CNC turning (also known as numerical control turning) is one of the most commonly used techniques in CNC machining. Simply put, it is a subtractive machining method where a metal or plastic material rod is clamped onto a machine and rotated at high speed. Then, a tool is used to gradually cut the material according to a pre written CNC turning program, and finally the desired shape and size are machined.

You may be wondering: what is the difference between a lathe and a turning center, how this technology works, and how it differs from CNC milling.

Let's have a comprehensive understanding together and help you determine whether CNC turning service are suitable for your machining needs.

What is CNC turning?

CNC turning is basically a manual lathe that existed two thousand years ago. At that time, craftsmen used pedals to energize wood to rotate and used chisels to gradually cut out dishes. Although now it has been replaced with computer control, the principle remains the same - to clamp the material and rotate it, and use a cutting tool to form it.

Nowadays, there are two types of CNC lathes: vertical and horizontal. The material inserted has no certain shape, whether it is a round rod, square material, or hexagon steel. As long as the chuck can clamp it, it can be processed into any shape.

The biggest distinction between the earliest hand cranking and the most recent full automatic machining is accuracy. Manual turning generally requires a half millimeter error, but CNC lathes can easily provide an accuracy of ±0.01mm today.

Although any complex component may be produced by a five axis machine tool, for components such as screws and bearings that may be turned by spinning them in a circle, CNC turning is still fast and cheap.

What is the machining process of CNC turning parts?

Step 1: Draw Drawings --Design Parts with CAD Software

First, draw the 3D model of the part on the computer utilizing CAD software (e.g., SolidWorks). We usually refer to CNC turning drawing PDF format when designing parts. This is like drawing a construction drawing before one can construct a house, noting down every dimension and angle carefully in order to refer to it later during processing.

Step 2: Format Conversion --Get Machines to Read Design Drawings

Grab the hand-drawn 3D model and transfer it to CAM software such as Mastercam. This process is equivalent to translating the 3D design into a language that the machine tool can understand, telling the machine tool where to cut first and where to cut second, converting the precise content.

Step 3: Tool path planning --Tell the machine the cutting path

Specify the tool path in CAM software:

Where the tool starts cutting.

Cutting travel speed (feed rate).

Material spindle rotation speed.

Tools to be replaced during different stages of processing.

Similar to routing navigation software between locations and determining the shortest path for the highest efficiency, the purpose of this step is to avoid the obstacles (such as fixtures) and travel via the shortest path for the highest efficiency.

Step 4: CNC turning programming --Write an operation manual for the machine

The CAM software converts the tool path into G-code, which is a sequence of commands consisting of letters and numbers. For example, G01 X50 Z-10 F200 represents: the tool moves straight to positions 50mm on the X-axis and -10mm on the Z-axis, with a feed rate of 200mm per minute.

Step 5: Simulation Testing --Rehearsing before actual combat

Before formal processing, simulate the entire process on the computer. It can detect in advance whether the tool will collide with the fixture, whether the cutting amount is too large, and other issues, avoiding accidents when machining has already begun.

Step 6: Transfer the program --Insert the instructions into the machine tool

Transfer the verified G-code to the machine controller via USB flash drive, local area network, or direct connection. Nowadays, most machine tools also support WiFi transmission, which is as convenient as transferring files from a mobile phone.

Step 7: Material preparation and knife loading --Preparation before startup

- Load the metal rod into the chuck with moderate clamping force (too loose will cause it to fly, too tight will cause deformation).

- Install tools such as external circular cutters, groove cutters, and thread cutters in the order of processing.

- Calibrate the tool reference point (tool alignment), usually with a tool alignment instrument accurate to 0.001mm.

Step 8: Automatic processing

When the program is opened:

- The spindle rotates with material between 500-3,000 revolutions per minute.

- The turret will switch automatically between different cutting tools.

- The outer circular knife cuts out the general shape first, the slotting knife cuts out the groove, and the threading knife threads out the screw design.

- Cutting fluid spraying in real time to cool, iron filings roll and fall off like springs.

- It takes only 10 minutes to process an iron rod into a precise shaft with threading.

Step 9: Size measurement --Only qualified products can be shipped out from the factory

- Vernier caliper: measure plain dimensions such as outer diameter and length.

- Thread gauge: Check whether the screw pattern is as per standard.

- Roughness tester: discovers whether the surface is smooth like a mirror.

- Critical features need to be measured using a coordinate measuring machine (CMM), and in case of an error exceeding 1/10 of the hair diameter (ca. 0.005mm), rework is obligatory.

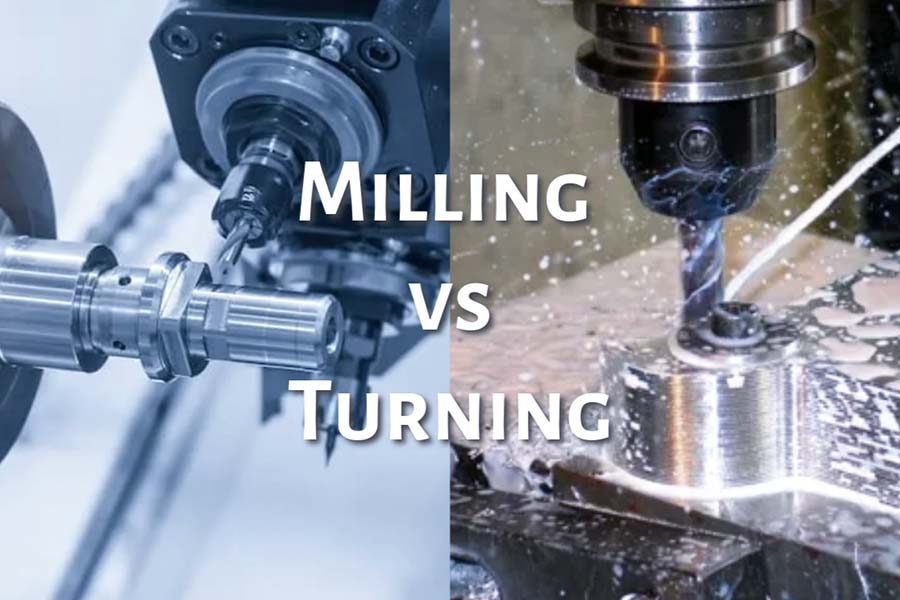

How to distinguish between CNC turning & milling?

CNC turning and milling are the two most commonly used processes in CNC machining, and their core differences stem from differences in equipment structure, tool motion, and applicable scenarios. Compare from 5 key dimensions:

1.Differences in tool structure

- Turning tool: Use a single edged tool (similar to a pencil cutting blade), with only one tip in contact with the material at a time.

- Milling tool: Multi edge tools (such as drill bits and end mills) are used, with multiple cutting edges distributed around the tool head, which can participate in machining simultaneously.

- For example:

Our factory always uses the same tool tip to cut a stainless steel shaft during turning. When machining mobile phone casings with a milling machine, a four edge end mill can simultaneously cut with four blades, resulting in a significant improvement in efficiency.

2.Comparison of equipment structures

CNC Turning centers can be considered as transitional equipment, more intelligent than lathes, but still weaker in functionality than CNC turning and milling center (which integrate five axis milling capabilities and support complex surface machining):

| Comparison items | CNC lathe | CNC milling machine |

| Spindle motion | Rotate the clamped workpiece. | Drive tool rotation. |

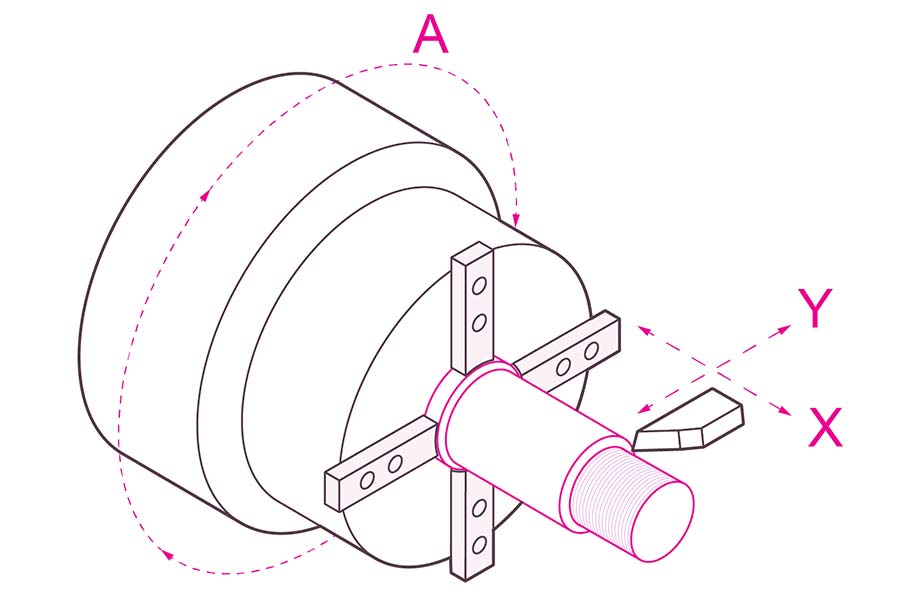

| Number of processing axes | Usually 2-axis (X/Z-axis). | Starting from 3 axes, high-end models can reach 5 axes. |

| Typical cost | The entry-level model costs approximately $150,000 to $300,000. | Basic payment of approximately 250,000 to 500,000 US dollars. |

3.Suitable for processing shapes

- Proficient in turning: Rotating symmetrical parts such as cylindrical and conical shapes, such as screws, bearing sleeves, and water pipe joints.

- Proficient in milling: Asymmetric structures such as flat surfaces, grooves, and curved surfaces, such as mold cavities, gear tooth surfaces, and electronic device casings.

4.Cutting motion mode

- Turning process: The workpiece rotates, the tool moves in a straight line, and the cutting process is continuous and uninterrupted.

- Milling process: The tool rotates and moves, the workpiece is fixed, and the blade periodically cuts in/out the material.

- Action breakdown: When turning, the material bar rotates like a Mutton shashlik, and the knife advances at a constant speed like peeling an apple skin. During milling, the tool rotates and moves like an electric drill bit, gnawing out shapes on the material.

5.Differences in chip morphology

- Turning chips: Depending on the material, continuous long strips (such as processed aluminum), fragmented pieces (such as cast iron), or broken chips (such as titanium alloy) may be generated.

- Milling chips: Always present as short fragments, and due to the continuous cutting and cutting of the tool, the debris is intermittently splashed.

Production impact: The long chips from turning are prone to entanglement and need to be cleaned up in a timely manner. The chips from milling are more easily carried away by the chip conveyor, but there is more metal dust.

CNC lathe and CNC turning center: what are the differences?

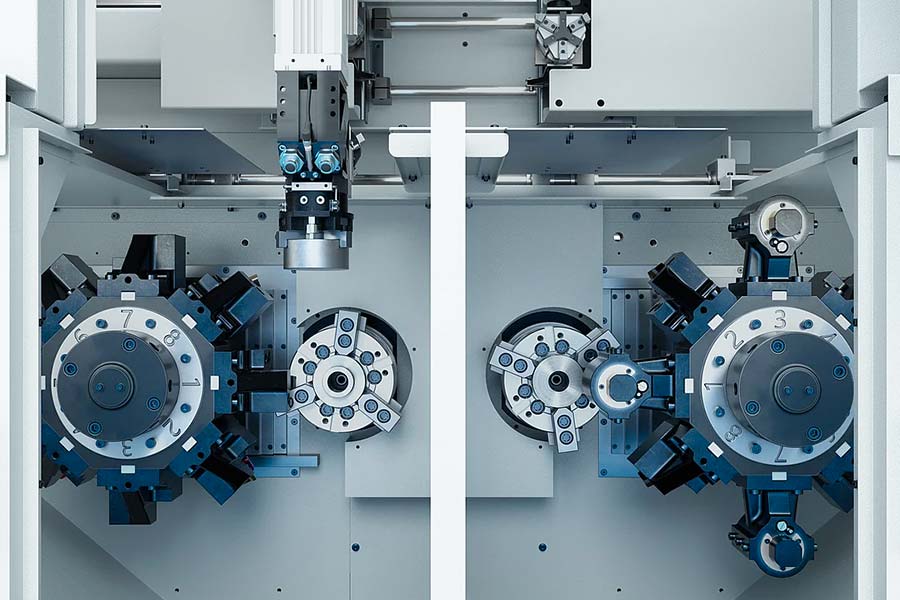

CNC lathes and turning centers look like "twins" and do similar work, but the actual ability gap is not small. Simply put, a turning center is equivalent to an upgraded version of a lathe. Here are the core differences between the two from a practical usage perspective to help you quickly determine how to choose:

1.Functional scope

CNC lathes are mainly used for basic turning machining, such as turning outer circles, cutting grooves, and threading, and are suitable for machining simple rotating parts such as shaft sleeves and bolts. On the basis of turning functions, the turning center has added capabilities such as milling, drilling, and tapping, which is equivalent to a combination of lathe and small milling machine. For example, when machining parts with side holes or keyways, the turning center does not require secondary clamping and can complete all processes in one go, resulting in higher accuracy and faster efficiency.

2.There are three fundamental differences in structural configuration:

The turning and cutting center is fully enclosed, with an automatic chip conveyor and cooling recovery system. The iron chips are tipped straight into the collection box, and the iron chips are not handled by the operator. The lathe is of open structure, with the iron chips being piled beside the machine. It must be shut down and cleaned with a shovel after every 1-2 hours of operation.

The bed of the lathe is tilted 30°-45°, and iron shavings are automatically discharged into the collection tank, and can be run continuously for 8 hours without clogging. The lathe has a flat bed, and the iron shavings will clog the gap of the guide rail. Failure to clean it will result in processing faults.

The turning center turns at 5000-8000 rpm (max 15,000 rpm), and cuts the aluminum bars in 1 minute. Lathe turns at 1000-3000 rpm, which is sufficient for turning the steel parts, but 3-5 minutes will be spent cutting through the same aluminum bar. Briefly, the turning center is suitable for mass-producing small-sized components in a efficient manner, and the general lathe is suitable for repairing or processing heavy components.

3.Processing accuracy and complexity

The processing accuracy of the lathe is generally ±0.01mm, and the turning center can reach ±0.002mm through a closed-loop control system.

Most lathes have 2 axes (X/Z axes), and turning centers are equipped with 3 axes as standard (adding C-axis rotation). Some models support Y-axis and B-axis, realizing 5-axis linkage processing, and can handle complex structures such as eccentric holes and curved surfaces.

Lathe programming is mainly manual G code; turning centers often use CAM software to automatically generate multi-process compound programs.

4.Cost investment and selection strategy

Equipment procurement cost:

The price of an entry-level CNC lathe is about 150,000-500,000 yuan (equivalent to the price of a family car), while the starting price of a basic turning center is $400,000, and the high-end model is more than $1 million.

Use and maintenance cost:

The maintenance cost of the hydraulic system and tool magazine of the turning center is relatively high (for example, the single service fee for turret positioning and calibration is about $4,000), but automated production can reduce 70% of labor demand-the work that originally required 3 technicians to work in shifts can now be monitored by 1 person.

Typical application scenarios:

- Optimal scenarios for lathes: Suitable for simple parts with a monthly output of less than 500 pieces, such as door and window hinge shaft cores and printer plastic rollers. These products have a simple structure and limited profit margins.

- Advantage scenarios of turning centers: Mass production of more than 2,000 pieces/month of complex parts, such as metal joints for heart stents and motor housings for drones. Taking the automobile turbine housing as an example, the turning center can complete the processing of internal and external threads, cooling fins and sensor mounting holes at one time.

JS's suggestion is:

(1)Because of small budget and simple processing requirements, lathes are more cost-effective.

(2)If the components are multi-process, special-shaped, or produced on 24-hour continuous basis, turning centers are utilized.

(3)In the initial stage, one can rent a turning center for trial production and, upon determining what is needed, purchase it.

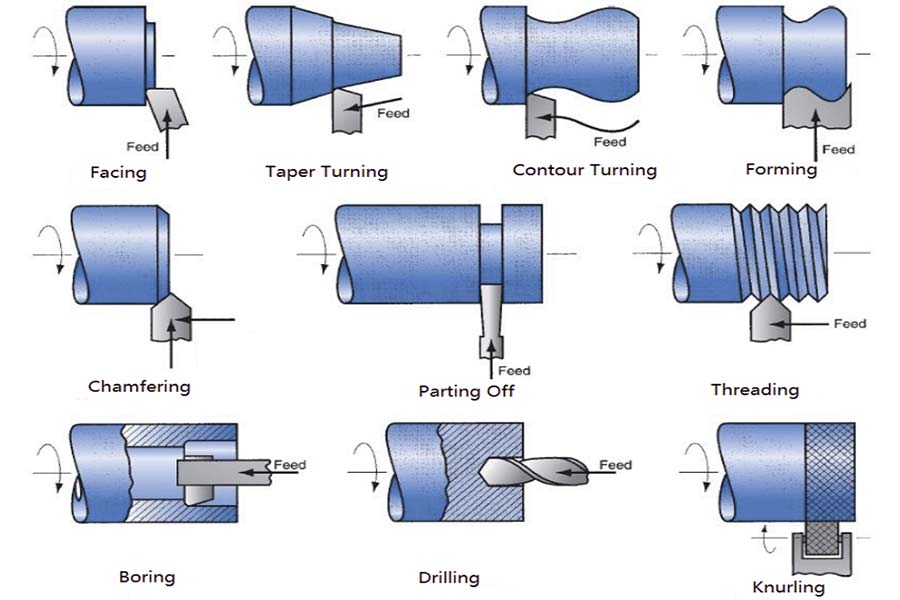

What types of operations are there in CNC turning?

1.Turning

This is the core operation of CNC turning, mainly used to process the outer surface of parts. During operation, the tool will move back and forth along the rotating workpiece, and different shapes will be shaped by adjusting the cutting depth. For example, when making a cylinder, the tool will move in a straight line (straight line cutting), and when making a tapered part, the tool will be tilted at an angle (taper cutting). Simply put, it is like sharpening a pencil, except that metal tools are used to cut metal materials.

2.Facing

End turning is used to machine a plane perpendicular to the workpiece rotation axis to ensure the flatness of the end face. The tool is fed from the outer circumference to the center horizontally, which can quickly remove the blank allowance (rough machining cutting depth 2-5 mm) or fine trimming (finishing machining cutting depth 0.1-0.3 mm), and widely used for gear end face and sealing surface machining.

3.Straight turning

Use wide-blade cutters to gradually turn down the workpiece diameter to the finished size in one cutting quantity of 3-8 mm maximum, normally with an allowance of 0.2-0.5 mm for roughing. Suitable for batch production of standard parts such as bearing rings and bushing blanks.

4.Taper turning

Used to form sloped components, such as taper-shaped components. By changing the cutting tool path angle or through the use of auxiliary fixtures, a growing diameter can be formed on the workpiece surface. Common applications are machine tool spindle taper holes, tool hardware taper shanks and other parts where matching is required.

5.Threading

Use triangular blades or elastic tool bars to cut internal and external threads, and the spindle speed is usually 200-800 rpm. The pitch error of external threads must be ≤0.02 mm, and internal threads must avoid vibration. It is common in bolt and pipe thread manufacturing.

6.Grooving

Use a 2-6 mm wide groove cutter to radially cut into the workpiece. Narrow grooves are formed in one go, and wide grooves are cut in batches. It is used to process back-cut grooves and sealing grooves. Special groove types (such as T-slots) require customized forming tools. The feed speed must be controlled during cutting to prevent chipping.

7.Parting

Use a 2-5 mm wide parting cutter to separate the finished product from the bar stock. The tool must be strictly centered (deviation ≤0.02 mm) and the feed speed is 0.05-0.15 mm/rev. Burrs are easily generated on the cut surface and subsequent deburring is required.

8.Drilling

Although drilling machines are mainly used, CNC lathes can also drill holes directly. Using the tailstock or power turret, holes can be drilled in the center of the rotating workpiece. Advanced models can also process eccentric holes or oblique holes. For example, when processing a gear blank with a center hole, the outer circle and drilling can be completed at one time.

9.Knurling

Use a roller with teeth to press out anti-slip patterns on the surface of a part. This process does not change the size of the part, and is mainly used to increase grip friction or decorative effects. The grid patterns on the surface of wrench handles and instrument knobs that we see in daily life are made in this way.

How to use different types of lathes for CNC turning?

1.Horizontal turning center

Structural features: Fully enclosed body, spindle horizontally arranged, tool located above rotating workpiece, equipped with automatic chip removal system.

Core functions: Integrated turning, milling, drilling, supporting lateral machining of power tools.

Processing advantages:

- Chips naturally fall into the collection tank due to gravity, increasing cleaning efficiency by 50%.

- Suitable for small and medium-sized complex parts (such as hydraulic valve bodies), single clamping can complete multiple processes.

- Typical parameters: spindle speed 3,000-8,000rpm, machining accuracy ±0.005mm.

2.Vertical turning center

Structural design: The chuck is placed flat on the ground, and the turret is fed from the side. It can be inverted (with the spindle at the bottom and the chuck at the top).

Applicable scenarios:

Processing large workpieces with a diameter greater than 500mm (such as wind turbine bearing rings).

Heavy duty parts (with a single weight of up to 10 tons).

Technical features:

Low speed (usually 200-800rpm) ensures machining stability.

Inverted design reduces chip accumulation, suitable for large-scale production of aluminum parts.

3.Horizontal CNC lathe

Basic functions: Standard turning (outer circle/end face/thread), boring.

Equipment characteristics:

Open or semi protective structure, large operating space.

Standard 4-8 workstation turret, supporting manual/automatic tool change.

Application areas:

Small and medium-sized production (monthly production of 100-2000 pieces).

Processing shaft and sleeve parts (such as engine crankshafts and hydraulic cylinder barrels).

Cost advantage: entry-level models are priced at $150,000 to $300,000, with low maintenance costs.

4.Vertical CNC lathe

Core feature: The workpiece is vertically clamped, and the spindle is driven to rotate from the bottom.

Core advantages:

40% reduction in floor space compared to horizontal.

Suitable for short and thick parts (such as gear blanks, large flanges).

Processing restrictions:

The height of the workpiece is usually less than 800mm (limited by the stroke of the column).

Not good at processing slender shafts (prone to bending and deformation).

Industry application: Mold industry processing guide columns, large rotating parts of engineering machinery.

Selection Comparison Table

| Type | Suitable for parts | Maximum machining diameter | Typical price range |

| Horizontal turning center | Complex multi feature small and medium-sized components. | Φ300mm | 800,000 to 2 million |

| Vertical turning center | Large/heavy rotating parts. | Φ2000mm | 1.5-5 million |

| Horizontal CNC lathe | Conventional shaft/sleeve components. | Φ500mm | 150,000 to 500,000 |

| Vertical CNC lathe | Short and thick/large diameter parts. | Φ1200mm | 300,000 to 1 million |

Summary

Numerical control turning technology has completely changed the traditional machining mode through digital control and has now become an important pillar of the manufacturing industry. Whether it is a small studio or a large production enterprise, mastering this technology can significantly improve efficiency while ensuring quality, helping enterprises gain an advantage in market competition.

Why choose our turning service?

After understanding the process characteristics of CNC turning, you may need a reliable partner. JS is equipped with a new generation of intelligent lathes and independently developed process systems, providing the best CNC turning services that can help you achieve:

- Complex structure processing: It can handle anything from a micro shaft with a diameter of 0.5mm to a heavy-duty roller with a length of 1 meter.

- Material Diversity: Supports over 50 types of materials including aluminum alloy, titanium alloy, PEEK engineering plastics, etc.

- Accuracy guarantee: The tolerance of key dimensions can be controlled within ± 0.005mm (equivalent to 1/5 of the diameter of red blood cells).

JS completes the three steps of custom processing:

1. Upload your 3D drawings (supporting common formats such as STEP/IGES).

2. The intelligent system instantly analyzes the process route and generates a quotation list within 30 seconds.

3. After confirming the order, production can start within 8 hours at the earliest (supporting small batch orders of 50 pieces or more).

📞 Phone: +86 189 2585 8912

📧 Email: Doris.wu@js-rapid.com

🌐 Website: https://jsrpm.com/

Disclaimer

The content of this page is for informational purposes only.JS Series No representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. choose JS Technology It means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

FAQs

1.What are the types of machining motion directions for lathes?

The main motion directions of CNC lathes are X-axis (radial), Z-axis (axial), and advanced models can expand Y-axis (vertical) and C-axis.

2.What are the advantages of CNC turning?

CNC turning has high precision, fast efficiency, and can process complex rotating parts. It has a wide range of material adaptability (metal/plastic), suitable for mass production, high degree of automation, and minimal waste.

3.What is the function of a CNC lathe?

CNC lathes automatically process rotating symmetrical parts (such as shafts and disks) through program control, achieving high-precision turning, slotting, threading and other processes, suitable for mass production of metal/plastic parts.

4.What materials are commonly used in CNC turning?

CNC turning commonly uses metal materials such as aluminum, steel, stainless steel, brass, as well as special materials such as nylon, PEEK engineering plastics, titanium alloys, etc., to meet various processing needs.

Resources