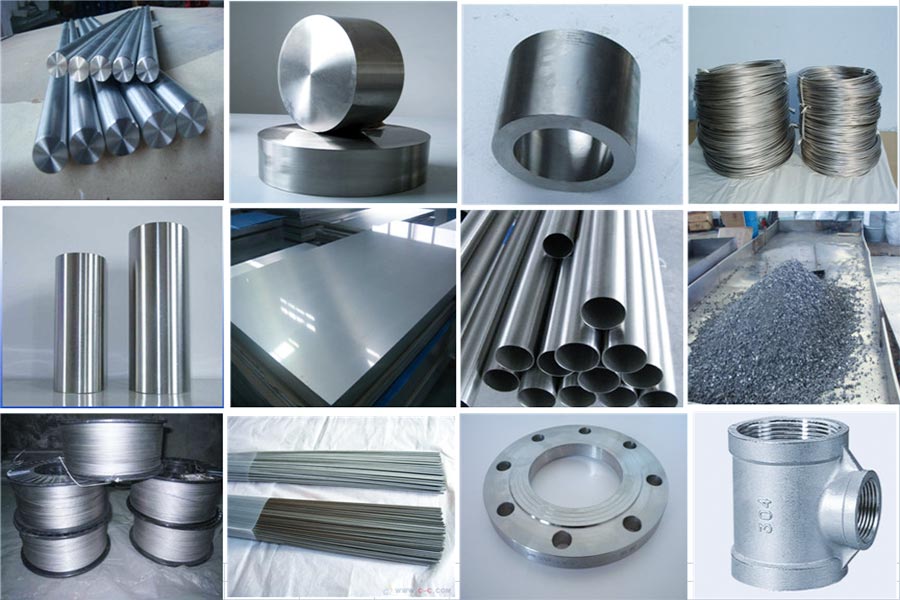

estampagem de metal é um processo de formação indispensável e eficiente na fabricação moderna. converte folhas de metal em componentes complexos e de alta precisão através de moldes precisos e equipamentos de estampagem de alta velocidade. data-translateId = "1B7B0AC94EE39732221C7B029786E2D17" Data-pos = "220" Data-Len = "167" Data-V-7b79c893 = ""> metal

o que é carimbo de metal?

Todo o processo envolve formação de metal precisa, flexão, corte e outros processos, Adequado para fabricação de componentes simples a complexos.

adequado para produção em massa de peças de precisão.

Quais são os processos básicos da estampagem de metal?

1. estampagem progressiva

através de vários conjuntos de apostas de metal vinculadas, vários processos, como perfuração, flexão e formação, estão gradualmente concluídos em uma única linha de montagem.

2. transfira carimbo de molde

Adequado para peças grandes ou intricadamente de formato, os tarugos de metal transportados entre estações de trabalho por braços robóticos ou paradas transportadoras.

3.Sliding estampagem de molde

Projetado especialmente para curva complexa de flexão de vários ângulos é alcançada através de carimbos metálicos deslizantes horizontalmente. O sistema de molde flexível da JS suporta ajuste on -line de ângulos de flexão. Por exemplo, uma única estampagem pode completar a flexão em três direções diferentes na produção de colchetes de componentes eletrônicos , aumentando a utilização do material em 15%. É particularmente adequado para pequenos ordens de personalização de volume.

4. data-len = "12" data-v-7b79c893 = ""> profunde

Em data-pos = "0" data-len = "77" data-v-7b79c893 = ""> esticando o carimbo de metal, as folhas de metal são transformadas em peças de cavidade profunda.

Quais são as principais etapas do processo de estampagem de metal?

Em data-translateid="7d30bfd2c347a651fc40415aa9fa2f95" data-pos="0" data-len="39" data-v-7b79c893="">1.Material pretreatment and mold matching

2.Mold Design and Comissioning

Com base no modelo 3D de peças, o caminho de geometria e estampamento do molde de carimbo de metal são projetados e a distribuição de tensão da matriz é otimizada por simulação de Cae.

3. estágio e formação de estágio

colocando a placa de metal na mesa de prensa, a deformação plástica é realizada através da colaboração do molde de selo de metal e da imprensa hidráulica/servo. O sistema de feedback de pressão em tempo real do JS pode ajustar dinamicamente a pressão da borda para aumentar a taxa de rendimento para 99,2%.

4.Post-tratamento e otimização da superfície Os produtos com carimbo de metal são aparados, com polimento eletrolítico ou aprimorados para remover as revas e melhorar o acabamento. 5. Inspeção de qualidade e fechamento de dados precisão dimensional de peças de carimbo de metal (por exemplo, espaçamento de orifícios ≤0.01mm) foi verificado com o CMM ou a verificação óptica. Metallic stamping molds é a ferramenta principal da indústria de fabricação. É dividido principalmente nas seguintes categorias: Punching Mold : usado para separar folhas de metal, completar os procedimentos de corte, punção, corte e outros para obter os contornos ou orifícios necessários. Deepening Mold : esticando os tarugos planos em peças tridimensionais ocas (como copos ou cilindros), pressionando os moldes côncavos convexos. Forming mold: Used for local plastic deformation of metal sheets, such as bulging, ripping, and constriction of neck, through which material is stretched or compressed to a specific shape, Adequado para processamento de superfícies curvas complexas ou estruturas de aço reforçado. Composite Mold : completa várias etapas como estampagem, corte, moldagem e assim por diante em uma única estampagem e realiza a usinagem eficiente através da combinação da estrutura da matriz convexa. enter molde (contínuo Single track mold: Only one stamping (such as stamping or cutting), simple structure, low cost, suitable for small batch production or simple parts Processamento.

composto Mold : Múltiplos processos (como corte e alongamento) na mesma estação de trabalho. progressivo Mold : Processamento contínuo (estampagem → flexão → corte) em diferentes posições de trabalho. According to the characteristics of stamping on metal process, the key techniques and As medidas de estampagem e prevenção de lascas de placas de metal ultrafinas (<0,1mm) são introduzidas abaixo: estampando no metal

Otimização do molde+Tratamento de lubrificação: Reduza a resistência ao fluxo do material e a adesão de molde, adequada para materiais macios, como folha de alumínio.

Step-stamping + flexible die: Phased deformation reduces single load, suitable for mass production of ultra-thin battery housing. Titanium alloy stamping requires hot stamping or hot stamping combined with high-precision CNC machining and special mold technology. The specific reasons are as segue -se: 1.High temperature plasticity improvement Titanium alloy have high hardness and resistance to deformation and are prone to cracking when pressed at room temperature. By heating the material to 600-850℃ (hot stamping) or 300-500℃ (warm stamping), the plasticity of the material can be greatly improved, forming difficulty reduced and the rebound minimized. 2.Precision CNC auxiliary processing Combined with JS company's ±0.005mm high-precision CNC equipment, titanium alloy parts can be pressed for precision polishing at the micrometer level to meet stringent tolerance requirements in aerospace, medical, and other fields. 3.Special molds and lubrication technology Adopt high temperature resistant mold materials(such as tungsten steel or ceramic coated mold), combine nitrogen or graphite lubricants, prevent mold wear and titanium alloy bond, prolong mold life. 4.Surface treatment matching After stamping, titanium alloys needs to be anodized, sandblasted or chemically passivated to improve its corrosion resistance and appearance. It is also an extension JS company's material processing technology. 1.Material fixation technology in microgravity environment Electromagnetic adsorption and vacuum clamping are used to overcome the limitation of traditional mechanical fixation.JS's automation system adjusts the clamping force in real time, ensuring the metal retains a positioning accuracy of 0.02mm even in weightlessness. The tolerance control of the numerical control equipment reaches ±0.005mm, which satisfies the strict requirement for the precision of spacecraft docking mechanisms. 2.Intelligent flow reconstruction Through the cooperative operation of industrial robot clusters, JS detects micro-scale displacement by gravity-free compensation algorithm and realizes automatic adjustment of stamping parameters. Its adaptive control system can control the machining error rate to less than 0.3%. The technology has been demonstrated in the production of satellite solar panel supports, with a 40% increase in productivity. 3.Improving adaptability to vacuum-environment processes The inert gas shielding arc cladding technology used to solve the problem of metal oxidation in vacuum. JS laboratory data show that 15μm of dense oxide film is formed on the surface of titanium alloy surface treated by this process. 4.Optimization of lightweight structural design Based on 3D printing additive manufacturing technology, JS can achieve integrated topology optimized structures. A case study of a certain type of rocket fuel nozzle shows that through lattice structure design, the weight is reduced by 45%, the pressure bearing capacity reaches 1.8 times that of traditional technology, and the space load requirement is perfectly balanced. 5.Extreme environment simulation verification system A comprehensive testing platform consisting of vacuum chamber, centrifuges and thermal shock chamber was established, capable of simulating temperature gradients ranging from -180°C to +300°C and 10^-6Pa degree. In vacuum environment, the fatigue life of the validated product increased to more than 5 times the ground condition. 1.Anodizing 2.Electroplating 3.Spraying 4.Chromate Conversion Coating 5.Polishing/Brushing 1.Ultra-high precision machining: With advanced CNC technology (such as CNC), tolerance of ±0.005mm can be achieved to meet the requirements of precision parts. 2.Multi material adaptation: Supports stamping of materials such as metals and composites and has processed more than 50 materials in the past year. 3.Process efficiency: 98% of orders are delivered on time, project cycles are reduced by an average of 15%, and stamping lead times are optimized. 4.Cost control: Reduce production cost by 20% and improve resource utilization through process optimization. 5.Green manufacturing: Reduce energy energy consumption and waste by 20% using energy-efficient equipment and material recycling systems. In the metal stamping industry, the performance of metal stamp is closely related to the accuracy and quality of the final product, and to achieve this goal, it must rely on high-precision pre-processing technology. Through steps such as surface cleaning, deburring, annealing, and surface modification (such as phosphating and lubricating coatings), not only can the ductility of metal materials be significantly improved and the risk of cracking or oxidation during stamping be reduced, but it can also lay a solid foundation for subsequent metal stamping operations. JS combines high-precision CNC machining technology with environmentally friendly processes, incorporating the concept of sustainable development into the pre-processing stage, ensuring that metal stamping parts can maintain consistency whether they are structurally complex or mass-produced. This full process optimization from material preparation to finished product delivery not only improves production efficiency (reducing project cycle by 15%), but also promotes the industry's transformation towards high efficiency, low consumption, and high added value through technological innovation. The content on this page is for general reference only. JS Series makes no express or implied warranties regarding the accuracy, timeliness, or applicability of the information provided. Users should not assume that the product specifications, technical parameters, performance indicators, or quality commitments of third-party suppliers are completely consistent with the content displayed on this platform. The specific design feature, material standards, and process requirements of the product should be based on the actual order agreement. It is recommended that the purchaser proactively request a formal quotation and verify product details before the transaction. For further confirmation, please contact our customer service team for professional support. JS is an industry leading provider of customized manufacturing services, dedicated to providing customers with high-precision and high-efficiency one-stop manufacturing solutions. With over 20 years of industry experience, we have successfully provided professional CNC machining, sheet metal manufacturing, 3D printing, injection molding, metal stamping and other services to more than 5000 enterprises, covering multiple fields such as aerospace, medical, automotive, electronics, etc. We have a modern factory certified with ISO 9001:2015, equipped with over 100 advanced five axis machining centers to ensure that every product meets the highest quality standards. Our service network covers over 150 countries worldwide, providing 24-hour rapid response for both small-scale trial production and large-scale production, ensuring efficient progress of your project. Choosing JS Team means choosing manufacturing partners with excellent quality, precise delivery, and trustworthiness. 1.What is the difference between stamping and casting? Stamping is a cold machining process in which metal plates is pressed into shape by die. It is high efficiency andprecision and is suitable for thin plate parts. Casting is a thermal process in which molten metal is poured into molds to form complex shapes, but with low precision. 2.How important are molds to stamping? Mold is the core tool of stamping, which determines the shape, precision and efficiency of parts. Without the die, stamping is impossible, its design directly affects the product pass rate and production cost, is the soul of stamping technology. 3.What should be paid attention to when stamping stainless steel? Stainless steel stamping requires the use of high-hardness die, control stamping speed, stamping with lubricating oil, and annealing in time to eliminate hardening of workpiece, to avoid cracking and excessive mold wear. 4.What thickness of metal is required for stamping automotive parts? The thickness of the sheet metal commonly used for stamping automobile parts is 0.6-2.5mm. Body coverings (such as car doors) are mainly made of 0.6-1.2mm ordinary steel plates, while structural components (such as collision beams) are made of 1.2-2.5mm high strength steel with balanced strength and molding. Quais são os tipos de moldes de carimbo de metal?

como evitar rasgar durante a estampagem de uma folha de metal ultrafina (<0,1 mm)?

tipo de tecnologia

Princípios principais

medidas específicas

cenários aplicáveis

Efeito anti-tear

otimização de molde

reduz a concentração de tensão.

Molde de ângulo R de gradiente + estampagem progressiva.

carimbo de precisão (como moradia do sensor).

RISCO DE REQUISTA ilha 40%.

seleção de material

Aumenta a escalabilidade.

folha de alumínio/aço inoxidável recozido.

Moldagem de deformação grande (como caixa da bateria).

A resistência à fratura aumentou 25%.

Controle de processo

otimize a pressão e a velocidade.

servo pressionar+estampagem de baixa velocidade.

produção contínua de alta velocidade.

A taxa de rendimento aumentou 35%.

Tratamento de lubrificação

Reduza a resistência de atrito.

Lubrificante aquático por água+revestimento DLC.

carimbo de precisão de alta velocidade.

arranhões de superfície ↓ 90%.

molde flexível

flutuações de pressão buffer.

molde macio de poliuretano+assistência de almofada de ar.

componentes compostos de parede fina (como microscoffolds).

Taxa de lacrimejamento ↓ 50%.

What type of process is required for titanium alloy stamping?

How to deal with zero gravity environment in space metal stamping?

What are the common surface treatment methods for aluminum stamping?

What are the technological advantages of JS company in the field of metal stamping?

Summary

isenção de responsabilidade

JS Team

For more information, please visit the official website: jsrpm.com FAQs

Resources