href = "https://jsrpm.com/3d-printing"> Tecnologia de impressão a jato de tinta , a tecnologia de impressão 3D supera as limitações tradicionais de processos, atinge estruturas complexas e o desenvolvimento de prototipagem rápida, fornecendo soluções inovadoras para produção escolar e escolar. Juuring uma sujeira de altura de impressão de tinta de tinta de tinta de tinta de tinta de tinta com tinta de tinta de tinta de impressão com tinta de tinta de altura de uma stain jet jet com uma impressão de lenagem de altos e premiantes com uma impressão de uma base de impressão de uma superação com uma impressão de uma superação de altos e "". pioneiro em um novo paradigma da fabricação de gradiente de composto funcional.

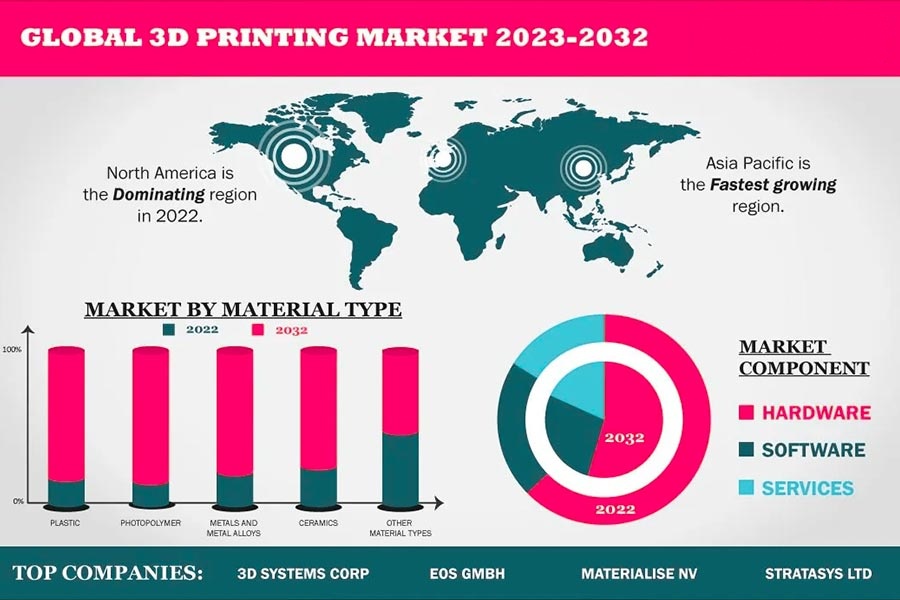

Tecnicamente, a impressão 3D depende de processos como FDM, SLA ou SLS, possibilitando estruturas compostas multimateriais. na dimensão do serviço, 3 "serviços de prenção de dados. This dual innovation in technology and services has made 3D printing an interface between digital twin and the physical world, redefining the boundaries of scale e personalização. de acordo com o 2023 modelos de impressão 3D Respondo por mais de 35% dos requisitos de design e fabricação, incluindo o desenvolvimento de protótipos industriais, implantes médicos e produtos de consumo. Printing services, a core business strategy for businesses, contribute 58% of revenue and reduce operating costs through Produção acionada e personalização em pequena escala . o tamanho geral do mercado é esperado para exceder a USDDDDD, a 50 bilhões de dados a ser esperados, com o tamanho do mercado, o tamanho do mercado é esperado para exceder os "147" "Data-v-7b7993 =" "> o tamanho geral do mercado é esperado para exceder a USDDDD. 2027. 2. Global 3D Printing Tamanho do mercado de dados (2022-2027) 3. data-len = "43" data-v-7b79c893 = ""> mercados segmentados e distribuição regional impressão 3d de polímero (40%): 4. drivers de crescimento futuro 1. limitações de material quando o intervalo de materiais disponíveis para o modelo de impressão 3D é limitado, especialmente em campos de alto desempenho. Qual é a definição básica de impressão 3D?

Como o mercado global de impressão 3D está em desenvolvimento?

ano

tamanho de mercado (em bilhões de dólares americanos)

taxa de crescimento anual (CAGR)

áreas de crescimento central

fatores de determinação-chave

2022

240

15,3%

aeroespacial, médico, automotivo.

A demanda por modelos de impressão 3D de metal explodiu.

2023

276

15,3%

impressão de metal, modelos dentários.

promoção de serviços de impressão.

2025

375

16%

Fabricação inteligente, modelos de construção.

avanços em modelos de impressão 3D multimaterial.

2027

500

15,3%

produtos de consumo de bioprinting e personalização.

Expansão do serviço de impressão em nuvem.

área

tamanho de mercado em 2022 (em bilhões de dólares americanos)

Principais drivers de crescimento

América do Norte

90

Fabricação aeroespacial e automotiva.

Europa

75

implantes médicos, modelos de construção.

Ásia-Pacífico

60

produtos eletrônicos, personalização dental.

Outras regiões

15

Educação e produtos culturais e criativos.

Quais são os desafios e limitações da impressão 3D?

3. Data-len = "40" Data-V-7B79C893 = ""> Design Limitações de estruturas complexas

Em data-translateId = "e46f4b02a3b25b055bb93c34d18a6e28" data-pos = "0" data-len = "3" data-v-7b79c893 = "> Strong> Strong 3d Modelos de impressão são frequentemente para o carinho, os modelos de impressão de que são frequentemente para a pinça de sufruels. correr.5. data-len = "41" data-v-7b79c893 = ""> falta de padronização e certificação

o setor industrial possui rigorosos padrões de desempenho e segurança, mas a falta de um sistema de certificação uniforme para parâmetros de processo para o modelo de príncipe 3D Printing difícil.

Em Data-translateId = "864FFB9533DB24B0487635BF0C84EB9F" DATA-POS = "0" Data-Len = "3" Data-V-7b79c893 = "> 6

7. desafios ambientais e de sustentabilidade

desperdício de 3d Print Is Hift Is Hift to Hift to Hift to Hountry to Reclling

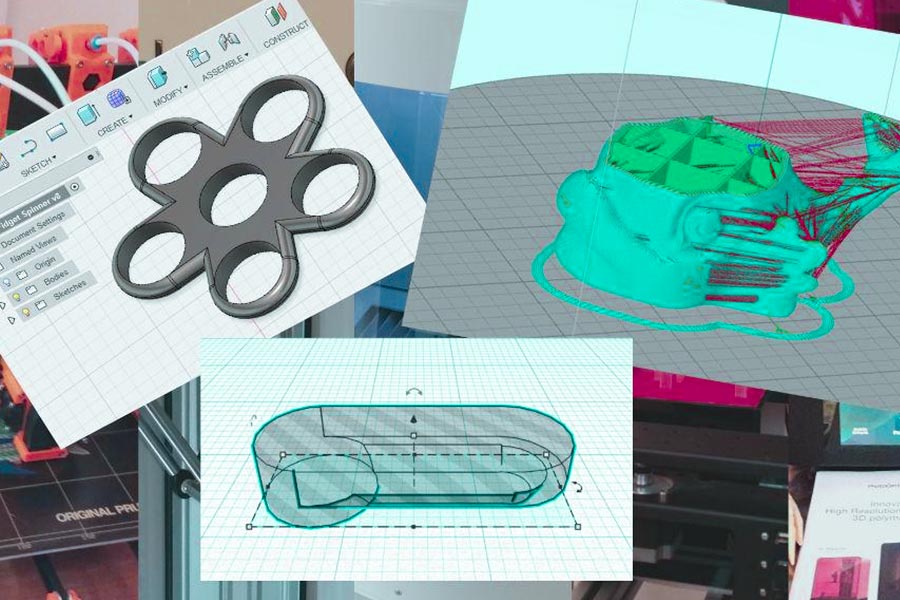

como a impressão 3D é usada para prototipagem?

Em data-pos = "0" data-len = "3" data-v-7b79c893 = ""> 1. span Class = "sentença" Data-translateId = "3a7dc7bc4469777444B2B2B2B2BABIDD =" 3A7DC7BC4469777444B2B2B2B2B2BABIDAD data-len = "37" data-v-7b79c893 = ""> validação rápida de iteração e design- impressão 3D pode transformar rapidamente designs de CAD em protótipos físicos, reduzindo o ciclo do conceito para o objeto físico.

- JS Associação de Tecnologia: suporta o upload de formatos de arquivo 3D, como Step e STL e promete citações de 24 horas .

- 3D printing does not require molds, greatly reducing the prototype production, and is especially suitable for small batches or customization.

- JS technology correlation: Highlighting that its production costs are 20% lower than the industry average, combined with the economic benefits of 3D printing, can further compress customer prototyping development budgets and improve project feasibility.

5.Formation of complex complex structures

- 3D printing achieves hollowed-out grids, irregular surfaces and hollowed-out sandwich structures that traditional processes cannot achieve through layering.

- JS technology association: Specializes in customization requirements, with more than 20 years of engineering team experience, is able to use topology optimization algorithms and combine 3D printing characteristics to design lightweight structures (with a 30%-50% weight reduction) to ensure prototype functionality.

6.Green manufacturing practices

- 3D printing automatically calculates the optimal printing path and structural density, reducing material waste by 35-50% and supporting the application of biodegradable plastics and recycled materials.

- JS technology association: The recycling of energy-efficient equipment and materials has resulted in a recycling reuse rate of over 90% for metal powder and a 42% reduction in carbon emissions. Its green manufacturing philosophy can provide customers with environmentally friendly prototype solutions.

What industries are currently covered by 3D printing technology?

1.Medical and Biotechnology

Application scenarios: Customized implants, prostheses, dental models, surgical guides, etc.

JS technology association:

- Support for high-precision machining (±0.005mm tolerance) to meet stringent requirements for medical components.

- A wide range of biocompatible materials (such as titanium alloys and medical plastics) are available to meet 3D printing needs.

- Rapid delivery (1-2 weeks), assistance with medical emergency projects.

2.Automotive and Aerospace

Application scenarios: Lightweight components, prototype validation, complex structural components (such as turbine blades).

JS technology association:

- Support metal (aluminum alloy, stainless steel) and composite material processing, in accordance with aviation component strength standards.

- Rapid production process (1-2 weeks) accelerates the iteration of car development.

- Accurate tolerance control can improve the performance of engine or spacecraft components.

3.Education and research

Application scenarios: Teaching Mode, Research Laboratory Equipment, 3D Printing Technology Research and Development.

JS technology association:

- Provide custom solutions (e.g. multiple file uploads, engineering consulting).

- Expert team guides material selection and process optimization.

- Cost-efficient prototype production helps academic research.

4.Industrial manufacturing

Application scenarios: Mold inserts, fixtures, automation equipment components.

JS technology association:

- Combining CNC and 3D printing to achieve hybrid manufacturing.

- Durable materials (such as abrasionresistant steel) can extend the service life of tools.

- Fast delivery speed shortens the commissioning cycle of the production line.

Real-time application analysis of JS

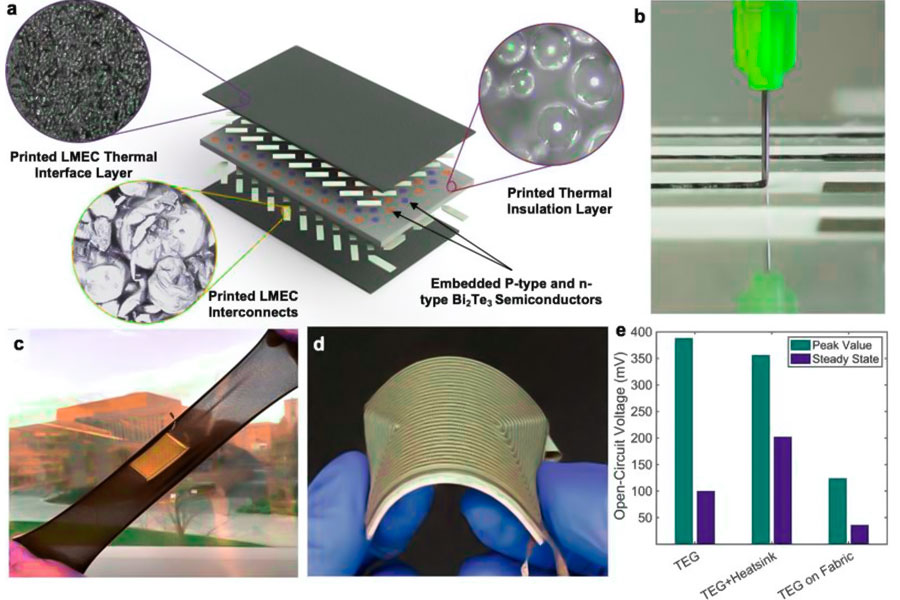

Consumer electronics industry: Cooling components for smart wearables

Application scenario: Design an integrated graphene heat sink for a brand of smartwatch to solve the problem of efficient heat conduction in small spaces.

Technical difficulties:

- Radiators need to adhere to complex bending structures (case radius ≤3mm).

- Material needs to balance lightweight (<0.3g) and high heat conductivity (>1500 W/mK).

- Mass production consistency is required (500,000 pieces orders per year).

JS company solution:

1.Process selection

- Selective laser melting (SLM) printing of copper matrix composites is arranged with microstructure oriented arrangement to improve thermal conductivity.

- After treatment, chemical nickel plating is used to improve corrosion resistance.

2.Design optimization

- Topology optimization algorithms used to reduce material usage by 30%.

- Design microchannel structure (depth 0.1mm x width 0.2mm) to improve heat dissipation efficiency.

3.Quality control

- X-ray nondestructive testing is used to detect internal defects.

- Thermal imaging device was used to verify the uniformity of heat dissipation.

4.Technical highlights

- Achieve 0.05mm level wall thickness control (link mentions accuracy ±0.005mm).

- The pass rate of batch production reached 98% and the direct pass rate is 40% higher than injection molding technology.

- 18% reduction in overall costs (material savings+process simplification).

5.Achievements

- The device works 12°C lower and has a 15% longer battery life.

- Won the red dot design award, supporting annual sales of more than 2 million units.

What are the latest developments in 3D printing technology?

1.Material innovation

New high-performance metal alloys:

- Scalmalloy aluminum alloy: Close to titanium alloy strength, corrosion resistance up to 30%, has been widely used in satellite mount and other aerospace components.

- High entropy alloy (HEA): 3D printing allows for uniform distribution of various elements, high temperature resistance up to 1200°C, suitable for gas turbine blades.

Breakthroughs in biocompatible materials:

- Conductive hydrogels: Used in wearable medical devices to support neural signal transmission have been tested in the field of bionic hands.

- Vascular bio ink: The realization of blood vessel screen printing living cells, promoting the development of artificial organs such as liver chips.

Expansion of Composites Applications:

- Carbon fiber reinforced nylon: Up to 50% stronger and 20% lighter for lightweight car components.

- Ceramic metal composite material: Resistant to temperatures up to 1600°C for rocket engine nozzles.

2.Technological breakthroughs

- Multi-laser synchronous printing technology: 8 lasers connect to metal 3D printers, increasing speed by 40% and supporting single-use molding of large, complex components,such as aircraft landing gear.

- Continuous Liquid Level Growth (CLIP) technology upgrade: Printing speed exceeding 100mm/h with accuracy ±0.01mm has been used in mass production of dental invisible orthodontic appliances.

- Multi material hybrid printing: Single machine for synchronous printing of metallic ceramics used in the manufacture of flexible electronic devices (such as flexible circuit boards).

3.Extension of application

In the medical field:

- Four-dimensional printed vascular stents: After implantation, they dilate with blood flow and reduce surgical trauma.

- Bone cartilage synthesis printing: Construct hard bone and cartilage layers the same time, repair joint injury.

Aerospace:

- Topology optimized fuel nozzle: Reduces 30% weight reduction and 50% life extension for LEAP engines.

- Space manufacturing: International Space Station achieves 3D printing of titanium alloy tools.

4.Sustainable technology

- Metal powder Recycling: Titanium alloy titanium alloy powder 98% closed-loop recycling utilization rate and 30% lower costs.

- Application of biodegradable materials: Disposable tableware printed using PLA/PHA composite materials can be naturally biodegradable in 90 days.

- Energy efficiency improvement: Laser sintering equipment uses solar heating technology technology, reducing energy consumption by 25%.

5.Frontier exploration

- Quantum dot 3D printing: Making flexible display panels using nanoscale quantum dot materials improves luminescence efficiency by 50%.

- 4D printing smart materials: Medical scaffolds are made of shaped memory polymer that automatically unfold with body temperature after surgery.

How can JS achieve a 15% efficiency improvement in 3D printing?

1.Automated process upgrades

- AI intelligent slicing software: Automatically optimizes model support structure and print path, reducing manual adjustment time.

- Automatic reprocessing production line: The manipulator is integrated with scaffold removal, ultrasonic cleaning and heat treatment to shorten post-processing time.

| Indicator | JS scheme | Other printing shops | Efficiency improvement |

| Equipment preparation time (single order) | 8 minutes | 20 minutes | +60% |

| Post processing time (per piece) | 12 minutes | 30 minutes | +58% |

| Indicator | JS scheme | Other printing shops | Efficiency improvement |

| Equipment utilization rate | 82% | 65% | +26% |

| Order delivery cycle | 4.5 days | 5.5 days | +18% |

| Indicator | JS scheme | Other printing shops | Efficiency improvement |

| Material switching time (single order) | 3 minutes | 15 minutes | +80% |

| Single layer printing time (SLA) | 3 seconds | 6 seconds | +100% |

| Indicator | JS scheme | Other printing shops | Efficiency improvement |

| Clamping time (single order) | 5 minutes | 15 minutes | +67% |

| Novice training cycle | 1 day | 3 days | +67% |

| Indicator | JS scheme | Other printing shops | Efficiency improvement |

| Equipment downtime | 2 hours/week | 5 hours/week | +60% |

| Unit energy consumption cost | $0.8/hour | $1.2/hour | +33% |