Hello everyone, I am an engineer at JS. I still recall when I first started in 2008, I saw the operation of a low-pressure casting machine in a German workshop for the first time. The molten aluminum alloy gradually rose up like a breath, and finally filled the complex cylinder head mold with high accuracy. At that moment, the ingenuity and efficiency of the process made a great impression on me.

Fifteen years have passed,low pressure casting is already a familiar tool to me. Today, I'll don my engineer's glasses and take you to observe this precision process that has revolutionized manufacturing circles.

What is low pressure casting?

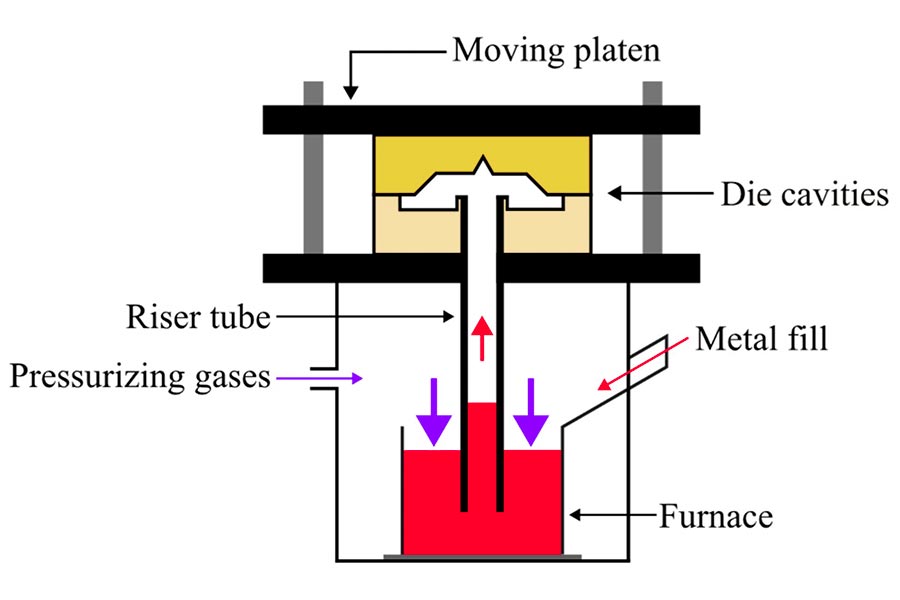

When we carry out low-pressure casting, we use compressed air to provide power mainly. We pass this air through the closed insulation furnace below and allow it to act on the liquid surface of the molten metal. This creates a pressure gradient between the furnace and the mold cavity above.

Under this low pressure (much lower than that of high-pressure die casting), the molten metal is pushed and rises along the riser tofill the mold cavity in a smooth manner.After filling metal, we will raise the air pressure a bit. This enables the molten metal to cool down, crystallize, and solidify in an orderly manner from the most remote place from the gate to the gate. After the casting is completely solidified, the air pressure is released. Now, the molten metal that is still not solidified in the gate and riser will flow down to the furnace below.

In the low pressure casting process, pressure, time, speed, and temperature are all controllable. Our molds can be reused numerous times, but thermal balance needs to be specially addressed at the design stage so that the metal can solidify from the far end to the gate in order to avoid internal defects.

"The key difference between low pressure casting and other processes is that it uses controlled air pressure to achieve smooth filling and directional solidification of molten metal from bottom to top." - American Foundry Society (AFS) "Casting Metal Handbook"

What is thefundamentaloperation process of low pressure casting?

Step 1: Prepare the mold

- I begin by getting the mold ready. This mold (usually a permanent steel mold, which is much more durable than a sand mold) will determine the form of the final product.

- Preheating of the mold is required so that the mold temperature is close to the aluminum melting point but not higher than that, to prevent the cold mold from coming into contact with hot aluminum water and creating "thermal shock."Sometimes some flux is sprayed to purify the mold surface from oxidation.

- The mold must be tightly sealed and no gas should be able to escape. There are a few minor steps that must be conducted before casting, such as degassing.

Step 2: Obtain aluminum water

- I melt the aluminum ingot into aluminum water in a furnace and heat it to a temperature slightly above the melting point (for example, aluminum must be heated to 710-720℃).

- The aluminum water is poured into the insulation furnace (or crucible) below the mold, where the temperature can be kept constant and also impurities can be removed at the same time. This furnace is like a thermos with a filter.

Step 3: Pressure casting

- I pressurize the gas in the insulation furnace. The pressure isn't high, perhaps 20 to 100 kPa (which is roughly a fraction of the tire pressure of a car).

- This gentle pressure pushes the molten aluminum continuously, from a tube in the furnace (a riser) upward, into the sealed mold cavity. There is no splashing, it's quite stable.

- The pressure is maintained to let the molten aluminum occupy all the details of the mold,whereas the excess gas within the mold easily escapes through the exhaust holes provided.

Step 4: Solidification and demoulding

- The molten aluminum slowly solidifies and hardens in the mold. The pressure is maintained throughout, so the aluminum is constantly fed when it shrinks, reducing inner contraction shrinkage cavities. The process allows the molten aluminum to imprint the mold shape with force.

- I let go of the air pressure in the holding furnace when the molten aluminum has completely solidified.

- Open the mold and take out the still warm aluminum low pressure casting part.

Step 5: Post-processing

- The edges of the just removed parts may be with burrs and flash, and I need to clean them up.

- As per the requirements,this low-pressure casting may also need to be milled twice or polished.

- I won't waste the cut gate material and scraps, I will collect and melt them for recycling.

How much investment is needed for low pressure casting?

I am often asked how much investment is needed for aluminum alloy low-pressure casting. This is indeed very important! Next, I will talk about it in several key points:

1. Equipment is the most expensive

In my personal experience,the core of aluminum alloy low-pressure casting part is equipment investment. You need a special casting machine. For new machines, small aluminum low-pressure casting factories may start at US$70,000, and large factories may cost millions or more. Second-hand ones can be cheaper, but the risk is high and later maintenance may cost more.

In addition, don't forget the accessories, such as molds, control systems and safety devices. These together can easily account for half of the total equipment cost. In short, the equipment investment depends on your production target. If the production is small, the money will be saved, and if the production is large, more money will be spent.

2. Underestimate the cost of raw materials

Talking about material,aluminum alloy is the hero when casting aluminum alloy low-pressure. As indicated in the above table, the global price of aluminum alloy ingots correlates straight to LME, and the domestic buying price is usually referring to LME plus tax and freight. In case you are producing in Europe, the material cost is roughly 15% more than in China (freight + tariffs), so remember to consider it in advance!

3. Venue and facilities

One cannot start processing without a venue. The investment is in finding a good factory or workshop. The rent differs according to the location. The rent of a place in first-tier cities starts from 10,000 yuan, and it is achievable with several thousand in small cities. Do not forget the conversion of electricity and water sources. These fixed costs are not inexpensive. For example, the upgrading of the power system to accommodate the devices costs tens of thousands of yuan upfront. Even if the leased land does not meet specifications, it must be renovated, a huge expense.

4. Manpower and operating expenses

Staff expenses cannot be ignored. I suggest hiring at least a few skilled workers and technicians. Ordinary workers start at 5,000 yuan per month, and technical supervisors may be tens of thousands. A small team has at least 100,000 to 200,000 yuan in labor costs a year. Operating expenses include daily equipment maintenance, training fees, insurance and environmental protection permits - all these miscellaneous costs are about 5,000 yuan per month. Don't feel sorry for this investment. In the long run, good employees can reduce losses.

5. Total investment estimation and key tips

In general, the minimum investment for aluminum alloy low pressure casting projects is about RMB 2 million, which is a realistic starting point if you start from scratch. But if you want to enter at a low cost, second-hand equipment plus small-scale operations can also be reduced to less than RMB 500,000.

I emphasize that this is not a one-time payment, and it is safer to invest in installments. The logic is very simple. Equipment, materials, venues, and manpower are closely linked.Good early planning can save a lot of money. Finally, don't forget market research. The return on investment is between 10% and 20%. You have to persist in this business for a long time to see profits.

How does low pressure casting compare with gravity die casting?

1. Essential difference: the competition of the "driving force" of molten metal

| Dimension | Low pressure casting | Gravity Die Casting |

| Driving force source | Controllable air pressure (0.1-0.5 bar) | Pure gravity (without external force) |

| Filling direction | From bottom to top (riser → cavity) | From top to bottom (gate → cavity) |

| Metal flow state | Laminar flow (smooth without turbulence) | Easy turbulence (high risk of gas entrapment) |

The "pressure delivery" of low-pressure casting is essentially a controlled physical process, while gravity casting relies on natural gravity - which means a narrow process window and sensitive fluctuations.

2. Comparison of core indicators (based on actual production data)

| Evaluate parameters | Low pressure casting | Gravity casting |

| Dimensional accuracy | ± 0.1-0.3mm (CT4-CT5 level) | ± 0.3-0.5mm (CT6-CT7 grade) |

| Surface roughness Ra | 3.2-6.3 μm (close to machining) | 6.3-12.5 μm (requires additional sandblasting treatment) |

| Porosity | ≤ 1% (X-ray inspection grade A) | 2-5% (thick areas are prone to exceeding standards) |

|

Tensile strength

|

240-280 MPa | 200-230 MPa |

| Elongation rate | 8-12% | 4-7% |

| Material utilization rate | 90-95% (without riser) | 60-75% (requires a large riser to compensate for shrinkage) |

| Mold lifespan | 80,000 to 150,000 cycles (thermal fatigue is the bottleneck) | 150,000 to 300,000 times (without high voltage impact) |

3. Comparison of production economy

The hidden cost advantage of low-pressure casting:

Case:In a new energy vehicle motor housing projectof JS Company:

▶︎ Low-pressure casting: net weight 12kg, blank weight 13kg (utilization rate 92%).

▶︎ Gravity casting: net weight 12kg, blank weight 18kg (riser accounts for 33%).

Result: The material cost of a single piece is reduced by 25%, and the annual production of 100,000 pieces saves more than 600 tons of aluminum alloy!

The explicit cost advantage of gravity casting:

| Cost item | Low pressure casting | Gravity casting |

| Equipment investment | ¥ 8-2 million (including insulation furnace) | ¥ 2-5 million |

| Mold development cycle | 3-6 months (requires thermal balance simulation) | 1-3 months (simple structure) |

| Single item cycle time | 3-8 minutes (holding pressure accounts for 60%) | 2-5 minutes (without pressure holding phase) |

My engineering practice suggestions:

Selection iron rule:

"Low pressure for load-bearing parts, gravity for decorative parts. Low pressure for thin-walled and complex parts, gravity for thick-walled and simple parts"

Practice to break through the limitations of gravity:

At JS, we solve problems through composite processes:

▶︎ Low pressure + local extrusion:Used in the hot joints of the subframe, which can effectively eliminate shrinkage.

▶︎ Gravity casting + differential pressure shrinkage compensation: Improve the density of the cylinder oil channel.

Is aluminum alloy suitable for low pressure casting process?

I have been an engineer for 15 years. When doing metal parts projects,aluminum alloy is definitely suitable for low-pressure casting process. This process is widely used in the industry, mainly because it can push molten metal into the mold at a relatively low pressure, avoiding common problems such as bubbles or cracks.

1. Good fluidity

Low-pressure casting relies on low-pressure gas to gently push the aluminum liquid from the furnace into the mold. This characteristic of aluminum alloy allows it to smoothly fill the corners of complex molds without much pressure, effectively preventing insufficient pouring and air holes.

2. Controllable shrinkage

Aluminum alloy shrinks when solidifying, but this shrinkage is relatively easy to manage. The beauty of low-pressure casting is:

- Smooth filling: The aluminum liquid rises steadily, greatly reducing the chance of air and impurities being drawn in (much better than high-pressure casting).

- Continuous feeding (key point): Under the aluminum low-pressure casting process, pressure will continue until the casting solidifies. The gate is at the bottom of the mold, continuously providing molten metal, whichcan greatly reduce shrinkage and shrinkage holes, making the inside of the casting denser.

3. Economical, stable and reliable

- Cost saving: Low pressure has low pressure, low machine tonnage requirements, and low investment and maintenance costs. Aluminum has a low melting point and low energy consumption.

- Stable quality: Smooth filling + directional solidification + continuous pressure holding, this combination of punches makes the internal structure of the casting dense, the grains fine, the mechanical properties uniform and high strength, and the surface smooth.

- High yield: Reduced the risk of air entrainment, slag inclusion, and shrinkage, the process control is in place, the comprehensive yield is guaranteed, especially good at parts with complex structures (such as wheels and chassis parts).

Which fields or industries will use low pressure casting technology?

1. Automobile industry:

We make auto parts, such as wheels, engine blocks, and cylinder heads, andlow pressure casting is absolutely the main force. The things it makes are strong and reliable. And the surface is smooth and beautiful, and it can handle parts exposed to the outside like wheels.

2. Medical equipment (high requirements):

When we make surgical instruments and diagnostic equipment parts, we really can't be careless at all. The material must be able to withstand high-temperature steaming and strong chemical disinfection. The most important thing is that there must be no pores, otherwise it will be troublesome to hide bacteria. The parts made by low-pressure casting just meet the stringent sterility and durability requirements of medical treatment.

3. Aerospace (Keep Improving):

When we process aerospace products, the parts cannot be any worse. For example, landing gear parts and some engine parts have extremely high requirements for dimensional accuracy and internal quality. The pressure used in low-pressure casting is relatively "gentle", and the parts made are high-precision and uniform and strong inside.

4. Household appliances:

The bracket of the rice cooker in your kitchen, the lid of the food processor, and the parts in the washing machine are all made by die casting.It can make various complex-shaped and thin-walled partsto meet the designer's fancy, and the cost is well controlled and the things are durable.

If low pressure casting is not used, what other casting methods can be chosen?

1. High-pressure casting (die casting):

This is the most common. It is fast and efficient, and is particularly suitable for large-scale, thin-walled, and complex-shaped parts. It relies on instantaneous high pressure (tens or even hundreds of megapascals) to smash the molten metal into the mold. The disadvantage is that high pressure easily entrains air and slag, and there may be pores inside the parts. The slowness and stability of low-pressure casting just avoid these disadvantages.

2. Sand casting:

The oldest and most flexible method, whichcan be used for single pieces to large batches, with almost no size restrictions, especially suitable for super large and complex single pieces or small batches of castings. The cost is relatively low, and the mold is made of sand. But the accuracy and surface finish are much worse than low-pressure castings, post-processing is troublesome, and production efficiency is also low.

3. Investment casting (lost wax method):

The main technology for making complex and fine small parts and parts of difficult-to-process materials. Super high precision and excellent surface. But the process is cumbersome, the cost is high, and the output is not high. I used it to replace low-pressure casting and produce small batches of automotive parts before? After practice, I found that the cost is not worth it.

4. Gravity casting:

The metal liquid flows into the mold by its own weight. The equipment is simple and the cost is low. It is okay for small and medium batches and small and medium parts of aluminum/copper alloys. However, the molten metal is easy to splash and oxidize, the filling is not stable enough, the internal quality and surface finish are usually not as good as low-pressure castings, and it is a bit uncertain to make parts with high requirements.

5. Counter gravity low pressure casting:

I almost forgot to mention this! This name sounds advanced, but it is essentially a more sophisticated variant of the "low-pressure casting family". The core difference is to move the crucible under the mold to face the gate, and use vacuum suction or differential pressure principle to allow the molten metal to fill the mold more smoothly from bottom to top. It can go a step further than ordinary low-pressure casting, reduce entrainment oxidation, and improve density and uniformity.

Summary

After working on site for 15 years, I can say frankly that aluminum alloy low-pressure casting is not just as simple as low pressure. It is a hard work of finely blending metal flow, temperature, mold, and pressure control! It is best at making parts that are both light, thin, and complex, and absolutely strong and dense.

At JS, we focus every day on how to use aluminum low-pressure casting to make larger, thinner, and stronger parts. Do you have a project and are looking for a reliable partner? Orif you want to know specific aluminum low pressure casting quotes, don't hesitate! Contact us directly, we will speak with technology!

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

FAQs

1. What is low pressure casting used to manufacture?

Low pressure casting is mainly used to manufacture small and medium-sized thin-walled metal parts that require high density, few pores and complex shapes. Typical products include automotive aluminum alloy wheels, engine cylinder blocks, cylinder heads, aerospace parts, motor housings and high-precision hydraulic system components.

2. What shapes of parts can low pressure casting make?

Low pressure casting can manufacture complex thin-walled parts with clear contours and uniform wall thickness. It is especially good at near-net-shape castings with curved surfaces, fine ribs, internal cavities or asymmetric structures, such as automotive wheels, complex brackets, etc.

3. Is low pressure casting suitable for mass production?

Low pressure casting is very suitable for mass production. It has a high degree of automation and a long mold life (usually 50,000-100,000 times). It can stably and efficiently manufacture standardized parts such as engine cylinder blocks, but the initial mold cost is high and needs to be shared by production.

4. How to reduce pores in low-pressure casting?

Low-pressure casting uses a relatively low pressure (0.01-0.1MPa) to smoothly fill the mold, avoiding turbulent molten metal and entraining gas. At the same time, it continuously feeds and solidifies under pressure, allowing the gas to be discharged in an orderly manner. It also cooperates with directional solidification to reduce pores and significantly improve density.