Com o rápido desenvolvimento da tecnologia de impressão 3D, a inovação material se tornou um fator -chave de sua ampla aplicação. Desde plásticos leves a metais de alta resistência, uma variedade de materiais de impressão 3D oferecem inúmeras possibilidades para o projeto estrutural complexo e a realização funcional. Seja usado para a rápida validação iterativa de modelos de impressão 3D Ou para fabricação direta de produtos finais, a seleção de materiais afeta diretamente o desempenho, o custo e a viabilidade do produto acabado.

Os materiais principais atuais incluem materiais termoplásticos (por exemplo, PLA, ABS), materiais metálicos (por exemplo, ligas de titânio, ligas de alumínio), compósitos, etc., desenvolvimento de protótipos, fabricação industrial e aeroespacial. No futuro, o desenvolvimento de novos materiais continuará a ultrapassar os limites do desempenho, ajudando o potencial de desbloqueio em 3D.

Quais são os tipos de materiais de impressão 3D?

A impressão 3D oferece uma variedade de aplicações em uma variedade de materiais e é dividida nas seguintes categorias, cada uma com seu próprio cenário de desempenho e aplicação exclusivo:

implantes dentários, restaurações ósseas e juntas artificiais.

cobrindo mais de 50 materiais , JS atende às necessidades de precisão de indústrias como saúde, aeroespacial e muito mais, fornecendo uma solução única para componentes complexos.

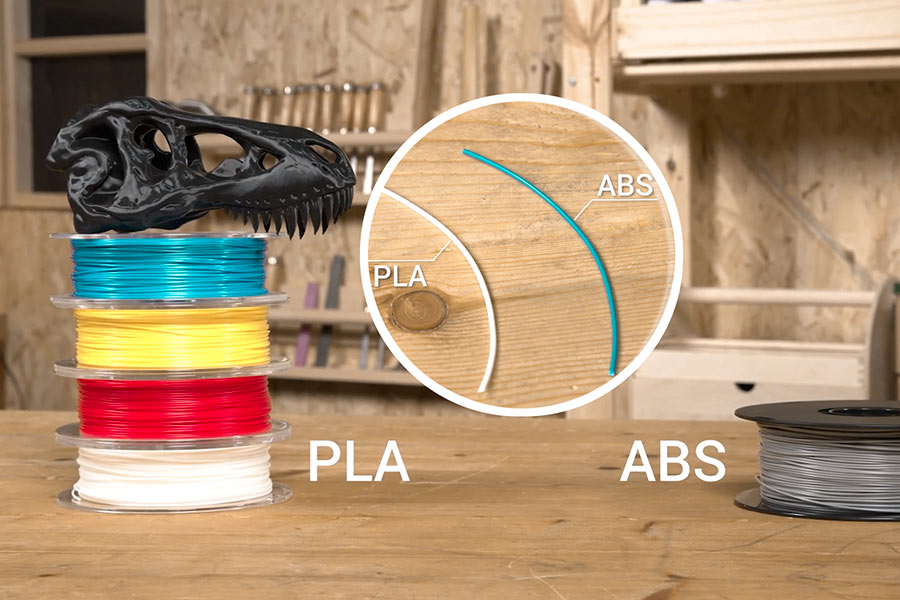

Como distinguir entre os materiais ABS e PLA?

ABS (acrilonitrila butadieno estireno) e PLA (ácido polilático) são os dois materiais mais utilizados no serviço de impressão 3D e suas diferenças nas características afetam diretamente o efeito de impressão e o desempenho acabado.

1. diferenças de núcleo

- fonte de material: PLA é um material biodegrada biodegradável (milho/cana-de-açúcar), enquanto o ABS é um material baseado em petróleo biodegradável.

- Temperatura de impressão: a temperatura de impressão do PLA é baixa e não é necessário um leito de aquecimento, o ABS requer alta temperatura e leito de aquecimento para evitar deformação.

- Desempenho do produto acabado: Alta temperatura ABS, resistência ao choque, adequada para componentes funcionais, dureza do PLA, alta brittless, adequada para modelo estático.

- Segurança ambiental: o PLA é inodoro e adequado para uso doméstico. O ABS emite gases levemente irritantes e requer ventilação.

O custo dos materiais de impressão 3D de plástico é alto?

The price of plastic 3D printing materials is influenced by various factors, including material type, printing process, model complexity, etc.

1. data-v-7b79c893 = ""> diferenças no tipo de material

- Material de baixo custo: o preço unitário do ácido polilático é de cerca de US $ 20-50/kg, adequado para modelos de validação ou decoração de protótipo.

- Material de ponta do meio: ABS e PETG Preço unitário na $ 50 -100/kg, equilíbrio de força, resistência à temperatura, adequado para componentes industriais.

- Materiais de alto desempenho: nylon (PA), TPU (elastômero) preço unitário de $ 100-300/kg, adequado para alta carga ou peças flexíveis.

2. data-v-7b79c893 = ""> sobretaxa de tecnologia de impressão

- tecnologia FDM: baixo custo, mas modelos complexos podem aumentar o consumo de material devido à estrutura de suporte (aproximadamente 10%-20%).

- SLS Tecnologia: a taxa de materiais em pó é alta (cerca de 95%), mas os custos de manutenção de equipamentos aumentam os preços da unidade de serviço (cerca de 30%-50%).

3. data-len = "27" data-v-7b79c893 = ""> perda de material e recuperação

- pó de nylon SLS pode ser reutilizado de 5 a 8 vezes, e o uso a longo prazo pode reduzir os custos do material em cerca de 20%.

- A estrutura de suporte FDM normalmente possui uma taxa de perda de material de 10% -30% e precisa ser considerada em custos totais.

JS Cost Optimization Strategy

1. data-v-7b79c893 = ""> custos de otimização de diversidade de materiais

JS Suporte inclui PLA, ABS, vários plásticos de engenharia, incluindo nylon, tpu, etc. necessidades.

2. span Class = "sentença" DatanslateId = "D439a939393D633333F036FDEDID =" data-len = "35" data-v-7b79c893 = ""> digitalize processos para reduzir perdas

suportando formatos de arquivos industriais, como etapa/IGEs, os dados CAD podem ser diretamente integrados para atingir a produção livre de moldes e reduzir os custos tradicionais de abertura de moldes.

js pode reduzir o custo de 30%-outimology

4. span Class = "sentença" DatanslateId = "2BF7FE0325950C12BD68555521080810810810810810810slateId = 2bf7fe0325950c12bd68555210810810. data-len = "33" data-v-7b79c893 = ""> controle preciso do processo de resíduos

JS atinge ± 0,005 mm de precisão, reduzindo bastante os custos de tentativa e erro.

Qual material deve ser selecionado para prototipagem rápida?

1. material comum: PLA

tornou-se um dos materiais preferidos para impressão em modelo 3D devido à sua conveniência e proteção ambiental.

2. Data-translateId = "3ed5A075D4CBA37F25C0F1E1364C8210" DATA-POS = "3" Data-Len = "61" Data-V-7B79C893 = ""> forças: 3. data-len = "84" data-v-7b79c893 = ""> material equilibrado: PETG forças: Fraquezas: A impressão é ligeiramente mais lenta que o PLA e requer controle preciso de umidade para prevenir a absorção e distorção da umidade.

4. data-len = "61" data-v-7b79c893 = ""> material flexível: tpu forças: fraquezas: velocidade de impressão lenta, precisa otimizar a adesão entre camadas. 5. Nylon (PA): Photosensitive resin: 1.Advantages ink jet printing technology in Industrial Manufacturing 2.Typical Industrial application scenarios 3.Synergistic effects with 3D printing services Professional 3D printing services combine inkjet technology with traditional additive manufacturing (e.g. SLA, SLS) to offer hybrid solutions: PEEK is a high-performance thermoplastic polymer commonly used in extreme environments such as aerospace. However, the extreme temperature differences faced by space missions (-150 °C to +120 °C) can seriously affect their structural stability, as demonstrated and countered by: Effect of Extreme Temperature Difference on the Stability of PEEK structure 1.Thermal expansion and contraction stress The thermal expansion coefficient of PEEK (about 60×10⁻⁶/ °C) tends to cause internal stress concentration when temperature fluctuates wildly, leading to deformation, cracking and even failure of the member. For example, satellite braces may develop fatigue cracks due to repeated expansion and contraction during the alternation of day and night. 2.Material performance degradation 3.Interface de-adhesion risk Composite materials (such as carbon-fibre-reinforced PEEK) may undergo interface debonding, which weakens structural integrity, due to different thermal expansion coefficients of the components. JS Process Optimization and Solutions As a professional 3D printing service provider, JS can alleviate the effect of temperature difference and improve the reliability of PEEK structure by technical means: 1.Topology optimization design Algorithms are used to generate lightweight honeycomb or lattice structures, reduce the use of materials and stress dispersion, and reduce the deformation risk caused by temperature difference. a satellite's insulation panel, for example, uses a 3D printed PEEK lattice structure that reduces weight by 40% and improves fatigue resistance. 2.Gradient material printing High temperature resistant fillers such as boron nitride (BN) were combined with multi-nozzle technology to embed gradients in PEEK matrix to form a composite structure with high temperature adaptability. 3.Processing reinforcement The residual stress is eliminated by hot isostatic pressing (HIP) or annealing process. The high temperature cycle life of 3D printed PEEK components annealed at 150 °C has been shown to increase threefold. In the field of 3D printing, cost-effectiveness depends not only on equipment costs, but also on a comprehensive assessment of accuracy, material suitability, delivery efficiency and post-production services. The following is a comparison of JS Precision Manufacturing's industrial grade technology with traditional printing shops and other printing service providers: 1.Core comparison dimension Accuracy fluctuates significantly (± 0.1-0.5mm) depending on manual calibration. 2.Comparison of typical cases JS's comprehensive cost-effectiveness advantage JS Precision Manufacturing combines industry-leading 3D printing services with automation technology to comprehensively outperform traditional printing shops and conventional 3D printing services in accuracy, materials, efficiency, and environmental protection. Its core advantages are: For projects that require high reliability and fast delivery, JS solutions is ideal for pursuing cost-effectiveness by significantly reducing overall costs. If you need further comparative analysis or custom pricing, you can upload design files directly to the JS platform for exclusive technical solutions. At the heart of 3D printing lies innovation and diversified applications of materials. From high-performance engineered plastics to lightweight metals, the birth of every 3D printing models depends on the combination of material properties and the depth of the printing process. Whether it's PLA prototypes that quickly validate design concepts, or titanium alloy components that meet extreme environmental requirements, breakthroughs in materials are driving the penetration of 3D printing services into a wider range of industries and consumer sectors. As technologies such as multi-material hybrid printing and bio-consumables mature, 3D printing services are gradually achieving seamless integration from prototype production to end-product manufacturing, offering new pathways for manufacturing flexibility and personalization. The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy, completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features,material quality and type or workmanship that the third-party supplier or manufacturer will provide through the jusheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information. JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers,we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services. 1.Which is more durable, metal or plastic? Metal 3D printouts are often more durable, with higher strength, temperature resistance and corrosion resistance, making them suitable for harsh environments. Plastic parts are lightweight, but easy to age, poor durability, suitable for no load bearing or short-term use scenarios. 2.What kind of material is suitable for printing high temperature resistant parts? High-performance plastics such as PEEK and ULTRAM, as well as metal materials such as titanium alloys and stainless steel, are more than 200 °C temperature resistance and suitable for high temperature environments. 3.How to choose the right material? Materials are selected according to their use, taking into account strength, temperature resistance, cost and difficulty in reprocessing. For example, functional components choose metal/nylon, prototypes choose PLA, and external components choose resin/ceramics. 4.Does 3D printing material support custom colors? 3D printing supports custom colors, and some technologies,such as multistage jet molding, can be printed directly using colored materials. Metal parts typically require post coating or use pre-colored powder. Plastic parts can also be material mixing or later sprayed to achieve colorful results.

JS Prototipagem rápida e especialista em fabricação rápida Especialize -se em usinagem CNC, impressão 3D, fundição de uretano, ferramentas rápidas, moldagem por injeção, fundição de metal, chapa metal e extrusão. Marcação:

Em Data-len = "136" Data-V-7B79C893 = ""> fraquezas: a impressão tem um odor pungente, requer ventilação, alta taxa de encolhimento e otimização de parâmetros.

Can ink jet printing be used in industrial manufacturing?

What are the effects of extreme temperature differences in space on the stability of PEEK structures?

Which 3D printing service offers the best value for money?

Comparison items

JS Precision Manufacturing

Traditional printing factories

Other 3D printing service providers

Precision control

±0.005mm (exceeding industry standard).

Some can reach ±0.02mm but are not stable enough.

Material diversity

50+materials (metal, plastic, ceramics).

Only paper, PVC and other basic materials are supported.

Material options are limited (mainly PLA/ABS).

Delivery speed

1-2 weeks (including complex process optimization).

Emergency orders call for expedited charges based on inventory.

Small-batch production is fast, but large-scale production lags behind.

Cost control

Save an average of 20% on manufacturing costs.

Significant human and material resources are wasted, with costs 30-50 per cent higher.

The cost of consumables is low but the unit price is high.

Technical support

Engineers provide full course guidance and automatic parameter matching.

No professional technical support.

Basic consultation, slow response to complex issues.

Environmentally friendly

Energy recovery+waste recycling to reduce carbon emissions by 20%.

Traditional printing is highly polluting.

Some manufacturers use biodegradable materials.

Type of project

JS solution

Traditional print solutions

Cost and efficiency differences

Medical implant prototypes

Titanium SLS printing, surface polished to Ra 0.8μm.

Mold casting required, cycle more than 2 months.

Costs are reduced by 40% and deliveries are 30 times faster.

Car cover mold

Nylon composite material 3D printing with a service life of over 50,000 cycles.

CNC machining wood die is easy to wear and requires to be replaced frequently.

Reduce maintenance costs by 60% and trial and error cycles 70%.

Resumo

Disclaimer

JS Team

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it's low-volume production or mass customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com FAQS

Resources

Blogs relacionados

Design de impressão 3D: 5 regras essenciais para estruturas de suporte, espessura da parede e otimização da topologia

Impressão 3D industrial: ganhos leves e de eficiência automotivos em 15%

Futuro da fabricação: Descubra as 5 tecnologias de impressão 3D mais avançadas em todo o mundo

Materiais de impressão 3D revelados: de plásticos a metais - que melhor se encaixa no seu projeto?

Interrompendo a fabricação tradicional: um mergulho profundo em como a impressão 3D funciona

O que é impressão 3D?

Criticism

Featured Blogs