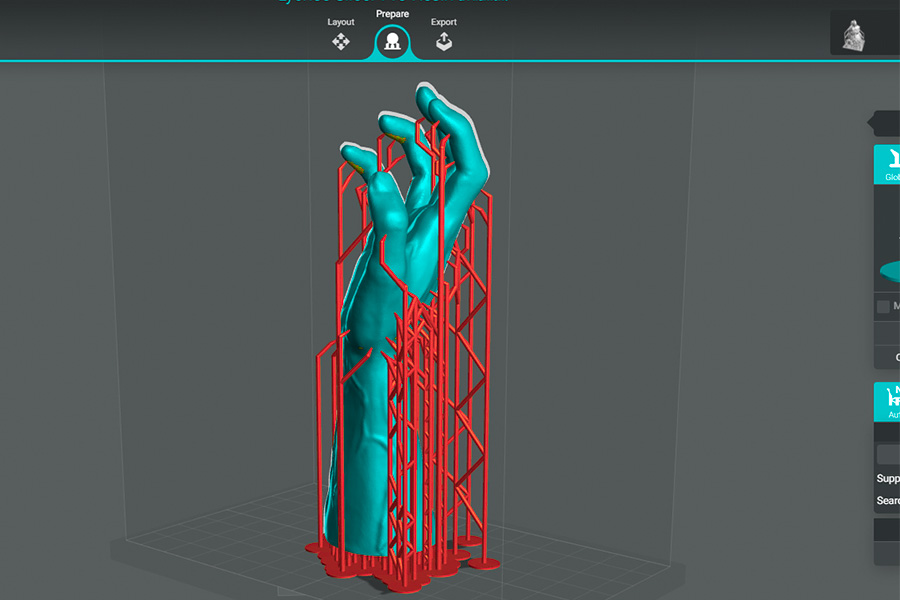

4.Choose the right location to optimize the support

- The area where the support touches usually leaves rough marks, and if the support is added on the appearance surface, it affects the appearance of the model very much.

- JS Solution: We manually set the supports in the slicing software so that the supports are concentrated on non-critical areas such as the bottom or back.

- Supports tend to create a lot of redundant structure, which wastes consumables and prolongs printing time.

- JS Solution: We manually add or remove supports in the preview screen to precisely control critical areas. Or switch to tree supports, generating supports only in critical locations, saving more than 30% of material and suitable for complex geometries.

How to control the surface roughness of 3D printed parts through sandblasting parameters?

Controlling the surface roughness of 3D printouts through sandblasting parameters requires a combination of the following key engineering factors, combined with our company's 3D printing services, for optimal results:

1.Selection of sandblasting medium

- Choose appropriate sandblasting media (such as alumina, glass beads or plastic particles) based on the material properties of 3D printing (such as metal, plastic or composite materials).

- JS company supports multiple material processing experiences (including more than 50 material processing cases) and can match the best media for different materials to ensure controlled surface roughness while eliminating print layer patterns.

2.Sandblasting pressure adjustment

- The pressure directly affects the strength of surface treatment. Low pressure (usually less than 0.4 MPa) applies to fine components and retains fine features, high pressure (greater than 0.6MPa) applies to industrial-grade parts.

- JS controls the pressure range through precision equipment combined with its ±0.005mm machining accuracy to avoid excessive wear and tear.

3.Distance and angle of nozzle

- The nozzle is between 10-30cm from the workpiece and the angle can be controlled between 30° and 60° to even out the texture of the surface for best results.

- JS company's automated production line is equipped with precise positioning system, which ensures the stability of parameters, reduces human error and improves batch processing consistency.

4.Sandblasting time control

The length of time determines the roughness (Ra value). JS company uses tests to determine the optimal printing time, such as a medical-grade surface with a titanium alloy components surface up to Ra 0.8μm, while being compatible with subsequent inkjet printing processes (such as marking scales or QR codes).

5.Co-optimized reprocessing

After sandblasting, ink jet printing technology can be used in special areas of functional coatings or prevention treatment. For example, in aerospace components, the bonding strength is first enhanced by sandblasting to achieve uniform roughness, and then integrated processing is achieved by printing conductive lines through ink jet printing.

What are the differentiated requirements for wall thickness of 3d printed models for different materials?

1.Wall thickness requirements for commonly used materials

Engineering plastics (e.g. ABS, PLA, nylon)

- Recommended wall thickness: 1.5-5mm.

- JS Advantage: Supports multi-nozzle printing technology to optimize wall thickness uniformity. Tolerance is controlled to ±0.05mm to reduce the risk of warp deformation.

Photosensitive resin (transparent/high temperature resistant resin)

- Recommended wall thickness: 0.8-3mm.

- Advantages: The SLA technology can achieve 0.025mm layer thickness, surface finish up to Ra 0.8μm, meet the high precision requirements.

Metal (aluminum alloy, stainless steel)

- Recommended wall thickness: 0.5-3mm.

- JS Advantage: Metal printing equipment supports laser smelting, reducing wall thickness to 50%.

2.Analysis of JS's technology adaptability

| Material Type | JS Core Technology | Efficiency improvement data |

| Polymer | Multi-material hybrid printing, temperature controlled chamber. | Molding speed increased by 40%, scrap rate <1%. |

| Metallic Materials | Laser power dynamic adjustment, powder recycling system. | Production cycle time shortened by 50%, cost reduced by 25%. |

| Composite Materials | Fiber orientation placement algorithm, high temperature sintering process. | Component life extended by 2 times, certification pass rate 98%. |

3.Design optimization recommendations

- Relationship between wall thickness and strength: Increasing wall thickness can improve bending strength, but excessive thickness can lead to stress concentration. Simulation software is used to determine the optimal parameters in advance for customers.

- Support structure design: The cantilever structure adopts soluble support material (such as PVA) to avoid post-processing damage, and wall thickness error is controlled to ±0.02mm.

- Cost control strategy: Using gradient thickness design (e.g. bottom 3mm → top 1.5mm), JS's algorithm optimization can reduce material consumption by 18%-22%.

What are the key engineering elements that affect the success of 3d printing?

In the area of 3D printing service, the key engineering factors that influence project success can be summarized in the following five points:

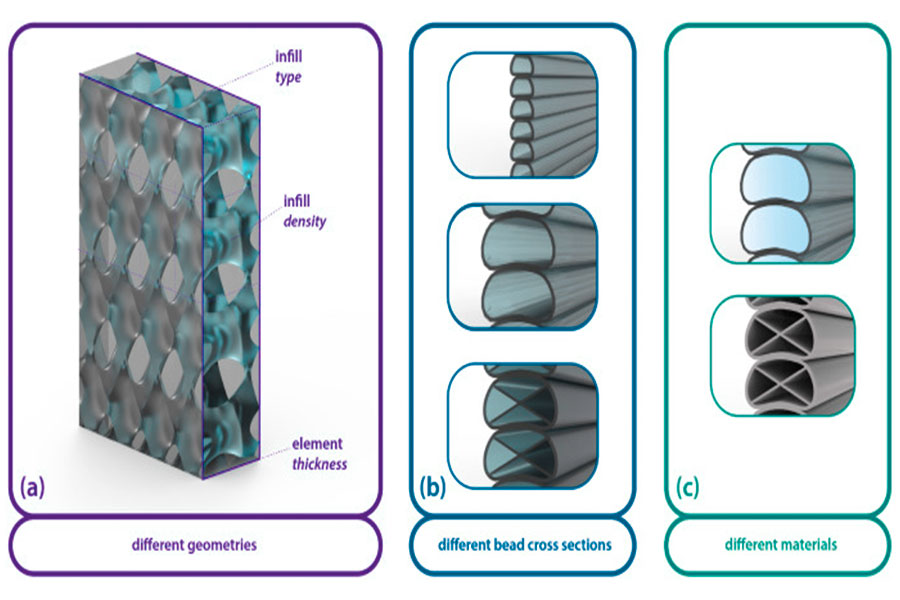

1.Strength and structural design

The final performance of 3D models printing depends to a large extent on topology optimization and material selection. JS company adopts CAE simulation technology to guide customers to optimize model structure in combination with customer usage scenarios. For example, in order to meet lightweight requirements, our engineers recommend using honeycomb structures or lattice filling, as well as material properties of metal or high-strength plastics, to ensure that the print meets strength requirements and weight control.

2.Hardware-software coordination

- JS's intelligent manufacturing center is equipped with industrial-grade 3D printers (such as metal powder bed melting equipment) and CNC machining equipment, forming a complete printing and reprocessing line.

- For large size or high precision components such as ±0.005mm tolerances, the system automatically matches the best print parameters and optimizes the support structure design to avoid deformation. Aerospace customers have solved the irregular cooling channels problem which is difficult to be solved by traditional technology through JS's customized printing services, and verified the high compatibility between equipment and process.

3.Post-printing technology

- Post-processing directly affects the consistency of product appearance and function. JS establishes a digital quality control process, including sand blasting, electrolytic polishing, PVD coating, etc.

- In recent times, among automobile customers, the corrosion resistance of 3D-printed aluminum alloy brackets has been increased threefold by our company's anodizing treatment, which directly enters the mass production stage.

4.Mass production management

Although 3D printing is generally considered suitable for small batch production, JS has achieved efficiency in medium batch production through modular production line design and process standardization

- Small batch customization: Simulation models is developed quickly, and the cost per piece is lower than CNC machining.

- Production at scale: Metal SLS equipment can mass produce aviation parts, but needs to be optimized for matching structural layouts to reduce material waste (saving 15-20%).

Running in parallel with a multi-nozzle 3D printing system and equipped with automatic loading and unloading devices, the delivery cycle of custom-made parts for a sports brand is shortened from 4 weeks to 72 hours for traditional injection molding.

5.Optimize costs

- Design optimization: Using topology optimization to reduce material waste, one aerospace customer saved 40% of material costs by lightweight design.

- Process integration: 3D printing is integrated seamlessly with CNC machining, heat treatment and other processes to reduce outsourcing.

- Material recycling: Recovery of unsintered metal powder and waste products with a utilization rate of over 90%.

How does JS provide customized services for color printing?

1.Multi-material and surface treatment capability

We offer more than 50 materials (metals, plastics, composites, etc.) and surface treatment technologies (e.g. paint, anodic oxidation, screen printing, etc.).

If color components are required, JS can be achieved in the following ways:

- Direct coloring of plastic parts: Dyeing or later dyeing with colored plastic materials.

- Metallic surface coating: Customize color coatings according to design requirements.

- Color integration of composites: Color fibers or particles are embedded in the material molding process.

2.Customized design capability

The company has more than 20 years of industry experience as an engineer, specializing in complex and precision design challenges, and according to customer needs, from conceptual design to production support.

3.Fast delivery and cost optimization

Provide technical feedback within 24 hours of uploading customer's design files, shortening iteration cycle. Through process prediction and material substitution solutions, we save our customers an average of 20% of their costs while ensuring 98% of orders are delivered within 1-2 weeks.

4.Environmental sustainability

JS reduces waste by 20% and energy consumption by 15% per cent by recycling energy-efficient equipment and materials. We also offer eco-friendly color coatings or bio-based materials to meet the demand for green manufacturing.

Summary

In the engineering practice of 3D printing, every step of the way, from material characteristics to fine tuning of process parameters, determines the success or failure of the final product. Engineering experience and technological innovation are always the core driving forces in complex structural design, be it the precise description of details or the balance of support and suspension.

JS as a professional 3d printing service provider, it combines multi-material adaptability, scalable production capacity and post-processing optimization to transform design intent into reliable entities.

Disclaimer

The content on this page is for general reference only. JS Series makes no express or implied warranties regarding the accuracy, timeliness, or applicability of the information provided. Users should not assume that the product specifications, technical parameters, performance indicators, or quality commitments of third-party suppliers are completely consistent with the content displayed on this platform. The specific design feature, material standards, and process requirements of the product should be based on the actual order agreement. It is recommended that the purchaser proactively request a formal quotation and verify product details before the transaction. For further confirmation, please contact our customer service team for professional support.

JS Team

JS is an industry leading provider of customized manufacturing services, dedicated to providing customers with high-precision and high-efficiency one-stop manufacturing solutions. With over 20 years of industry experience, we have successfully provided professional CNC machining, sheet metal manufacturing, 3D printing, injection molding, metal stamping and other services to more than 5000 enterprises, covering multiple fields such as aerospace, medical, automotive, electronics, etc.

We have a modern factory certified with ISO 9001:2015, equipped with over 100 advanced five axis machining centers to ensure that every product meets the highest quality standards. Our service network covers over 150 countries worldwide, providing 24-hour rapid response for both small-scale trial production and large-scale production, ensuring efficient progress of your project.

Choosing JS Team means choosing manufacturing partners with excellent quality, precise delivery, and trustworthiness.

For more information, please visit the official website: jsrpm.com

FAQs

1.What are the advantages of composite printing?

It collaboratively enhances structural properties (such as strength and toughness) through a variety of materials, supports integrated molding of complex and irregular structures, reduces traditional assembly processes, and is suitable for high-precision customization fields in areas such as aerospace and medical implants. It combines lightweight and functional integration.

2.What is the role of the support structure?

It is a key auxiliary design to support suspension or complex geometry, prevent sagging and deformation of material in printing process, ensure model precision and structural integrity, and reduce the risk of failure.

3.What is print resolution?

The minimum level of detail accuracy of 3D printers, horizontally and vertically, is usually measured by layer thickness (e.g. 0.1mm) or XY pixel density (e.g. DPI). High resolution can provide finer structure, but can add to printing time and cost.

4.How to evaluate the technical capability of the service provider?

Focus on material suitability, equipment progressiveness (e.g. covering multiple technology models), process optimization level (accuracy/surface quality), industry certification and success stories, with a focus on solution capability and aftermarket technology responsiveness.