Almost everything around us, from daily necessities to buildings and bridges, cannot be separated fromwelding. We have all seen the dazzling sparks when welders are working, but how does welding work? Does it just stick metals together? Not at all!

Welding is much more than that spark. In essence, it is a profoundmetallurgical processthat turns two separate pieces of metal into a new and complete whole at the atomic level. Simply put, it uses high temperature, high pressure, or both to fuse the contact parts of the metal together. When it cools down, it forms a very strong connection point (we call it a weld). Understanding this atomic-level reconstruction is the key to understanding all welding processes.

Therefore, welding is the skeleton of construction and manufacturing, especially steel structures. It can reliably connect cut metal parts into the shape and size we need. There are actually many methods, such as ultrasonic welding, which uses high-frequency vibration friction to generate heat to connect materials. Different applications, choosing the right welding method directly affects the final quality and efficiency.

Core Answer Summary:

| Core issues | Concise answer | Key technology |

| What is the essence of welding? | By heating, applying pressure, or a combination of both, the workpiece material can achieve interatomic bonding. | Metallurgy, Thermodynamics. |

| The most common welding method? | Arc Welding is the process of melting metal at high temperatures generated by an electric arc. | MIG, TIG, Stick. |

| What is the goal of welding? | Form a defect free weld with a strength not lower than (or even higher than) the base metal. | Process control, materials science. |

This article will answer your questions:

- In this guide, I will take you to the heart of welding. I will explore how metals really fuse together at the atomic level and understand its fundamental principles.

- Focus on the most popular arc welding and reveal the electrical and physical processes behind it.

- A real case will illustrate the serious consequences of choosing the wrong welding process.

- Finally, I will dismantle typical welding operations and answer the most confusing common questions.

Why Should You Trust This Guide? Real Records from JS's Welding Workshop

To be honest, welding is far more than just connecting two pieces of metal for us.It is more like the intersection of the entire project, and the key to success or failure is often here.

We think about how to use TIG welding every day to make 304 stainless steel welded with that kind of uniform and beautiful fish scale pattern. We also know how to usesubmerged arc weldingto efficiently penetrate thick structural steel. The welding service we provide, in the final analysis, is to promise that your things are strong, durable, and can be used.

The things in this guide are not copied from books, but the real experience I have gained in the workshop every day. We have welded everything from small welding spots smaller than rice grains in precision instruments to large steel frames supporting the entire structure in factories. We know the difference between book theory and actual operation on site.

"As Mr. Omer Blodgett, an authority in the welding industry, said: Excellent welding quality is rooted in precise control of details."

Therefore, every key point and every technique you read here is a reliable method that we have practiced and verified repeatedly. We share these to help you ensure that every weld is firm, reliable and safe. Because this is not only about product quality, but also the responsibility ofour engineersand welders.

The Microscopic World of Welding: When Metal Atoms "Hand in Hand"

As a welding engineer at JS, I want to talk to you about the wonderful changes that happen inside the metal during welding, just like watching a documentary about the microscopic world. Let's zoom in, to a millionth of a millimeter, andobserve the key changes of metal atoms in welding.

Molten pool: The core area of metal fusion

Imagine that when the heat of thewelding gunis concentrated on the metal joint, it is like lighting a small ultra-high temperature furnace locally. This furnace is what we call the molten pool.

In this molten pool, the edges of the originally solid parent material (the two pieces of metal you want to weld) and the welding wire or welding rod (filler metal) we added are heated and melted into liquid metal.

The most critical moment has come:The atoms from the parent material and the filler metal completely break their original lattice structures in this liquid "melting pot", fully diffuse and mix. They no longer belong to any single piece of metal, but are preparing to form a new connection.

Cooling and crystallization: Building a new metal structure

When the welding gun is removed, the heat begins to dissipate, and the molten pool begins to cool and solidify.

The atoms that were still moving freely in the liquid just now begin to slow down as the temperature drops. They begin to look for the most stable arrangement and form new, tiny metal crystals.

You can completely understand this process as casting a brand new piece of metal at theweld position! This new piece of metal is the link between the two parent materials.

Why is this process so important?

Because it has a direct effect on the mechanical characteristics of the weld! Like strength, toughness, and if there are internal defects. In the event of too fast cooling or adverse conditions, there could be problems with the atomic structure, which can easily form flaws like pores and cracks.

Shielding gas and flux: Essential barriers to the molten pool

The chemical activity of molten metal at heat is very active and will easily react with the oxygen (O₂) and nitrogen (N₂) available in the air.

These will form oxides and nitrides, or trap the gas itself inside the metal to form pores. These will be stress areas in the weld, and they will seriously degrade the strength, toughness and corrosion resistance of the weld.

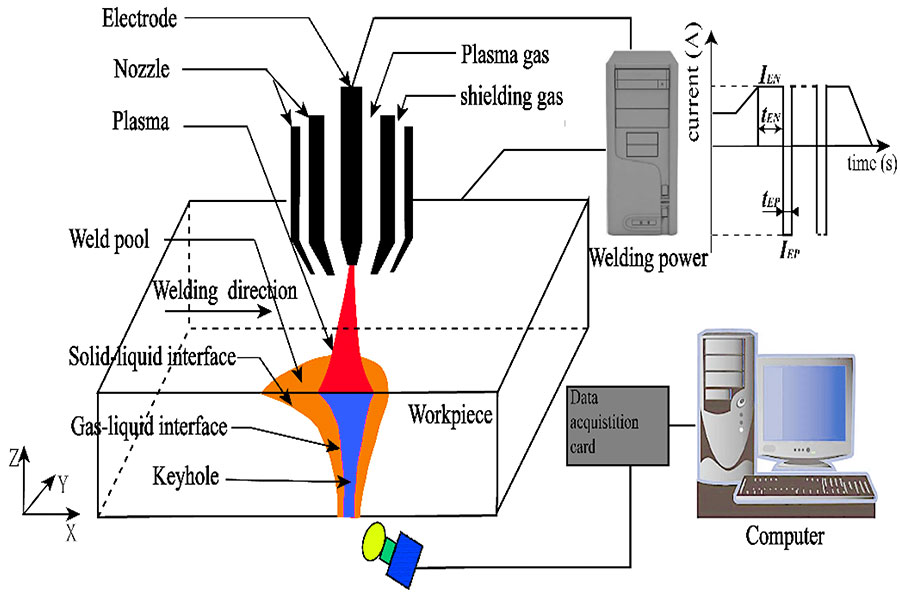

Isolation of air is the key:We have equipped "guardians" for all mainstreamwelding methods:

- Gas shielded welding (e.g. TIG, MIG/MAG):Use inert gas (e.g., argon Ar) or active mixed gas to generate a steady airflow barrier to separate the molten pool from surrounding air.

- Submerged arc welding:Use granular flux to protect the welding area. Upon melting, the flux will form a liquid slag layer and produce protective gas at the same time, which also provides insulation for the air and ensures the purity of the molten pool.

And now you can see, welding is far more than a matter of sticking two pieces of metal together. Under the microscope, it's an atomic recombination party. Understanding how the molten pool is created, solidification and crystallization principles, and the critical role of protective techniques are the basis on which we cancontrol the qualityof the weld.

"At JS, we focus on these details every day and transform theory into solid and reliable welds. If your project has strict requirements on structural strength and life, please talk to us and let us overcome the welding challenges together."

Mainstream Welding Process Analysis: The Power of the Arc

Today, I’m going to talk aboutarc welding, the cornerstone of modern manufacturing! If the principles of welding are similar, why are there so many different methods?The key lies in how they generate heat and protect the weld pool. Arc welding is the most widely used because it is efficient and reliable. Let me explain from the basics.

How does arc welding work?

- You can think of the welding machine as a highly controllable short-circuit tool. It creates an electrical circuit between the tip of the welding torch in my hand and the metal workpiece: the current is high, but the voltage is low.

- When the welding torch is close to the workpiece, the current jumps through the air to form a super bright arc. The arc temperature can soar to thousands of degrees and melt metal in an instant. In short, it uses the power of electricity to melt metal and form a strong weld.

Four Mainstream Arc Welding Processes

I will introduce thesefour common methods in points. Now let me talk about the characteristics of each process and how I use them in JS:

(1) MIG/MAG welding (GMAW):

- Core features: This method is fast and labor-saving. The welding gun can automatically and continuously feed metal welding wire as electrode andfiller metal, and at the same time spray shielding gas to cover the molten pool to prevent air from disturbing it.

- Advantages: Very fast speed, relatively easy to operate, especially suitable for mass production and long welds. The weld quality is stable and the spatter is relatively controllable.

- JS application scenario: For large-scale structural parts and frame welding in the workshop, or manufacturing tasks that require faster speed, we often choose MIG/MAG.

(2) TIG welding (GTAW):

- Core features: That is a case of precision and simplicity. It utilizes a tungsten alloy rod which will not melt as an electrode to form an arc. The molten pool is protected by an inert shielding gas (pure argon in most cases). The welder must hold the welding torch with one hand to control the arc, and manually add welding wire when needed with the other hand.

- Advantages: Welding is very spatter-free and clean. It can weld very thin metal and hard-to-weld metals.It is the best first choice in high welding quality requirement areas.

- JS application scenarios: If I need to weld thin plates, pressure pipes, components with high appearance requirements, or process stainless steel and aluminum alloys,TIG weldingis always my first choice. More techniques are required, but the result is worth it.

(3) Manual arc welding (SMAW / Stick welding):

- Key features: The master of flexibility and versatility. Use a surface-coated welding rod as an electrode. When the coating is burned off, it releases shielding gas and slag that shields the melted pool by encasing it.

- Advantages: The simplest and lightest equipment with the lowest environmental requirements is most versatile for outdoor, high altitude or maintenance sites. Practically all general structural steels can be welded.

- JS application sites: Flexibility of manual arc welding is priceless when on-site installation, equipment repair, or somewelding anglesare difficult to clean. It is almost a contingency plan for all locations.

(4) Submerged Arc Welding (SAW):

- Core Features: The "main equipment" for thick plate welding. The arc burns under the granular flux layer, and the arc light is completely invisible. The flux melts to form protective slag and gas.

- Advantages: Extremely deep penetration, fast welding speed, good and stable weld quality, almost no spatter and smoke. Especially suitable for automated welding of long straight welds or circular welds.

- JS application scenarios: When I face the task of welding thick steel plates (such as large storage tanks and heavy machinery bases),submerged arc welding is the key to improving efficiency and quality. Usually used in fixed stations orautomated equipment.

The key to choosing which arc welding process is to control heat and protect the molten pool in different ways. Understanding the principles and characteristics of these welding methods can help you choose the most suitable tools in the project.

"At JS, we flexibly use these processes according to project requirements. If you want to learn more about actual operations or applications, please feel free to communicate. Practice is the key to mastering welding technology."

Practical Case Analysis: The Tragedy and Rebirth of Welding of Pressure Vessels

I would like to share a practical case that I personally experienced. This project taught us a profound lesson: choosing the wrong welding process for pressure-bearing equipment is tantamount to burying a time bomb.

Customer challenge: Hydraulic oil tanks with frequent oil leaks

I met an engineering machinery manufacturer whose batch of customizedhydraulic oil tanksproduced in their own workshop had problems. The tanks were made of 4mm thick Q345 high-strength steel plates with a designed working pressure of 2MPa. In order to meet the deadline, their workshop used MIG welding throughout the process to weld all the seams.

The idea was very direct:MIG welding is fast and efficient. Unfortunately, the reality is not like this. During the pressure test, about 30% of the tanks had leakage near the welds, and some even cracked directly in the subsequent fatigue test.

JS's diagnosis: Find the root cause of failure

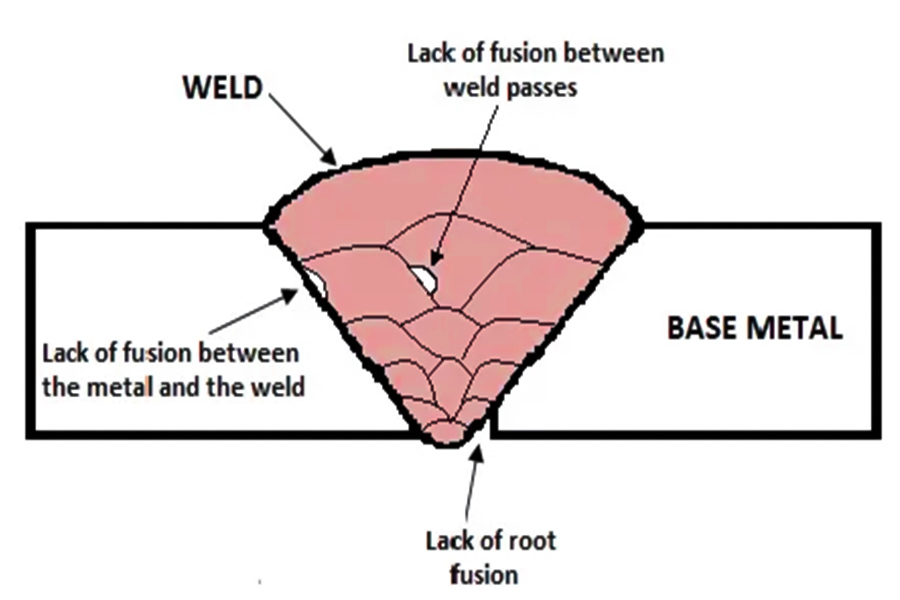

The customer came to us for analysis. We conducted a detailed inspection of the failed welds and found two major culprits:

- Incomplete penetration: The weld looks good on the surface, but at the critical root of the T-joint, the metal is not completely fused together! It's like there is only a thin layer of mortar between two bricks, and it is not compacted at all. Under a pressure of 2MPa, this weak point becomes a natural crack starting point, and all the stress is concentrated here.

- Porosity: In order to speed up, the operator moves the welding gun too fast, and theshielding gasdoes not cover the molten pool, allowing air to get in. As a result, many tiny pores are left in the weld, like honeycomb coal, greatly weakening the density and overall strength of the weld.

| Failure mode | Reason for occurrence (improper process) | Fatal impact on pressure bearing components |

| Lack of penetration | The MIG welding speed is too fast and the heat is insufficient. | The starting point of natural cracks is formed, and the stress is highly concentrated. |

| Porosity | Excessive welding speed leads to poor coverage of protective gas. | Reduce the density of the weld seam and significantly weaken its load-bearing capacity. |

Analysis basis: American Welding Society (AWS) D1.1 structural welding specification and failure analysis experience

"As Dr. Tomasz Węgrzyn, an authority on welding reliability and professor at MIT, emphasized: 80% of the service life of a pressure-bearing weld depends on the quality and integrity of the root weld, not the surface formation. "This case is a proof of this assertion."

JS Solution: Process Optimization of TIG Primer + MIG Filler

After finding the reason, we decisively abandoned the single MIG welding solution and adopted the process combination of TIG Primer + MIG Filler:

Step 1: TIG Primer - Ensure Root Quality

- For the root welds of all joints, use TIG welding (Tungsten Inert Gas Shielded Welding). Although the speed is much slower than MIG, the heat and arc of TIG welding are super controllable.

- Core Purpose: Ensure 100% penetration of the root to form a uniform and dense basic weld. Just like laying the foundation for building a house, it must be absolutely solid.

Step 2: MIG Filler Weld - Improve Overall Efficiency

- After TIG has laid a solid and reliable foundation, useMIG weldingto quickly and efficiently complete the subsequent filling welds and cap welds.

- Core Advantages: It not only takes advantage of the MIG welding's fast filling speed and high efficiency, but also perfectly avoids its shortcomings of poor melting and poor protection in base welding. At the same time, the MIG porosity problem is greatly reduced by surfacing on the TIG base.

Step 3: Strict quality control

To ensure that everything is foolproof, we have included 100% X-ray flaw detection (RT) in the final mandatory acceptance criteria. Whether there are any defects inside is clear at a glance, leaving no hidden dangers.

Final result: Reliable rebirth from tragedy to zero leakage

- Zero leakage goal achieved: All fuel tanks manufactured using the new process have passed the rigorous 4MPa (2 times the working pressure) static pressure test and fatigue life test at one time, achieving zero leakage!

- Cost optimization: Although thewelding timeof a single piece increased by about 15%, theproduct qualification rate soared from 70% to 100%. Expensive rework, scrapping costs and huge potential safety risks were completely avoided, and the comprehensive manufacturing cost was effectively reduced.

This case tells us bloodily that welding does not mean welding firmly, especially on pressure vessels. When choosing a process, you cannot only look at the speed, but must consider the essential needs of the application scenario. Through the combination ofTIG primer + MIG filling,we accurately balance quality and efficiency.

"At JS, we firmly believe that safety is not a cost, but the most core investment. If your key components also face welding challenges, don't hesitate to come to us with your specific needs and pain points."

FAQ - Solve All Your Doubts About Welding

Welding and brazing (Brazing) What is the difference?

I am often asked what is the difference between welding and brazing.

- Welding is to heat the two pieces of metal (parent metal) to be connected until they are melted, so that they and the welding wire are fused into a high-strength joint.

- Brazing is different. It does not melt the parent metal. It only uses a metal with a lower melting point (brazing filler metal) to melt and penetrate into the tightly fitting gap like glue. Therefore, the welded joint is usually much stronger than the brazed joint.

Can I learn welding by myself? How to start step by step?

Of course you can! But safety is an absolute prerequisite. Let me break down the basic steps for you:

- Safety first: Before welding, you must wear a professional mask, thick gloves, and flame-retardant work clothes. Ensure good ventilation and no flammable materials around.

- Clean thoroughly: Wipe the metal surface to be welded thoroughly, and remove oil, rust, and paint, otherwise the weld will not be strong.

- Adjust the equipment: Carefully adjust the current and voltage on the welding machine according to the type and thickness of the metal you are welding. For example, a thin iron plate needs a low current.

- Hands-on welding: After lighting the fire (arc initiation), keep your hands steady! Control the distance (arc length) and movement speed of the welding rod/tungsten from the workpiece, and move it like drawing a line at a constant speed.

- Post-weld inspection: After welding, knock off the welding slag and take a good look at the weld. Is it uniform and strong enough? Are there any pores or undercuts?

Important reminder:It is strongly recommended that novices first enroll in a formal training class, or find a master to guide them before practicing on their own. Safety always comes first!

Why is the weld sometimes stronger than the original metal?

There are two main reasons:

- Stronger filler material: The welding wire or welding rod we use when welding is specially designed, and its own strength is usually higher than the parent piece we weld.

- Welding heat changes the metal structure: During the welding process, the small area experienced instantaneous heating and extremely rapid cooling. This rapid change makes the internal structure of the weld after solidification super fine and dense, and naturally stronger.

Of course, the premise is that the entire welding process is standardized and there are no problems such as cold welding and pores.

Summary

Welding,this ancient art of connecting metals,is still a real skill in modern manufacturing. It is far more than a simple fusion. It involves a deep accumulation of material properties, electrical principles and operator skills. Understanding how it works and accurately matchingthe welding processfor your project is the basis for ensuring high product quality, safety, reliability and long life.

Take action!

Don't let welding become the short board of the product: the wrong process selection may bury hidden dangers.

What can the JS team do?

We have experienced welding engineers and certified welders,providing full-process services, from TIG welding that requires delicate operation to strong welding of large structures.

Contact us nowto talk about your specific needs!

- What we can deliver: We combine metal and sparks with our expertise and experience to create strong and durable products for you.

- And of course, a clear and realistic metal welding quote!

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsrpm.com