During these years of working in low pressure casting at JS, I have deeply realized that it is far from enough to only focus on the aluminum alloy used to make a light, strong, smooth and beautiful casting. Behind this is the result of the collaborative work of key materials.

Molten aluminum alloy is the key core. But to accurately fill every corner of the mold with molten aluminum, it is inseparable from the special ceramic riser below. It must withstand high temperatures and maintain excellent chemical compatibility with molten aluminum to ensure that no harmful reactions occur.

And the high temperature resistant and extremely strong mold steel in our mold is what withstands huge pressure and thousands of degrees of high temperature, and is repeatedly used to ensure the precise shape and size of the casting.

When many people mention casting, they subconsciously only think of the metal material itself. Butin the low pressure casting process, if we only discuss aluminum alloys, we really only see the most superficial layer. What really supports high-quality castings is this set of special mold steel, special ceramic riser and aluminum alloy material system. They each play an irreplaceable role. Without any link, this perfect casting is impossible to achieve.

Core Answer Summary:

| Material Category | Core Function | Common Materials |

| Cast Alloy | Forming the final component determines its performance. | Aluminum alloy (A356.0, ZL101), magnesium alloy (less commonly). |

| Die Material | The shape of the component needs to withstand thermal cycling. | Hot work mold steel (H13, SKD61). |

| Key equipment materials | Ensure stable operation of the process. | Silicon nitride/silicon carbide ceramics (riser), graphite (crucible). |

This article will answer your questions:

- In this guide, I will focus on aluminum alloys for low-pressure casting.

- And explain the criticality of mold and riser materials.

- Finally, I will use a real case to show you how this set of materials works closely together to create a high-performance and reliable part.

- After reading it, you will understand that good castings are the result of material teamwork.

Why Trust This Guide? A Comprehensive Perspective From The JS Casting and Material Science Team

The casting projects our company has to do are far more than justaluminum low pressure casting quotes. The key is that every time we quote, we come with a material feasibility report, which is the most valuable part.

Years of experience have given me a deep understanding of the complexity of material selection. For example, for car wheels, we often use the grade A356, plus T6 heat treatment, it can be light and durable. But if you make an engine cylinder head, the material grade and treatment process must be re-selected, because the forces, temperatures, and even failure modes thatthe wheel and cylinder headhave to withstand are completely different.

For the mold, we use H13 mold steel for heat treatment process, accurately controlling the quenching temperature and tempering times. I pay great attention to these aspects, because the service life of the mold will eventually be calculated into the cost of the customer's product.

Our real experience:

- A customer's product had scale impurities in the casting, and the pass rate hovered at 85%, which was a headache for the customer.

- After careful analysis, we found that the problem was with the traditional cast iron riser, and the molten aluminum reacted with it. Later, we suggested replacing it with asilicon nitride ceramic riser, which is resistant to high temperatures and not easy to react chemically with aluminum.

- In the end, the impurity problem was solved, and the pass rate soared to 99%! This case shows that it is not enough to have a good aluminum alloy. How the materials interact with each other is the most important.

"As Professor Harry Bhadeshia, a famous materials engineer, emphasized: In engineering, material failure rarely comes from a single factor. It is usually the result of a mismatch between materials, processes and design."

This guide is what our JS team has accumulated little by little based on these practical experiences and material science knowledge. It is authentic and reliable. I just want to tell you clearly the pits I have stepped on and the roads I have verified, so as tohelp you manufacture high-quality castingswith more reliable performance and more competitive costs.

The Protagonist Appears: The Ideal Partner of Low Pressure Casting Aluminum Alloy

In daily projects of casting that I undertake, I often find myself seeing how low pressure casting process and aluminum alloy are a perfect couple.Aluminum alloy low pressure casting technologyfinds extensive application because the characteristics of aluminum alloy are in perfect harmony with low-pressure casting.

Simply speaking, what is low pressure casting?

It is a pressure casting process where molten metal is forced into the mold cavity by a low pressure (usually between 0.5-1.5 bar), hence reducing defects such as pores and shrinkage, to get denser and precise castings. Below is a discussion of whyaluminum alloy is an ideal companionand the most used grades employed.

Why use aluminum alloy as the top pick for low-pressure casting?

- Aluminum alloys, especially aluminum-silicon alloys such as A356, have superior casting properties, offer good fluidity and readily fill complex mold contours, being significant in precise shaping in low-pressure casting.

- It is strong but has low weight with a density of only about one-third that of steel, yet it can form good tensile strength, which is a major advantage for light construction in the motor vehicle andaircraft industries.

- Finally, aluminum alloys are a good conductor of corrosion and heat: it is resistant to oxidation and chemical attack, yet is a good conductor of heat, which makes it an ideal material for the cylinder head of an engine, radiator or casing of an electronic device. All these roles serve to make the low-pressure casting process effective and reliable.

The most commonly used aluminum alloy grades:

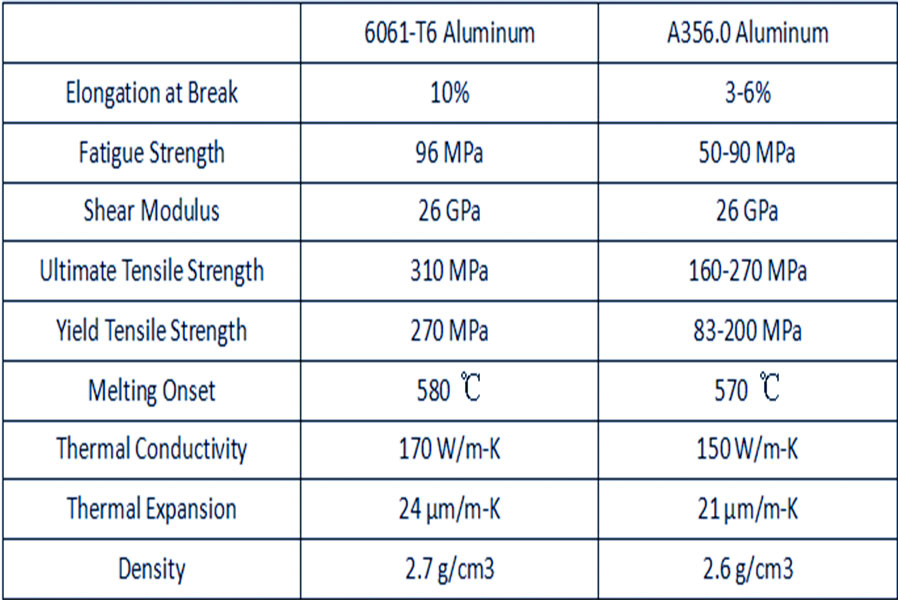

- A356.0 or ZL101A: In our practice at JS, they are the star players in low-pressure casting. This is analuminum-silicon-magnesium alloywith good castability and high air tightness. After T6 heat treatment, its strength and toughness can be improved, which is particularly suitable for manufacturing high-performance wheels, suspension arms or engine components.

- AlSi7Mg or ZL101: They are widely used in European standards and have similar performance to A356. Depending on the specific project requirements, such as higher tensile strength, elongation or heat resistance, we also use other aluminum alloy grades, but A356 and AlSi7Mg account for more than 80% of our daily work.

"Aluminum alloy low-pressure casting combines process efficiency and material advantages to produce high-precision, lightweight parts. If I were responsible for this project, I would start with customer needs, analyze the application scenario, select the appropriate aluminum alloy grade (preferably A356), optimize low-pressure parameters, and ensure the quality of the casting. JS focuses on this efficient solution, and we invite you to contact us to discuss how to make aluminum alloy low-pressure casting part."

Behind-The-Scenes Heroes: Molds and Equipment Materials That Make Perfection

Let's continue to talk aboutaluminum low pressure casting. This time, we will talk about those "behind-the-scenes heroes" that are easily overlooked but absolutely critical, molds and equipment materials. Imagine that aluminum alloy is the protagonist on the stage, and the mold and equipment are the stage and lighting. Without them, no matter how good the protagonist is, he can't perform a good show!

Mold material: Durability is the hard truth!

- Core challenge: The mold must repeatedly withstand the 600-700°C boiling aluminum water and the pressure of cooling shrinkage. It cannot be deformed or cracked over time. This strength requirement is very high!

- Our first choice: Hot work die steel, such as the familiar H13 (American standard) or SKD61 (Japanese standard).

Why is this type of steel so powerful?

It contains materials such as chromium, molybdenum, and vanadium, which make it strong and tough at high temperatures, and can especially withstand the fatigue caused by repeated hot and cold changes.In our JS workshop, H13/SKD61 is the absolute main force in manufacturing low-pressure casting metal molds.

Lifting pipe: The core channel of counter gravity low pressure casting

This pipe is very critical! The aluminum liquid is poured into the mold "upstream" by it. We generally have extremely high requirements for it:

- Stable chemical properties: It must not react with aluminum water, pollute the molten metal, and impurities in the casting will be scrapped.

- Control temperature: The aluminum water cannot cool too quickly when it rises in the tube, otherwise it will freeze before filling the mold.

- Strong durability: It must withstand the erosion of high-temperature aluminum water and hot and cold shocks, and cannot be easily broken.

Our first choice is silicon nitride ceramic tube(that is, Si₃N₄). What's so great about this thing? It is particularly corrosion-resistant, high in strength, not afraid of thermal expansion and contraction, and has a long life. The castings made with it are of the best quality. Of course, there are also cost-saving solutions, such as adding a layer of coating inside cast iron pipes or steel pipes, but to be honest, the durability and anti-pollution effect are inferior to ceramic tubes.

Other "key supporting roles" that cannot be ignored:

- Crucible: A "pot" used to melt aluminum water. We generally use graphite crucibles because they are resistant to high temperatures and aluminum water will not react when soaked in them.

- Release agent: It should besprayed into the mold before each pouring. The main functions are: first, to allow the solidified casting to be demolded smoothly; second, to form a protective film on the inner wall of the mold to reduce the direct damage of high-temperature aluminum water to the mold and extend the life of the mold.

To make high-quality and stable products in low pressure casting of aluminum alloy, it is far from enough to have good aluminum alloy alone. The material selection of each link of "little helpers" such asmolds, riser tubes and release agents directly affects the final success or failure.

"At our JS company, we are well aware of the value of these "behind-the-scenes heroes". From the selection of mold steel, the application of ceramic riser tubes, to the fine control of process parameters, we have accumulated rich practical experience. If you have the need for low-pressure casting of aluminum alloys, please feel free to talk to us. We will help you match the most suitable material solution and process route!"

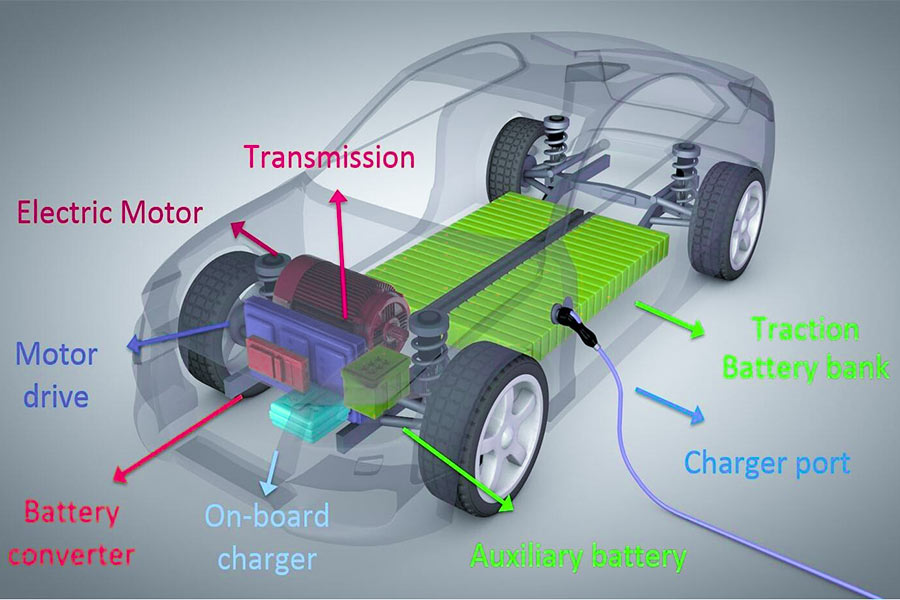

Practical Case Analysis: Developing An Integrated Battery Cooling Plate For Flagship Electric Vehicles

In the field of electric vehicles, the battery is the core, and itscooling system is the key life guarantee. We undertook a challenging project: developing a battery cooling plate with an extra-large size (1.5 meters long) and extremely complex internal flow channels (S-shaped design) for a top electric vehicle manufacturer. The core requirements are: absolute reliability and zero leakage.

Customer challenge: Make a large and complex cooling plate that must not leak

The customer's previous solution faced two major pain points:

- Traditional welding solution:Welding multiple small componentsinto a whole. This brings hundreds of potential leakage points, high risk of failure under long-term vibration, and more parts lead to increased weight.

- High-pressure die-casting attempt: Limited by the extra-large size and complex internal flow channels, small pores are easily formed during high-speed filling, which also cannot meet the strict zero-leakage requirements.

JS's solution: A complete low pressure casting material system

After analysis,we found that the key to success lies in materials and processes: we have to choose a material and process combination that can form a complex structure in one go and leave no seams. So, we locked in low pressure casting technology:

- Preferred casting alloy:We used A356 aluminum alloy. It has good fluidity, high density after solidification, and can fully fill complex flow channels. More importantly, after the standard T6 heat treatment, it can obtain high strength and toughness, and has extremely high air tightness, which is the basis for leak prevention.

- Precision process and mold design: Low-pressure casting allows aluminum water to slowly fill the mold, which can effectively avoid air entrapment and completely replicate those tiny flow channels. At the same time, we made the mold with H13 steel, added cooling pipes inside, accurately controlled the solidification process, and effectively prevented shrinkage.

- Key equipment: Considering the high requirements for the purity of the coolant flow channel, we insist on using silicon nitride ceramic riser tubes on low-pressure casting machines. This inert material ensures the purity of the casting from the source. The final delivery is such a high-performancealuminum low pressure casting part.

Comparative advantages of low pressure casting process:

| Process type | Average leakage rate | Weight reduction (compared to traditional welding) | Potential for improving production efficiency |

| Low pressure casting | 0% | ~20% | High (70%+) |

| High pressure die casting | 2.5% | ~10% | Medium (40%) |

| Traditional welding | 5.0+% | 0% | Low (20%) |

Source: SAE International, Advanced Casting for EV Cooling Systems, 2024.

Final result: lightweight, high-reliability safety core

Our solution has brought significant improvements:

- Overall structure: Successfully transformed the complex component originally composed of more than 20 welded parts into a single integral casting, eliminating the risk of weld leakage and improving structural reliability.

- Zero leakage verification: Passed the most stringent helium leak test to achieve zero leakage judgment. At the same time, passed 100% pressure cycle and vibration tests,fully meeting safety standards.

- Significant weight reduction: Compared with the customer's original welding solution, our cooling plate is 20% lighter, helping to improve the energy efficiency of the whole vehicle.

- Improved production efficiency: The one-piece molding process simplifies the production process and improves production efficiency compared to manual welding.

Core inspiration: System optimization is the king

After successfully completing this project, I realized a truth: Thesuccess of low pressure castingof aluminum alloys is not blindly guessed, butrelies on the systematic optimization of the three major areas of casting alloys, molds and equipment.Every detail must match to produce a quality product.

"If I were to lead this project, I would first dig deep into customer needs, then use our JS low-pressure casting expertise to select the right A356 aluminum alloy and customize the H13 mold to ensure a pure process. During the testing phase, I would tighten the pressure cycle and plug leaks in advance. JS is committed to solving complex challenges with casting technology and looks forward to empowering your next-generation electric vehicle platform."

FAQ - Answering More of Your Questions About Casting Materials

Question 1: What is the fundamental difference between low pressure casting materials and sand casting materials?

The core difference betweenthe two processes lies in the mold material:

- Low pressure casting uses a reusable metal mold, such as the H13 steel we commonly use. This hard mold ensures accurate casting dimensions, smooth surface, and high efficiency.

- The mold for sand casting is disposable, mainly a sand mold made of quartz sand and a binder. Sand molds are cheap to make and are particularly suitable for large and relatively simple parts. But compared with metal molds, the precision and finish of parts produced by sand molds are much worse.

So which process to choose, the mold material (metal or sand) is the key starting point.

Question 2: Why is low pressure casting not often used in steel materials?

- The key core is temperature! Steel melting requires about 1500℃, which is much higher than the aluminum alloy we often make (about 660℃). Such a high temperature is a big test for equipment.

- Insulation furnaces, risers, especially metal molds that we use repeatedly (such as H13 steel), are prone to problems at such high temperatures, and their lifespans will be sharply shortened. They will have to be replaced soon, and the cost is too high.

So, low-pressure casting is like tailor-made for light alloys such as aluminum and magnesium. Using them is the most suitable and cost-effective.

Question 3: What is the difference between low pressure casting and high pressure die casting in material selection?

The working methods of these two processes are very different, which directly affects the choice of materials:

High pressure die casting:

- It is fast, and the molten metal is instantly rushed into the mold by high pressure. We often use materials with good fluidity, such as aluminum alloy and zinc alloy, which can quickly fill every corner of the mold.

- But the problem is here too. If it is rushed too hard, it is easy to trap the air inside and form tiny pores.

- This makes it difficult to perform strengthening processes such as T6 heat treatment on it in the future. Once the pores expand when heated, the parts may bulge and become scrapped.

Low pressure casting:

- It feeds slowly and steadily, and relies on air pressure to steadily push the molten metal into the mold. In this way, the gas is not easily drawn in, and the inside of the casting is very dense, with almost no pores.

- Therefore, the parts made by it are particularly suitable for T6 heat treatment. After heat treatment, the strength and hardness of the material can be greatly improved.

Summary

To really make good use of low-pressure casting, it is not enough to just look at the aluminum alloy parts made in the end.The key lies in the core materials and process systems that support the entire process, such as durable H13 mold steel, corrosion-resistant ceramic riser and other key components. As one of manyaluminum low pressure casting factories, we know that only by selecting the right materials and ensuring that the entire process system is in place can high-performance and high-reliability parts be produced.

Does your project need such a solution?

- Are you looking for a method to manufacture aluminum alloy parts that can make complex shapes and ensure top quality?

- Do you think that choosing materials cannot only look at the grade, but also how the entire manufacturing process cooperates?

JS provides you with professional support:

- We not only focus on the selection of aluminum alloy grades, but also provide you withend-to-end process optimization solutions:

- Material matching: Analyze your design requirements and recommend the most suitable aluminum alloy grade.

- System optimization: The core lies in optimizing mold design, process parameters and supporting material systems to ensure maximum part performance.

- Transparent quotation: You will get a clear and detailed project quotation.

Take action now: Please upload your design drawings!

We combine professional material knowledge and mature low-pressure casting technology to give you a reliable manufacturing plan and a realistic quotation to help you make good parts.

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsrpm.com

Resource