In the last few years, the mechanical processing field has developed very quickly. Some of the machining processes and equipment that were formerly quite simple have become complicated and cumbersome to use and are gradually being replaced by more advanced technologies and equipment.

The 5 axis CNC machining center successfully simplifies the process, not only markedly improves accuracy, but also offers excellent stability and reproducibility, and the completed parts are almost identical.

But when it comes to 5 axis CNC machining, most individuals' first impression is actually that the technology is new, expensive, and complicated and difficult to comprehend. The purpose of this guide is to lead you to a greater understanding of the true situation in five-axis machining and familiarize you with the necessary information that you must know about this technology.

What is the basic definition of 5 axis CNC machining?

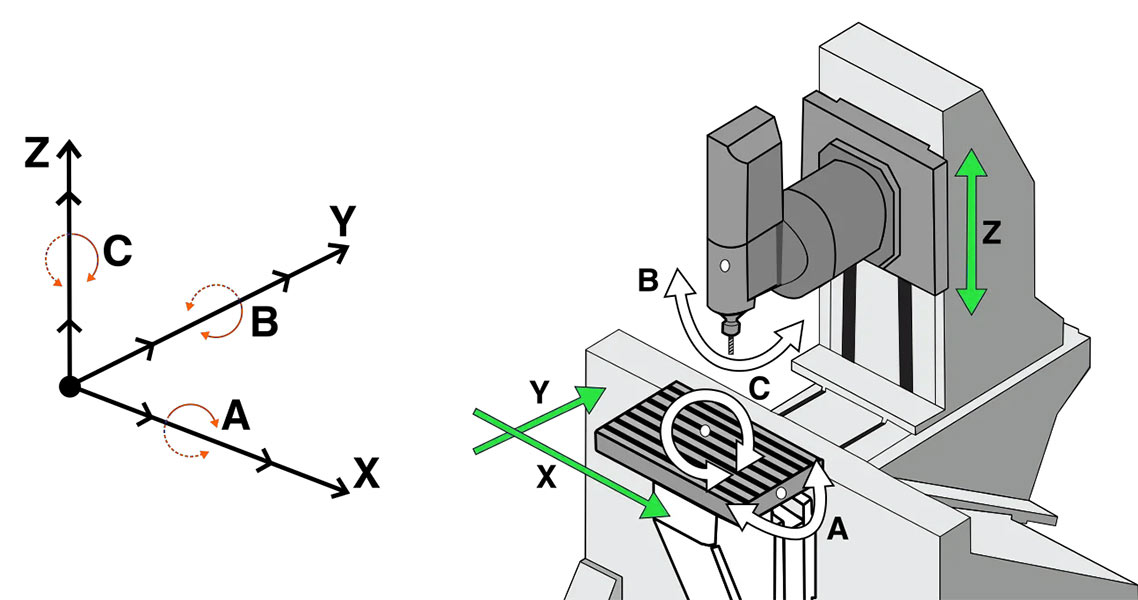

The 5 axis machining center is a powerful processing tool. Its core advantage is that it can simultaneously control five motion axes, the three linear axes (X, Y, Z) and two rotation axes (usually called A-axis and C-axis). This ability makes it much more capable than ordinary 3-axis machine tools, and it can process parts with particularly complex shapes and higher requirements, and its application range is also wider.

The more practical benefit is that it can greatly save the trouble of repeatedly clamping the workpiece. Think about it, in the past, to process a complex part, you may have to turn it over and over on the machine tool several times, which is not only time-consuming and labor-intensive, but also prone to errors. Now with five-axis machining, all processes can often be completed with one clamping. This not only improves efficiency, but also ensures better processing accuracy.

What materials are used for 5 axis CNC machining?

5 axis cnc machining service is a leading-edge machine process where the tool head can move freely in five directions. It is particularly suitable for machining parts of complex shapes and high precision requirements. A lot of various materials are used in this service, mainly because such materials can be easily cut and processed, and can make fine details. Let's consider the most common types of materials:

1.Metal materials

- This is the most used form in 5 axis cnc machining services. For example, aluminum alloy, stainless steel, titanium alloy and copper alloy are each extremely popular.

- The reason why is simple: Metal is strong and hardy, and 5 axis machining directly handles intricate curved surfaces or hole configurations.

- For example, titanium alloy has common usage in aerospace parts because of its strength and light weight, and five-axis machining services can cut out such curved shapes with precision without wasting any material.

2.Polymers and plastics

- Plastic materials are also common in 5 axis cnc machining services, especially engineering plastics such as ABS, nylon, and PEEK.

- The benefits are low weight, easy processing, and affordability. 5 axis CNC machining can machine thin plastic parts very quickly.

- For example, phone cases or parts of medical devices. Of course, plastics are less durable than metals, so they are more time-efficient to produce and can be applied for prototyping or small batches.

3.Composite materials

These like carbon fiber reinforced plastics (CFRP) or glass fiber are being more and more used in 5 axis CNC machining. Composite materials are very light and strong but a bit difficult to process. The advantage of 5 axis machining is that it can process such difficult-to-process materials, such as machining light car or drone parts without cracking the material surface.

4.Other materials

Apart from the above, 5 axis CNC machining sometimes also mills wood, foam or wax material. These materials are mostly used for prototyping or model testing because of quick processing and economical cost. For example, a complex model is cut out from foam and then the design is inspected before production of metal takes place.

What are the common uses of 5 axis CNC machining materials?

1.Aerospace parts manufacturing

5 axis CNC machining is very useful in the aerospace field. Key parts such as aircraft engine blades and fuselage brackets are often produced by it.

In terms of material selection, aluminum alloy and titanium alloy are frequent visitors here. They are light and strong enough, and are not easy to deform during processing, which is very important for aviation parts with extremely high precision requirements.

In order to handle particularly hard materials such as titanium alloys and meet the huge pressure that aircraft parts have to bear when flying at high altitudes, 5 axis cnc machining center manufacturers will specially adjust and optimize the machines. Only in this way can the parts processed be truly reliable.

This processing method is also popular on rocket parts. Five-axis machining can often process them in one go, saving the trouble of repeated clamping, saving both time and effort.

2.Medical equipment manufacturing

In the medical industry, 5 axis CNC machining center are good at precision manufacturing. High-demand implants such as artificial joints and complex surgical tools are often produced by them.

In terms of material selection, titanium alloys and specific medical-grade plastics are particularly commonly used. They are very compatible in the human body, that is, they are unlikely to cause rejection reactions in the body and are safe and reliable.

To give a practical example: In a recent project, JS machined a knee implant. Using five-axis technology, we can very accurately cut out a shape that is highly matched to the patient's bones. The direct benefit of this is that a lot of trouble for manual grinding and adjustment in the later stage is saved, and efficiency and accuracy are improved.

As a 5 axis cnc machining center manufacturers, we are well aware of the particularity of the medical field. In order to ensure a safer processing process and more reliable results, we have also developed customized software modules specifically for such applications.

3.Auto parts production

We often use 5 axis CNC machining to make parts such as automobile engine cylinders and gearbox gears. Materials such as aluminum alloys and steel are commonly used because they are wear-resistant and cheap. During the processing, the 5 axis machine can quickly switch angles and process the complex grooves inside the engine, improving overall efficiency.

| Material type | Common uses | Main advantage |

| Aluminum alloy | Engine hood and chassis components. | Lightweight and fuel-efficient. |

| Steels | Transmission gears, brake discs. | High strength, durable and impact resistant. |

| Engineering plastic | Interior panel, sensor cover. | Low cost, easy to shape. |

4.Mold and prototype development

5 axis CNC machining is particularly efficient when making injection molds or product prototypes, such as quickly prototyping a new mobile phone case with plastic or composite materials.

In terms of material selection, ABS plastic or fiberglass are common because they are easy to process and cheap. Machining centers can directly carve fine textures, eliminating traditional manual steps and speeding up product time to market.

5.Energy and electronics industry applications

Wind turbine blades or circuit board molds are also often made with 5 axis CNC machining. Materials such as carbon fiber or copper alloys are used more because they are corrosion-resistant and conductive. During machining, five-axis technology can handle large curved surfaces of blades to ensure higher energy conversion efficiency.

When is it necessary to use 5 axis CNC machining technology?

1.When machining multi-angle surfaces

Some parts have strange shapes, or the surface or hole position requires a specific tilt angle. For parts that need to be drilled, grooved, and tapped at different angles on five surfaces, five-axis machining is specifically designed to handle such complex angle requirements.

2.When complex designs require flexible processing

For molds or aerospace parts, it is often necessary to process things with strange shapes. 5 axis machine tools allow workpieces or tools to rotate and move flexibly along multiple axes, which solves a major problem for engineers. Even complex shapes can be designed and processed, making the overall solution more complete.

3.When the batch is small but the demand is high

When you have to accept small batch orders and deal with frequent return orders. Now many industries are beginning to popularize this small-batch and frequent-meal production model. Customers are reluctant to place large orders at one time, but first test the water in small batches, and then add more if needed later. This places high demands on the equipment of the processing plant, and the production rhythm must be switched at any time.

At this time, the advantages of 5 axis machine tools are revealed. The multi-angle processing capability of the equipment, combined with the automatic tool changing system, can make the production line switch flexibly like a Transformer. Manufacturers do not have to hold a large amount of inventory to occupy funds, and can adjust the quotation strategy in time when encountering market fluctuations.

4.When processing ultra-high precision and complex parts

For example, special-shaped blades in aircraft engines, implants of medical devices, or precision parts on cars. Such orders are particularly common in the fields of aviation, medical care, and automobiles. Even oil drill bits and semiconductor precision parts often require such high-end processing.

Such parts either have extremely high precision requirements or have a complex surface structure that is a headache. Orthopedic implants must be both tightly fitted and smooth in surface, and ordinary equipment cannot process them at all. At this time, we use five-axis machining equipment to ensure that the parts are high in precision, long in life, and particularly stable in performance. After all, these industries cannot tolerate any errors, and a problem with a part may cause a major accident.

5.When efficiency needs to be improved

The most powerful thing about 5 axis CNC machining is that a set of universal fixtures can handle complex parts, without having to toss parts back and forth between different machines like traditional machining.

Especially now, many customers require both fine parts and small batches of fast delivery. Traditional processing will waste most of the day just to change the fixture and adjust the machine, and the five-axis technology directly maximizes the production efficiency.

For example, the order for precision parts of drones we received, the first sample was produced in 24 hours using the five-axis equipment, and it would take at least three days to toss according to the old method. Not to mention those special-shaped parts that need chamfering and oblique hole processing, which saves the trouble of repeated positioning and has a much higher yield rate.

Even in a studio or workshop with limited space, a mini 5 axis cnc machining center can bring this efficiency improvement.

6.When improving processing accuracy

5 axis CNC processing does not need to repeatedly disassemble and assemble the workpiece like traditional processing. Just avoiding the errors caused during the handling process can greatly improve the accuracy.

For example, if you want to process a special-shaped part with an inclined hole, the traditional method requires changing the fixture three times to complete the process, and each repositioning will accumulate errors. However, with a five-axis machine tool, the rotating table automatically finds the angle with the workpiece, and the whole process is fixed in one position, and the dimensional accuracy is very high.

Moreover, this technology can handle various tricky angles with ordinary tools, without the need for specially customized extended tools or special-shaped tools, and the tool fee alone can save tens of thousands of dollars each year.

What factors should be considered when selecting materials for 5 axis CNC machining?

1.Material properties

First, we need to look at the strength and hardness of the material itself. For example, high-hardness materials such as titanium alloys are suitable for complex surface machining using the multi-directional cutting characteristics of five-axis equipment. Some 5 axis CNC machining UK companies have accumulated a lot of experience in processing such materials, but the current mainstream equipment has the corresponding capabilities.

2.Processing feasibility assessment

Prioritize materials with good cutting response, such as aluminum alloys, which can maintain efficiency and reduce tool loss in five-axis linkage machining. On the contrary, materials like stainless steel, which are hard and sticky to the tool, need to adjust the processing parameters specifically, otherwise the equipment will easily overheat and stop running.

3.Deformation control at high temperatures

Plastics or certain composite materials are prone to blistering or warping when encountering high temperatures generated by high-speed cutting. At this time, the precise temperature control system of the five-axis equipment comes in handy, and the temperature can be adjusted while machining.

4.Cost-effectiveness

Under the premise of ensuring performance, cost-effective materials are preferred. For example, medical parts can use cobalt-chromium alloy instead of precious metals, and achieve the same surface quality through five-axis machining, saving about 30% of material costs.

5.Post-processing

For workpieces that need electroplating or anodizing, 0.1-0.3mm machining allowance should be reserved when selecting materials. Currently, the 5 axis cnc machining center for sale on the market is mostly equipped with an online detection module, which can monitor dimensional deviations in real time and significantly reduce the rework rate.

How to improve the 5 axis machining capability?

1.Make good use of machining simulation

Most CAD software provides program simulation functions. This is like a virtual exercise before actual machining, which can find out in advance where problems may occur in the program, or whether the machining process will collide with the tool or make mistakes. Develop a habit of using simulation before the program sends instructions to the machine to work, which can save a lot of trouble.

2.Choose the right tool

5 axis machining has complex movements and requires tools designed specifically for it. When choosing, pay attention to the effort of loading and unloading the tool. The ideal is that the machined parts can be taken down with a light hand without the need for laborious knocking.

Key points for tool selection:

| Tool characteristics | Applicable scenarios | Main advantages | points for attention |

| Specialized five axis knife handle | Complex surface and deep cavity machining. | Avoid interference and have high processing flexibility. | The cost may be slightly higher. |

| Solid carbide | Precision machining, high hardness materials. | Good rigidity, high processing accuracy, and high efficiency. | High cost, not resistant to impact. |

| Coated cutting tools | High speed processing and difficult to process materials. | More wear-resistant, longer lifespan, and better surface quality of the workpiece. | Matching the coating and material is required. |

| Modular tool system | Frequent tool replacement is required. | Fast tool changing speed and high flexibility. | The system accuracy needs to be guaranteed. |

3.In-depth understanding of equipment capabilities

Before considering the introduction of 5 axis CNC machining near me equipment, you must think clearly about what kind of parts you want to process and have a deep understanding of what the 5 axis technology can achieve. This can accurately determine whether 5 axis machining is really suitable for you and help make a more cost-effective investment decision. Many people save costs through this step.

4.Optimize the processing program

5 axis machining has high precision and flexible movements, and often uses fewer processing steps to make the final part. Therefore, it is particularly important to write efficient and optimized programs. This requires experienced programmers who can plan shorter and smoother tool paths to truly bring out the advantages of five axes.

Summary

In the world of five-axis CNC machining, materials are not just blanks waiting to be cut. It actually determines the function, performance and ultimate successful use of your final parts, and is the foundation for the success of the entire project.

There is no such thing as a universal material, only the material that best suits your needs. The key is to carefully consider these aspects:

What is the part used for?

Is it easy to process?

Can the price be afforded?

What other steps are needed after completion?

After calculating these factors, you can find a truly suitable material partner for those complex and precise five-axis machining projects. In this way, advanced 5 axis machining technology can truly help you make excellent products.

If you want to learn more about 5 axis machining services, please send us your part design drawings. We will give you a clear quote within 24 hours and help you choose the most suitable technical solution based on your specific production goals and needs.

Disclaimer

The content of this page is for informational purposes only.JS Series No representations or warranties of any kind, express or implied, are made as to the accuracy,completeness or validity of the information. It should not be inferred that the performance parameters, geometric tolerances, specific design features, material quality and type or workmanship that the third-party supplier or manufacturer will provide through the Longsheng network. This is the responsibility of the buyerAsk for a quote for partsto determine the specific requirements for these parts.please Contact us Learn more information.

JS Team

JS is an industry-leading companyFocus on custom manufacturing solutions. With over 20 years of experience serving more than 5,000 customers, we focus on high precisionCNC machining,Sheet metal fabrication,3D printing,Injection molding,metal stamping,and other one-stop manufacturing services.

Our factory is equipped with more than 100 state-of-the-art 5-axis machining centers and is ISO 9001:2015 certified. We provide fast,efficient and high-quality manufacturing solutions to customers in more than 150 countries around the world. Whether it’s low-volume production or mass customization,we can meet your needs with the fastest delivery within 24 hours. choose JS Technology It means choosing efficiency, quality and professionalism.

To learn more, please visit our website:jsrpm.com

FAQs

1.How does 5-axis machining work?

5-axis machining uses the XYZ linear axis and two rotary axes to synchronize, allowing the tool to cut flexibly from multiple angles, and a single clamping can efficiently complete the processing of complex curved surfaces and special-shaped parts.

2.Can plastic materials be processed with 5 axes?

Yes. Plastics such as ABS and nylon can be processed with 5 axes. The cutting speed and tool sharpness need to be controlled to avoid overheating and material melting or deformation. They are suitable for precision and complex parts.

3.Is titanium alloy difficult to process?

Yes, titanium alloy is difficult to process. Due to its high strength and low thermal conductivity, it is easy to cause rapid tool wear. Special tools, low-speed cutting and sufficient cooling are required to ensure accuracy.

4.How to choose materials suitable for 5 axis machining?

According to the hardness, structural complexity and thermal stability of the material, metals (such as aluminum alloys) with good cutting properties and multi-angle forming or high-temperature resistant plastics are preferred, and the tools and cooling solutions are matched.

Resource