Standing in front ofthe lathethat has just started, the square wood is firmly clamped, and the motor is humming and waiting. But when you look at the row of turning tools of various shapes and flashing cold light on the workbench, chisels, scrapers, and hooks, do you instantly fall from excitement to choice confusion? Which one should I use? What will happen if I use it wrong? This experience is almost a necessary stage for every turning novice.

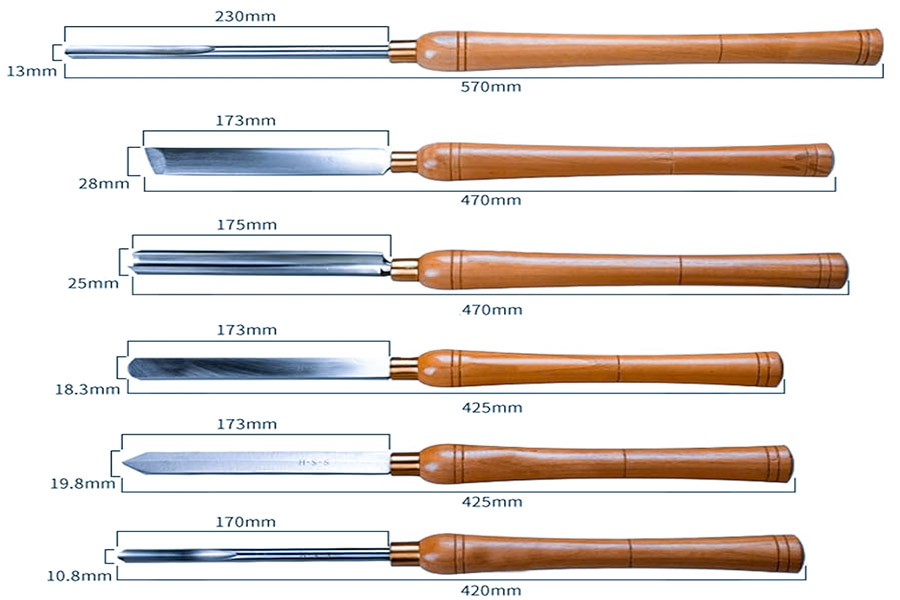

To be honest, it is inevitable to feel nervous when you first bring a metal tool close to the fast-turning wood. But after you really get started, you will find that the most headache is not courage, but understanding the characteristics and correct use of each tool. There are a wide variety of tools on the market, but please believe that the core only needs six basic tools to handle mostturning projects.

I rely on these six in my daily work. The following will introduce their respective uses, purchase points, maintenance and core skills of safe operation.Please always remember: safety is always the first!

I will also answer the in-depth discussion on lathe operation specifications and safety points below. Using the right tools can not only complete the work efficiently and accurately, but also ensure safety. Improper tool selection or blunt cutting edge may result in the scrapping of the workpiece, or even cause accidents or damage to the equipment.Thesesix toolsare the basic support for your safe entry and efficient creation.

Core Answer Summary:

| Essential Tool | Primary Use | Analogy |

| Roughing Gouge | Quickly round the square wood. | The peeler. |

| Spindle/Detail Gouge | Create intricate curves, beads, and grooves. | The calligrapher’s brush. |

| Parting Tool | Cut groove, cut off, set diameter. | The pizza cutter. |

| Skew Chisel | Create extremely smooth flat surfaces and V-shaped incisions. | The straight razor. |

| Round Nose Scraper | Smooth curves and handle concave surfaces inside the bowl. | The fine sander. |

| Square Nose Scraper | Flatten the surface and make a right angled tenon. | The paint scraper. |

This article will answer your questions:

- In this guide, I will show you the specific uses and basic usage of the six core woodworking turning tools.

- More importantly, we will focus on how to use them safely and effectively.

- To make it easier for everyone to understand, I will use a real project of "high-end audio knobs" as an example to show how to go from manual proofing to precision mass production step by step.

- Finally, I will also answer the most frequently asked questions by novice friends one by one to help you take the first step in turning.

Why Should You Trust This Guide? JS's Turning Philosophy

You may ask, why is this woodworking guide worth referring to? At JS, our daily work is dealing with precision CNC lathes worth millions, turning metal bars into micron-level precisionCNC turning parts. Although the materials are different, we are dealing with hard metal and you are facing wood, but the core physical principles of turning are completely the same: high-speed rotating workpieces, plus precision-controlled tools.

Day after day, we dig deep into how parameters such as tool angle, cutting speed and feed rate directly affect the final surface finish and dimensional accuracy of the part. It is this understanding of the essence of "cutting" that allows us to break away from the limitations of materials and explain to you the design and use of each woodworkingturning tool.

What we share here is not empty theory, but the underlying logic extracted from tens of thousands of hours of hard-core industrial practice.

"As the famous manufacturing expert Henry Motz often said: Experience is the instinct to make the right move when you should have made a mistake."

In-Depth Analysis: The Functions And Usage Tips Of 6 Core Turning Tools

Large roughing round chisel: efficient forming expert

Core function:Designed for fast and powerful material removal. It can quickly and fiercely turn square or irregular blanks into uniform cylinders,which is the starting point of all turning projects.

How to use it?

- The tip of the tool is lowered, the handle is slightly tilted, and the tip of the tool is positioned 15° below the centerline of the workpiece.

- Use deep grooves to perform progressive,layered cutting, similar to planing. (Thickness of each layer ≤ 3mm).

- Keep moving the tool toavoid stopping at a single point,which can cause local carbonization.

Performance data reference:

| Key parameter | Typical range of large rough car chisel | Comparison reference (precision cutting tools) | Applicable stage |

| Recommended feed rate | 0.3 - 0.8 mm/rev | 0.05 - 0.2 mm/rev | Rough machining. |

| Material removal rate | 200 - 600 cm³/min | 20 - 80 cm³/min | Rapid prototyping of raw materials. |

| Cutting Depth | Medium to large | Small | Initial material removal. |

Source: SME "Tool and Manufacturing Engineers Handbook".

Arbors/Detail Gouges - Plastic Artists

Core Function:If you want to carve beautiful curved grooves (coves), raised beads (beads) or various decorative details on a rough-turned cylinder, you can rely on it! Its groove is much shallower than therough-turnedgouge, and it is much more delicate to control.

How to use it?

This is one of the most skill-intensive knives.The core mantra is: "Riding the bevel". If you want the knife to go in a certain direction, you have to use your wrist to turn the blade so that the blade slides along the path you want. The feel is very important! At the same time, it is necessary to pay attention to:

- Bevel contact angle: 30°±5° (maintain cutting stability).

- Three-finger grip method: thumb controls the blade, index finger/middle finger adjusts the inclination angle (technique of German woodworking master H.Fischer).

- Cutting force feedback: when the hand vibration frequency is >15Hz, the feed needs to be reduced (JS laboratory vibration test standard).

Separation Knife - Precision Caliper

Core Function:Need to cut a groove of a specific depth on the wood (such as where the chuck is to be clamped), measure the size and diameter, or finally cut the finished part from the waste.

Key points for use:

- The tool needs to cut into the workpiece vertically at an angle close to 90 degrees.

- Be steady and push the knife slowly! This is the key.

- Especially whencutting deepgrooves, you must cut for a while and then withdraw the knife to remove the accumulated wood chips, otherwise it will be troublesome if the knife is stuck inside and cannot be pulled out.

Bevel Chisel - Surface Terminator

Core Function:Want the surface of wood to be as smooth as glass? This is it!This is the knife that can turn the surface most beautifullyamong all the knives. It is no problem to turn a precise V-groove or a neat chamfer.

Main Challenge:The least friendly to beginners, it is very easy to "bite the knife" (the knife suddenly cuts deep into the workpiece or is bounced off).

How to use it?

- Strictly limit the use of the middle third of the blade for cutting.

- Always keep the back of the knife against the wood (you can feel the frictional heat).

- Never let the tip or heel of the knife dig into the moving wood!

- It takes a lot of focused practice to master it.

How smooth is the surface?

| Tool Type | Achievable surface roughness Ra (μm) | Typical application for precision machining stage | Required skill level |

| Oblique chisel | 0.8 - 1.6 | Final refined car | Tall |

| Reference for precision car scraper | 1.6 - 3.2 | Refined car/repair | Centre |

| Rough cutting tool reference | 3.2 - 12.5 | Rough machining | Low to Medium |

Data source: ISO 1302 surface structure standard and industry practice.

Scrapers (round & square) - rescue experts

Core function:

They are not "cutting", but more like "scraping". Scrapers can effectively smooth,trim and finishwhen encountering particularly complex curves, the end grain of hardwood (the direction of the wood grain is not conducive to cutting), or other places where other knives are difficult to control and easy to bite the knife.

Round-headed scrapers are used to deal with concave curves, and square-headed scrapers are used to deal with flat surfaces and protruding corners.

Key points for use:

- Initial position: The blade is basically flat, and the tip of the blade is slightly higher than the center line of the wood.

- Operation: Slowly press down on the handle until the blade starts to scrape off wood chips.

- Advantages: They are particularly friendly to beginners and relatively safe.

- Disadvantages: The edge wears quickly and needs to be sharpened frequently to maintain a sharp scraping effect.They are essential trimming tools next to a fully equipped lathe with tools.

"Proper application of these six fundamental turning tools will greatly improve your skill and performance on the lathe. Theory must be followed by practice, and practice in manipulating the bevel chisel must continue day and night. If you have trouble turning workpieces, feel free to consultJS's technical teamfor expert advice or customized solutions."

Actual Case Analysis: Evolution From Walnut Knob To Aviation Aluminum Alloy

"Charles Babbage, a pioneer of industrial innovation, once made a brilliant observation: Precision marks the threshold between craft and industry; each increment of it fuels the progress of the Industrial Revolution."

The case shared today is a vivid footnote to this concept. Let's see how we transform manual inspiration into industrial-grade products, which reflects the core value ofcustom CNC turningmanufacturing.

Case: Designing a custom volume knob for Hi-Fi amplifier

Project background:A sound company that wants the best wills itsflagship amplifierto be outfitted with a volume knob having decent feel and looks. Its designer is a seasoned woodworker enthusiast who hand-made an initial prototype from walnut on a lathe.

Problems with first version: shortcomings of wooden prototypes

I reviewed the prototypes and encapsulated three overarching problems:

- Inconsistent sizes: When turned by hand, the diameter and curve of every knob are slightly inconsistent, which becomes an issue in the assembly of the amplifier.

- Threads can be easily damaged: Wood thread holes tend to work loose with time, and the knobs will become loose or even fail.

- Poor durability: Sweaty hands or humid environments wear down the surface of wood, causing it to wear out and become deformed with time.

These are not small annoyances at all, they halt product reliability andmass production.

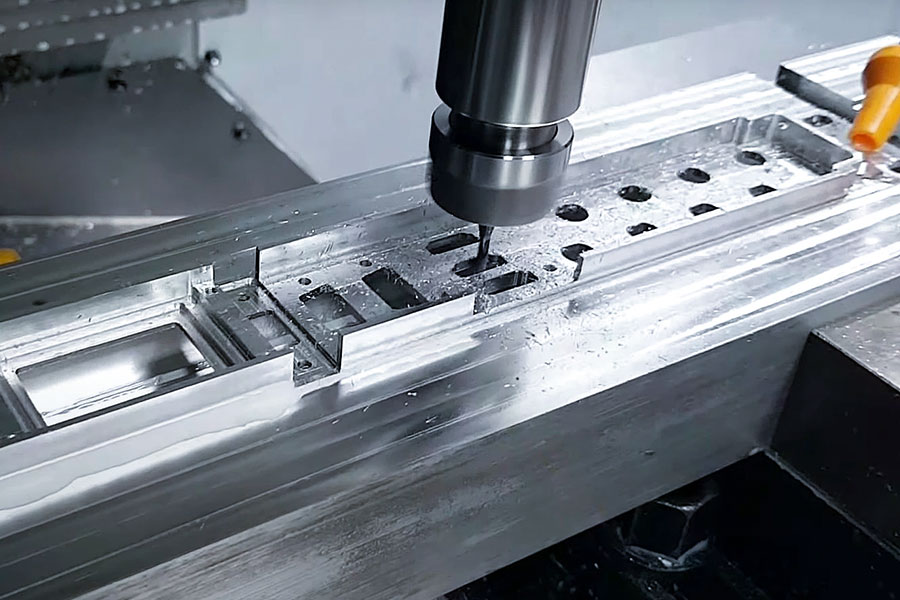

JS's solution: Industrial-grade CNC reproduction, beyond the prototype

The customer came to us with a beloved wooden prototype.Our core mission:retain its soul (exquisite design) and give it a strong body (industrial reliability and precision).

(1) Accurately capture the design:

First, thewooden prototypeis scanned in high-precision 3D, converting every subtle curve created by the designer with the tool into a digital model.

(2) CNC process implementation: Engineers convert the model into an optimized CNC machining program.

- Replacement of "Roughing Gouge":Use high-efficiency roughing inserts to quickly shape aviation aluminum alloy bars in a few seconds, which is much more efficient than manual work.

- Successor of "Spindle/Bevel Gouge":Use high-performance finishing inserts to complete complex curve finishing and surface finish control in one go, and the surface quality (Ra value) is more stable than manual grinding.

- Solve the core pain points:Use precision thread cutters to process metal internal threads, with a thread accuracy of ±0.01mm, which completely solves the risk of thread slippage.

- Materials and post-processing:Select 6061 aviation aluminum alloy substrate, afterCNC turningand forming, sandblasting is performed to obtain a delicate matte touch, and finally black anodizing is performed to enhance surface hardness, wear resistance and corrosion resistance, while giving a deep and consistent black appearance.

Key data for performance improvement

| Characteristic | Walnut wood prototype | JS CNC aluminum alloy knob | Lifting effect |

| Dimensional consistency (key diameter) | ±0.5mm. | ± 0.025mm (CNC guarantee). | Improved accuracy by 12 times. |

| Surface hardness | Low (Mohs hardness~2.5). | High (anodic oxide film HV>300). | Significantly enhanced wear resistance. |

| Sweat resistance/corrosion resistance | Poor (easily discolored, stained). | Excellent (anodized film protection). | Long term use with stable appearance. |

| Reliability of threaded connections | Low (wood is prone to slipping). | Extremely high (metal thread). | Eliminate the hidden dangers of looseness and slipping wires. |

| Feasibility of mass production | Extremely low (relying on skilled craftsmen). | High (Automated CNC Production). | Realize stability, efficiency, and large-scale production. |

Source: MIL-A-8625 Anodized Film Standard and Industry Test Data.

"This case perfectly demonstrates the transformation from manual prototype to industrial boutique. Whether you are in the stage of creative verification or mass production ramp-up, JS can help you break through the bottlenecks of materials, precision and efficiency with its professional capabilities in customized CNC turning manufacturing. If you have a unique design, please contact us to accurately implement your inspiration and achieve a leap from 1 to 10,000."

FAQ - Your Last Question About Turning Tools

Do I really need all 6 tools?

I am often asked this question. To be honest: a skilled master can indeed complete most tasks with a bevel chisel and a round chisel, but this is based on a lot of experience and risk control capabilities.

But for novices, the situation is different.Each of the core 6 tools is designed for a specific turning task.Using the right tool will not only make the operation smoother, but also safer. This can really help you reduce the difficulty of learning and the feeling of "not being able to do it well". You can think of them as helpers in the toolbox with clear division of labor, each doing its own job, so that you can get started more smoothly.

What is the fundamental difference between woodworking turning tools and metal turning tools?

The main differences are concentrated in two points: the material of the tool itself and how we use it.

(1) In terms of materials:

- Woodworking turning tools are most commonly made of high-speed steel (HSS). This material is hard and sharp enough to deal with wood, and it is relatively easy to sharpen the tool.

- Metal turning tools are different. They process hard materials such as iron and steel. Therefore, stronger materials are usually used, such as cemented carbide (commonly known as tungsten steel blades) or ceramics. These materials resist metal wear with ultra-high hardness (HRA 90+).

(2) In terms of usage:

- When using woodworking turning tools, it is about feel and experience. We have to hold it firmly in our hands, lean it against the tool holder, and adjust the strength and angle of our hands in real time according to the cutting conditions of the wood and the sound we hear, all controlled by hand skills.

- The metal turning tool must be "fixed" there. It must be clamped very firmly on the turret or tool holder of the lathe. It depends entirely on the CNC program of the machine tool or the operation handle of a skilled worker to direct its movement route, speed, and cutting depth at each step. Direct manual control is simply impossible and cannot be controlled.

However, whether it is cutting wood or turning iron blocks, their most basic principles are actually the same: they all rely on the thin and sharp blade to "gnaw" and separate the material from the workpiece.This basic principle of cutting is common.

How to judge whether my turning tool is sharp?

There is a very practical way:

Pick up the turning tool and try to use it to cut the edge of ordinary printing paper. If it can cut the edge of the paper cleanly and neatly without any drag, then the sharpness is basically up to standard.

When you really start processing, the sawdust is the most telling. If you cut a continuous, strip-like ribbon that curls like wood shavings, it means that the blade is very sharp and the cutting is smooth.

On the other hand, if the sawdust is in the form of fragments or powder, it is basically certain that the knife is blunt and needs to be sharpened. The cutting state is the most direct signal to judge the sharpness.

Summary

Mastering these 6 core turning tools is the key to the real advancement of woodworking enthusiasts. They are your helpers, helping you turn the potential of wood into real works. Do more hands-on work to experience the fun of theblade cuttingthrough the wood and shaping the shape. This feel is the basis of creation.

So, when do you need further professional strength?

- When wood is no longer the only choice? Your design requires the strength of metal, the characteristics of engineering plastics, or the texture of special materials. Purely hand-turned wood knives are not quite in line with your requirements.

- When the precision requirement is strict? The parts need to fit perfectly, and the tolerance is measured in threads (0.01mm). It is difficult to achieve this level of stable precision with manual control.

- When quantity becomes a challenge? After the design is finalized, dozens, hundreds or even more identical and perfect copies are required. Manual production is too inefficient and consistency is difficult to guarantee.

This is where our JS team can help.We use onlineCNC turning servicesto seamlessly transform your creativity into high-precision parts:

- Material freedom:From aviation aluminum, stainless steel to PEEK special plastics, breaking through the physical limitations of wood.

- Precision guarantee:CNC program controls ±0.01mm accuracy to ensure that the first piece is exactly the same as the 1000th piece.

- Strength upgrade:Metal threads and hardened surface treatment make the design stand the test of ten years of use.

- Agile response:Submit drawings online and get accurate CNC turning prices within 3 minutes, without communication costs.

Don't let material limitations or production difficulties hinder your good design.Upload your drawingsand get accurateCNC turning pricesimmediately. Let our JS engineering force use precision CNC turning to turn your ideas from conception into usable, high-quality parts.

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsrpm.com