Why do some metals crack when welded, while others bond well? Why is aluminum alloy always more difficult to weld than ordinary steel? The key lies in the material itself.Weldingis essentially a process that uses heat or pressure to bond two pieces of metal together strongly. It is a very significant process in the manufacturing, construction, and repair sectors. Yet the key to successful welding lies in the choice of materials. Not all metals are readily weldable, and each material seems to require a particular process.

There are actually three significant materials beneath the welding gun:base material, filler material (welding wire/electrode), and shielding gas. The performance can be severely compromised if any one is chosen incorrectly. The strength of the final product, as well as its corrosion resistance, are all aided by the material and weld quality.

There are many metals that can be welded on the market: steel, aluminum, copper, titanium, nickel alloys and their alloys are very common. Faced with a multitude of materials, do not panic. The idea is to figure out what your project will need and whichwelding processyou will utilize. If you combine them appropriately, the entire processing process will naturally go well.

Next, let's talk about the most commonly used and most reliable metal materials in welding. Understanding their characteristics is the first step to welding a joint that can stand the test of time.

Core Answer Summary:

| Material category | Central role | Common examples |

| Base Metal | The main body being welded determines the basis of the welding process. | Carbon steel, stainless steel, aluminum alloy. |

| Filler Metal | After melting, fill the weld seam and connect the base material, and its composition is crucial. | Wire, Rod. |

| Shielding materials | Isolate the air to prevent oxidation and contamination of the weld seam. | Argon, carbon dioxide, solder flux. |

This article will answer your questions:

- In this guide, we will focus on the three core materials in welding: base metal, filler material (like welding rods and wires), and shielding gas.

- Then we will talk specifically about which metals are most commonly used in welding (such as steel and aluminum).

- And what exactly are the welding rods themselves made of.

- Through a real case, stainless steel welding caused serious corrosion due to the wrong welding wire selection, you will see how critical material matching is.

- Finally, we will sort out a practical material selection reference list for you to help you avoid common pitfalls and answer key questions.

Why Trust This Guide? JS's Material Science Perspective

At JS, our daily work is to deal with various metals and solve practicalwelding problems.For example, when welding 304 stainless steel, you must use a specific grade of welding wire (such as ER308L) to achieve the best corrosion resistance.For welding the commonly used 6061 aluminum alloy, choose ER4043 or ER5356 welding wire, and then use pure argon protection to avoid pores and cracks.

These are not theories from books, but experiences that have been repeatedly verified under our welding torches.

This guide embodies the deep understanding accumulated by our engineers in countless project sites. We have seen too many troubles caused bythe wrong material selection: cracked welds, corrosion resistance, and even the scrapping of the entire workpiece. Similarly, we have also witnessed time and again how the right material selection can achieve a solid and reliable product. What you see here is these core experiences from the welding site.

"As William Irrgang, former president of the American Welding Society, said: Welding without understanding the material is like walking on a tightrope with your eyes blindfolded."

A deep understanding of the characteristics of materials is the cornerstone of welding reliability. We share this knowledge from practice in the hope that it will help you to walk more steadily and efficiently in yourwelding projectsand avoid unnecessary detours and losses. This is not a sales pitch, but an experience transfer from us as welding practitioners.

The Protagonist Appears: Weldable Base Metals

Want to weld two pieces of metal into one? Not all metals are so compatible. Their "weldability" mainlydepends on three points: chemical composition, thermal conductivity, and degree of thermal expansion and contraction.

Carbon Steel: The well-deserved "main force"

- Features and applications: The most widely used material in the welding industry is carbon steel, especially low-carbon steel such as Q235 and A36. It has excellent weldability, is not picky about welding methods (hand arc welding, gas shielded welding, etc.), and has low cost. It is the first choice for large equipment such as building frames, pipeline systems, andmechanical equipmentbases.

- Expert reminder:But! Once the carbon content goes up (medium carbon steel, high carbon steel), the difficulty of welding rises sharply, and it is particularly easy to crack. To weld this type of steel, we usually have to preheat the workpiece first, and may need to do heat treatment after welding, and the process requirements are much stricter.

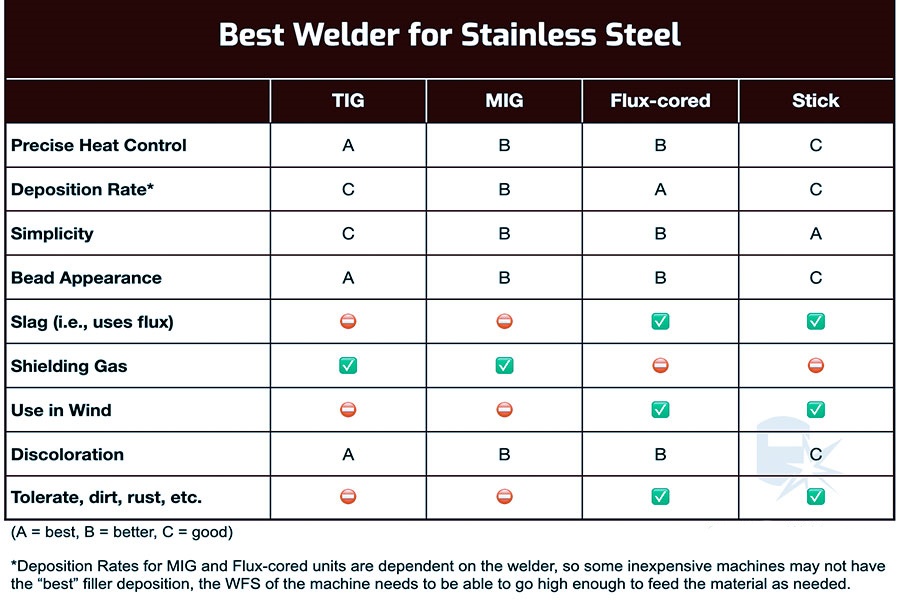

Stainless Steel: Excellent performance

- Features: Austenitic stainless steels such as common 304 and 316 are first-class in corrosion resistance and beautiful in appearance. They are suitable for food equipment, chemical pipelines, or places that need to look good.

- Welding challenges: This material has slow heat dissipation and is easy to expand when heated. As a result, heat is easily accumulated in theweld area, and thin plates can be burned through accidentally, and the deformation after welding may be very serious. Therefore,when welding stainless steel, controlling the heat input is the top priority, and the technique and parameters must be refined.

Aluminum Alloys: Lightweight "High-Difficulty Player"

- Features: It is extremely light in weight, but not low in strength. It can be seen in airplanes, cars, mobile phone and computer cases. It is the pursuit of lightweight.

Welding Challenges:

- Stubborn oxide film: When aluminum is exposed to the air, a layer of aluminum oxide film (Al₂O₃) is instantly formed on the surface. The melting point of this film is as high as 2072°C, while aluminum itself melts at 660°C! If this film is not thoroughly cleaned before welding, the parent material will not melt together. This is why alternating current (AC) is often used in aluminum welding (especiallyTIG welding), because it can effectively break this film.

- Heat dissipation too fast: Aluminum conducts heat very quickly, and the heat dissipates too quickly. To melt it and form a molten pool, the heat required is much greater than that of welding steel.

- Easy to produce pores: Liquid aluminum is like a sponge and is particularly easy to absorb hydrogen. As it solidifies and cools, hydrogen has no place to go and pores form in the weld. Therefore, the purity of theprotective gasand the cleanliness of the workpiece are the top priorities for preventing pores!

The aluminum alloy welding challenges I encountered at JS Company are mainly the two problems of oxidation and heat dissipation:

| Challenge factors | Scoring the impact of welding difficulty (1-10 points) | Main impact areas | Common solutions | Data sources |

| Surface oxide film | 9 | Difficulty in fusion and risk of inclusion. | Strict cleaning, mechanical/chemical treatment, communication TIG. | AWS D1.2 |

| High thermal conductivity | 8 | Difficult to melt through, requiring high input. | Higher current/voltage, preheating (limited). | IIW Doc. IX |

| Hydrogen induced pore sensitivity | 7 | Weld porosity and weakened strength. | High purity protective gas, ultra clean workpieces, controlled environment. | ISO 9692-3 |

Note: The rating is based on the consensus assessment report on aluminum alloy welding by the International Institute of Welding (IIW) and the American Welding Society (AWS). AWS D1.2, IIW Doc. IX, ISO 9692-3 are relevant standards.

Understanding the material is the foundation for good welding. Carbon steel requires good welding of large quantities, stainless steel requires fine heat control to prevent deformation and burn-through, andaluminum alloysneed to overcome the three major difficulties of oxide film, heat demand and hydrogen pores.

"JS knows the material properties and welding locations very well. Whether your project pursues strength, corrosion resistance, lightweight or cost-effectiveness, choosing the right parent material and welding it well is the core of success. Have you prepared your list of materials? We are always available to provide professional advice."

The Soul Role: The Selection of Filler Metals

Now, let's talk about anotherkey role in welding, filler metal (welding wire, welding rod). You can think of it as a "bridge" material connecting two pieces of parent metal. Its selection directly affects the strength, toughness and life of the weld. Only by choosing the rightfiller metalcan the performance of the weld be guaranteed.

Core principle: matching and exceeding

The first rule of thumb for selecting filler metal is to match the base metal. Its chemical composition, strength, ductility, etc. must match the base metal you are welding.

"According to "Welding Principles and Applications": The success of a weld ultimately depends on its weakest link."

Therefore, quite frequently we will deliberately choose filler metals a little bit higher than the base metal. Why? So that we can ensure that the weld is the most and strongest section of the entire assembly.

Typical filler metal inventory

Steel welding:

- ER70S-6 (MAG/MIG wire): Most versatile "jack of all trades" welding wire for welding low-carbon steel. Silicon and manganese are alloyed to it, which can make the weld smoother and smoother and reduce welding defects.

- E6013 (manual rod): Very versatile manual rod that is simple to handle with a stable arc. Can be used in allwelding positions(horizontal, horizontal, vertical, and vertical) and has a low entry point.

Stainless steel welding:

- ER308L: Used solely to weld the most common 304 stainless steel. "L" refers to low carbon, which is highly important and can effectively be used to resist corrosion in the area surrounding the weld after welding.

- ER316L: Weld it when butting 316 stainless steel that contains molybdenum.It also contains molybdenum, providing improved resistance tochlorides corrosion, and is suitable for coastal exposure or chemical processing equipment.

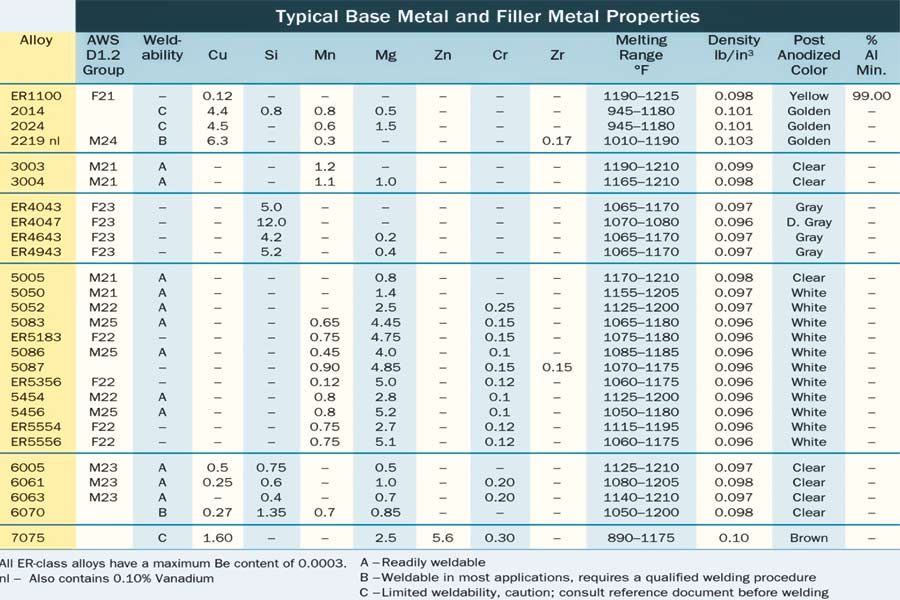

Welding aluminum alloy:

- ER4043: Silicon (Si)-containing aluminum welding wire, most widely used. The weld pool has excellent fluidity, the weld color is good, and heat cracks are difficult to create.

- ER5356: Magnesium-bearing aluminium welding wire. Generalized strength and weld toughness are generally higher than ER4043. Another benefit is that in the event that the workpiece will be anodized, the colour of the weld welded together with it is closer to the base metal and appearance is more pleasing.

In filler metal selection, being alike to the base material is the foundation, and proper "high configuration" is more reliable. Familiarity with the characteristics and applicable scenarios of main models such as ER70S-6, ER308L, and ER4043 is the key to weldinghigh-quality welds.

"At JS, we are well aware of the characteristics of each welding wire or electrode. Don't get entangled in material selection, tell us your base material and working conditions, and we will help you accurately match the best filling solution."

Behind-The-Scenes Hero: Shielding Materials

Having worked several years as a welder, I can say one thing: no matter how good the base metal and wire are, it is difficult to make an excellent weld without a good "protection umbrella".They are the behind-the-scenes heroes of welding,nameless but indispensable. Today we are going to talk about these two behind-the-scenes heroes:

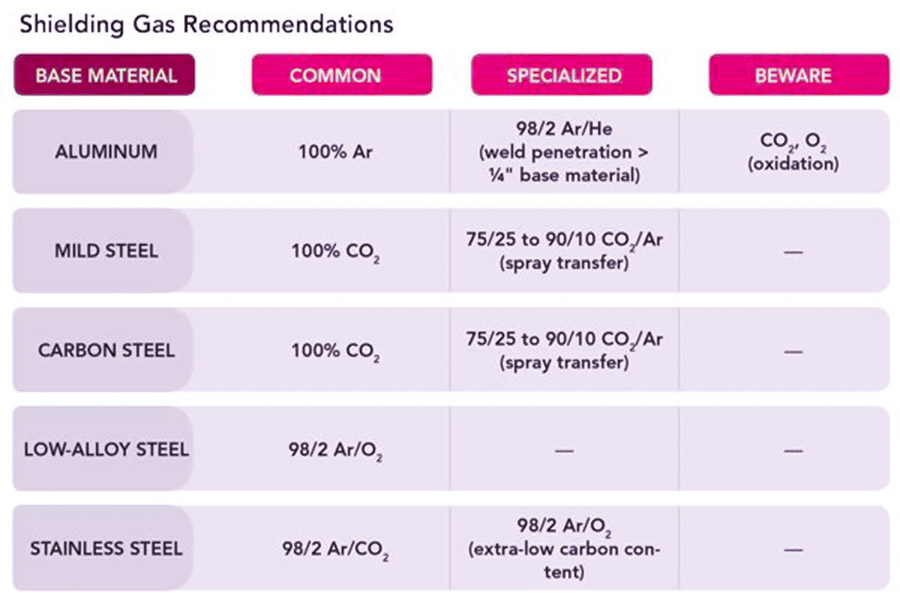

Shielding Gases - The crucial ingredient of TIG & MIG

(1) Pure argon (Argon, Ar):

It is my golden mate for stainless steel, aluminum, titanium and other metals.

What makes pure argon my golden mate?

It is aninert gasthat doesn't participate in any chemical reaction at high temperature, providing a very clean protective environment for molten pool, virtually excluding oxidation and nitridation.

(2) Carbon dioxide (CO₂):

It is not cheap, but arc stability is poor if it is used alone, and high welding spatter is readily formed. Therefore, it is usually not used alone.

(3) Argon/carbon dioxide blend (Ar/CO₂ Mix):

- It is the most commonly used process for joining plain carbon steel (MIG welding), with the typical 75% argon and 25% carbon dioxide. Higher argon concentration significantly improves the stability of the arc and reduces spatter.

- CO₂ serves the purpose ofincreasing arcand molten pool penetration heat, resulting in greater weld penetration at a relatively cheap price.

Comparison of shielding gas characteristics:

| Gas Type | Skilled in welding materials | Splashing degree | Arc stability | Relative cost |

| 100% argon gas (Ar) | Stainless steel, aluminum, titanium. | ★☆☆☆☆☆ (very low) | ★★★★★ (Extremely stable) | ★★★☆☆ (higher) |

| 100% CO₂ | Carbon steel (specific case). | ★★★★★☆ (very high) | ★★☆☆☆☆ (unstable) | ★☆☆☆☆☆ (minimum) |

| 75% Ar / 25% CO₂ | Carbon steel (mainstream choice). | ★★☆☆☆☆ (Medium) | ★★★★★☆ (very stable) | ★★☆☆☆☆ (Medium) |

Data source: AWS public data compilation of the American Welding Society.

Flux: The soul of welding rods and submerged arc welding

The coating on the outside of the welding rod, or the particles sprinkled bysubmerged arc welding(all called flux), will melt and react under the high temperature of the arc, playing three core roles:

- Producing shielding gas: It disintegrates upon heating, and the formed gas isolates air covering the molten pool in an attempt to bar oxygen and nitrogen from interfering.

- Forming slag layer: It melts to create a liquid shell layer known as "slag" and covers the still hot weld.This shell is to isolate the air, and secondly, it allows the weld to cool down slowly, making it less likely to crack, and improves the weld formation and surface finish.

- Adjusting metal: Some advanced fluxes contain alloying elements or deoxidizers, which are mixed into the weld metal when melted, which can improve the strength and toughness of the weld.

"Choosing the right shielding gas and flux isn't a laughing matter, and it has a direct impact on the quality, efficiency and even cost of the weld. Don't just focus on the base material and welding wire. Use these protective materials correctly so that the welded workpiece can stand the test. Want to find the most suitable "protective umbrella" for your welding process? Feel free to talk to our JS, and we will produce the parts perfectly together!"

Actual Combat Case Analysis: "Catastrophic" Corrosion of 316L Stainless Steel Pipes

Next, I will share with you a costly lesson I personally experienced, a real case of "catastrophic" corrosion caused by the wrong material selection for 316L stainless steelpipe welding. This is a living proof that when welding, the consequences of choosing similar materials may be far beyond imagination.

Customer Challenge: Rapid Rusting of New Pipelines in Chemical Plants

Project Background:A chemical plant built a new key pipeline, and the medium it transported contained chlorides. The design specified the use of 316L stainless steel because of its excellent resistance to chloride corrosion (especially pitting corrosion).

Problem:When the construction team was welding, they had the commonly used ER308L welding wire (usually used for welding 304 stainless steel) on hand. They thought that since they were all stainless steel, they should be similar, so they directly used it to weld the entire pipeline.

Disaster:Less than three months after the pipeline was put into use, serious rust and pitting appeared in the weld area, which completely failed to meet the design life requirements, and the system was at risk of leakage!

JS failure analysis: Finding the "real culprit"

After receiving the request for help, we immediately conducted an in-depth analysis of the failed weld, especially the material composition analysis (PMI test). The results are very clear:

Where did the molybdenum (Mo) go?

- The "trump card" of 316L stainless steel for chloride corrosion resistance is the 2-3% molybdenum (Mo) element it contains. However, the test found that there was almost no molybdenum in theweld metal!

- The reason is simple: the ER308L welding wire used by the construction party does not contain molybdenum. The weld lost the key armor to resist chloride corrosion.

- The "battery effect" accelerates destruction: What's worse, the weld (with a composition close to 304 stainless steel) and the base material (316L stainless steel) form electrochemical corrosion in the corrosive medium. Like a tiny battery, the weld lacking molybdenum (similar to the anode) is sacrificed and the corrosion rate is accelerated. The molybdenum-rich base material (similar to the cathode) is protected.This combination leads to rapid and catastrophic failure in the weld area.

Key data comparison: chemical composition of base material, wrong welding material and correct welding material:

| Material type | Cr (%) | Ni (%) | Mo (%) | C (max, %) | Standards |

| 316L base material | 17-20 | 10-14 | 2.0-3.0 | 0.030 | ASTM A240/A240M |

| ER308L welding wire | 18-21 | 9-11 | 0 | 0.030 | AWS A5.9 ER308L |

| ER316L welding wire | 18-20 | 11-14 | 2.0-3.0 | 0.030 | AWS A5.9 ER316L |

Note: ER308L welding wire does not contain molybdenum (Mo) at all, while ER316L welding wire completely matches the molybdenum content of 316L base material.

JS's solution: Correct mistakes and rebuild the defense line

(1) Thoroughly eliminate hidden dangers:

All weld areas where the wrong ER308Lwelding wirewas used must be removed.

(2) Accurately match materials:

It is mandatory to use ER316L welding wire for re-welding. ER316L welding wire contains sufficient molybdenum (Mo) to ensure that the corrosion resistance of the welded joint completely matches the 316L base material, forming a complete corrosion resistance system.

(3) Strictly control quality checkpoints:

- Welding materials must be inspected before entering the warehouse: All welding materials must be inspected for material certification and component sampling before entering the warehouse.

- Post-welding sampling: Post-weld non-destructive testing (such as PT/RT) and component sampling (PMI) are performed on key welds to ensure that there is no risk.

Results and reflections: Small price, big loss

- Final results: The pipeline system rebuilt according to the correct plan has long-term stable operation in chloride-containing media, excellent corrosion resistance, and fully meets the design life requirements. The customer is very satisfied.

- Painful lesson: The direct economic loss of this accident is millions of rework costs and serious production delays. And the starting point of all this is simply because of the selection of welding wires that "look similar" but may only cost a few dollars per kilogram. This huge disparity deeply reveals the utmost importance of accuratematerial matchingduring welding.

Key revelation:

Which type of welding metal is used?

The answer is not just the welding wire itself, but a complete system that accurately matches the performance of the parent material. The core of professionalcustomized welding manufacturinglies in a deep understanding of material science to ensure that every choice from parent material to welding material is accurate. A wrong almost, the cost can be catastrophic.

"This case warns us that the selection of welding materials is not a trivial matter, especially when it comes to corrosive environments. Be sure to strictly match the chemical composition and performance requirements of the welding material and the parent material. JS has a professional materials and welding team that can provide you with accurate material selection suggestions and reliable welding solutions to ensure that your project has a solid foundation."

FAQ - Answer Your Material Selection Questions

Why can't you use steel welding rods to weld aluminum?

This is absolutely not possible!The reason is simple. The properties of steel and aluminum are too different. They have different melting points, different atomic arrangements, and different electrical conductivity.

If you force steel welding rods to weld aluminum, they will not only fail to fuse well at high temperatures, but will form a very brittle compound. As a result, the weld you get will be as fragile as a biscuit, which may break at the slightest touch and has no strength at all.

What is the smoke produced during welding? Is it harmful to the human body?

The smoke you see during welding is actually a mixture of steam, gas and very fine particles produced by the high temperature melting of metals and welding materials. For example, welding galvanized sheet will emit zinc smoke, and welding stainless steel will emit metal components such as chromium and nickel.

This smoke is absolutely harmful to the body!If you inhale it for a long time, it will seriously damage your respiratory system and even increase the risk of cancer. So don't be careless! No matter where you weld, ensure that the site is well ventilated, and be sure to wear a professional protective mask or respirator.

How to choose the right welding material for my project?

- First figure out what metal you are going to weld?This is the most fundamental. Is it ordinary steel, stainless steel, aluminum, or something else? Once the material type is determined, the general direction is determined.

- Then refer to the standard!Each commonly used metal has a corresponding recommended welding material model, such as the AWS (American Welding Society) standard. You need to find the official recommended model that matches your parent material.

- Evaluate where it will be used?Is it placed indoors, outdoors in the rain, in a high temperature environment, or has to withstand a lot of force? These usage conditions will directly affect which specific welding material you will eventually choose.

- Seek professional technical support: If there are complex working conditions or uncertainties, be sure to consult a welding engineer. Wrong material selection may cause weld failure, and we can provide material matching verification services.

Summary

The core of successful welding is theprecise matchingof materials.What are the characteristics of the base material you use, which welding wire and welding rod to choose to match, and even the ratio of shielding gas, each step directly affects the quality of the final weld. Truly understanding the interaction between materials is the key sign to distinguish professional manufacturing from amateur attempts.

Are you still worried about what material to weld? Don't let it become the shortcoming of your project!

At JS, we not only have skilled welders, but also a group of engineers who are proficient in material properties. In what environment will your workpiece be used? How much force does it need to withstand? Anti-corrosion or high temperature resistance? We will help you analyze your needs, accurately match the entire set of welding material solutions, and provide clear andtransparent quotes.

Contact us now!Let JS use the right materials to help you weld a good product that is both strong and durable.

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsrpm.com