As an all-around player in the manufacturing industry, CNC turning can easily handle metals such as aluminum and copper, as well as handle materials such as plastic and wood, and even process ultra precision complex parts.

But don't think that just choosing materials is enough. Choosing the right one can save time and money, while choosing the wrong one may directly affect processing efficiency.

Today, we will take you to learn about the commonly used material properties in CNC turning, as well as how to select materials and help you find the most suitable one.

What is the basic definition of CNC turning?

CNC turning belongs to subtractive machining technology, which simply means cutting out parts by continuously cutting solid materials and removing excess parts layer by layer until the target shape is obtained.

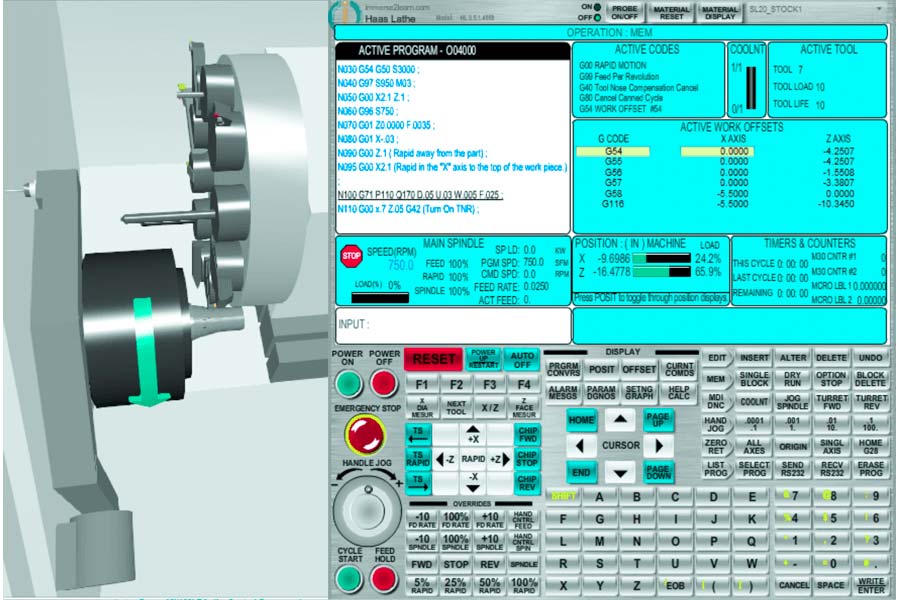

There is a special phenomenon during processing, where the CNC turning center or lathe itself is fixed and stationary, while the clamped raw material rotates at high speed. At this point, a sharp single point tool will move synchronously along the X and Z directions, accurately cutting the rotating material.

The core of the entire process lies in the computer program, which, like a command center, controls the tool's movement trajectory, speed, and feed rate in real time. This automated operation not only ensures a precision of ±0.01 millimeters, but also enables mass production of complex cnc turning parts.

How is CNC turning programming performed?

CNC turning programming is actually writing a dedicated operating guide for the machine tool. The whole process can be broken down into three key actions: drawing, programming, and adjusting details.

First, our engineers refer to the CNC turning drawing pdf file and use CAD software to draw a three-dimensional model of the part.

Then, the CAM software takes over the baton and converts this design drawing into a CNC turning program that the machine tool can understand, that is, a G code containing instructions such as tool path, speed, and feed speed.

Finally, this program is input into the CNC lathe, and the machine tool will strictly follow the code instructions to rotate the material, move the tool, and cut out precise parts one by one.

The core here is the flexibility of the turning program. For example, when processing the same shaft, the program will increase the speed for fast and accurate cutting when using aluminum alloy, and automatically reduce the speed when changing to stainless steel to prevent the tool from overheating. This ability to adjust parameters at any time not only ensures the accuracy of the parts (the error is less than 1/5 of a hair), but also prolongs the life of the tool. From screws to engine crankshafts, almost all rotationally symmetrical metal parts require this precise command.

What materials are often used for CNC turning?

CNC turning can accurately shape various raw materials. Choosing the right material is not only related to the quality of the finished product, but also directly affects the processing efficiency and cost. We divide common materials into two categories: metal and non-metal, to help you quickly lock in the best choice.

Metal materials: The main force of CNC turning

1.Aluminum alloy

- Features: The density is only 1/3 of that of steel, the natural oxide film provides rust protection, and the thermal conductivity is high (about 200 W/m·K).

- Advantages: Low cutting resistance, suitable for high-speed processing (speed can reach more than 3000 rpm), and long tool life.

Processing suggestions:

Use diamond-coated tools to prevent aluminum chips from sticking to the tool.

Recommended cutting parameters: Feed rate 0.2-0.5 mm/rev.

2.Stainless steel 304

- Composition characteristics: 18% chromium + 8% nickel austenitic structure, hardness HRB 85-95.

- Processing difficulties: Easy to produce work hardening during cutting, and the tool is easy to wear.

Solution:

Use cobalt-containing high-speed steel or CBN (cubic boron nitride) tools.

Force coolant supply and control the temperature below 60°C.

3.Zinc alloy

- Process characteristics: Melting point is only 419°C, suitable for die casting, surface can be electroplated.

- Economic advantage: Material cost is 30% lower than aluminum alloy, suitable for mass production.

4.Titanium alloy (such as TC4)

- Performance parameters: Strength-to-weight ratio is twice that of steel, temperature resistance can reach 600°C.

- Processing challenges: Low thermal conductivity (7W/m·K), cutting heat is easy to accumulate.

Professional skills:

Use low speed (200-400 rpm) + high feed strategy.

Use high-pressure internal cooling tools, and the cutting fluid pressure is recommended to be ≥10MPa.

5.Brass (H59-H96 series)

- Composition effect: Zinc content ranges from 40% to 60%, and zinc content is lower, the hardness is lower.

- Self-lubricating properties: No coolant requirement in cutting, and surface roughness is Ra 0.8μm.

Main points for non-metallic material processing

| Material type | Recommended cutting tools | Speed range | Typical application scenarios | Precautions |

| ABS plastic | High speed steel end mill. | 1500-2500 rpm | Electrical casing, toy gears. | Prevent overheating and deformation. |

| POM (sai steel) | Carbide turning tool. | 800-1200 rpm | Bearings and sliding component. | Control the cutting depth to be ≤2mm. |

| Hardwood (oak) | Diamond carving knife. | 2000-4000 rpm | Furniture carving, musical instrument heads. | Regularly clean the sawdust. |

| Carbon fiber composite material | PCD cutting tools. | 500-800 rpm | Drone arm, racing chassis. | Special anti layering fixture. |

Material Selection Guide:

1.Determine core requirements

If the strength has to be high, titanium alloy is preferred over stainless steel and finally, carbon steel is considered.

In applications where costs matter, zinc alloy is the most affordable, then comes aluminum alloy, and brass is relatively costly. It must be remembered that when exposed to special environments, one has to "prescribe the right medicine": 316L stainless steel has to be considered in seawater environments, and Inconel alloy has to be chosen directly for high-temperature environments.

2.Precautions in processing

Be careful while machining titanium alloy on a standard lathe, and ensure the spindle power is 5kW or more. When designing products that are made of carbon fiber, you need to prepare special cutters as hard as diamonds beforehand. The workshop equipment is like the athlete's equipment, they need to be matched so as to create the best effect.

3.Surface treatment and assembly

Aluminum alloy is most suitable for anodizing treatment, while electrolytic polishing is commonly used for stainless steel. For components that require precision assembly, it is recommended to use POM plastic, which has a low coefficient of friction.

Which industries use CNC turning?

CNC turning technology plays an important role in many fields due to its high precision and good efficiency. This processing method is like a precision chisel directed by digital instructions. It can maintain stable quality in mass production and meet personalized customization needs. The following are typical application scenarios of CNC turning service in different industries:

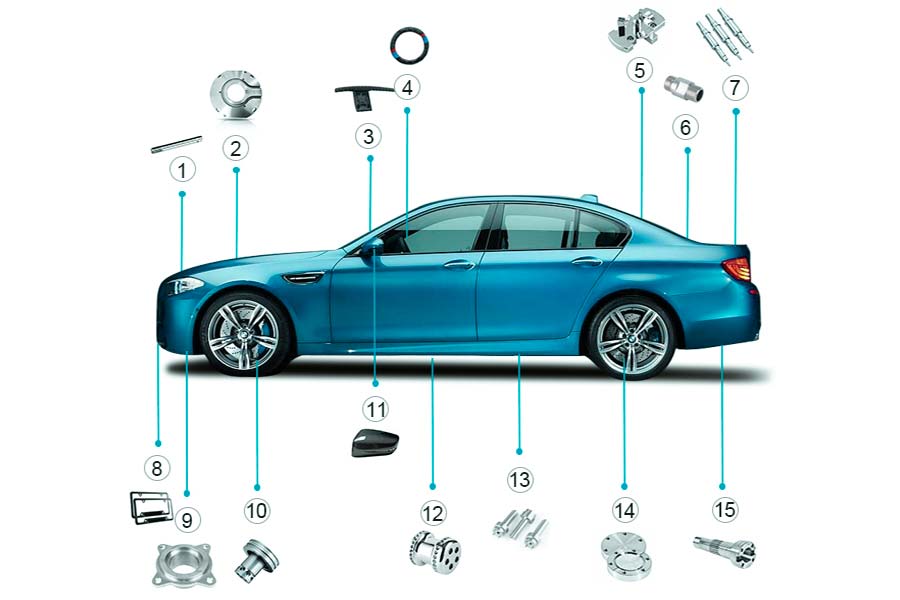

1.Automobile manufacturing

From transmission gears to suspension links, more than 60% of metal parts on cars cannot be separated from turning. Whether it is a family car or a heavy truck, parts that need to withstand high-intensity and high-frequency movement often use CNC turning to ensure dimensional accuracy and durability.

2.Mechanical system

In various types of mechanical equipment, "joint" parts such as shaft cores and bearing sleeves are basically CNC turning parts. They are like screws and nuts in mechanical systems, which must accurately connect various parts and ensure smooth power transmission. Common turning parts also include key transmission parts such as piston rods and couplings, which are widely used in engines, production lines and other scenarios.

3.Medical devices

The medical field has the most stringent requirements for the precision of turned parts, such as orthopedic implants and surgical instruments, which often require processing precision at the level of hair. As a professional manufacturer with ISO medical certification, JS is particularly good at processing biocompatible materials to ensure that each medical turned part is safe and reliable.

4.Aerospace

Aircraft engine blades, landing gear connectors and other "air lifelines" are generally made of high-strength titanium alloys through precision turning. Such parts must not only be as light as a feather, but also as hard as a rock, and must strictly comply with the special process standards in the aviation field.

5.Electronic automation

In robots and industrial control equipment, many precision sensors and transmission gears hidden in metal casings are completed by micro-turning. Although these parts are small in size, the precision requirements are not ambiguous at all, and often require micron-level dimensional control.

Although the turning process is widely applicable, different industries have special requirements for materials, precision, and certification. It is recommended to communicate with us in detail about specific needs before proofing, especially in special fields such as medical and aviation, where we have both qualification certification and process experience.

How to determine the key factors in material selection?

In CNC turning services, material selection requires a systematic analysis of the following three factors:

1.Performance matching is the basis

Material selection must first match the actual use scenario of the part. Three key parameters must be clarified: the mechanical pressure to be borne, the operating temperature range, and the type of media in contact.

For example, the hydraulic valve body needs to withstand high-pressure impact, and stainless steel or alloy steel is usually selected. Medical implants must use human-compatible materials, such as medical titanium alloy. There was a typical case: an aviation fastener frequently broke after use because the fatigue strength of the material was not considered, and the problem was finally solved by switching to Inconel 718 alloy.

2.Processing feasibility must be verified

The processing difficulty of different materials directly affects production efficiency and cost. Easy-to-cut materials such as aluminum alloys and brass can quickly process high-precision surfaces and are suitable for precision parts. Difficult-to-process materials such as titanium alloys and high-temperature alloys require matching special tools and coolants, and require machine tools to have specific functions.

For example, when processing titanium alloy, it is necessary to confirm whether the machine tool can maintain a constant cutting speed and the spindle power is not less than 5kW. This is like driving uphill requires sufficient horsepower, otherwise it is easy to stall midway.

3.Comprehensive cost must be calculated accurately

On the premise of ensuring performance, it is necessary to balance material cost and processing cost. For mass production, economical materials such as zinc alloy and low carbon steel can be given priority to reduce costs through economies of scale. Small batches of precision parts require overall consideration. For example, although the unit price of pre-hardened steel is higher, it can save the heat treatment process and is more cost-effective.

In the automotive parts enterprise project we cooperated with last month, after we switched to ductile iron, the material cost increased by 15%, but due to the 40% reduction in tool loss, the total cost decreased by 8%.

What are the main tool materials used in CNC turning?

For lathe cutting tools, only the right materials can cut out beautiful parts. There are four major categories of mainstream tool materials, each with its own strengths:

1.High-speed steel (HSS)

- Material formula: Contains tungsten, molybdenum, chromium and other elements, It is a versatile material in the metal industry.

- Advantages: Good toughness, affordable price, suitable for intermittent cutting conditions.

- Classic scenario: Rough processing of ordinary steel parts, recommended speed ≤30m/min.

2.Cobalt alloy (such as M42)

- Heat-resistant characteristics: Contains 8% cobalt elements, and the high-temperature hardness is 20% higher than that of ordinary high-speed steel.

- Applicable scenarios: Continuous cutting of stainless steel and heat-resistant alloys, the cutting temperature can reach 600℃.

3.Tungsten carbide (hard alloy)

- Performance parameters: Hardness up to HRA90, wear resistance is 5 times that of high-speed steel.

- Practical performance: When processing cast iron, the cutting speed can reach 200m/min.

- Coating upgrade: TiAlN coating can extend tool life by 3 times.

4.Metal ceramics

- Material structure: Ceramic matrix + metal bonding phase, like wearing a heat-insulating suit.

- Special advantages: When cutting titanium alloy, the surface roughness can reach Ra 0.4μm.

- Use restrictions: It is relatively brittle and not suitable for intermittent cutting.

Material selection decision reference table

| Processing Materials | Prefer | Alternative solutions | Use type with caution |

| Mild steel | Coated carbides. | High-speed steel. | Cermet. |

| Stainless steel | Cobalt based hard alloy. | Cermet. | Ordinary high-speed steel. |

| Titanium alloy | diamond coated tools. | Cermet. | Uncoated hard alloy. |

| Aluminum alloy | PCD cutting tools. | Ultrafine grained hard alloy. | High-speed steel. |

For example, when processing automotive brake discs (gray cast iron HT250), using CBN (cubic boron nitride) cutting tools can increase efficiency by 5 times compared to hard alloys. When refining medical titanium alloy bone nails, silicon nitride ceramic cutting tools can achieve a mirror effect.

The key is to remember: there is no universal tool, only the most suitable choice for the current working condition.

Based on material processing, how does CNC turning challenge?

1.The protracted battle of tool life

Although CNC turning tools are small, they have great responsibilities. The wear of the blade directly affects the processing quality. In actual operation, only the front edge of the tool is truly involved in cutting.

When encountering high-toughness materials or improper cutting parameters (such as too fast feed speed and too large cutting depth), the blade will age prematurely. There was a processing plant that did not adjust the parameters in time when cutting heat-resistant alloys, causing the tool life to drop from the conventional 8 hours to less than 1 hour.

2.The individuality of materials

The processing characteristics of different materials vary significantly. Aluminum is easy to process like an obedient student, brass is like an experienced craftsman with self-lubricity, and stainless steel requires special treatment. Especially when encountering new composite materials, it is recommended to conduct trial processing verification first, which is like a clinical trial before a new drug is launched, which can effectively avoid unexpected situations during mass production.

3.Precision control

Even if automated equipment is used, precision assurance still requires cooperation in multiple links. The numerical error in the programming stage may be magnified dozens of times and reflected in the finished product. JS often uses the concept that design determines quality, requiring precision control from the CAD modeling stage, and predicting possible dimensional deviations through simulation software.

4.Equipment capacity limit

CNC lathes are not universal tools, and their processing capabilities are limited by physical structures. When facing prismatic parts or irregular surfaces, lathes often need to use other processes such as milling to complete. For example, when processing the plane structure of hexagonal nuts, it is difficult to achieve the right-angle accuracy requirements at the edge line with a simple turning process.

What is the future development trend of CNC turning materials?

Trend 1: Rapid development of composite materials

Carbon fiber metal-based materials: This type of high-performance composite material is rapidly replacing traditional single materials. It is not only one-fifth lighter than conventional aluminum alloys, but also has a 40% increase in strength indicators. It has been successfully applied to precision parts such as UAV movable joints.

New ceramic-based alloy: In the field of high-temperature working conditions, it can stably withstand a high temperature environment of 1100℃. In a cooperative project with a certain aerospace enterprise, our company used it to manufacture rocket nozzles, and the processing cycle was shortened by nearly one-third. JS technicians reported that the cooling process that was originally interrupted due to material softening can now be processed continuously.

This type of material needs to switch to the CNC turning & milling mode in the CNC turning and milling center. First, the main contour turning is completed with a diamond tool, and then the carbide tool is replaced to mill the connecting groove structure. We have successfully compressed the single-piece processing time by 20% by optimizing the tool path and cooperating with the automatic tool changing system.

Trend 2: Smart materials enter the practical stage

Currently, smart materials are moving from the laboratory to the production workshop. The medical application of memory alloys is quite representative. The vascular stent formed by turning can automatically expand its shape after contacting the human body temperature. This feature reduces the implantation operation time to 50% of the traditional method.

There are also breakthroughs in the field of self-healing materials. The micro-repair capsules embedded in the new aluminum alloy can automatically repair surface micro-damage after turning. After a precision instrument manufacturer adopted this material, the service life of key moving parts was extended by 30%.

Special processes are required to process such smart materials. Modern CNC turning and milling centers have achieved synchronous processing of functional layers and structural layers. For example, when processing memory alloys, it can not only ensure the shape accuracy of parts, but also retain the memory characteristics of materials through temperature control.

Trend 3: Environmentally friendly materials are forced to enter the market

| Environmental pressure | Alternative solutions | Processing challenge |

| Lead free requirements | Silicon bronze replaces lead brass. | Cutting speed needs to be reduced by 10% -15%. |

| Carbon neutrality target | Recycled aluminum alloy. | Pre treatment to remove impurity particles. |

| Biodegradation demand | Medical magnesium alloy. | Nitrogen protection for anti-oxidation turning. |

A new energy vehicle company approached us and requested to process the motor casing. JS uses recycled aluminum for manufacturing and completes the composite processing of turning the inner cavity and milling the heat dissipation teeth at the turning and milling center, reducing costs by 12% and carbon emissions by 25%.

Summary

The material selection for CNC turning needs to balance performance, cost, and process feasibility. In fact, if a suitable material is missing in CNC turning, the performance of the entire part will be compromised.

The reason why JS's turning services are targeted by medical and aerospace companies is based on two pillars: one is the pile of hard core certifications such as ISO13485 and AS9100 in hand, and the other is the ultra high precision equipment in the workshop.

Others are afraid of tool breakage when processing titanium alloys. We can use a five axis linkage equipment with a 20MPa high-pressure cooling system to achieve a mirror effect on TC4 titanium alloy bone nails. We can understand the material properties and combine them with specific application scenarios to maximize the advantages of CNC machining.

Disclaimer

The content of this page is for informational purposes only.JS Series No representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. choose JS Technology It means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

FAQs

1.Which parts are suitable for aluminum alloy turning?

Suitable for turning aerospace parts, automotive parts, electronic equipment housings and radiators and other precision parts that need to be lightweight, taking into account both strength and processing efficiency.

2.Why is titanium alloy difficult to process?

The poor thermal conductivity of titanium alloy leads to heat accumulation, and the high material strength increases cutting resistance. It is easy to stick to the tool during processing. Special tools must be used and cutting parameters must be strictly controlled.

3.Can composite materials be turned directly?

It can be turned, but special tools (such as diamond-coated tools) and precise control parameters are required to prevent material delamination or cracking. It is recommended to operate in steps during processing.

4.How to judge whether the material is suitable for turning?

It mainly depends on whether the material hardness is moderate (within HRC30), whether it is easy to produce burrs or stick to the tool, whether the processing accuracy can be maintained stably, and whether the cutting parameters are easy to control.

Resource