O princípio central da estampagem de metal é usar moldes de alta precisão para pressionar , dobrar ou alongamento em branco de metal em uma forma específica, com as vantagens de alta eficiência, baixa consumo e boa consistência.

class = "sentença" data-translateId = "CCCC4cc9De9. data-pos="0" data-len="3" data-v-7b79c893="">1. precisão e consistência

Metal stamps mold adopts CNC machining technology, tolerance accuracy ±0.005mm, suitable for automotive size Requisitos . The consistency of the product in the mass production process is very High.

2. span Class = "sentença" data-translateId = "a76c84d97b8e0fe1a437733aaaaRaDaD =" a76c84d97b8e0fe1a437773aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaala data-len = "26" data-v-7b79c893 = ""> produtividade

Moldes de carimbos de metal podem ser alterados rapidamente e, com a ajuda de pressões automatizadas, um dispositivo pode produzir centenas de peças por hora, tornando-o particularmente 3.Cost Vantagens

Em Data-pos = "0" Data-Len = "154" Data-V-7B79C893 = ""> O molde pode ser reutilizado milhares de vezes, dilui os custos unitários ao longo do tempo e atinge a taxa de utilização de materiais acima de 85%.4.complex Shape Processing Capacity

Through multiple progressive molds, the process of punching, bending and stretching can be completed in one go to realize three-dimensional forming of complex structures, such as irregular curved components of bandejas de bateria de novos veículos de energia .

Em data-translateId = "b9e96f7419734a36b27974e4fc833482" data-pos = "0" data-len = "25" data-v-7b79c893 = ">metal stamps support custom designs, from titanium alloy components for medical devices to aerospace titanium plate stamping, which can be quickly adapted to different Indústrias ajustando os parâmetros do molde.

402 "Span-len =" 158 "" METANTO "METANTO" ">"> span Data-7b-7b. Stamping?

1.Design and mold Fazendo

span-len = "158" ""> "> span-len =" 158 "" ""> span-len = "158" ""> "> span-len =" 158 "" ">"> span-len = "158" ""> "> span-len =" 158 "" ">"> span-len = "158" "" "> span-len =" 158 ". data-translateid = "2F57C446C1Bed99C2929CE73BA1FE7C8" data-pos = "0" data-len = "200" data-v-7b79c893 = ""> depois do cliente enviar os arquivos CAD conforme necessário, o Otimizará o esquema de design para garantir a conformidade com os requisitos de estampagem de precisão. Eles usam software avançado para projetar moldes de alta precisão de metal que atendem às especificações rigorosas exigidas pelos clientes.

2. span Class = "sentença" Data-translateid = "F89A88B90BDD276E3108B32EID =" Data-len = "30" Data-V-7B79C893 = ""> Seleção e corte de materiais

de acordo com os requisitos de engenharia, de mais de 50 materiais de metal (como aço inoxidável, alumínio, cobre etc.) para selecionar a placa apropriada.

4. span Class = "sentença" Data-translateId = "5B2C6a0856eaeB9efe78De7De77De7BE7B.CaSlateid = 5B2C6a0856eaeB9efe78De7De77BE7BE7BE7BSE77B.C. Data-len = "40" Data-V-7B79C893 = ""> tratamento de superfície e inspeção de qualidade

Em data-pos = "0" data-len = "112" data-v-7b79c893 = ""> Após o estampamento, forneça serviços de remoção, revestimento, pulverização e outros serviços de valor agregado.1. equipamento de estampagem hidráulica: acionado pelo sistema hidráulico, é adequado para a alta de carimbos de metalas

2. equipamento de estampagem hidráulica: O sistema hidráulico fornece pressão estável, adequada para carimbos de metais que requerem alta precisão, como a formação de vigas automobilizadas e estruturas de máquinas pesadas.

4. span Class = "sentença" DatanslateId = "024f5fce6cce9361e25dfb4ac. data-v-7b79c893 = ""> máquinas de estampagem cnc:

5.Servo stamping presses: Usando motores de servo para controlar o STEW de estampagem e a pressão

7. máquina de dobra: é um método comumente usado na dobragem ou no processamento estrutural 3D de lençóis de chapa para obter flexão e formação através da pressão de molde.

8.Fine blanking presses: Through the combination of stamping and shearing technology, a burr free and high-quality stamping metal process, applied to gearbox gears sensor housings shell and other componentes de precisão. 9.Laser-assisted stamping systems: A eficiência do processamento do metal de estampagem é melhorada pela combinação de laser que precitava e estampando, especialmente para o processamento de precisão da superfície irregular ou a aço de alta resistência.

1. Data-translateid = "C6D0154640EB12BD1B3996B671076756" DATA-POS = "3" Data-Len = "17" Data-V-7b79c893 = ""> PROCESSO

- estampagem de metal realiza estrutura complexa através da deformação plástica profunda e requer alta ductilidade do material.

- chapas e span/span/span/cpan/cpan//span

itens de comparação estampagem metálica ">" Data-len = "142" Data-7b79993 ">"> "Data-len =" 142 "Data-7b7993s =" 0 "Data-len =" 142 "" Data-7B7993 " Metal fabricação custo unitário (produção em massa) ≤ $ 0,5 (ao produzir 100.000 peças por ano $ 2-5 (lote pequeno). Tempo de produção de peça única (segundos) 0,5-5 (o estampamento de alta velocidade pode atingir menos de 0,1 segundos). 30-300 (dependendo do processo). custo do molde (US $ dez mil) 5-50 (mais alto para moldes complexos). 0,1-5 (algumas peças não requerem moldes). economia de lote mínimo Mais de 10.000 peças.1-100 peças. ciclo de produção típico O desenvolvimento de moldes leva de 2 a 4 semanas, e a produção em massa começa a partir de 1 semana. Desenvolvimento livre de moldes, processamento de peça única leva de 3 a 7 dias. Taxa de utilização de material 85% -95% (o molde progressivo reduz o desperdício). 70% -90% (perda de corte+material de canto). Custo de descarte de resíduos baixo (menos desperdício, alto valor de reciclagem).High (com muitos restos, exigindo processamento adicional). - estampagem de metal pode ser alcançado por meio de metallico carimbo com o nível de micrômetro superfície.

- Because sheet metal In short, metal stamping is a subtractive+plastic forming technology driven by metallic stamp, while sheet metal fabrication is a combination of cutting and bending, which complement each other to meet the needs of different industries.

What are the applications of combining composite materials with metal stamping?

1.Car lightweight components

- Application: JS helps car companies reduce weight by more over 30% maintaining crash collision safety combining metal stamping structural components, such as frame crossbeams, with carbon fiber composites. Metal stamping parts are formed by a metal stamp process that provides high rigidity support in key areas, while composite material covers non-bearing areas to reduce overall weight.

- Technical highlights: JS's CNC machining technology can accurately control the tolerance (±0.005mm) of metal punch to ensure seamless connection with composites and reduce assembly errors.

2.Aerospace heat resistant components

- Application example: A satellite project combines titanium alloy punch and ceramic matrix composites for use in rocket engine nozzles. Metal stamping parts can withstand high temperature and pressure environment, while the outer layer of composite material provides thermal insulation.

- Technical highlights: JS's automated production line can complete metal stamping and composite material coating at the same time, shorten the production cycle to 60% of traditional processes and achieve a yield rate of 98%.

3.Consumer electronics cooling module

- Application example: The high-end smartphone heat sink adopts the aluminum alloy stamping frame and graphene composite integrated design. Metal stamping parts are processed by metal stamp technology to ensure the electromagnetic shielding performance of the finished product, while composite materials effectively conduct heat.

- Technical highlights: JS's precision machining technology can achieve 0.02mm of micropore processing to meet the density requirements heat dissipation holes, while reducing overall thickness by 0.5mm through material composite.

4.Medical devices

- Application example: Stainless steel stamping frame and PEEK composite material for external fixation support of orthopedics. Metal stamping parts provide precise support, while composite materials reduce weight and prevent X-ray interference.

- Technical highlights: JS's flexible manufacturing system supports small volume customization of production, up to 7 working days from design to delivery, and serves multiple international medical device manufacturers.

5.New energy storage systems

- Application example: The battery shell adopts the composite structure of aluminum magnesium alloy punch and fiberglass composite to ensure mechanical strength and improve corrosion resistance.

- JS's process can reduce the weight of the casing by 18% while improving battery life through simulation.

Which industries does metal stamping help?

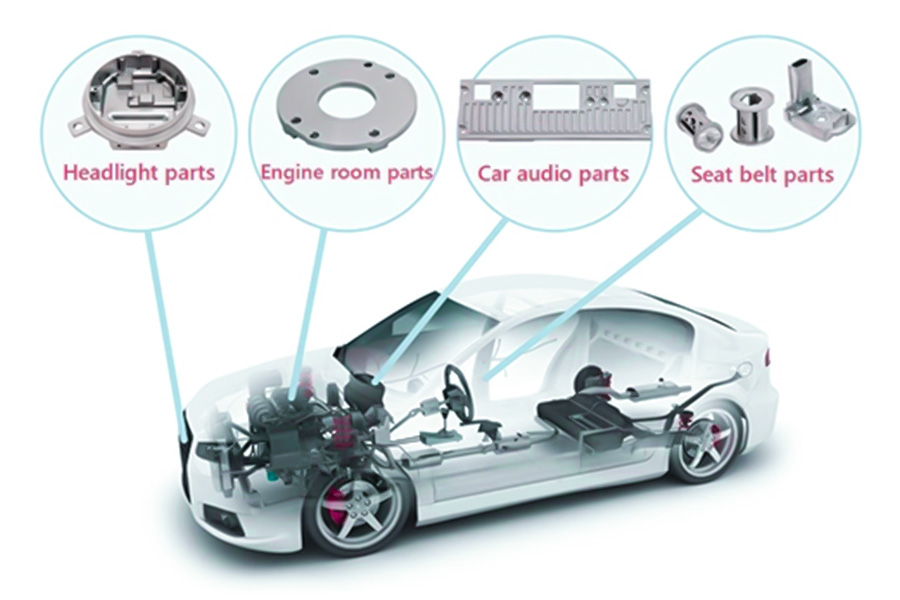

1.Automotive industry

This is definitely the biggest beneficiary! Think about it, how many things on a car are stamped out of metal? Doors, roofs, hoods, trunk lids and other shells (body coverings), the supporting skeletons (frames, chassis parts), and various brackets, brackets, fuel tanks, exhaust pipe parts, etc., are too numerous to count.

Stamping allows automakers to produce these key parts quickly and cheaply, and with stable quality. Now everyone is pursuing lighter and more fuel-efficient cars, and materials such as high-strength steel and aluminum alloys are also mainly handled by advanced stamping technology.

2.Home appliance industry

Many of the shells of home appliances such as refrigerators, washing machines, air conditioners, microwave ovens, ovens, and range hoods are stamped out of metal plates. Stamping ensures that these parts have regular shapes and accurate sizes, making home appliances look beautiful, easy to install, and durable to use.

3.Electronic products industry

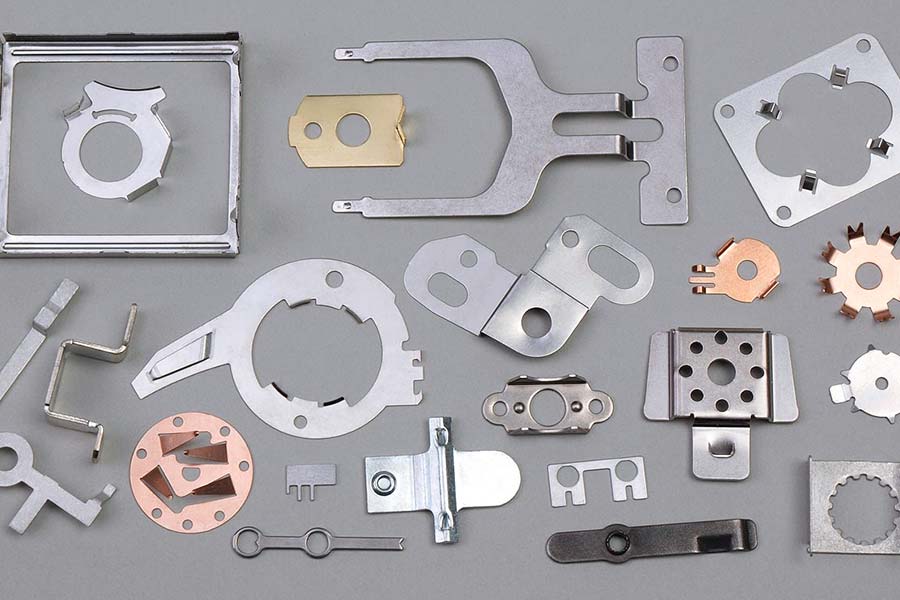

Computer cases, laptop shells, server cabinets, metal brackets inside mobile phones, connectors, heat sinks, metal shells and chassis of various electronic devices, all of which require very precise metal parts. Stamping technology, especially precision stamping, can efficiently and in large quantities produce these small parts with high size requirements and complex shapes, which is essential for the manufacture of electronic products.

4.Industrial equipment and machinery industry

Shells, protective covers, bases, brackets, gears, sprockets, conveyor belt parts, motor housings, pump body parts, etc. of various machine equipment. Stamping provides a large number of sturdy and reliable structural parts and functional parts for these industrial equipment, and is one of the basic links in equipment manufacturing.

5.Other fields

- Aerospace: Non-load-bearing structural parts, brackets, panels, etc. inside some aircraft (very high requirements).

- Medical equipment: Some instrument shells, brackets, surgical instrument parts, etc. (with requirements for precision and cleanliness).

- Lighting industry: Lamp housings, reflectors, lamp holders, etc.

What are the restrictions on stamping materials for engine blades?

1.High temperature stability

Leaves need to work in a high temperature (800°C to 1100°C) gas environment for a long time, the material needs to resist creep, oxidation and low thermal expansion coefficient.

- Typical materials: Nickel based superalloys (such as Inconel 718), titanium alloys (Ti-6Al-4V).

- Technical response: JS company uses vacuum heat treatment and surface coating (such as DLC or ceramic coating) to improve the material's high temperature resistance.

2.Mechanical strength and fatigue life limitations

- The blades need to withstand centrifugal force, vibration, and thermal stress, and the materials need high yield strength (≥800MPa) and excellent fatigue resistance.

- Typical materials: ultra-high strength steel (e.g. Maraging Steel), directional solidification alloys.

- Technical response: JS's precision stamping equipment achieves micrometer level tolerance control (± 0.005mm), reducing the risk of stress concentration.

3.The contradiction between lightweight and specific strength

- Density must be reduced while maintaining strength to increase the thrust to weight ratio of the engine.

- Typical materials: Titanium alloy, carbon fiber reinforced composites (CFRP).

- Technical response: JS adopts topology optimization design to embed lightweight composite reinforcement ribs in metal stamping parts to reduce weight by over 20%.

4.Material processability limitations

- High-strength materials, such as nickel alloys, have severe job hardening and are prone to cracking, while titanium alloys exhibit significant knife stabbing.

- Technical response: JS uses gradient stamping technology, combined with professional lubricating oil and multi-process forming technology, to reduce the risk of material tearing.

5.Corrosion resistance and oxidation limitations

- Sulfide and chloride in gas can easily cause material corrosion and shorten blade life.

- Typical material: Corrosionresistant alloys such as Hastelloy X, surface nitrogen treatment.

- Technical response: JS's precision cleaning and passivation process can remove stamping residue and combine with anodic oxidation to improve corrosion resistance.

How does JS's material library match the needs of the automotive industry?

Core advantages of JS material library

1.High-strength and lightweight materials

- Typical materials: 6 series/7 series aluminum alloy, titanium alloy, carbon fiber composite.

- Application scenarios: Body coverings, battery pack Case, suspension system Component.

- Strengths: 30%-50% weight loss, improvement, a tensile strength over 600MPa.

2.Corrosion resistant and high-temperature resistant materials

- Typical materials: 316L stainless steel, 625 heat resistant alloy, PEEK plastic.

- Application scenarios: Exhaust system components, high temperature bracket for electric drive system, fuel cell bipolar plate.

- Strengths: Spray corrosion resistance of more than 2,000 hours, long-term working temperature up to 300℃.

3.Precision processing specialized materials

- Typical materials: Copper alloy (C18150), mold steel NAK80, optical grade PMMA.

- Application scenarios: Sensor precision Shell, motor gears, car light reflectors.

- Advantages: Processing tolerance ±0.005mm, surface roughness Ra <0.4μm.

4.Environmentally friendly and sustainable materials

- Typical materials: Recycled PA66, biobased PLA, low VOC ABS.

- Application scenarios: Interior, charging station housing, child safety seats, etc.

- Strengths: Reduced carbon emissions by 40% and EU RoHS certification.

Material solutions for the automotive industry

Industry demand JS material solution Automotive industry adaptation cases Lightweight Aluminum alloy+topology optimization design. A new energy car company has lost 3.2kg of battery pack weight and increased its range by 15%. Wear resistance POM+DLC coating. Automatic transmission valve body lifespan has been extended to 800,000 kilometers. Electromagnetic shielding Nickel plated graphite fiber. the onboard ECU improved anti-jamming by up to 40dB. Rapid iteration 3D printing nylon prototype. New air conditioning vents have a 60% reduction in the validation cycle. Differentiation in JS

- Technology integration capability: Seamless integration CNC machining, 3D printing, surface processing and other technologies to achieve integrated manufacturing of complex parts.

- Materials Database: A physical/chemical performance database covering more than 50 materials that supports the selection of AI assisted materials.

- Sustainability certification: 100% material traceability through IATF 16949 and ISO 14001 system certification.

Summary

Metal stamping, as the cornerstone process of modern industry, has permeated dozens of fields such as automobile, electronics, healthcare, aerospace and so on. Regardless of the type of complex and irregular structures, stamp metal technology achieves one-off molding of complex structures by balancing strength, precision and cost efficiency through the synergy of high-precision molds and presses.

In the future, as smart factories and green manufacturing advance, stamp metal will continue to define the limitless possibilities of industrial manufacturing in an efficient and low-carbon manner.

Disclaimer

The content on this page is for general reference only. JS Series makes no express or implied warranties regarding the accuracy, timeliness, or applicability of the information provided. Users should not assume that the product specifications, technical parameters, performance indicators, or quality commitments of third-party suppliers are completely consistent with the content displayed on this platform. The specific design feature, material standards, and process requirements of the product should be based on the actual order agreement. It is recommended that the purchaser proactively request a formal quotation and verify product details before the transaction. For further confirmation, please contact our customer service team for professional support.

JS Team

JS is an industry leading provider of customized manufacturing services, dedicated to providing customers with high-precision and high-efficiency one-stop manufacturing solutions. With over 20 years of industry experience, we have successfully provided professional CNC machining, sheet metal manufacturing, 3D printing, injection molding, metal stamping and other services to more than 5000 enterprises, covering multiple fields such as aerospace, medical, automotive, electronics, etc.

We have a modern factory certified with ISO 9001:2015, equipped with over 100 advanced five axis machining centers to ensure that every product meets the highest quality standards. Our service network covers over 150 countries worldwide, providing 24-hour rapid response for both small-scale trial production and large-scale production, ensuring efficient progress of your project.

Choosing JS Team means choosing manufacturing partners with excellent quality, precise delivery, and trustworthiness.

For more information, please visit the official website: jsrpm.comFAQs

1.What is the definition of metal stamping?

The process of manufacturing parts by applying pressure on metal materials by mould and press is characterized by high precision and high efficiency.

2.Key points of stamping mold design?

In order to optimize processing cost and production efficiency, attention should be paid to reasonable structure, material strength and abrasion resistance, accurate control of suitable clearance and slope removal, and ensure stamping accuracy, mold life and operation safety.

3.What are the characteristics of aerospace stamping parts?

High-strength and lightweight materials (titanium alloy/hyperalloy), precision molds, multi-process stamping are required, with high temperature resistance, high pressure resistance, micrometer level tolerances, lightweight structure, etc.

4.What are the application fields of metal stamping?

Widely used in automotive, electronics, home appliances, medical, aerospace, new energy, construction, manufacturing structural components, precision parts, lightweight components and other fields.

Resources