High pressure casting is a widely used method for efficiently producing metal parts. Its process is actually very direct: first heat and melt the metal into a liquid state, and then use very high pressure to quickly press it into a steel mold. The metal quickly cools and hardens in this mold, and then the part can be taken out and the entire casting is completed.

The high pressure casting process is particularly suitable for producing parts with complex shapes and very precise dimensional requirements. Compared with many other casting methods, it wastes less material, especiallywhen large-scale production is required, it is particularly cost-effective.It also accommodates a very large variety of metal materials such as regular aluminum alloys, zinc alloys, and magnesium alloys.

Next, we will also introduce its specific working principle, what factors should be considered in design, and what are the key steps in actual operation.

What is high pressure casting?

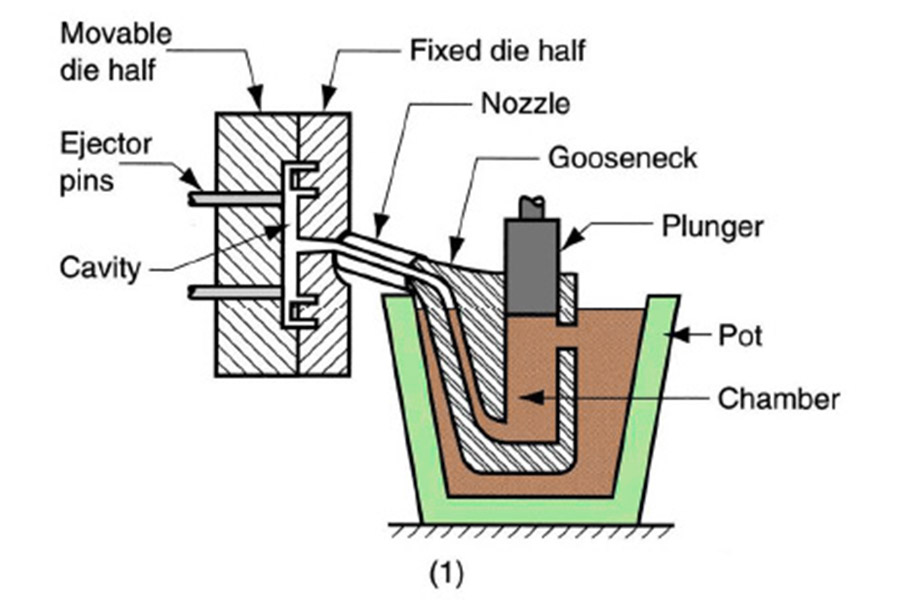

High pressure casting is to melt and melt such alloys such as aluminum, zinc, magnesium or copper into a liquid state. Then, use very high pressure to quickly force these molten metal liquids into a special steel mold. This steel mold is made of two extremely hard steel blocks. When they are put together, the gap in the middle is what the final part looks like. One of the steel molds is fixed, and the other can be moved open and closed.

After the molten metal quickly fills the entire mold cavity, the strong pressure does not disappear. It will continue to act and press the metal more tightly.Make the high pressure casting aluminium componentscompact in internal structure and tough in strength.

After the metal is completely cooled and solidified into a solid part, the mold will open.Now the small ejectoronthe mold willthrust outthe moldedpiece at this stage.Then, the mold closes again and prepares to start pouring the next part, so that the production can be circulated quickly.

Because of this high pressure, high speed and fast cycle, high pressure casting is particularly suitable for mass production of complex parts. High pressure, high speed, and continuous and fast production are the biggest differences between high pressure casting and other casting methods.

Why is aluminum high pressure casting generally chosen in the manufacturing industry?

1. High production efficiency

High pressure casting is very fast, andcan press the molten aluminum into the mold at high speed, and the production cycle time of a single part is very short.That is, the machine can producea large number ofparts per minute.This high-yield feature makes it very suitable for things that need to be produced in large quantities, such as auto parts and electronic product housings.

2. Good quality of parts

The parts made by this method are very accurate in size and very smooth in surface. In this way, there is much less need for subsequent polishing or other surface treatments such as electroplating. At the same time, the metal structure inside the part is very tight, which ensures that it has good mechanical strength, overall uniformity, and the size will not be easily deformed.

3. Thin parts

High pressure casting has a lot of pressure, which can press aluminum into very small mold gaps. Therefore,it can stably produce parts with very thin walls, and some wall thicknesses can even be less than 0.5 mm. The direct benefit is that it can reduce the weight of the product.

4. One-time molding

The molds for high-pressure casting can be designed to be quite complex, so parts with fine details, complex geometric shapes, and even small things embedded in them (such as threaded bushings) can be made in one casting.This saves a lot of subsequent assembly stepsand there is no need to make too many small parts.

5.Mould life cycle islong

Although the molds for high-pressure casting are indeed expensive at the beginning, they have a very long service life and can be used continuously for hundreds of thousands or even millions of times. In addition, it has a high production speed and a high qualified product rate. When the production batch is large, the mold cost per part is very low. Therefore, when making large batches, the cost advantage of this method is very obvious.

What is high pressure castingprocess flow?

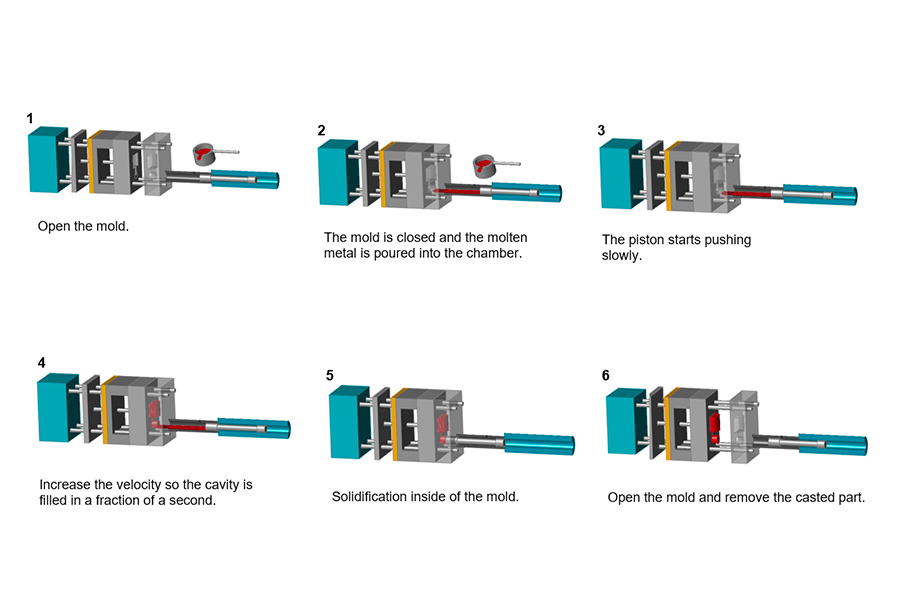

The core of high-pressure casting is to highly and quickly pressure-inject molten metal into the mould to produce parts with complex shapes. Its normal process consists of the following key steps in order:

1. Mold preparation and lubrication

Before each cycle starts, the operator needs to carefully prepare the aluminum high pressure casting mould.The key is to evenly spray a layer of special lubricant, also known as a release agent, on the surface of the mold cavity. This layer of lubricant can effectively control the mold temperature, form an isolation film between the metal and the mold surface, ensure that the subsequent castings can be smoothly ejected, and protect the mold to extend its service life.

2. Molten metal injection

The prepared molten metal, which is aluminum alloy liquid for aluminum die casting, is transferred to the injection chamber of the die casting machine. In aluminium high pressure casting,the cold chamber die casting process is mainly used,and the molten metal is scooped or automatically poured into a horizontally placed cold chamber sleeve.

Next, a powerful hydraulic plunger is quickly advanced, and the molten metal is injected into the tightly closed mold cavity at high speed in a very short time at extremely high pressure, usually between 1,500 and 25,000 PSI. The huge clamping force, which can reach thousands of tons, ensures that the mold does not move at high pressure.

Cold chamber die casting vs. hot chamber die casting:

| Comparison items | Cold chamber die casting | Hot chamber die casting |

| Mainly applicable to alloys | Aluminum alloy, magnesium alloy, copper alloy. | Zinc alloy, magnesium alloy, lead, tin. |

| Injection pressure range | Very high: 10000-25000 PSI. | Lower: 1500-6000 PSI. |

| Injection velocity | Extremely high: 5-45 m/s. | Medium to high: 0.5-7 m/s. |

| Machine cycle time | Slow: 15-120s. | Faster: 3-30s. |

| Maximum component weight | Up to 50 kg+(aluminum alloy). | Generally ≤ 5 kg (zinc alloy). |

| Minimum wall thickness accessibility | 0.7 - 1.2 mm. | 0.3 - 0.8 mm. |

| Metal transfer method | Manual/automatic scooping and pouring of cold chamber sleeves from independent furnaces are required. | The injection system is immersed in the machine's built-in furnace and automatically feeds materials. |

3. Holding pressure and solidification

The molten metal fills every corner of the mold instantly under high pressure, completely replicating the shape of the mold. Subsequently, the pressure will continue to be maintained for a period of time to allow the metal to cool and solidify in the mold. This continuous high pressure state is critical to obtaining dense, defect-free castings. It can squeeze internal bubbles and compensate for the shrinkage of the metal when it cools.

4. Mold opening and casting ejection

Now, the casting will be fully solidified in the mold and possess sufficient strength, the die-casting machine will open the mold. Now, the ejection mechanism mounted on the movable portion of the mold (moving mold),usually an ejector pin or ejector pin, will start to move and will start pushing the fully formed casting out of the mold cavity.

5. Removal and cleaning

The ejected casting is taken out or transported away by automated equipment. At the same time, the operator needs to clean up the excess metal material remaining around the mold parting surface and cavity, such as waste from the pouring system and overflow tank. These wastes will be collected and recycled.The mold canthenbere-setand ready forreuse inthe next die-castingoperation after cleaning.

Which metals are suitable for high pressure casting?

Main metals suitable for high pressure casting:

| Metal type | Process adaptability | Liquidity characteristics | Core advantages | Typical applications |

| Aluminum alloy | Cold Chamber Die Casting | Good liquidity | The most widely used. Capable of efficiently producing lightweight and structurally complex parts. | Aluminum high pressure casting parts such as automotive components and home appliance parts. |

| Zinc alloy | Hot chamber die casting | Excellent liquidity | Good surface smoothness, precise dimensions, and high strength. | Hardware accessories, decorative parts, small precision components. |

| Magnesium alloy | Cold or hot chamber die casting | Excellent liquidity | The lightest engineering metal. | Fields that pursue ultimate lightweight, such as laptop casings and camera frames. |

| Copper alloy (such as brass) | Cold Chamber Die Casting | Liquidity is still acceptable | Wear resistant, corrosion-resistant, and have good conductivity. | Gears, bearings, electrical connectors. |

What is the core equipment of high pressure casting?

1. Injection system

This is the core power source of the whole equipment. The core component is a large hydraulic cylinder with strong output force, with a very strong push rod.

- Its core task: to push the molten high-temperature aluminum water into the mold cavity (cavity) at a very fast speed and with great force.

- Key point: The speed of this push and the huge pressure applied are very important.They ensure that the aluminum water can quickly and completely fill every tiny corner of the mold. At the same time, this system must react quickly, and the control of speed and pressure must be very precise, so as to ensure that good parts are made.

2. Clamping mechanism

This mechanism is specifically responsible for closing the two halves of the mold tightly and locking them with great force to prevent them from separating.

- The role is very critical: when high-pressure aluminum water is injected into the mold, it will generate huge pressure to open the mold. If the clamping mechanism is not strong enough or unstable, the aluminum will leak out and burrs will appear. In serious cases, the equipment may be damaged or even an accident may occur.

- Core requirements: This locking force must be very reliable and able to withstand the impact of the entire aluminum extrusion process and the huge pressure inside the mold.

3. High-pressure mold

This is aluminum high pressure casting tooling, which is the heart of the entire technology. It is usually made of special steel that is particularly hard and resistant to high temperatures, and its own precision is very high. The cavity engraved in the mold is the shape of the part to be made.

- Complex internal design: There are cooling channels designed inside to allow the parts to cool and harden quickly. There are ejector components that can be pushed out after the parts are hardened. There are also carefully designed aluminum water flow channels that control the route and method of aluminum water flowing into the mold.

- Importance: The level of mold design directly determines whether the parts can be successfully made, the quality is good, and the production speed is fast.

4. Aluminum molten metal melting and feeding equipment

This set of equipment is responsible for melting the aluminum alloy block into uniform aluminum molten metal in advance and keeping it at the appropriate temperature.

- Especially for cold chamber die casting (most common): It is also necessary to transfer the hot aluminum molten metal with the appropriate temperature in the furnace to the barrel in front of the injection system in a timely and accurate manner.

- Feeding method: This transfer can be completed by manual operation, but now it is more common to use various automatic feeding devices.

- Principal guarantee: Ensure that the temperature of the aluminum molten metal fed in is steady, the amount is proper, and there is no dirt added to it.

This is a particularly basic and important step for the smooth extrusion of good parts later.A good automatic feeding systemis a key helper to ensure smooth and efficient production.

What typical parts can be manufactured by high pressure casting?

1. Aerospace parts

The requirements for aircraft parts are very high, and safety and reliability are the first priority.

High-pressure casting can make very precise, complex and lightweight parts with particularly good quality.

In addition, it can produce stably and the size is accurate and consistent, which just meets the needs of strict control of aircraft manufacturing.

2. Medical equipment parts

Medical equipment has extremely strict requirements on the precision and accuracy of parts,which is related to the performance and safety of the equipment.

High-precision components produced by high-pressure die casting are needed in high-tech equipment such as ultrasonic equipment, pacemakers, dialysis machines, and medical robots.

These parts are made light and more convenient for medical staff to use in wards or operating rooms.

3. Auto parts

In order to save fuel and reduce emissions, automobile factories have been trying to reduce the weight of cars.

High-pressure casting is particularly good at producing aluminum alloy high pressure casting part,such as engine cylinders, gearbox housings, oil pans, engine brackets, and crossbeams.

The parts made by this process are both strong and durable, and can meet the requirements of weight reduction, so they are very popular.

4. Electronic and electrical parts

Many parts in the electronics industry,such as housings, connectors, heat sinks, handles, and knobs, are produced by high-pressure die casting.

It is chosen because the parts made are accurate in size, can be complex in shape (such as thin-walled parts), and are strong and durable, and the cost is relatively cost-effective.

Similar to zinc alloys, aluminum alloys are also widely used in the manufacturing of various components in the electronics industry.

What key factors should be prioritized in mold design?

When designing high-pressure casting molds, in order to ensure efficient production and high-quality parts, the following key factors should be given priority:

1. Part style

The part you want to make, what shape it looks like, how big it is, whether the structure is simple or extremely complex, all determine how the mold should be made. The more complex the part, the more mold action mechanisms (such as sliders, inclined tops, and movable cores) are required, so that complex features, holes or undercuts can be achieved.

2. Mold material properties

The mold deals with hot molten metal and extremely high pressure, so the steel used to make it must withstand high temperatures and high pressures, and not be easily deformed or worn.Suitable materials are the key prerequisite for long mold life and stable production.

3. Design of runner and gating system

Where the molten metal enters the mold and the route it takes in the mold cavity, this is a highly important design

This runner system can ensure that the molten metal fills the entire mold cavity quickly, smoothly and sequentially, effectively reducing casting problems such as voids and cracks, which is a key link in achieving the best high pressure casting effect.

4. Efficiency of cooling system

Thecooling water channel buried in the mold body playsa decisive role in production efficiency and part quality. They mainly help us stabilize and control the temperature of the mold so that the molten metal can cool and harden evenly according to our plan. Efficient temperature control helps stabilize part quality and shorten production cycle.

5. Reliability of ejection system

After the part has cooled and hardened, it will need to rely on the ejection system (ejector, ejector plate, etc.) to pull it out of the mold cavity unharmed. The position, number and thrust design of the ejector need to be in a balanced manner so that the part demolds smoothly and does not create part deformation or surface damage due to excessive ejection force.

6. Exhaust system

When the molten metal rushes into the mold cavity, the original air inside and the gas generated by the metal itself must have an outlet to be discharged, otherwise bubbles will be left in the parts or the parts will turn black. Open the exhaust groove at the appropriate position of the mold, and sometimes even set up a special overflow groove to collect the excess metal with gas. It's an essential design to ensure thequalityof the casting.

7. Surface quality of parts

The surface characteristics required for the final part (such as smooth surface, leather grain/etching, special texture) directly determine the surface treatment process of the mold cavity. This includes a specific polishing grade, surface etching texture depth or the selection of special coating materials to meet the final appearance requirements.

Summary

High pressure casting has been widely used in the large-scale production of thin metal shell products.The molten metal is poured into the mold at a very fast speed and then formed. So it can quickly and well produce many products we use in daily life, such as auto parts, mobile phone cases, etc.

Of course, it also has challenges such as high mold cost and possible internal pores. However, if you are a large-scale production enterprise, it is very important tochoose an experienced and reliable high pressure casting company. Our JS company is an expert in this field. With advanced equipment and strict quality control, we are committed to providing customers with high-pressure casting solutions that combine efficiency and quality, and continue to consolidate its irreplaceable position in mass manufacturing.Choose JS, choose a reliable partner for efficient and precise manufacturing.

Disclaimer

The content of this page is for informational purposes only.JS SeriesNo representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. chooseJS TechnologyIt means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

FAQs

1. What role is played by the mould in the process of high-pressure casting?

Form with precision to the shape desired, withstand high-speed and high-pressure blow of molten metal, and speedily cool the solidified metal to form. Directly determine the final product's size accuracy, surface finish and production efficiency, and are an important tooling which is costly and significant.

2. What are the key advantages of high-pressure casting?

It can efficiently produce thin-walled, complex-shaped and precise-sized castings in large quantities, with high surface finish and high material utilization, which greatly reduces the cost of a single part, and is particularly suitable for large-scale manufacturing fields such as automobiles.

3. Whatisbetter than sand casting?

Theefficiency ofproduction isveryhigh and batch molding can becompleted in a short while. The cast size is morepreciseand the surface ismore smooth. Itcan also makemorethinandcomplicatedmetalparts(such asautomotive aluminum alloyparts), andsignificantly lowertherequirementfor post-processing.

4. How does the molten metalget intothe mold?

In high-pressure casting, the molten metal is quickly pressed into the mold through the injection system: the molten metal is first injected into the pressure chamber, and then pushed at high speed by the high-pressure driven piston (injection punch), and the closed mold cavity is instantly filled through the runner, and cooled and formed under high pressure.

Resource