Tintenstrahldrucktechnologie , 3D-Drucktechnologie überwindet traditionelle Prozessbeschränkungen, erreicht komplexe Strukturen und schnelle Prototyping-Entwicklung und bietet innovative Lösungen für personalisierte, skalierbare Produktion. Kombination mit einem Stlop-Profik-Abfaltungsdienst. Pionierarbeit ein neues Paradigma der funktionellen Verbundgradientenherstellung.

Was ist die grundlegende Definition des 3D-Drucks?

3D-Pressing (additive Herstellung) ist ein digitales Molekular-Molkulations-Molekular-Molekular-Molekular-Molekular-Molekular-Molekular-Molekular-Molekular-Molekular-Molekular-Molekular-Molekular-Molekular-Molekular-Molekular-Molekular-Molekular-Molekulations-Rezination. in eine physikalische Komponente durch präzise Photopolymerisation oder heiße Schmelzlaminierung. Dies hat durch den phyellierenden Data-V-7b79c893 =" "> " Data-V-7b79c893 = "". Realisierte die organische Kombination aus biomimetischer Morphologie und Funktion.

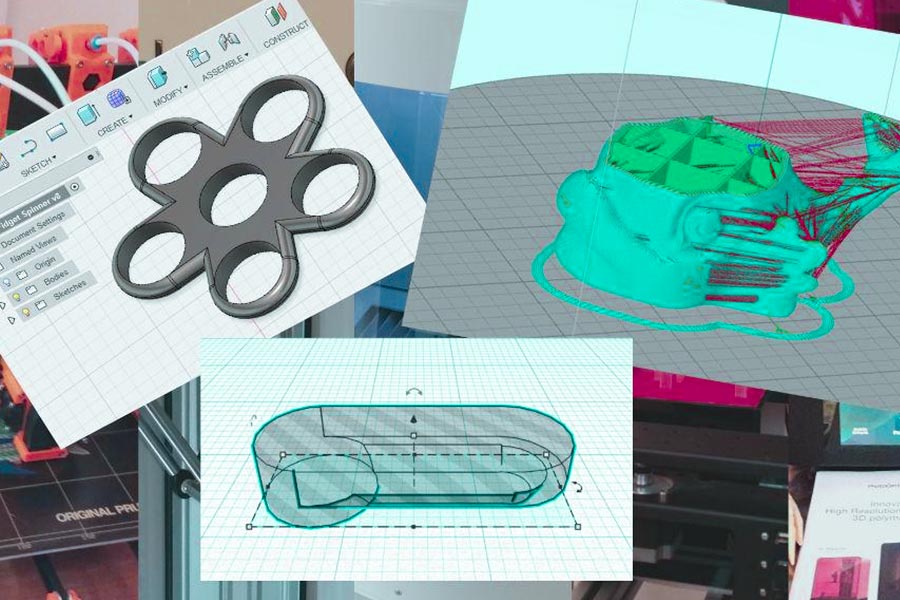

Technisch gesehen basiert 3Dprinting auf Prozesse wie FDM, SLA oder SLS, wodurch multimaternische Verbundstrukturen möglich sind. Diese doppelte Innovation. Die Dienste. Die Dienste. Die Dienste. Die Dienste, die in der Technologie gedrückt wurde. Anpassung.

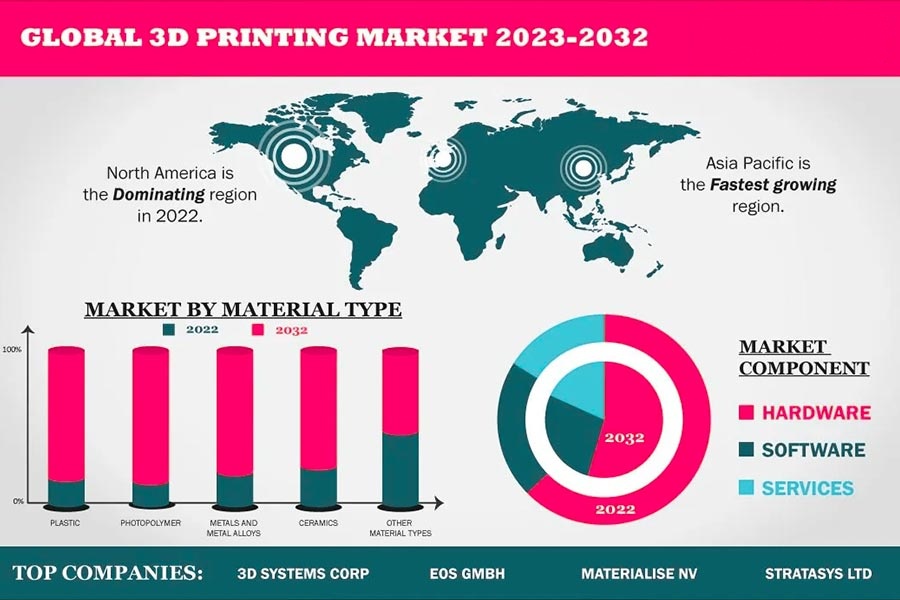

Wie entwickelt sich der globale 3D-Druckmarkt?

Das schnelle Wachstum des 3D-Drucks fördert das weltweit Expanding-Global-Vermarkten. 1. Global Scale und Wachstumstrend

Nach der 2023 3D-Druckmodelle Berücksichtigen Sie über 35% der Design- und Fertigungsanforderungen, einschließlich der Entwicklung von industriellen Prototypen, medizinischen Implantaten und Konsumgütern. Printing services, a core business strategy for businesses, contribute 58% of revenue and reduce operating costs through angetriebene Produktion und Small-Scale-Anpassung .

2. GloBal 3D-Druckmarktgröße Daten (2022-2027)

| Marktgröße (in Milliarden von US-Dollar) | jährliche Wachstumsrate (CAGR) | Kernwachstumsbereiche | Schlüsselantriebsfaktoren | |

| 2022 | 240 | 15,3% | Luft- und Raumfahrt, Medizin, Automobile. | Die Nachfrage nach Metall-3D-Druckmodellen ist explodiert. |

| 2023 | 276 | 15,3% | Metalldruck, Zahnmodelle. | Werbung für Druckdienste. |

| 2025 | 375 | 16% | Intelligente Fertigung, Gebäudemodelle. | Durchbrüche in multi-materiellen 3D-Druckmodellen. |

| 2027 | 500 | 15,3% | Bioprinting und personalisierte Konsumgüterprodukte. | Cloud-Druckdienst Erweiterung. |

3. segmentierte Märkte und regionale Verteilung

By Technology Type:

Metall 3D-Druck (35%):

- Kernbereiche: Luft- und Raumfahrt (85% des Metalldruckmarktes), Luftfahrtmotor-Brennstoffdüsen (25% Gewichtsreduzierung, 5 Erhöhung der Lebensdauer), wie Flugzeugstrukturen von Titanlegierungen führen.

- Technische Hindernisse: Technologische Durchbrüche wie ein Multi-Laser-Kooperationssintern (z. B. EOS M400) und Elektronenstrahlfusion (EBM) haben die großqualifizierte Sm-scale-Produktion, aber die komplexen topologischen Strukturen, aber die komplexen Topologischen Strukturen ($ 2 Millionen) haben 2 Millionen/$ 2 Mio. $ 2 Mio. $ $ $ $ $ $ $ $ $ $ $ $ $ ermittelt. Eintrag.

Polymer 3D-Druck (40%):

- Consumer Electronics: Die Polyjet-Technologie kann wasserdichte Strukturen für Mobiltelefone (Genauigkeit ± 0,05 mm) produzieren, die 32% der Verbraucherelektronikbefehle darstellen.

- Medizinische Anpassung: unterstützt Massenproduktion unsichtbare orthodontische Modelle.

- Schnellprototyping: Industrielle Entwurfszyklen können mit 70% unter Verwendung parametrischer Konstruktionswerkzeuge komprimiert werden, und Prototypen können innerhalb von 48 Stunden geliefert werden.

- Medizinische Anpassung: unterstützt Massenproduktion unsichtbare orthodontische Modelle.

| Fläche | Marktgröße 2022 (in Milliarden von US-Dollar) | Hauptwachstumstreiber |

| Nordamerika | 90 | Luft- und Raumfahrt und Automobilherstellung. |

| Europa | 75 | Medizinische Implantate, Gebäudemodelle. |

| asiatisch-pazifik | 60 | Elektronische Produkte, Zahnanpassung. |

| Andere Regionen | 15 | Bildung und kulturelle und kreative Produkte. |

4. zukünftige Wachstumstreiber

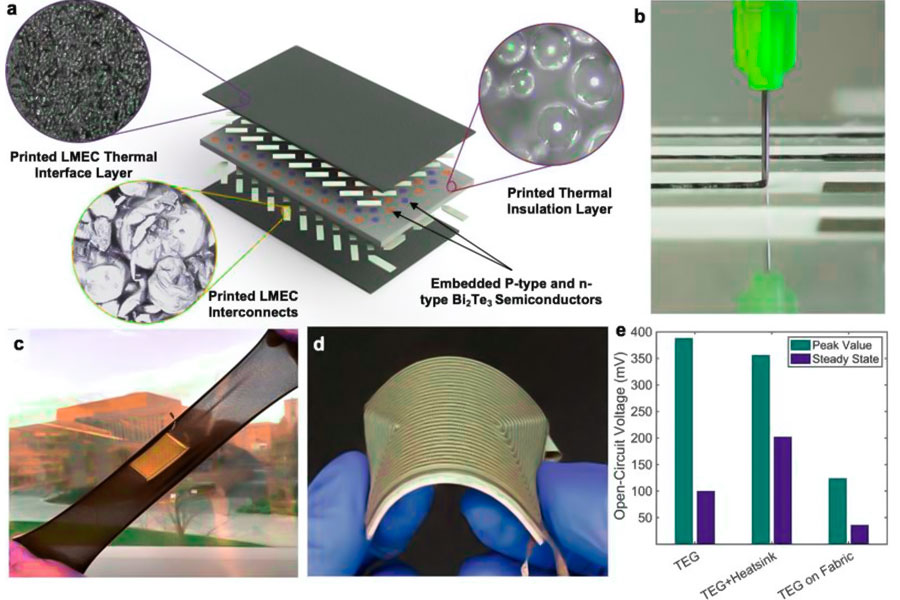

- technologische Iteration: Multi-Material 3D-Druckmodelle Antriebsmassenproduktion komplexer funktionaler Bestandteile wie bioprintierte Gewebe.

- Service-Modus-Upgrade: 3D-Druckdienste integrieren Sie AI-Design-Tools, um den Prozess vom Modell zu fertigen Produkten zu automatisieren.

- Richtlinienunterstützung: Occidental Industry 4.0 Pläne zur weiter

Was sind die Herausforderungen und Einschränkungen des 3D-Drucks?

1. Data-Len = "20" Data-V-7b79c893 = ""> Materialbeschränkungen

Wenn der für das 3D-Druckmodell verfügbare Materialiensbereich, insbesondere in Hochleistungsfeldern, begrenzt ist.

2. Data-Len = "35" Daten-V-7b79c893 = ""> Probleme mit der Genauigkeit und der Oberflächenqualität

Trotz der technologischen Fortschritte wird die Genauigkeit des 3D-Druckmodells immer noch durch die Auflösung der Geräte und die Schichtdicke beeinflusst. für Beispiele Fdm (molten-v-7b79c893 Erzeugen Sie sichtbare Schichtmuster, während die Photopolymerisation (SLA) eine hohe Genauigkeit aufweist, aber eine unsachgemäße Wiederaufbereitung zu Oberflächenrauheit führen kann. Dies ist eine Herausforderung. href = "https://jsrpm.com/3d-printing"> erfordern die micron-scale precision wie Miniaturzähne.

3. Data-V-7B79C893 = ""> Entwurfsbeschränkungen komplexer Strukturen

wob Komponenten, die auf Stützstrukturen angewiesen sind, die Entwurfskomplexität und Wiederaufbereitung erschweren. If the middle support is not well designed, it may lead to Verformung oder Oberflächendefekte.

4. Data-Len = "32" Data-V-7b79c893 = ""> Produktionsgeschwindigkeit und Kostenprobleme

5. Data-Len = "41" Data-V-7B79C893 = ""> Mangel an Standardisierung und Zertifizierung

Der Industriesektor hat strenge Materialleistung und Sicherheitsstandards, aber das Fehlen eines einheitlichen Zertifizierungssystems für Prozessparameter für 3D-Printemodell macht die Kommerzialisierung von kommerziellem Kommerzialisierung schwierig.

6. Data-Len = "34" Data-V-7b79c893 = ""> stark abhängig von der Wiederaufbereitung Die meisten 3D-Druckmodell benötigen Schleifen, Polieren oder Wärmebehandlung, um die endgültigen Leistungsanforderungen zu erfüllen. für Beispiels. und Kalibrierung mechanischer Eigenschaften, während Harzmodelle Reinigung und sekundäre Heilung erfordern, was die Vorlaufzeit erheblich verlängert.

Abfall von 3D-Prinzips ist schwer zu recyceln. Wie wird der 3D-Druck zum Prototyping verwendet?

1. Data-Len = "37" Data-V-7B79C893 = ""> Rapid Iteration and Design Validierung 2.p Recision-Prototyp 3.Material Diversity Adaptation 4. Low-Versuch und Fehlerkosten 5.Formation of complex complex structures 6.Green manufacturing practices 1.Medical and Biotechnology Application scenarios: Customized implants, prostheses, dental models, surgical guides, etc. JS technology association: 2.Automotive and Aerospace Application scenarios: Lightweight components, prototype validation, complex structural components (such as turbine blades). JS technology association: 3.Education and research Application scenarios: Teaching Mode, Research Laboratory Equipment, 3D Printing Technology Research and Development. JS technology association: 4.Industrial manufacturing Application scenarios: Mold inserts, fixtures, automation equipment components. JS technology association: Real-time application analysis of JS Consumer electronics industry: Cooling components for smart wearables Application scenario: Design an integrated graphene heat sink for a brand of smartwatch to solve the problem of efficient heat conduction in small spaces. Technical difficulties: JS company solution: 1.Process selection 2.Design optimization 3.Quality control 4.Technical highlights 5.Achievements 1.Material innovation New high-performance metal alloys: Breakthroughs in biocompatible materials: Expansion of Composites Applications: 2.Technological breakthroughs 3.Extension of application In the medical field: Aerospace: 4.Sustainable technology 5.Frontier exploration 1.Automated process upgrades 2.Intelligent scheduling and resource management 3.Innovations in materials and processes 4.Standardization and lean production 5.Energy and equipment maintenance management The application of 3D printing technology has pushed the boundaries of traditional manufacturing, from lightweight smart wearable devices in the consumer electronics industry to precision parts maintenance and complex structural innovations in industrial equipment. Not only does the technology shorten product development and reduce customization costs, it also provides unprecedented solutions for the industry through the diversity of materials and process flexibility. A pioneer in 3D printing technology, JS is driving the transition 3D models printing from prototype validation to mass manufacturing with its high precision processing capability (e.g. ±0.005mm tolerance), multi-material compatibility and intelligent manufacturing processes. Whether personalized prosthetics in the medical field or abrasion-resistant coating repairs for industrial devices, 3D models printing is redefining manufacturing possibilities. The content on this page is for general reference only. JS Series makes no express or implied warranties regarding the accuracy, timeliness, or applicability of the information provided. Users should not assume that the product specifications, technical parameters, performance indicators, or quality commitments of third-party suppliers are completely consistent with the content displayed on this platform. The specific design feature, material standards, and process requirements of the product should be based on the actual order agreement. It is recommended that the purchaser proactively request a formal quotation and verify product details before the transaction. For further confirmation, please contact our customer service team for professional support. JS is an industry leading provider of customized manufacturing services, dedicated to providing customers with high-precision and high-efficiency one-stop manufacturing solutions. With over 20 years of industry experience, we have successfully provided professional CNC machining, sheet metal manufacturing, 3D printing, injection molding, metal stamping and other services to more than 5000 enterprises, covering multiple fields such as aerospace, medical, automotive, electronics, etc. We have a modern factory certified with ISO 9001:2015, equipped with over 100 advanced five axis machining centers to ensure that every product meets the highest quality standards. Our service network covers over 150 countries worldwide, providing 24-hour rapid response for both small-scale trial production and large-scale production, ensuring efficient progress of your project. Choosing JS Team means choosing manufacturing partners with excellent quality, precise delivery, and trustworthiness. 1.How to use 3D printing to customize prosthetics in the medical field? Through medical scanning modeling, biomaterial 3D printing and other methods, personalized prosthetics are designed to meet patients' needs accurately. 2.Can 3D printing produce complex mechanical parts? By using SLM and other technologies, complex metal parts such as aircraft engine blades and automobile transmission components can be manufactured directly, breaking through the limitation of traditional technology. 3.What parts can be 3D printing for cars? Cars can be 3D printed with lightweight components such as brackets and gears, interior parts, prototypes and tool fixtures to improve design freedom and productivity. 4.How can 3D printing help with school teaching? 3D printing supports students to build hands-on models, visualize abstract concepts, improve practical skills, and think creatively.

What industries are currently covered by 3D printing technology?

What are the latest developments in 3D printing technology?

How can JS achieve a 15% efficiency improvement in 3D printing?

Indikator

JS scheme

Other printing shops

Effizienzverbesserung

Equipment preparation time (single order)

8 minutes

20 minutes

+60%

Post processing time (per piece)

12 minutes

30 minutes

+58%

Indikator

JS scheme

Other printing shops

Effizienzverbesserung

Equipment utilization rate

82%

65%

+26%

Order delivery cycle

4.5 days

5.5 days

+18%

JS scheme

Other printing shops

Effizienzverbesserung

Material switching time (single order)

3 minutes

15 minutes

+80%

Single layer printing time (SLA)

3 seconds

6 seconds

+100%

JS scheme

Other printing shops

Effizienzverbesserung

Clamping time (single order)

5 minutes

15 minutes

+67%

Novice training cycle

1 day

3 days

+67%

JS scheme

Other printing shops

Effizienzverbesserung

Equipment downtime

2 hours/week

5 hours/week

+60%

Unit energy consumption cost

$0.8/hour

$1.2/hour

+33%

Summary

Disclaimer

JS Team

For more information, please visit the official website: jsrpm.comFAQs

Resources