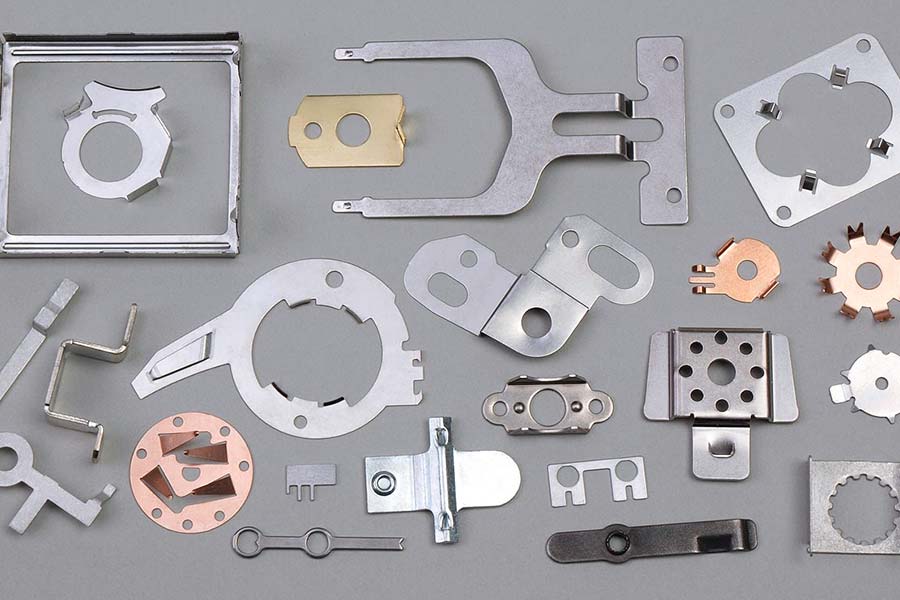

金属スタンピングの中核原理は、高精度の金型を使用して、高効率、低消費量、良好な一貫性の利点を持つ特定の形状にプレスまたは伸ばすことです。

1。 data-len = "30" data-v-7b79c893 = ""> 精度と一貫性

2。 data-len = "26" data-v-7b79c893 = ""> 生産性

金属スタンプ金型はすぐに切り替えることができ、1時間あたり数百個のピースを生成することができます。生産、ホームアプライアンスケーシングや3C製品構造コンポーネントなど。

3.コストの利点

金型は何千回も再利用でき、時間の経過とともにユニットコストを希釈し、85%を超える材料利用率を達成できます。 特にアルミニウム合金やステンレス鋼などの高価値材料の場合

4.コンプレックス形状処理機能

複数のプログレッシブ金型を通して、パンチング、曲げ、ストレッチのプロセスを完了することができます。 href = "https://jsrpm.com/industry/automotive">新しいエネルギー車のバッテリートレイ。

metal spants サポートカスタムデザイン金型パラメーターを調整することにより、異なる産業。

作成

顧客が必要に応じてCADファイルを提出した後、は、設計スキームを最適化して、精密スタンピング要件へのコンプライアンスを確保します。彼らは高度なソフトウェアを使用して、顧客が必要とする厳しい仕様を満たす高精度のメタルスタンパー金型を設計します。

2。 data-len = "30" data-v-7b79c893 = ""> 材料の選択と切断

エンジニアリング要件によると、50を超える金属材料(ステンレス鋼、アルミニウム、銅など)から適切なプレートを選択します。

high-speed

自動スタンピング装置では、スタンピング、曲げ、ストレッチングなどのプロセスが金属プロセスの単一のスタンピングで完了します。 data-pos = "0" data-len = "3" data-v-7b79c893 = "" "> 4。 data-len = "40" data-v-7b79c893 = ""> 表面処理と品質検査 スタンピング後、burr除去、めっき、噴霧、その他の付加価値サービスを提供します。 廃棄物リサイクルシステムを使用して、スタンピングプロセスのエネルギー消費は15%減少し、環境保護の要件を満たします。 1。 data-len="28" data-v-7b79c893="">Hydraulic stamping equipment: Driven by hydraulic system, it is suitable for high-precision stamping of large metal sheets and is commonly used in the production of automobile overlay or heavy machinery構造。 data-pos = "0" data-len = "3" data-v-7b79c893 = "" "> 2。 data-len="28" data-v-7b79c893="">Hydraulic stamping equipment: 油圧システムは、自動車ビームや重機の構造の形成など、高精度を必要とする金属ジョブをスタンプするのに適した安定した圧力を提供します。 ホームアプライアンスシェル、3C製品メタルブラケットなど、高速、大きなスタンピングメタル生産に適しています。 data-pos = "186" data-len = "78" data-v-7b79c893 = "" "> それは高い生産効率と高い安定性によって特徴付けられます。

data-pos = "0" data-len = "3" data-v-7b79c893 = "" "> 4。 Data-V-7B79C893 = "" "> cncスタンピングマシン: 5.Servoスタンピングプレス: サーボモーターを使用してスタンピングストロークと圧力を制御するために、アルミニウム、マグネシウム合金、その他の軽量材料の金属処理、その他の軽量材料を維持するのに適しています。

6。 Data-V-7B79C893 = "" "> せん断機: それは直線の金属シートを切断するために特別に設計されており、多くの場合、スタンピングラインの前面でコイルまたは大きなサイズのプレートを処理するために使用されます。

7。 data-len = "16" data-v-7b79c893 = ""> ベンドマシン: これは、折りたたみまたは3D構造処理で一般的に使用されるメソッドであり、金型のプレスを介して曲げと形成を実現するためのシートメタルシートの3D構造処理です。

8。 data-len = "21" data-v-7b79c893 = ""> 細かいブランキングプレス:

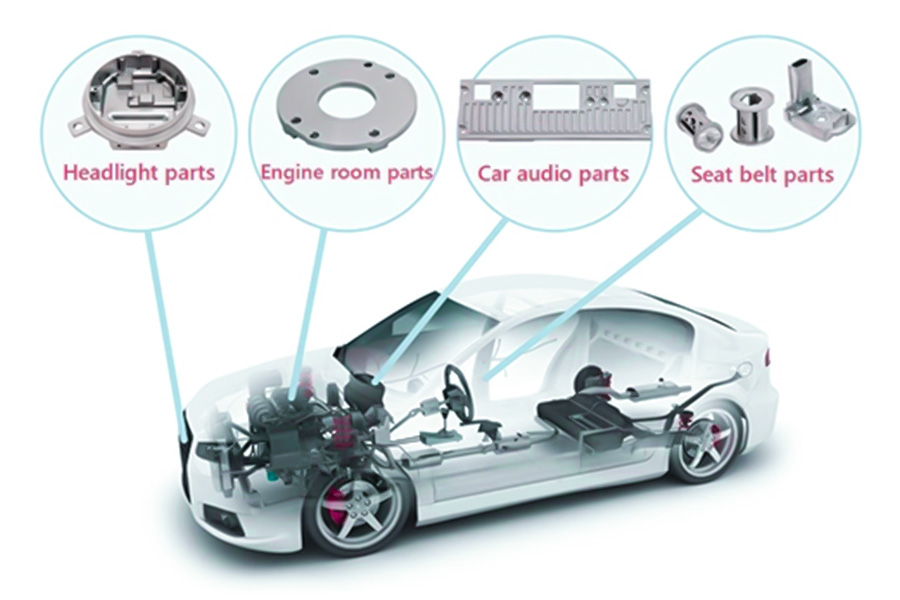

2。 Data-V-7B79C893 = ""> 機器とカビの依存関係 5。 data-len = "15" data-v-7b79c893 = ""> 表面品質 略して、金属スタンピングはmetallic stamp, while sheet metal fabrication is a combination of cutting and bending, which complement each other to meet the needs of different industries. 1.Car lightweight components 2.Aerospace heat resistant components 3.Consumer electronics cooling module 4.Medical devices 5.New energy storage systems 1.Automotive industry This is definitely the biggest beneficiary! Think about it, how many things on a car are stamped out of metal? Doors, roofs, hoods, trunk lids and other shells (body coverings), the supporting skeletons (frames, chassis parts), and various brackets, brackets, fuel tanks, exhaust pipe parts, etc., are too numerous to count. Stamping allows automakers to produce these key parts quickly and cheaply, and with stable quality. Now everyone is pursuing lighter and more fuel-efficient cars, and materials such as high-strength steel and aluminum alloys are also mainly handled by advanced stamping technology. 2.Home appliance industry Many of the shells of home appliances such as refrigerators, washing machines, air conditioners, microwave ovens, ovens, and range hoods are stamped out of metal plates. Stamping ensures that these parts have regular shapes and accurate sizes, making home appliances look beautiful, easy to install, and durable to use. 3.Electronic products industry Computer cases, laptop shells, server cabinets, metal brackets inside mobile phones, connectors, heat sinks, metal shells and chassis of various electronic devices, all of which require very precise metal parts. Stamping technology, especially precision stamping, can efficiently and in large quantities produce these small parts with high size requirements and complex shapes, which is essential for the manufacture of electronic products. 4.Industrial equipment and machinery industry Shells, protective covers, bases, brackets, gears, sprockets, conveyor belt parts, motor housings, pump body parts, etc. of various machine equipment. Stamping provides a large number of sturdy and reliable structural parts and functional parts for these industrial equipment, and is one of the basic links in equipment manufacturing. 5.Other fields 1.High temperature stability Leaves need to work in a high temperature (800°C to 1100°C) gas environment for a long time, the material needs to resist creep, oxidation and low thermal expansion coefficient. 2.Mechanical strength and fatigue life limitations 3.The contradiction between lightweight and specific strength 4.Material processability limitations 5.Corrosion resistance and oxidation limitations Core advantages of JS material library 1.High-strength and lightweight materials 2.Corrosion resistant and high-temperature resistant materials 3.Precision processing specialized materials 4.Environmentally friendly and sustainable materials Material solutions for the automotive industry Differentiation in JS Metal stamping, as the cornerstone process of modern industry, has permeated dozens of fields such as automobile, electronics, healthcare, aerospace and so on. Regardless of the type of complex and irregular structures, stamp metal technology achieves one-off molding of complex structures by balancing strength, precision and cost efficiency through the synergy of high-precision molds and presses. In the future, as smart factories and green manufacturing advance, stamp metal will continue to define the limitless possibilities of industrial manufacturing in an efficient and low-carbon manner. The content on this page is for general reference only. JS Series makes no express or implied warranties regarding the accuracy, timeliness, or applicability of the information provided. Users should not assume that the product specifications, technical parameters, performance indicators, or quality commitments of third-party suppliers are completely consistent with the content displayed on this platform. The specific design feature, material standards, and process requirements of the product should be based on the actual order agreement. It is recommended that the purchaser proactively request a formal quotation and verify product details before the transaction. For further confirmation, please contact our customer service team for professional support. JS is an industry leading provider of customized manufacturing services, dedicated to providing customers with high-precision and high-efficiency one-stop manufacturing solutions. With over 20 years of industry experience, we have successfully provided professional CNC machining, sheet metal manufacturing, 3D printing, injection molding, metal stamping and other services to more than 5000 enterprises, covering multiple fields such as aerospace, medical, automotive, electronics, etc. We have a modern factory certified with ISO 9001:2015, equipped with over 100 advanced five axis machining centers to ensure that every product meets the highest quality standards. Our service network covers over 150 countries worldwide, providing 24-hour rapid response for both small-scale trial production and large-scale production, ensuring efficient progress of your project. Choosing JS Team means choosing manufacturing partners with excellent quality, precise delivery, and trustworthiness. 1.What is the definition of metal stamping? The process of manufacturing parts by applying pressure on metal materials by mould and press is characterized by high precision and high efficiency. 2.Key points of stamping mold design? In order to optimize processing cost and production efficiency, attention should be paid to reasonable structure, material strength and abrasion resistance, accurate control of suitable clearance and slope removal, and ensure stamping accuracy, mold life and operation safety. 3.What are the characteristics of aerospace stamping parts? High-strength and lightweight materials (titanium alloy/hyperalloy), precision molds, multi-process stamping are required, with high temperature resistance, high pressure resistance, micrometer level tolerances, lightweight structure, etc. 4.What are the application fields of metal stamping? Widely used in automotive, electronics, home appliances, medical, aerospace, new energy, construction, manufacturing structural components, precision parts, lightweight components and other fields.

比較項目

メタリックスタンピング

" v-v-79c Metal <スパンクラス="文 "" " Data-TranslateID = "C9F07EC5B158500D898F8A8FB17DDD28" data-pos = "0" data-len = "data-v-7b79c893 =" ""

単位コスト(大量生産)

≤0.5(年間100,000個のピースを生産する場合

$ 2-5(小さなバッチ)。

シングルピース生産時間(秒)

0.5-5(高速スタンピングは0.1秒未満に達する可能性があります)。

30-300(プロセスによって異なります)。

金型コスト($ 1万)

5-50(複雑な金型の場合は高く)。

0.1-5(一部の部分は金型を必要としません)。

最小バッチエコノミー

1-100ピース。

典型的な生産サイクル

金型開発には2〜4週間かかり、大量生産は1週間から始まります。

金型の無料開発、シングルピース処理には3〜7日かかります。

材料利用率

85%-95%(進行性カビは廃棄物を減らします)

70%-90%(損失+コーナー材料の切断)

廃棄物処理コスト

high(多くのスクラップがあり、追加の処理が必要です)。 >

What are the applications of combining composite materials with metal stamping?

Which industries does metal stamping help?

What are the restrictions on stamping materials for engine blades?

How does JS's material library match the needs of the automotive industry?

Industry demand

JS material solution

Automotive industry adaptation cases

Lightweight

Aluminum alloy+topology optimization design.

A new energy car company has lost 3.2kg of battery pack weight and increased its range by 15%.

Wear resistance

POM+DLC coating.

Automatic transmission valve body lifespan has been extended to 800,000 kilometers.

Electromagnetic shielding

Nickel plated graphite fiber.

the onboard ECU improved anti-jamming by up to 40dB.

Rapid iteration

3D printing nylon prototype.

New air conditioning vents have a 60% reduction in the validation cycle.

Summary

免責事項

jsチーム

For more information, please visit the official website: jsrpm.com FAQs

Resources