Why do we pursue calmness when casting? Imagine what would happen if liquid metal was poured roughly into a complex mold? Bubble, turbulence and various problems will arise, which are common problems for many peopleOld-style casting method(e.g. gravity casting).

But change your mind: let the metal liquid slowly fill every corner of the mold from the bottom like spring. This is the charm of low-pressure casting, which pursues high-quality art.

In our workshop,Low pressure castingIt is a good helper in the manufacture of precision aluminum parts. In short, it uses low pressure control to stably push liquid aluminum (such as common aluminum alloys) into the mold cavity, allowing it to fill every detail before solidification and formation. This gentle push method can produce tighter internal structures, thinner surface effects and fewer defects than direct casting.

Because it can be produced stablyHigh-quality complex parts, it is especially suitable for high demand products such as automotive wheels. Industry data also show that low-pressure and gravity casting accounts for the majority of global aluminum castings (about 67%), while automotive fields account for more than half of demand. Electric vehicles are now working to lose weight. Tesla-type Y-chassis assembly uses this process, which is 18% lighter. Choosing the right method will make the product differently.

Core Answer Summary:

| feature | Low-Diet Casting (LPDC) | High Pressure Mold Casting (HPDC) | Gravity casting |

| Filling method | Resistant to gravity, bottom-up, smooth filling. | High speed and high pressure injection for quick filling. | Rely on gravity to fill from top to bottom. |

| pressure | Low pressure (0.02-0.15 MPa). | Extremely high pressure (30-200+MPA). | Only the static pressure of liquid metal. |

| Casting quality | Extremely high, dense tissue with few pores. | Very good, but may have air pockets and pores. | Medium, with possible shrinkage and porosity. |

| Typical applications | Car wheels, engine cylinder heads and complex shells. | Thin walled mass-produced parts (such as laptop sleeves). | Thicker fences, simple components, such as valve bodies. |

This guide will make you the core of low-pressure casting:

- We will clearly introduce the complete low pressure casting process.

- Explain how it injects metal through gravity resistance to avoid air entrainment.

- We will then compare the key advantages and disadvantages of low-pressure casting and high-pressure casting to help you understand their respective application solutions.

- Finally, through real production cases, we will explain why low-pressure casting is particularly suitable for high-end aluminum alloy products.

Why Believe This Guide? Insights From JS Senior Actor Lab

At JS, we handle low-pressure casting machines all day long. After a long time, we learned that this technology is not only about pressing a button, but also about taming pressure.

Different aluminum alloy parts have different thicknesses, and the required air pressure rhythm (pressure curve) must be as delicate as a tuned instrument. How long does the riser last, and how to make a coating to cool less aluminum water? These details are our experience of repeated trial and error and optimization. For us, the low-pressure casting process is not a dead rule.But crafts that can be adjusted flexiblyto ensure solids are cast from the inside out.

Previously, the customer's car-oriented knuckle had key safety components, which always contracted in the central position and could not pass the fatigue test. They found that we solved the problem. We studied the parametersLow pressure casting timeAnd adjust it immediately.

Guess the result? The problem was solved and the parts passed the most rigorous tests steadily. This process makes us more convinced that the root of perfect casting lies in controlling these process details.

“In the casting industry, there is an old saying that I think this is particularly reasonable: 90% of the mass of casting depends on the way the molten metal enters the cavity.”

Isn't this the smooth filling we are pursuing? This guide summarizes the key experience our team has learned over the years and hopes to help you go more smoothly on the road to high-quality casting.

Core Principle: What Is Anti-Recasting?

In short, low-pressure casting is a metal formation technique that abandons the traditional way of pouring molten metal and instead uses the idea of pushing, such as gently squeezing the liquid to make it flow upwards. This is actuallyAnti-gravity low-pressure casting, it uses low pressure to achieve metal filling from the bottom instead of relying on gravity to freely fall to complete the filling process. Now, let me explain it clearly to you.

What is low-pressure casting?

Low-pressure casting is a method we useSealing furnace to hold molten metal(e.g., aluminum alloy), then apply a small pressure to allow the metal to run smoothly from the mold base instead of pouring it on top. Low pressure casting avoids splashing and oxidation of metals and can provide more dense parts.We like to use it extensively on JS's automatic or precision partsBecause it works and there are no risks involved.

How anti-gravity casting works (three simple steps):

- Sealed Insulation Furnace: We place molten liquid aluminum alloy into a fully sealed insulating furnace. The stove is not opened, sealed and placed under the mold we are going to use.

- Special lifter: At the bottom of this closed jar, a tube (Stand tubes, usually ceramic or special metal) rises, which is heat resistant. It resembles a super strong straw that rises directly and carefully inserts into the bottom door of the mold above our heads.

- Low Pressure Air: We started slowly introducing some compressed air (sometimes also nitrogen, such as nitrogen, to prevent aluminum from oxidizing) into the vacuum insulating furnace. Note that this pressure is actually small, only about 0.07 MPa higher than the air pressure we usually breathe, which feels like inflating the balloon over a little bit of pressure.

How to do peaceful filling?

The secret is revealed! By introducing air into the sealed furnace, the pressure in the furnace due to the air is only slightly higher than that outside, which results in a smaller positive pressure gradient (ΔP). This additional air pressure is only slightly imposed on the liquid aluminum alloy surface inside the furnace. Aluminum metal faces stable upward pressure, onlyGo to the top along the bottom of the riser. Until the mold cavity is completely filled.

What are the biggest benefits of doing this?

- It avoids the big trouble caused by traditional "high dumping"! Molten metal falls from a high place and easily absorbs air to form bubbles. More importantly, liquid aluminum will oxidize rapidly and produce impurities upon exposure to air.

- However, our low-pressure castings push up steadily from the bottom, with little turbulence and liquid aluminum has little contact with air. thisReduce pores and slagInclusions in castings. For us, it is crucial for us to make parts that require high strength, high seals and a perfect appearance.

As an engineer at JS, you must successfully apply low-pressure casting.I will pay attention to two basics:Sealing of the fixing furnace and riser system, as well as control of the magnitude and rhythm of air pressure. This is the core that ensures the liquid aluminum liquid rises smoothly and fills perfectly.

"We JS pursue high density and low defect factory standards. Want to see how aluminum liquid in liquid aluminum rises? Welcome to join our seminar at any time, or please provide me with a process parameter manual so that we can make more perfect castings together!"

Step By Step: The Complete Process of Low Pressure Casting

Today, I will dismantle a complete processProduction of aluminum low-pressure castings. Our low pressure casting process is made by carefully designed steps to ensure molten metal enters and fills the mold in optimal condition.

“As internationally renowned actor expert Professor Diran Apelian emphasized: the mass of the cast is determined the moment the metal contacts the mold.”

The complete process of low-pressure casting:

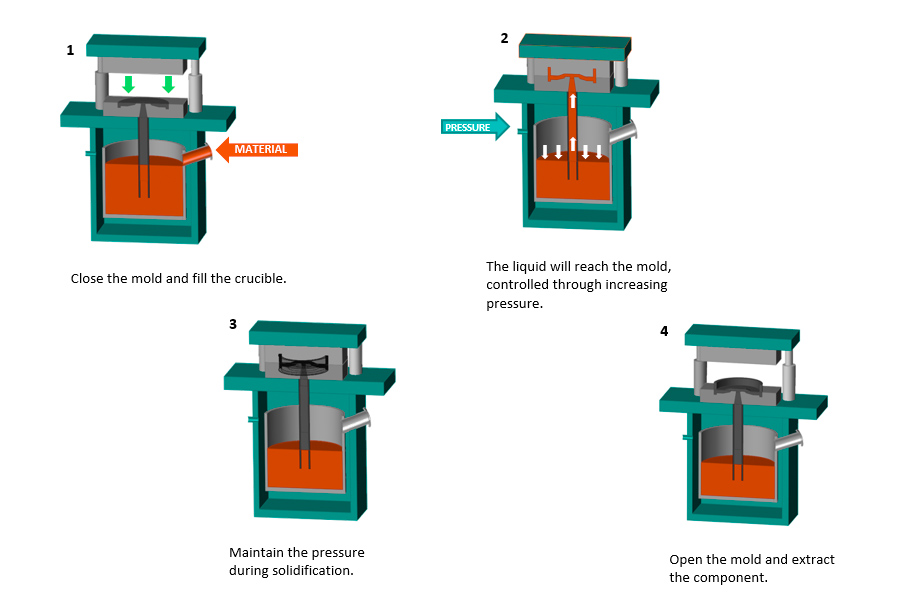

Step 1: Mold Close and Preparation

We close and lock the upper half of the preheated and mold-released coating of the steel mold.

Key Step: Ensure that the top of the riser extending from the lower insulating furnace is accurately opposedThe reserved doorAt the bottom of the mold. The accuracy of this connection is directly related to whether the aluminum liquid can rise smoothly in the future.

Step 2: Pressure and Fill

Lock and close the cover of the insulating furnace with molten aluminum alloy, and no air leakage is allowed.

The control system starts working: it can be filled with low pressure gas accurately and continuously (usually dry air or inert gas is applied).

The furnace pressure continues to rise. The soft but continuous pressure keeps the furnace's aluminum level level level.

Molten aluminum can only flow from the bottom to the top through the only riser into every corner of the mold. The mold air is raised by molten aluminum and passedReserved exhaust passage. The whole process is about the pursuit of "stability".

Step 3: Maintain pressure and cure

Does aluminum liquid just occupy the mold? Don’t worry, now is the most critical moment! Now, the pressure in the furnace should not be released immediately, but should remain for a while.

Why is this the soul? Because when aluminum liquid changes from liquid to solid, the volume shrinks! If you are not careful at the moment, it is very easy to have a cavity or looseness in the casting.

Pressure maintenance isApply pressure in the furnaceStill forcing a little liquid aluminum from the riser to fill the solidified space. This is the main secret to creating aluminum low-pressure castings, we generate dense internally without shrinking cavity and shrinkage!

Step 4: Pressure Reduction and Mold Opening

Once the cast body (especially the door connection) becomes solid, the control system will automatically release the pressure in the furnace in a safe manner.

Once the pressure is removed, liquid aluminum that has not been frozen in the riser will automatically return to the insulating furnace below with ultra-high utilization!

Finally, the mold is opened, our robot arms are neatly moved to pull out the mold cast, and thenThe cycle is completed.

At the heart of the LPDC process lies in precise control: Through four key steps of mold preparation, pressurized filling, pressure-keeping curing and pressure-relieving mold openings, we produce high-quality low pressure castings with dense structures.

When JS completes the project, the priority action is to introduce intelligent monitoring systems, deploy sensors at critical nodes to adjust pressure and temperature in real time, and simultaneously optimize mold design. The goal is to increase the overall yield by more than 15%. This improves our response to market demand. ”

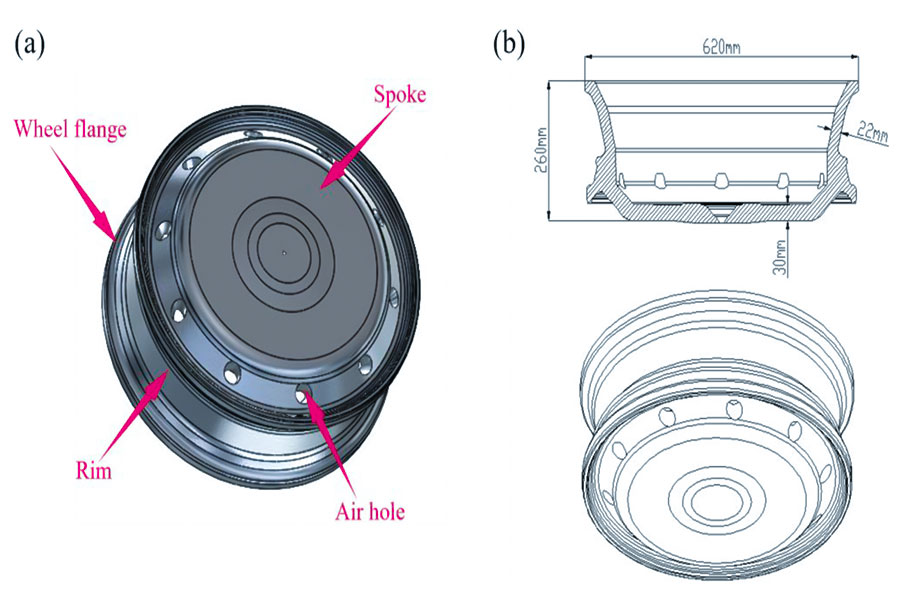

Practical Case Analysis: Lightweight and High-Strength Aluminum Alloy Wheels For High-End Electric Vehicles

Let me share with you a real project we did recently and discuss how to use aluminum alloy low pressure casting to help customers solve problems. For electric cars, endurance and control are at the core. The wheels look pretty, but they actually affect unreserved weight and safety. This time, our JS company is the most skilledLow-pressure casting technologyThis project really comes in handy.

Customer Challenge: Complex Design, Strict Standards

A new oneHigh-end electric carsBrand developed a 21-inch wheel with the following features:

- Intricate design: It has long and uniquely shaped spokes.

- High surface requirements: It needs to achieve mirror polishing effect.

- High safety level: It must pass the most stringent impact and fatigue tests.

The production bottlenecks they encounter:

- Inadequate gravity casting: The flow rate of aluminum liquid is slow and has low momentum, making it difficult to completely fill the corners of thin spokes. The thick portion of the rim cools slowly, making it easy to create a cavity inside. Not strong enough, it won't pass the test, andFailed to meet the surface qualityMirror requirements.

- High pressure mold castings are limited: although it can fill in complex details, the high-speed filling process will involve gases and form internal pores. During heat treatment, the expansion of pores can cause surface expansion. This internal defect is a fatal injury to safety components and cannot meet the strength and toughness requirements at all.

JS's solution: low-pressure casting, stable victory

We carefully analyzed the pain points of our customers andThe core is two: the appearance must be flawless, and the internal structure must be 100% reliable.This is the strength of low pressure casting.

Our steps:

- Smooth filling, perfect reproduction: the key is stability. We let the molten aluminum alloy lift from the bottom of the mold and gently fill every corner like breathing. Those complex thin spokes can also be fully filled!Very smooth surface, laying a good foundation for mirror polishing.

- Eliminate continuous pressure in the cavity: Filling is just the beginning, the key is the curing process. We precisely control the pressure and continuously push more liquid metal to supplement it as the aluminum liquid cools and shrinks. Especially in the thick walled areas of the rim, we ensure that the interior is dense and without shrinkage, which is a critical step in ensuring strength.

- High purity, guaranteed performance: throughout the process, the aluminum liquid in the enclosed system flows, has little contact with the air, has little oxidation impurities, and the casting itself is very pure. After heat treatment, strength and toughness can reach the highest level. We finally delivered such high qualityAluminum alloy low-pressure castings.

Results: Amazing customers, exceeding standards

After sample delivery, customer feedback exceeded expectations:

- Top Appearance: Design details are fully presented, the surface surface is very high, and the mirror polished effect is perfect.

- Internal Excellence: X-ray defect detection shows that internal tissue is denser than they expected and that defects are hardly found.

- Data as evidence: The real benefits

| index | Achievement | Comparative reference |

| Weight loss | It is about 12% lighter than the gravity casting wheel of the same size. | The industry average weight loss range is 8-15% (American Metal Society AMS). |

| First pass rate | > 98% | The industry average qualification rate is 85% (German Institute of Engineers VDI). |

| Fatigue/Impact Test | 100% passed stringent standards. | Exceed industry standards (Japan Society of Materials Science JIS Standard). |

Safety: The most stringent radial fatigue, bending fatigue and impact tests have passed steadily, and the safety performance has reached 100% of the standard.

“Aluminum alloy low-pressure casting is the best solution when the final appearance, highest internal quality and absolute safety are essential. It brings high density, high purity and high yields, while it is difficult to meet other processes. At JS, we are not only in JS, we can find reliable technology and strict standards not only in your parts, but also in your spirit.JS TeamTogether we will overcome difficulties! ”

FAQ - Answer More Questions About Low Pressure Casting

Question 1: What are the main differences between low-pressure castings and high-pressure mold castings?

High-Diet Casting:

It relies on a huge force to quickly inject molten metal into the mold and inject it into the mold with rapid and powerful pressure. It is suitable for thin-walled, less complex shapes and large-scale parts such as shell parts. But it's in a hurry, which can easily roll gas into the metal and create pores.

Low-pressure casting:

It is relatively gentle and relies on a small amount of pressure from the fuel tank under the mold (above the atmospheric pressure) to steadily push the molten metal upward, allowing it to slowly fill the mold cavity. In this way, the manufactured parts are denser and have higher quality, especially suitable for those with thicker walls, complex structures or high internal quality requirements, such as automotive wheels and engine cylinder parts. However, the entire cycle process is relatively slow and the efficiency is not as high as that of high-pressure mold casting.

Question 2: What are the main advantages and disadvantages of low-voltage castings?

advantage:

- Low-pressure castings make parts stronger, denser inside, with fewer bubbles and holes, thus ensuring overall strength and service life.

- It is particularly material savings, with less waste of aluminum water and can be used up to over 90%, which is very beneficial for controlling costs. This process is stable and controllable, and it is especially easy to use an automatic production line. In the process of large-scale production, quality and efficiency are better managed.

shortcoming:

- Its production speed is indeed not as fast as high pressure mold casting.

- In addition, its equipment and molds are much more complex than gravity casting, so the initial investment cost will be higher.

- Furthermore, we don't usually use it to make small parts with particularly simple structures because it is not cost-effective.

Question 3: What is the LPDC process?

Let me briefly tell you what LPDC is, and this is what we often call low pressure casting:

LPDC is a casting method that uses low pressure gas to fill molten metal from the bottom to the top with mold. It is not as violent as high pressure, so the parts made have good internal quality and high material utilization. This is our preferred process for making many important aluminum castings. This principle is not complicated, but it is very smart and practical.

Summary

Low pressure casting is indeed not a common choice for all parts. However, if you are looking for aluminum alloy parts with high strength, high reliability and excellent appearance,This is usually a very ideal solution. Compared with traditional casting, low-pressure casting can solve some inherent problems more accurately and stably, especially in the manufacture of high-performance aluminum alloy castings.

Your project is also a headache:

- Want to form a complex structure?

- Want it to be both bright and strong?

- Still working on which process is most suitable and most cost-effective?

Let us help you find the answer:As a professionalAluminum low pressure casting factories, the JS team faces these challenges every day. Let's provide you with a free process evaluation instead of guessing which process is the best. We can clearly answer:

- Is your part suitable for low-pressure casting?

- Provides transparent and detailedAluminum low pressure casting market.

It’s easy to take action: Upload your design files now!

Let JS transform the idea of complex aluminum alloy parts into high-quality reality using advanced low pressure casting technology.

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsrpm.com

resource