精密な製造の分野で、 cnc-maching">精度。

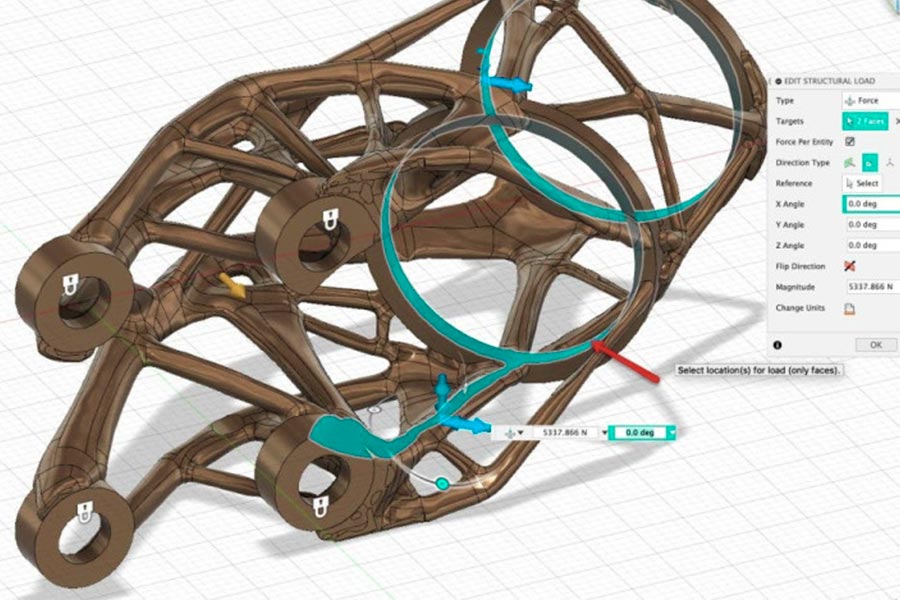

高度な多軸軸機械とAI駆動型プロセスの最適化を組み合わせることにより、JSは95%のプロジェクトで±0.005mm精度を達成し、20%を拡大します。 JSのエンジニアリングチーム(平均20年以上の経験を持つ)は、ドキュメントレビュー(ステップ、IGES、STLなどのサポート形式)からのプロセス全体をサポートできます。

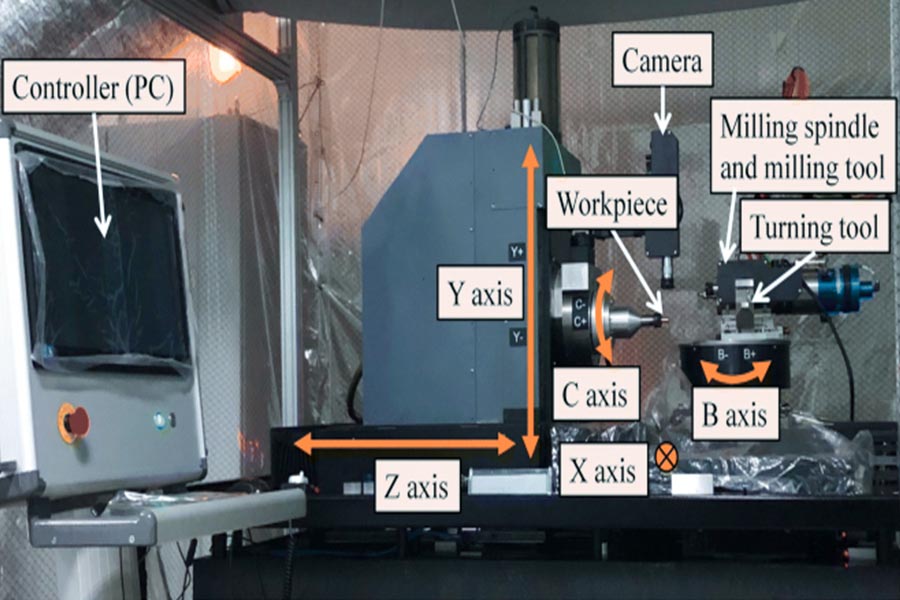

cnc maching by a compate maching a a compate ste a a contex as a conpicate as a scent machingは旋盤やフライス機などの工作機械。 href = "https://jsrpm.com/blog/what-are-the-types-of-cnc-machining"> CNCテクノロジーは、シャフト部分や正確な外側の円の表面などの回転ワークピースの複雑な輪郭の機械加工を実現し、ヒューマンエラーを軽減します。 CNC加工の定義は何ですか?

CNCプログラミングに必要なスキルは?

cncプログラミングには、マシニングプロセス全体を使用する次のコアテクニックの習熟が必要です。

1.壁の厚さは変形を避けるために均一です ミルの機械加工では、不均一な壁の厚さがストレス濃度とゆがんだり亀裂につながる可能性があります。 設計プロセス中に、壁の厚さを一貫した維持するか、必要に応じてサポート構造を追加する努力をする必要があります。

旋盤の機械加工には、薄壁の部品に高い同心度が必要です。最小壁の厚さ≥0.5mmが一般的に推奨されます。 3.腱の構成と遷移コーナーの最適化 data-pos = "0" data-len = "61" data-v-7b79c893 = "" "> 4.処理におけるマテリアル特性と技術適応

壁の厚さ設計の予防策は何ですか?

High-strength materials, such as titanium alloys, require thicker wall thickness to accommodate the cutting force of milling machining, while lightweightアルミニウム合金などの材料は適切に希釈できますが、旋盤の機械加工と組み合わせて速度制御が必要です。

5. shrinkageレートと耐性予約

鋳造または射出成形部品は収縮率を必要としますが、精密なCNC部品(医療コンポーネントなど)は、グラインディングの補償を介してサイズを補償する必要があります。設計用に予約されています。

Complex wall thickness structures requires optimization of the milling 機械加工ツールパス頻繁なツールの交換を避けます。 lealical cotingは、dep/span >>>>>>>>>スパンに使用できます。

7.表面処理後の次元変化 さらに粉砕 幾何学的複雑さは、特に粉砕の機械加工と機械加工旋盤にCNCの機械加工に大きな影響を与えます。以下の違いと課題を強調する必要があります: 1。 data-len = "43" data-v-7b79c893 = ""> ツールパスの計画と加工効率 data-pos = "0" data-len = "3" data-v-7b79c893 = "" "> 2。 data-len = "31" data-v-7b79c893 = ""> ツールの選択と摩耗制御 3。 data-len = "39" data-v-7b79c893 = ""> 精度と表面品質の処理 data-pos = "0" "data-len =" 3 "data-v-7b79c893 =" ""> 4。 data-len = "31" data-v-7b79c893 = ""> 処理コストと実行可能性 span class =" date-translateid = " data-pos = "0" data-len = "3" data-v-7b79c893 = "" "> 5。 data-pos = "3" data-len = "35" data-v-7b79c893 = "" "> 再処理と品質管理 data-pos = "0" data-len = "3" data-v-7b79c893 = "" "> 1。 Data-V-7B79C893 = ""> コアコンピテンシーの比較 2。 Data-V-7B79C893 = ""> 生成ai 3.The manifestation of collaborative value Algorithms are tools, experience is irreplaceable The practical logic of JS: Using generative AI for initial design exploration (such as quickly generating multi version shell structures), followed by engineers screening and optimizing based on CNC process constraints (such as JS's ±0.005mm tolerance), material properties (such as titanium alloy processing temperature), and customer case experience (such as batch consistency of automotive molds). Generative AI can improve design efficiency, but the core of machining CNC experience and quality control-still needs to be led by senior engineers. The success of JS demonstrates that the human-machine collaboration model (AI assisted+manual verification) is the most optimal solution for current manufacturing. 1.Minimize empty motion 2.Optimization of dynamic cutting parameters 3.Tool load and life management 4.Machine tool kinematic adaptation 5.Optimization of material removal rate 6.Process constraints and tolerance control 7.Sustainable manufacturing integration Processing difficulties 1.Treatment of complex irregular structures 2.Characteristics of high-temperature alloy materials 3.Cleanliness and consistency of internal flow channels 4.Thermal deformation control JS company's core advantages Typical cases JS company uses nickel-based superalloy to forge blank in integral, processing a new type of rocket engine shaped cooling cavity. Through CNC multiaxial machining and electrolytic polishing, the uniform cooling channel with 0.3mm wall thickness is achieved, and the thermal conductivity efficiency improved by 40% and engine thrust by 15%. 1.Special cutting tools and cutting techniques Using diamond coated tools or cubic boron nitride (CBN) and other ultra-hard tool materials to optimized cutting parameters, such as speed and feed speed, can effectively solve the problem of high hardness of ceramics and cemented carbide, reduce tool wear and improve machining efficiency. 2.High precision CNC machine tools and control systems With ±0.005mm level ultra high precision machine tools and advanced CNC systems, the processing requirements of complex shapes and strict tolerances such as micrometer level are ensured, satisfying the application requirements of superhard materials in precision components. 3.Customized process plan Design specialized machining strategies based on material characteristics (such as brittle ceramics vs. high-toughness hard alloys), such as using micro lubrication (MQL) or dry cutting techniques to optimize surface smoothness and avoid material cracking or thermal damage. 4.Integrated cross-material processing experience Based on the experience of dealing with multiple materials in the past year, the mechanical models and parameters of metal and composite materials processing were transferred to the field of superhard materials, and the processing risks predicted by finite element analysis. 5.Support green manufacturing systems Energy recovery system and environmentally-friendly coolant circulation technology can reduce energy consumption and pollution in superhard materials processing. At the same time, it can be used automatically to reduce material loss to a minimum, in line with its sustainable improvement target of 20%. In CNC machining, the core of design and engineering considerations lies balance precision, material properties and process feasibility. From the structure optimization of machining mill to tool path planning of CNC machining, every step needs to be focused on tolerance control, material strength and machining efficiency. JS Precision Manufacturing integrates multi-axis coupling technology, specialized cutting tools and AI-driven process optimization to successfully solve the processing challenges of superhard materials such as ceramics and cemented carbide. Its ±0.005mm level accuracy and 98% on-time delivery rate confirm the importance of design, engineering and manufacturing integration. CNCに対する幾何学的複雑さの影響は何ですか?

従来のCADモデリングと生成AIデザイン:アルゴリズムはエンジニアエクスペリエンスを置き換えることができますか?

dimension

伝統的なCADモデリング

生成AIデザイン

js Company Practice

デザインロジック

物理学と経験の法則に応じて手作業でモデル。

人工知能は、アルゴリズムを通じてデザインを生成し、パターンマッチングのためのトレーニングデータに依存しています。

JSエンジニアは、CADエクスペリエンスを利用してAI出力ソリューションを最適化します。

精密制御

±0.005mmの許容値(JSの場合は95%)。

人工知能は、アルゴリズムを通じてデザインを生成し、パターンマッチングのためのトレーニングデータに依存しています。

jsは、エンジニアリングエクスペリエンスを通じてAI生成設計の処理リスクを補います。

効率の改善

複雑な構造には、より長い反復が必要です。

複数のデザインをすばやく生成します(たとえば、JSはサイクルを15%短くします)

人工知能は初期設計を短縮し、エンジニアがキーノードを制御するのを支援します。

コストの最適化

体験型の素材とプロセス選択(JSでの20%のコスト削減)。

低コストのソリューションの自動生成、検証可能性。

JSは、AIの推奨事項をエンジニアエクスペリエンスと組み合わせて、コストと品質のバランスを取ります。

業界の適応性

航空宇宙、自動車、その他の高精度フィールドで広く使用されています。

汎用部品などの標準化されたコンポーネントでは顕著です。

jsは、産業用ロボットコンポーネントをカスタマイズするための2つのアプローチを統合します。

Step by Step

The role of AI

The role of engineers

JS case results

Conceptual design

Generate multiple solutions to shorten the cycle (e.g. JS reduces design time by 15%).

Choose a solution that meets the processing logic.

Client projects were completed an average of 15% ahead of schedule.

Optimization

The combination of cutting parameters is recommended.

Adjust parameters according to machine performance and material characteristics.

Precision ±0.005mm (95% JS compliance rate).

Cost control

Provide lightweight design advice.

Verify manufacturability and balance costs.

Help customers reduce manufacturing costs by 20%.

Innovation breakthrough

Explore the possibilities of non-traditional structures.

Evaluate the feasibility of mass production and improve the design.

Develop multiple patented precision components.

What is the core logic of tool path optimization in CNC multi axis machining?

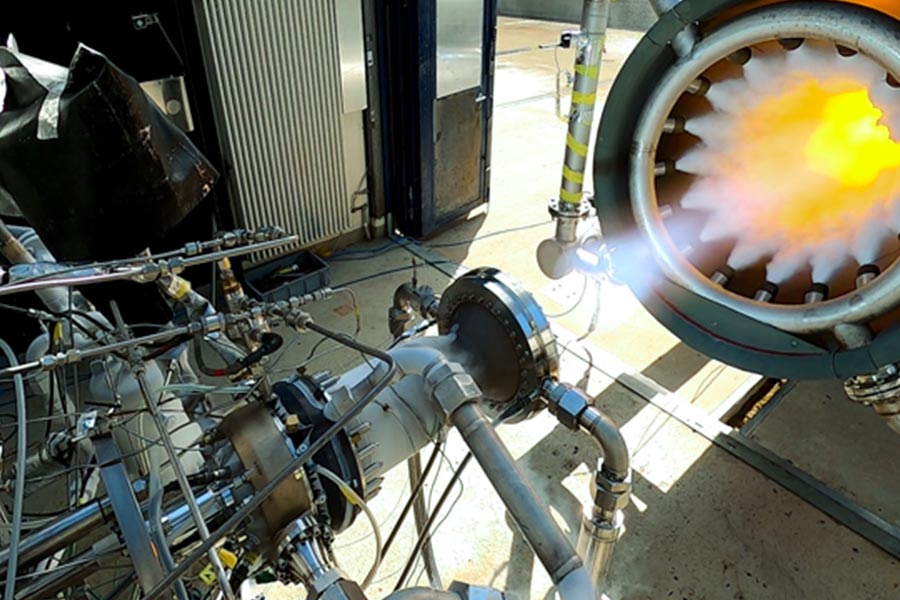

What are the difficulties in processing the irregular cooling chamber of rocket nozzle?

Technical capabilities

Specific measures

Application effect

Multi axis precision machining

Five axis coupled CNC system to support complex surface machining.

The cooling chamber channel is formed in one go to reduce clamping errors.

Special material processing

Experience in working with high temperature materials, such as Inconel and titanium alloys, with CBN cutting tools.

Surface roughness ≤0.8μm, strength loss<3%.

Digital quality control

Comparison and verification between CMM and CAD.

The pass rate is over 98% and the rework rate is down by 70%.

Efficient production process

Modular programming, automated loading and unloading system.

Average distribution cycle reduced to 10-14 working days.

Aerospace grade certification

Certified by 9001 and AS9100D aerospace quality management system certification.

We supply components for SpaceX, Blue Arrow Aerospace and others.

How does JS process superhard materials?

Summary

Disclaimer

The content on this page is for general reference only. JS Series makes no express or implied warranties regarding the accuracy, timeliness, or applicability of the information provided. Users should not assume that the product specifications, technical parameters, performance indicators, or quality commitments of third-party suppliers are completely consistent with the content displayed on this platform. The specific design feature, material standards, and process requirements of the product should be based on the actual order agreement. It is recommended that the purchaser proactively request a formal quotation and verify product details before the transaction. For further confirmation, please contact our customer service team for professional support.

JS Team

JS is an industry leading provider of customized manufacturing services, dedicated to providing customers with high-precision and high-efficiency one-stop manufacturing solutions. With over 20 years of industry experience, we have successfully provided professional CNC machining, sheet metal manufacturing, 3D printing, injection molding, metal stamping and other services to more than 5000 enterprises, covering multiple fields such as aerospace, medical, automotive, electronics, etc.

We have a modern factory certified with ISO 9001:2015, equipped with over 100 advanced five axis machining centers to ensure that every product meets the highest quality standards. Our service network covers over 150 countries worldwide, providing 24-hour rapid response for both small-scale trial production and large-scale production, ensuring efficient progress of your project.

Choosing JS Team means choosing manufacturing partners with excellent quality, precise delivery, and trustworthiness.

For more information, please visit the official website: jsrpm.com

FAQs

1.How to optimize tool path and reduce vibration?

The tool path is optimized by increasing the step distance, using spiral/cycloid cutting, adjusting the cutting direction to disperse the cutting force, maintaining the cutting load the same, avoiding the concentration of resonance point, and using axial layered cutting to reduce vibration.

2.What should I do if thin-walled parts are prone to deformation?

When thin-walled parts are easy to deform during processing, the cutting force and vibration can be reduced by segmental cutting, decreasing feed speed, increasing support fixtures or vacuum suction clamping fixture, and optimizing tool paths to maintain uniform force distribution.

3.What are the key points of daily maintenance for CNC machine tools?

Clean and lubricate machine tool daily, regularly calibrate coordinate system and tools, check coolant and fixture status, ensure system stability and machining accuracy.

4.Do complex surfaces require multi axis machine tools?

Multi-axis machine tools are needed for complex surface machining because they can be used for multi-angle connecting rod cutting to ensure accuracy and efficiency and avoid multiple clamping errors.