Have you ever carefully looked at the high-end laptop shell in your hand? Isn't that one-piece, thin, but strong metal shell amazing? To be honest, relying on traditionalCNC machining, such complex parts often mean long processing time and high costs.

In fact, many shells like this, as well as automobile engine blocks and precision medical equipment parts, are madeusing high pressure casting. At our JS company, this is our specialty in manufacturing precision metal parts.

Simply put, it is to heat and melt metals such as aluminum alloys, and then inject them into precision molds made of high-strength steel at extremely high pressure and super fast speed. The whole process is very fast, and complex shell molding may not even take a second!

The advantages of this high pressure + high speed combination are:

- High production efficiency! Especially suitable for things like laptop shells that need to be produced in large quantities.

- Parts with particularly complex shapes and precise dimensions can be made at one time.

- The finished products have high consistency and smooth surfaces, and in many cases, even subsequent finishing is saved.

It is precisely because of this comprehensive advantage of efficiency, precision and cost thatthe high pressure casting processis so popular in the consumer electronics, automotive and medical industries. How to better control this speed and precision so that it is both efficient and guarantees top quality is what we study every day.

Core Answer Summary:

| Characteristic | High pressure die casting (HPDC) | Low pressure die casting (LPDC) | Sand Casting |

| Production speed | Extremely fast (in seconds/piece). | Slow (minute level/piece). | Slow (hourly/item). |

| Product accuracy | Very high. | Higher. | Generally. |

| Wall thickness capability | Can manufacture extremely thin-walled parts (up to<1mm). | Thick wall thickness. | The thickest wall thickness. |

| Mold cost | Extremely high. | Higher. | Low. |

| Suitable for batch production | Mass production (>10,000 pieces). | Small and medium-sized batches. | From single item to medium batch. |

This article will answer your questions:

- In this guide, I will take you through the complete process of high pressure die casting (HPDC) step by step.

- Explain how the machine works, analyze its most critical advantages and challenges.

- Finally, use a real case we have handled to explain why HPDC is often the preferred solution for efficiency and precision.

Why Trust This Guide? Professional Insights from JS Die Casting Workshop

In JS's high pressure die casting workshop, we know that it is far more than just pressing molten metal into the mold. It is more like a comprehensive knowledge that allows you to know how metal flows, how it cools and solidifies, and how to design the mold precisely. We rely on professional software to simulate the flow and solidification of molten metal in the mold cavity every millisecond. The core goal is to predict and eliminate potential porosity defects.

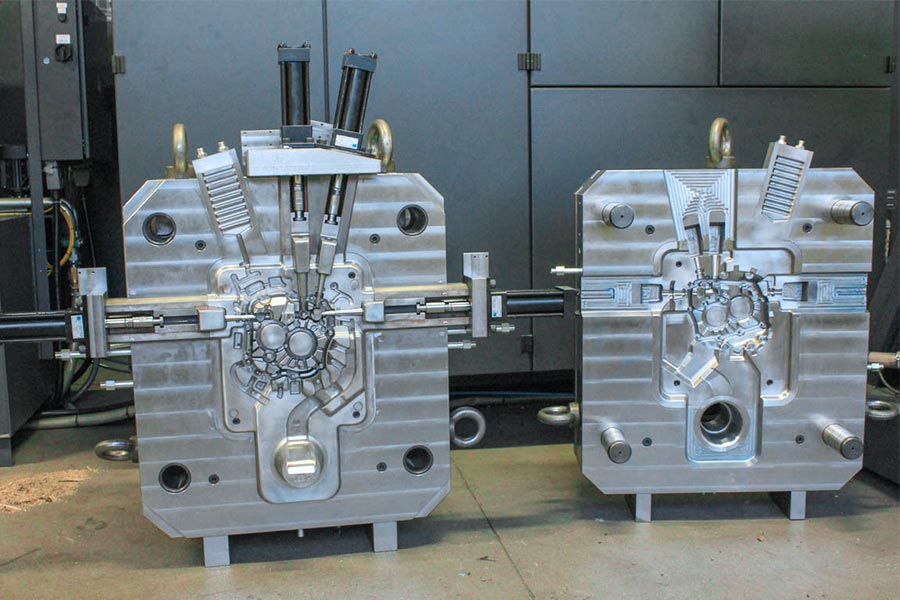

Take the mold as an example. Thealuminum high pressure casting mouldwe designed, the internal cooling water channel, is sometimes more complicated than the part itself! The reason is simple: we want to ensure that the part size is accurate, and the mold temperature control must be precise.

"As automotive manufacturing expert James Womack often says: The secret to excellent manufacturing is to digest complexity internally and deliver simple and reliable products to customers. We digested this complexity in mold design."

The value of this guide comes from real cases. For example, we helped anautomotive electronics customersolve the long-standing electromagnetic shielding (EMI) failure problem of its ECU housing. Through in-depth analysis, we adjusted the feed port position and exhaust channel design of the housing. Guess what? The problem was solved at one time and passed the most stringent test! The insights in the guide are the experience and solutions we have accumulated day after day in the front line of high-pressure, high-speed, and high-precision die-casting production.

Core Principle: A "Super Syringe" for Molten Metal

High pressure casting is to use a powerful and super-fast machine toinject hot liquid metal into the steel mold cavity at high speed under huge pressure, and then let it cool and shape instantly to make complex-shaped parts.

Two core systems of high pressure casting machines:

(1) Clamping system:

Just think about it, if you pour molten metal with a very high pressure and velocity, how massive will the impact be? If the mold is not sealed, it will be opened, and the liquid metal will spew out, no joke.

The inherent function of the clamping system: It is driven by a massive hydraulic cylinder, which can clamp together the two halves of the precision steel mold (e.g, so-called aluminum high pressure casting tooling), weighing a few tons or dozens of tons. This force of clampingis called "clamping force" in tons. It must be able to resist the great impact of injection. Insufficient clamping force will result in mold expansion, splashing of metal, and even safety accidents. Excessive clamping force will cause excessive energy consumption and machine loads.

(2) Injection system:

- This is the heart of the whole machine and is utilized for metering, transporting and pressurizing metal. In cold chamber die casting, we scoop up a known amount of molten aluminum initially.

- Finally, comes the main function-a huge piston named a punch. It can speed up to a very high velocity (as high as 10 meters per second, several times faster than Bolt running!) under hydraulic or electrical power.

- The punch propels the aluminum melt within the barrel ahead, in a channel, and pressurizes it into the mold cavity. Pressure utilized in this process is tremendous, usually to hundreds or thousands of atmospheres (more than 100 MPa). Pressure like that in the deep sea, but instantaneous!

High pressure + high speed, the role of the function is one: to allow thealuminum liquid to fillall of the corners of the entire mold cavity in one thousandth of a second or even less, and even such structure as thin as a hair would be duplicated perfectly, with fewer internal flaws.

Key performance parameter range of modern high pressure die casting machines:

| Parameter | Typical range | Technical significance and application |

| Clamping Force (Tonnes) | 100-5000+(up to 10000+for large machines). | Determine the maximum projected area and structural complexity of the component. Automotive structural components typically require>3500 tons. |

| Maximum Injection Speed (m/s) | 4-10 (the air velocity can reach higher). | Ensure complete filling of thin-walled and complex features, which affects surface quality and internal defects. |

| Maximum Injection Pressure (MPa) | 50-150+(can be higher during the boost phase). | Provide filling power and compression pressure. The application pressure of vacuum die casting is often greater than 90 MPa. |

| Dry Cycle Time (s) | <2.0-10.0+(depending on machine size). | Reflecting the efficiency of the machine motion system and affecting the overall production rhythm. |

Data source: NADCA Standards and Industry Practices of the North American Die Casting Association.

High-pressure die casting relies on the clamping system to provide a solid "fortress", and the injection system plays the role of a precise "shooter". The two work perfectly together to turn liquid aluminum intoprecisely shaped parts.

"We at JS are thinking about how to make this "super injector" more accurate, faster, and better, and produce zero-defect, high-performance die castings. If you have high-demand, complex-shaped aluminum alloy parts, don't hesitate to contact JS directly to chat!"

Step by Step: Lightning Cycle of High Pressure Casting

As an engineer who has been working on the front line of high pressure casting for a long time at JS, I will take you through the manufacturing process that we have every day in our workshop -the core cycle of aluminum high pressure casting.From aluminum water to parts, the whole process is as fast as lightning, usually completed within tens of seconds, highly automated and full of precise control.

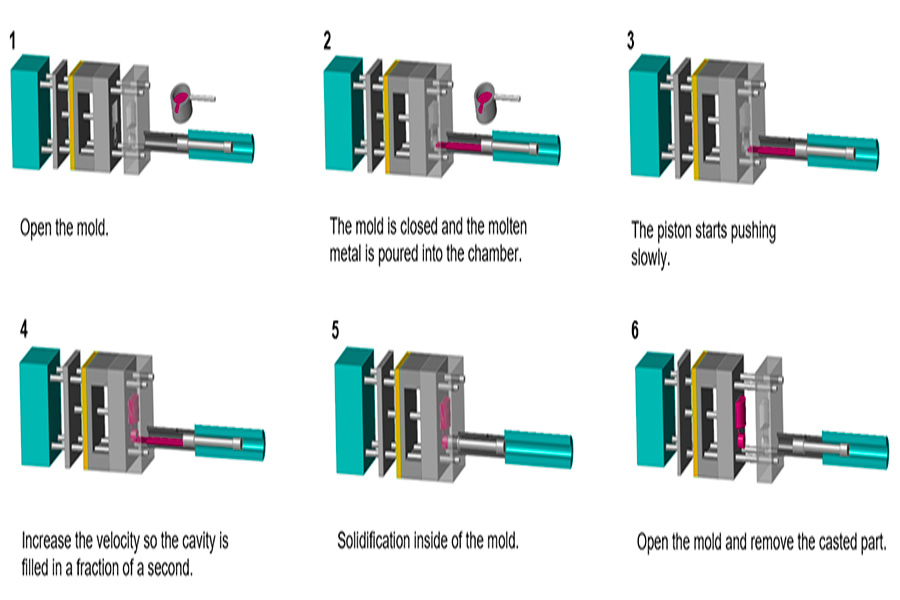

Step 1: Spraying and mold closing

After the mold is opened, the robot arm will immediatelyspray a layer of special coating(release agent) on the surface of the cavity.

This coating has a great effect:

- First, it allows the solidified parts to be demolded smoothly, just like applying a layer of "non-stick coating" to the mold.

- Second, it helps to remove the heat from the mold surface to prevent local overheating from affecting the quality of the parts and the life of the mold.

After spraying, the huge clamping system immediately exerts force, and the two halves ofthe precision steel moldare locked with hundreds or even thousands of tons of clamping force. This space must be strong enough to withstand the huge impact of the high-speed injection of the lower metal liquid.

Step 2: Injection

The metering spoon accurately measures the molten liquid aluminum alloy into the injection sleeve (barrel).

The injection punch starts to move, and the process is very finicky:

- Slow stage: The punch is first accelerated with a lower speed, the purpose is to push the metal liquid into the ingate of the mold, and exhaust the air in the sleeve and runner at the same time to reduce air entrainment. This is the first step for ensuring the internal quality of the part.

- High speed stage: After the metal liquid reaches the ingate, the punch will speed up to a velocity of several meters or even more than ten meters per second at one time! Fill all the corners of the entire mold cavity with high-speed and high-pressure aluminum liquid exactly replicating the structure of the mold.

Step 3: Boosting and Cooling

As soon as the cavity is filled, the die-casting machine delivers a temporary boost pressure (also known as supplementary pressure) higher than the injection pressure.

This brief secondary pressurization is absolutely essential:

- It pressurizes the metal freezing and contracting tightly, pushes out possible shrinkage cavities, and pressurizes the metal structure, thus improving the strength and density of the resultingaluminum high pressure casting parts.

- Meanwhile, the cooling water pipe inside the mold begins to operate at its best, and circulating cooling water quickly draws out the heat of the casting and mold. Precise temperature control regulates the rate and uniformity of casting solidification, which has a direct effect on the dimension accuracy and internal quality of the part. Cooling time generally ranges from a few seconds to tens of seconds.

Step 4: Ejection and opening of the mold

When, after cooling and solidification of the casting inside the mold to a satisfactory extent to retain its shape, the clamping force is released and the mold opens.

Next,the ejector pin systemin the mold moves to eject the molded part from the mold cavity. The ejected part usually falls automatically onto the conveyor belt or receiving device and enters the next link.

Step 5: Part finishing

The part that has just been ejected, the material handle and gate connected to the pouring system, may have a small amount of overflowed metal edges. These are necessary parts in the filling process, but not required for the final product.

We will remove these excess parts, which may be stamped out by an automated trimming machine or manually trimmed and polished with tools. After this finishing process, an aluminium high pressure casting is truly completed and can be sent forsubsequent processing(such as CNC, surface treatment) or assembly.

The precision cycle of high pressure die casting:spraying, mold closing, injection, pressurized cooling, mold opening and ejection, finishing, are linked together, reflecting the essence of engineering control.

"At JS, I ensure that each aluminum high pressure casting parts has excellent quality and consistency through strict process control and experience accumulation. If you are looking for efficient and reliable high-pressure die-casting solutions to manufacture complex and precise aluminum alloy parts, welcome to have an in-depth discussion with the JS team."

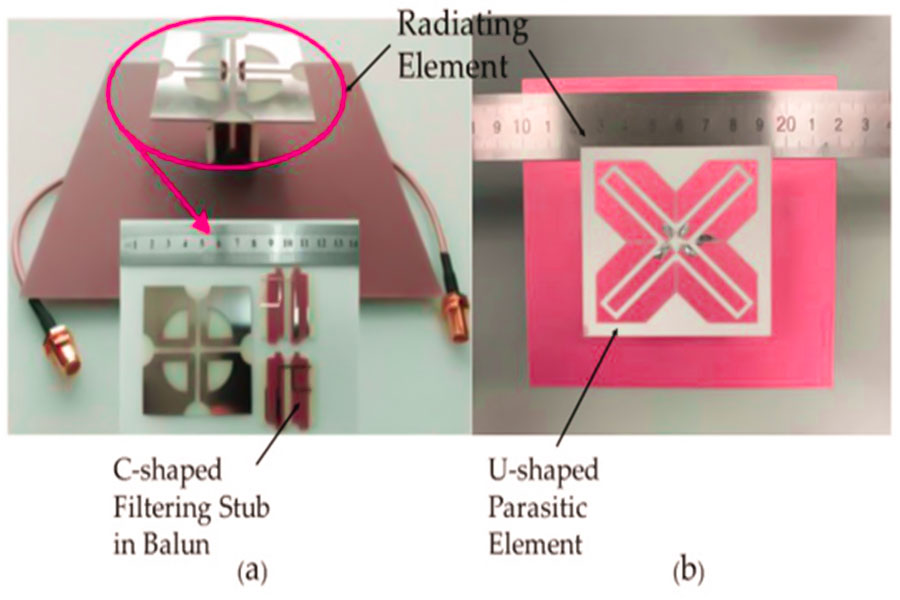

Actual Combat Case Analysis: Manufacturing Lightweight, High Heat Dissipation Filter Housing for 5G Base Stations

5G base stations are getting smaller and smaller, but the requirements are getting higher and higher, especially the core component - the filter housing. It has to be like a precision work of art, light as a feather, fast heat dissipation, and mass production. This is where high-pressure die-casting can show its strength.

Customer challenge: Make a 5G housing that is both light and complex, and mass-produced in millions!

Background:A global communications giant approached us to develop a new filter housing for their latest 5G base station.

What is the main difficulty?

- Design limit: The housing wall thickness is required to be less than 1.5 mm, and it is covered with tall and thin heat dissipation fins.

- CNC machining does not work: Want to use a whole piece ofaluminum for milling? The processing time is too long, the tool wear is huge, and the cost per piece is too high to bear, which is completely unable to meet the demand of millions of pieces per year.

- Limitations of ordinary casting: The metal liquid inlow pressure castingflows relatively slowly and the applied pressure is also low. When facing those thin and deep (fin gap) cavity areas, the front end of the metal liquid may begin to solidify before it flows completely to the end. This will inevitably lead to incomplete filling.

JS Solution: Advantageous application of high pressure casting aluminum technology

The customer's core demand is clear: tomass produce thin-walled partswith highly complex structures while ensuring ultra-low unit costs. High-Pressure Die Casting Aluminum Technology can perfectly meet these requirements!

Our response strategy:

(1) Technical route: Locking high-pressure die casting

The parts have complex shapes, extremely thin walls, and need to be produced in large quantities. Therefore, high-pressure casting is the only viable option. It relies on high speed and high pressure to press the molten metal into the mold, specifically solving the difficult molding problems such as thin walls and deep cavities.

(2)Material: Choose the right aluminum alloy

We usehigh-flow aluminum materialssimilar to ADC12. After this alloy is melted into liquid, it flows as easily as water and can perfectly fill complex thin-walled structures. The resulting parts are both strong and light.

(3) Mold: The core of the core

The mold determines whether it can be evenly mass-produced. We pay a lot of effort to the mold flow analysis and optimize the pouring system to ensure that the aluminum liquid can flow in high speed and stable flowing into the entire mold cavity, especially those tiny heat sink gaps.

In order to prevent bubbles from being generated during high-pressure casting of aluminum heat sinks and ensure the integrity and effect of the heat sink, the mold is specially equipped with a vacuum function. This device can instantly remove the air in the mold cavity before the metal is injected, greatly reducing the risk of bubbles being involved. This is the key to using high pressure casting aluminium well.

(4) Automation: Guaranteed to be fast and good

We have equipped customers with afully automatic production line. The robot is responsible for all steps such as spraying release agent, taking parts, trimming, etc. This system can operate 24 hours a day, greatly reducing manual operations, ensuring that the quality of each part is equally good, and perfectly meeting the large quantities required by customers.

Final results: Breaking the constraints and serving global 5G construction

Dramatic moment:When the first sample came off the production line, the customer saw the paper-thin but intact heat sink fins, and their eyes grew wide with wonder. They had not expected that we could really do it!

Data confirmation:

- Single-piece production time: shortened from several hours of CNC processing to 45 seconds of die-casting!

- Single-piece cost: reduced by more than 90% compared to CNC solutions!

- Product qualification rate: as high as more than 99.5%, fully meeting customers' global scale delivery needs.

My suggestion:

If you are manufacturing something that is light, thin-walled, and intricate such as a maze, and you want to manufacture millions of them at low cost. Don't hesitate, high-pressure die casting is not only a fine choice, it may be your only way to an end. It turns the impossible into the possible, and it is fast, good, and cheap.

"The 5G shell product was completed with high pressure casting, which is fast, accurate, and economical. It perfectly solves the world problem of ultra-thin and complex mass production structures. If you are also interested in mass-producing similar high-difficulty, large-scale metal parts, I highly recommend that you learn more about high-pressure die casting. It may be your most valuable weapon to break through the bottle neck and dominate the market. Feel free to talk to our JS on how to help you make your dreams a reality!"

FAQ - Answer More of Your Questions about High Pressure Casting

1. What are the advantages and disadvantages of high pressure die casting?

Advantages:

When mass-producing, it is incredibly fast (one piece in tens of seconds), and the cost per piece can be kept very low. The parts are accurate in size and beautiful in surface, and many parts do not need secondary processing. The most important thing is that it can handle parts with particularly complex structures and thin walls, and thousands of them are the same.

Limitations:

The biggest limitation is the large initial mold investment, so it is not cost-effective to use it for small-scale production. In addition, because the molten metal is injected into the mold at high speed, it is easy to form tiny bubbles, so this type of parts is not suitable for enhanced heat treatment. Finally, the types of aluminum alloys that can be used for die casting are relatively limited, unlike other processing methods.

2. What materials are mainly used for high-pressure die casting?

High-pressure die casting is most commonly used for non-ferrous metals that are easy to flow.

- Aluminum alloy is the absolute main force, such as the commonly used ADC12, A380 and other grades, they have good fluidity and strength. For example, the 5G shell with complex heat sinks we made is a typical aluminum alloy high pressure casting part.

- Zinc alloys (such as Zamak 3, 5) are also very common, and are particularly suitable for small-sized parts with high surface requirements.

- Magnesium alloys are used for products that require extreme lightness (such as ultra-thin notebook shells). Although copper alloys can be used, they cause great damage to the mold and are rarely used in practice.

3. What is the core difference between high-pressure die casting and low-pressure casting?

The key lies in how the molten metal enters the mold and how fast it is.

- High pressure casting relies on huge mechanical pressure to inject molten metal into the mold cavity at high speed within a few seconds. This speed is extremely fast and can make very thin and complex shapes, but it is also easy to wrap gas into the parts at high speed.

- Low pressure casting is much gentler. It relies on stable air pressure at the bottom to "support" the molten metal into the mold from bottom to top steadily. The filling is slow and orderly, and the inside of the part is denser and stronger, but it cannot make particularly thin or fine structures, and the speed is much slower.

Summary

High pressure casting, this technology can really be calledthe best high pressure casting solutionfor modern mass production! The most amazing thing is that a set of precision molds can be used to exchange for fast production speed, extremely high part precision, and can also handle those particularly complex shapes. Think about it, the mobile phones we use every day, the cars we drive, and various communication equipment can be made quickly, well and cheaply. High pressure die casting has played an indispensable role behind it. It is a manufacturing philosophy that wins with efficiency and scale.

So, what about your products?

- Are you also having a headache?Can't reduce the cost? The parts are too heavy to affect the performance? The design is too complicated to find a suitable production method?

- Do you want to find a reliable partner?Turn your design drawings into thousands of high-quality, lightweight and strong aluminum alloy die castings?

Find us!

The JS team is not just a high pressure casting company.We can help you from start to finish:

- How to design the mold most reasonably and durable?

- Which aluminum alloy material has the best performance and the best cost?

- Finally, how can we use automated production lines to produce efficiently and stably?

Feel free to upload your design at any time!

Our team of engineers will immediately provide you with a professional mold and parts quotation. Let us use the speed and precision of high-pressure die casting to help your product get a head start in the market!

Disclaimer

The contents of this page are for informational purposes only.JS seriesThere are no representations or warranties, express or implied, as to the accuracy, completeness or validity of the information. It should not be inferred that a third-party supplier or manufacturer will provide performance parameters, geometric tolerances, specific design characteristics, material quality and type or workmanship through the Longsheng Network. It's the buyer's responsibilityRequire parts quotationIdentify specific requirements for these sections.Please contact us for more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. We have over 20 years of experience with over 5,000 customers, and we focus on high precisionCNC machining,Sheet metal manufacturing,3D printing,Injection molding,Metal stamping,and other one-stop manufacturing services.

Our factory is equipped with over 100 state-of-the-art 5-axis machining centers, ISO 9001:2015 certified. We provide fast, efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it is small volume production or large-scale customization, we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyThis means selection efficiency, quality and professionalism.

To learn more, visit our website:jsrpm.com

Resource